Problems with IDEX printer configuring

-

Yes you can check the PanelDue firmware version in the setup page on the PanelDue.

And update it like this

https://duet3d.dozuki.com/Wiki/PanelDue_Firmware_update -

I got the printer working otherwise but:

-

X-axis positions relation between extruders seems to change randomly. This is seen as offset on dual color/material prints. Something seems to affect homing accuracy.

-

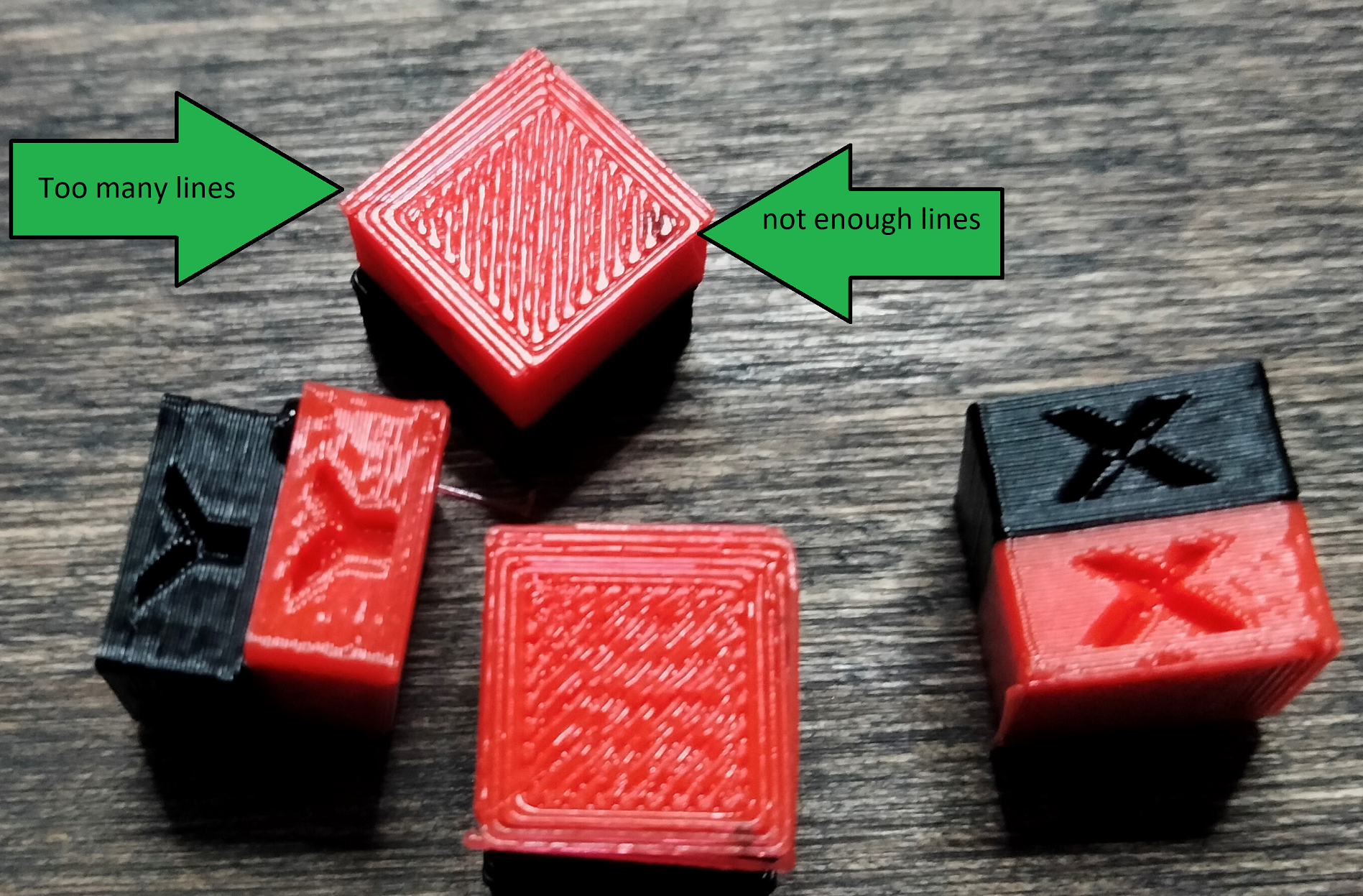

Something caused offset on print bottom infill in relation to walls of the print. The other side of the print has more outer walls than the other even though they slicer shows the same amount of lines.

-

I need stealthchop tune move macro

-

-

Is the Z axis intentionally compressed for shorter prints?

Maybe try some IDEX calibration prints to get it tuned in?

There are many variations. Here is one.

https://www.thingiverse.com/thing:4565745 -

The print objects are compressed on purpose to shorten print time and minimize print material usage. I've tried printing "proper" dual calibration models but those are hard to check for alignment because the tips of the spikes are often quite nonuniform (especially when prints don't seem to stick well to my print bed that is made of glass). Printing two cubes with the other on top the other allows feeling the edges of the cubes on each side. It should be accurate.

I just found a post that explains possible causes of inaccurate homing:

@dc42 said in Z homing fails often after update from 3.1.1 to 3.2:

It's as I expected. If two endstops are triggered with a delay of about 2.2ms between them, only the first one is registered until another input changes. When the delay is shortened to 1ms or lengthened to 5ms, the problem does not occur.

Now I can test fixes.

So I changed homingall.g move distances so that each axis is home slightly different time than the others. I'm still testing if this is the case.

-

Repeating same print job without changing offsets in config or changing any slicer settings resulted with two prints that had different offsets on X/U-axis. The difference was 0,5 mm.

I also tested repeatability of X- and U-axis endstops by homing them and moving back 10 to 100mm and homing again and repeating. They seemed to be fine as difference for each measurement was within 0,05 mm.

I'm not sure what causes this. Position of Y-axis doesn't matter and Z-axis moves very slowly and it too has variance with position, but that is most likely just because heat expansion.

-

I solved the issue with first layers (brim) not aligning with body of the part. It was caused by lost steps when tools are switched and the other extruder went to its minimum axis location and hit the other extruder slightly. This only happens with first layer and not with higher layers.

I still have problems with setting offsets. If I calibrate the extruders with any calibration object to correct offsets, offsets on prints will eventually change to something else and a new calibrations is required. This happens relatively randomly and I got about 10 print jobs done with one calibration and after that even the calibration was hard as correcting the values did not give the results it should have.

-

I think found the issue: printed parts (ABS) on X- and U-gantries were attached by M3 bolts were loose. The printed part had given in slightly. Weird thing is that it didn't seem to affect one extruder printing (no shifted layers during printing).

-

I'm glad you solved it. Nice frog print!

-

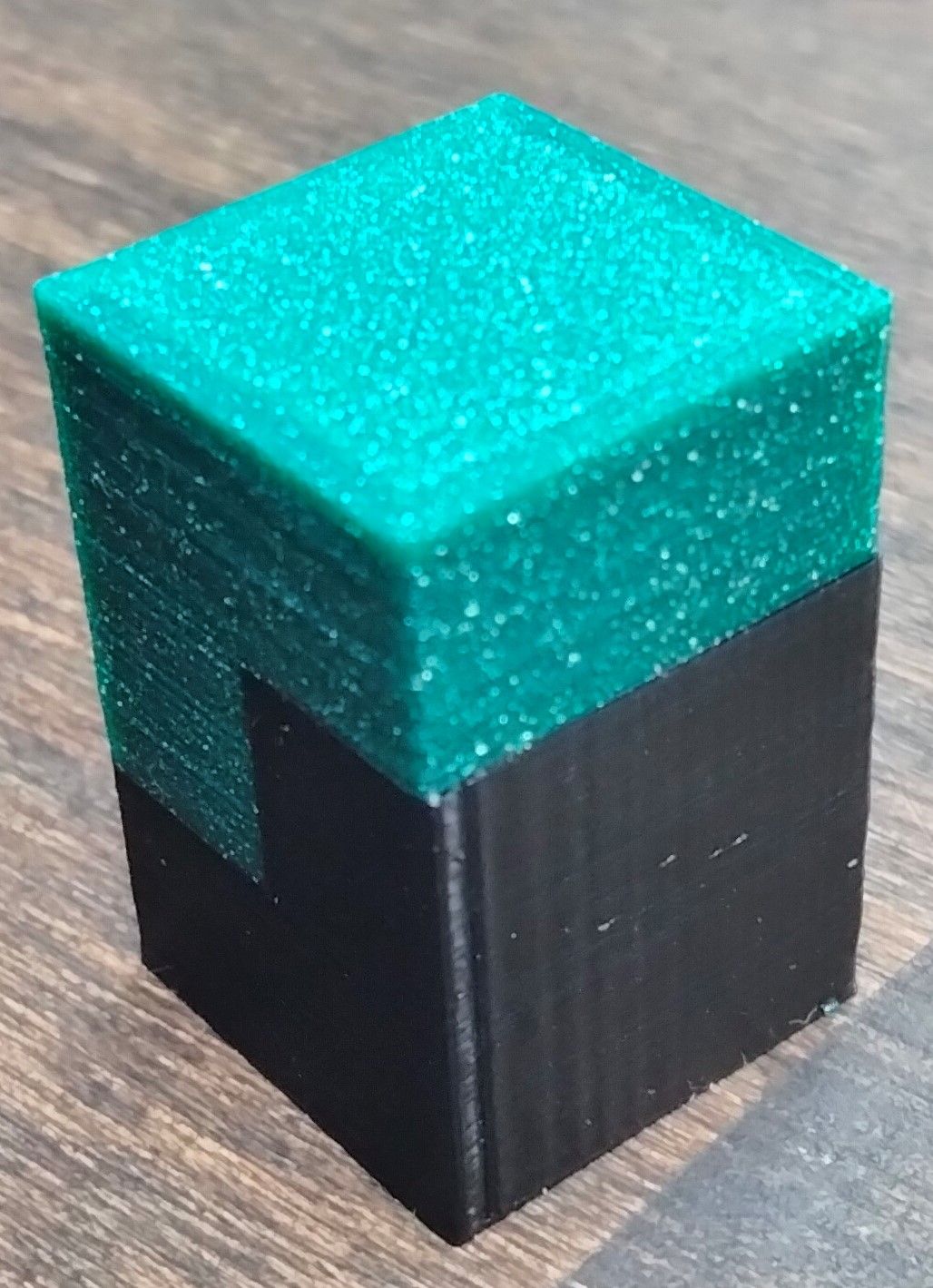

Thanks. I still need to do some tuning, but I think I'm getting close. It is possible to see some inconsistencies in black parts of the frog (green glitter hides those inconsistencies). I had line width set

to low (0,38) on the frog, which probably causes the issue along with not quite right extrusion multipliers.I'll probably post more detailed description on my machine on "my Duet controlled machine" -section when I got the time.

-

FWIW I printed the same frog some time ago.

-