Duet 3 6HC configure firmware dual Z motors Please Help

-

except for an occasional fan speed and feed rate change it is pretty much G1 X(number), Y(number), extrude length. I ran it again today and it seem to do fine for the first 3 layers and then it acts like the BLtouch is trying to do a self test and after a few attempts it stops trying. I added a self test, alarm release, plunger in and out macro so this time I stopped the program and brought the tool head to home position and attempted to do a self test. no response, I pushed the plunger in and attempted a self test again, the plunger cycled out once and stopped faulted. I could not electronically retract the plunger.

-

It sounds like it's got an intermittent 5v connection and is rebooting the BLtouch.

-

is the BLtouch subject to EMF or heat related failures? my bed is set to 80C and the wires run through a harness to a junction box that the extruder and fan motors are running out of. I also have the ground wire doubled up going to the BLtouch from my Duet 3 6HC.

What I think might have happened during installation I had the 3.3vdc pin on the digital out (white) wire instead of the #7I/O(in) like it should have been by mistake. -

@supertb1 said in Duet 3 6HC configure firmware dual Z motors Please Help:

What I think might have happened during installation I had the 3.3vdc pin on the digital out (white) wire instead of the #7I/O(in) like it should have been by mistake.

Has that been corrected?

-

yes, this problem was corrected after the first few minutes of trouble shooting

-

it just seems like it is solid until I am a few minutes into printing... kind of hard to call it an intermittent 5V.... I suppose I could recheck my terminations again

-

Intermittent wire connection based on print head position is pretty common.

-

-

4.8vdc on the red wire at all times

-

@supertb1 said in Duet 3 6HC configure firmware dual Z motors Please Help:

It is generally felt that you should not turn your printer on it's side while it is printing.

Frederick

-

lol.... well if I turn the printer upside down maybe the BL touch will work better... I have several friends that have many expletive's to describe the BLtouch.... I double checked my wire terminations and everything is solid, there is no movement in the terminations of the BLtouch as everything is in junction boxes. I have proper voltages at all times... i guess the next thing is to bite the bullet and order another BLtouch... at least then I can rule out weather it is something in the the BL touch or if the problem follows... are there any tests I can do to trouble shoot besides ohming ends of wire, voltage checks, BLtouch on board testing... it self calibrates on start up...

-

Does the BLtouch have a length of wire issue,(resistance) on my machine there is probably 6 or 7 feet of wire between the board and the BLtouch...

-

Very strange. Testing with another BLtouch would be informative.

Maybe it's picking up noise on the servo signal wires?

-

Tomorrow I'll try to short whip it and see if that could be the case... going to piss me off if I have to run a shielded cable just for the BLtouch...lol... wouldn't surprise me I guess... I lack the experience with this sensor to know if EMF is an issue with other electronics

-

Update, I looked at another forum page and saw that some one changed there "P" value in there G31 P500 X10 Y10 Z2.5 ; set Z probe trigger value, offset and trigger height line from P500 to P100 and they claimed that this solved their problem. I made this same change with no effect. then I ran a 2 meter long cable outside of the wire tray to the sensor and vwala, it is homing and printing perfectly. So in my case it appears that EMF and wire length plaid a role in the culprit

-

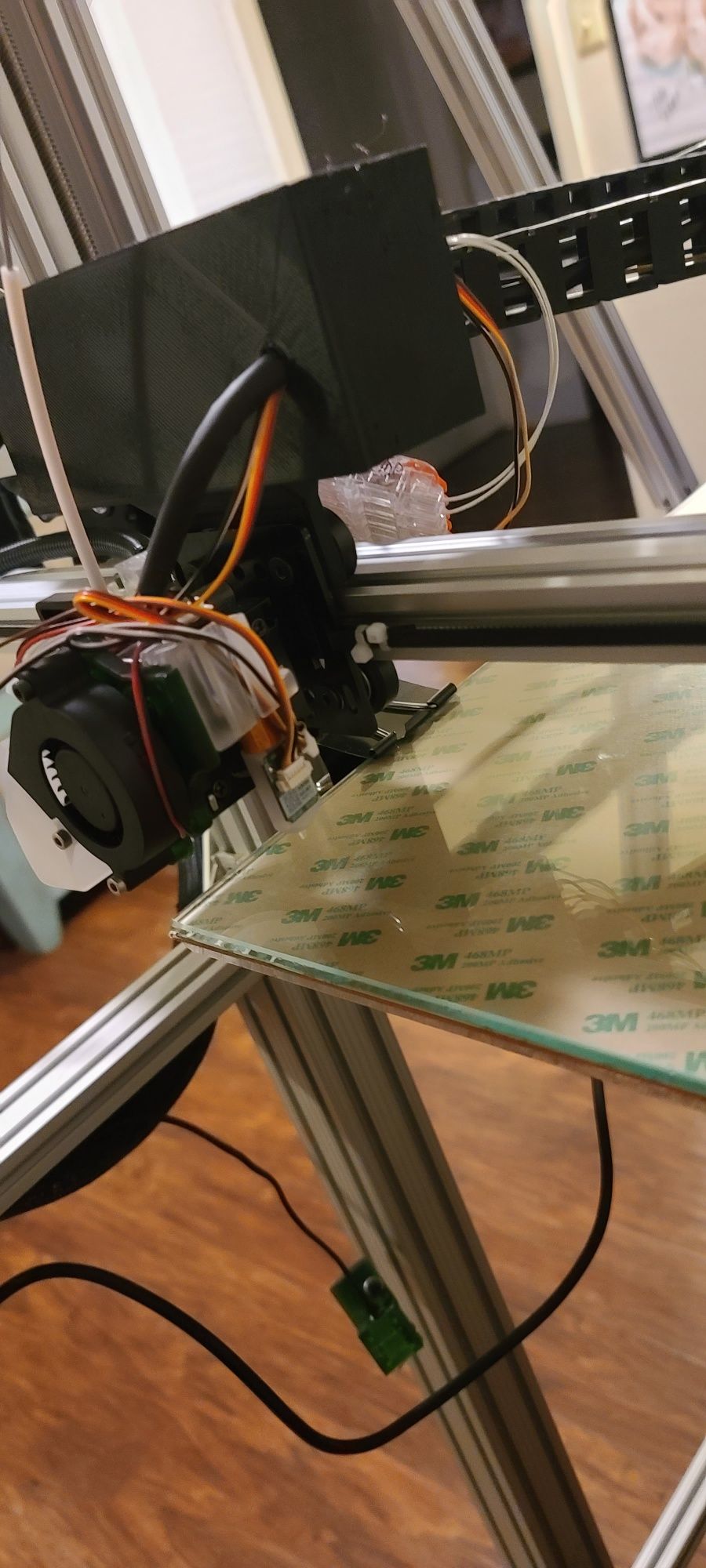

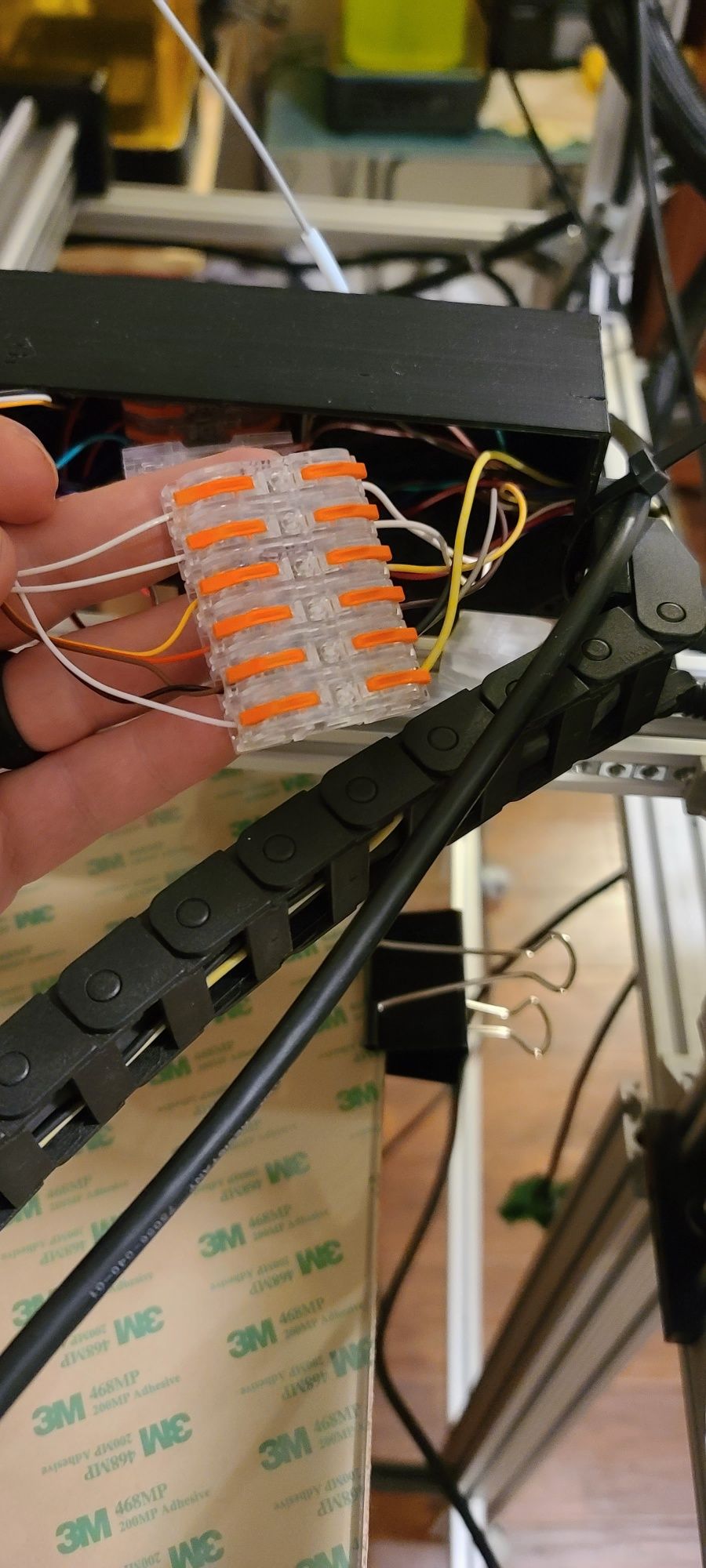

Thanks for the update. Care to share a photo of what the cable run looked like that cause issues? What all was running in it? How long was the run?

-

-

it is about 3 meters of wire from one end to the other and the harness has 16 conductors in it to run several fans, temp sensor, heater wires, extruder motor and the BLtouch. I use those speed butt connectors for my wire ends as it makes terminations very easy. once I get all the terminations finalized I will stream line it and work on cable management.