[IDEX] independent Z-axis for Z-hop and mesh leveling?

-

Hi guys,

I'm currently designing a tool holder for the Hitchhiker.

I want to implement a servo or linear actuator to allow independent Z-axis micro-adjustment (see headline)

But I have no idea, how to write a G10/G11 macro with servo support.

Would RRF even run that macro if it's in the /sys folder and called G10.g G11.g?

Even worse, how would I use the heightmap in YV-copy mode, where both nozzles need their own Z-height adjustment.

Would I need two Z-probes and create different heightmaps? -

Like a compound Z axis? Seems needlessly complex?

-

@o_lampe Do you believe the Z axis offset, if any, varies with XY position.

-

@fcwilt said in [IDEX] independent Z-axis for Z-hop and mesh leveling?:

@o_lampe Do you believe the Z axis offset, if any, varies with XY position.

According to my heightmap it does.

While the 'main' tool is at the right height due to G29, the second tool has an XY offset ( copy mode!) and the height is probably wrong. Therefor it need it's own mesh compensation. The Z-motor can only obey one tool, so the second tool needs a separate mini-Z axis. -

@o_lampe said in [IDEX] independent Z-axis for Z-hop and mesh leveling?:

@fcwilt said in [IDEX] independent Z-axis for Z-hop and mesh leveling?:

@o_lampe Do you believe the Z axis offset, if any, varies with XY position.

According to my heightmap it does.

While the 'main' tool is at the right height due to G29, the second tool has an XY offset ( copy mode!) and the height is probably wrong. Therefor it need it's own mesh compensation. The Z-motor can only obey one tool, so the second tool needs a separate mini-Z axis.Probably?

Unless the Z offset between the two tools varies with XY position only one height map is needed.

-

@o_lampe said in [IDEX] independent Z-axis for Z-hop and mesh leveling?:

Even worse, how would I use the heightmap in YV-copy mode, where both nozzles need their own Z-height adjustment.

Would I need two Z-probes and create different heightmaps?A better question for your mirror/duplication query is, does RRF track the position of the hitchhiker (or U axis tool), and can it correlate it to the mesh file?

To setup the mirror or copy tool, you map the second toolhead (classical the U axis, with the X used with T0, although realistically you could map this any way you want) to the first - with M563. To me, that reads as if there is no independent control over a mapped axis. Lacking independent control, could you use a tool-mounted stepper or servo to live-adjust that mapped tool?

I don't see utility for a second z-probe, as you assign an offset in G10 anyways.

For any mirror/duplication mode, your print file is essentially going to look like

T2 ... G1 X-84.203 Y66.592 E0.03521 ... -

@fcwilt said in [IDEX] independent Z-axis for Z-hop and mesh leveling?:

Unless the Z offset between the two tools varies with XY position only one height map is needed.

For you my doubtful friend I draw a picture with exaggerated bed tilt. Guess what happens to Tool 1, when mesh leveling tries to compensate the height for Tool 0?

Off course I could adjust tool 1 offline, but the bed tilt varies over the length and width of the bed. If my bed would be 100% flat and straight it would be OK, but in real life the heightmap looks like it's twisted and wavy.

I don't blame the MIC6 cast aluminum plate nor the 2040 bed frame resting on three ballscrews. It's just what I measure and what mesh leveling tries to compensate. -

I think, I found a partial workaround for the Z-hop. For my feltpen texture mapping, I can switch to laser mode and use G1 Sx to drive a servo (instead of laser-PWM). I can even have two feltpens on that toolholder. Servo in center-position would then lift both pens from the bed while the servo-endpositions would push one pen down and the other pen further up.

Back to the drawing board... -

@o_lampe said in [IDEX] independent Z-axis for Z-hop and mesh leveling?:

@fcwilt said in [IDEX] independent Z-axis for Z-hop and mesh leveling?:

Unless the Z offset between the two tools varies with XY position only one height map is needed.

For you my doubtful friend I draw a picture with exaggerated bed tilt. Guess what happens to Tool 1, when mesh leveling tries to compensate the height for ...

I only said that one height map was needed.

There is still the problem of needing to use a different entry in the height map for each tool and how to adjust the Z position for each tool.

I have no idea how to do that easily.

-

@o_lampe How about using the bed centre as the X0Y0 and then when you change tool apply the offset of the second tool such that the home position puts it at the origin and then do a Z-Probe and you should be good with the one mesh!

-

@dougal1957

Ofcourse that would work for a tool change but not, when both tools work at two parts in parallel. (Copy-mode)

The Z-motor can only work for one tool at a time.

The mesh-leveling routine would have to spit out two values. One for tool0 (as usual) and the other for tool1 with the given offsets in mind.

@chrishamm

Maybe the DWC print-simulation could be enhanced with a post processor, which adds the tool1 Z-height difference into the gcode.?

It can't be done in a slicer, because it has to be unique for each machine, no matter how many printers run that print. (that's the goal of copy-mode, mass production of identical parts ) -

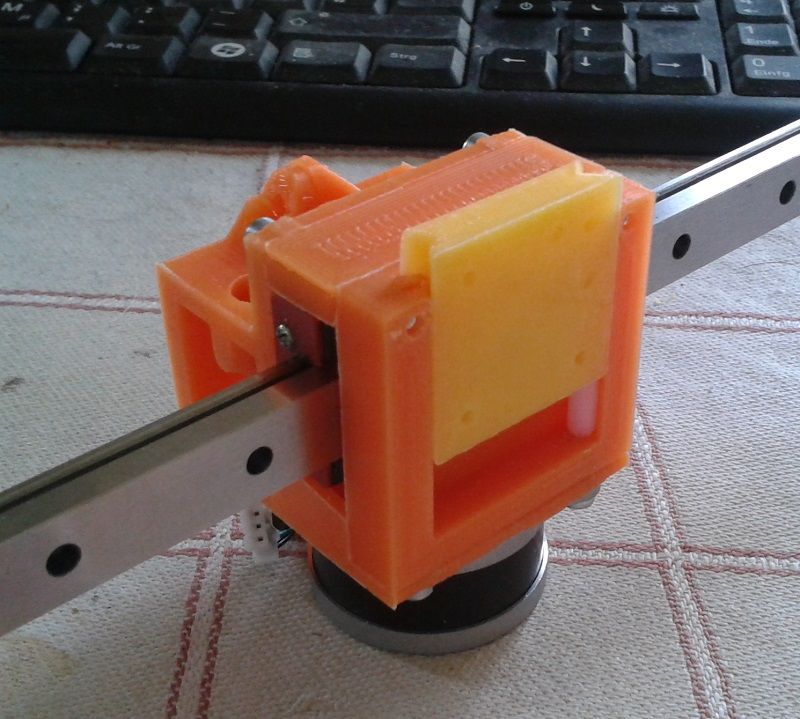

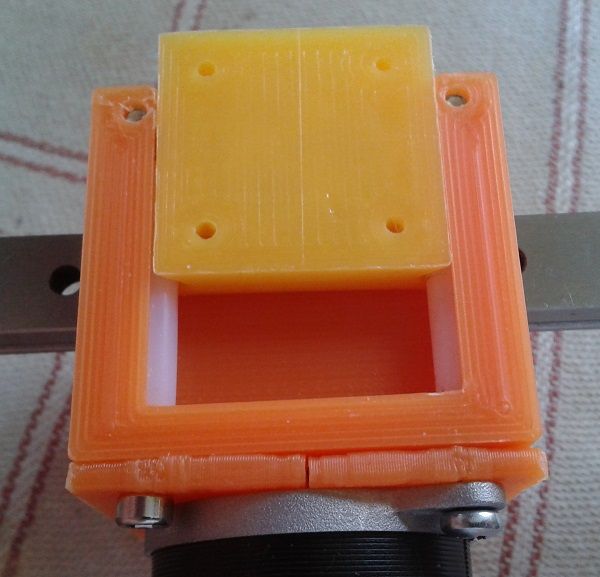

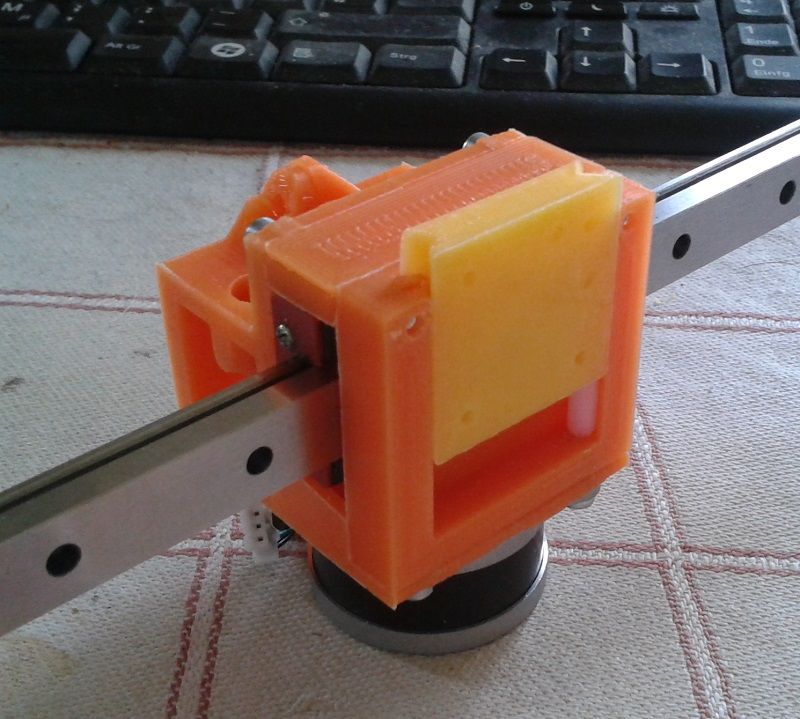

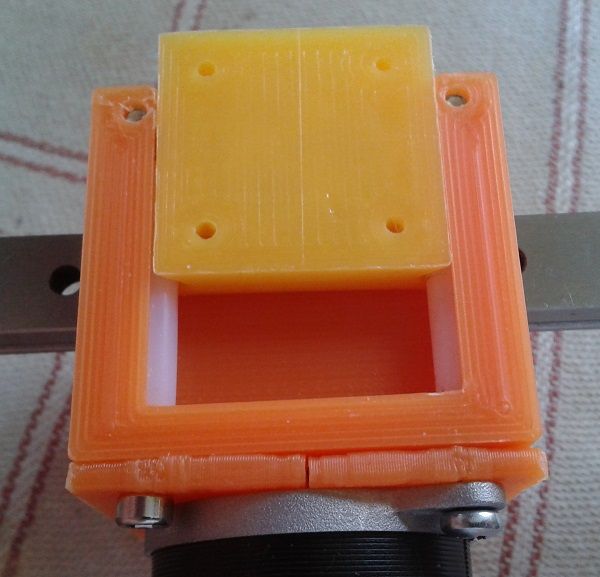

Don't know where to put it, but here is a candidate for an independent Z-axis.

I've added a 'dovetail' slider to the Hitchhiker, which slides on our common 4mm PTFE tubes.

I may have to change a few dimensions, but it works that way.

Next step is to integrate a servo driven excenter and add a feltpen holder.You can see, it has a benefit against moving the bed 1000x up/down.

-

@o_lampe said in [IDEX] independent Z-axis for Z-hop and mesh leveling?:

Don't know where to put it, but here is a candidate for an independent Z-axis.

I've added a 'dovetail' slider to the Hitchhiker, which slides on our common 4mm PTFE tubes.

I may have to change a few dimensions, but it works that way.

Next step is to integrate a servo driven excenter and add a feltpen holder.You can see, it has a benefit against moving the bed 1000x up/down.

I like this as I want a small milling tool for tidying up the top layer and clearing holes for fixings, the ability to retract the tool in this way is very nice

.

.Definitely following...

-

@cncmodeller

Thanks for the warm words.

The Slider is pretty small and I will mount a hotend with Bowden extruder at most. The hole pattern is 20x20mm.

But the concept is scalable. You can use bigger Delrin or PTFE rods to beef it up.

A few years back I tried to build a Delta printer with such sliders, not sure why I stopped.