Easier to use Software

-

@jmshep Nicely summarised if I may say so. This is from a long term user who's experience goes back to the original 06 board. My machine is quoted as being an advanced "edge case" machine because it has 3 XY gantries and range of mixing hot ends with up to 6 inputs. But essentially it's just a CoreXY with a mixing hot end and hasn't fundamentally changed for at least 3 years. Yet the gen 3 hardware and firmware that I've been using for the last 19 months, still lacks some of the basic functionality that I had with gen 2, three or more years ago.

It still puzzles me why, in all this time, the focus has been on adding things like object models, conditional gcode, support for neopixel LEDs, and copious other new "features", rather than basic stuff like tuning heaters or homing axes (because only certain combinations of switch/probe/board are supported).

-

@deckingman I mean no disrespect to you by what I'm about to say, honestly. I've found much of your blog content, posts here and YouTube videos to be interesting and informative, and on one hand I understand your frustration, it is in part of your own making.

Your printer is very advanced, easily one of the most complex CoreXY builds I certainly have ever seen, but if it being in a state is such an issue, why not simply revert back to using the Duet 2 + Duex + RRF2 where it all worked? You spend a lot of time here lambasting @dc42 and the other developers, but from your own admission, everything worked to your satisfaction with the older hardware, no?

I have seen you say multiple times on your own videos that you refuse to try beta or RC firmware, and yet complain when things don't work for you. Problems cannot be found and fixed without assistance from those who suffer from the issues. An issue which isn't reproduceable for a developer is almost impossible to fix, and I say this with a software development background.

Again, if your printer has to be working, why would you have changed from the working electronics? Why not change back to those after all of the issues? I don't understand the your mentality of "it must work the way I want it, even if there is another way that DOES work".

Maybe it's just me, but it's saddening to see the constant attacks from you towards the Duet developers

I'm truly sorry if you feel I am attacking you, or your character, but I'm just sharing an opinion from an outside perspective with no bias towards either side.

I'm truly sorry if you feel I am attacking you, or your character, but I'm just sharing an opinion from an outside perspective with no bias towards either side. -

@jmshep said in Easier to use Software:

Taking the same poll, nearly all are asking for help for various problems. surely it can be seen that this is not good. It would be nice to have more sharing of ideas, good practice etc but it appears people are too busy fault finding than having time for printing.

That's the nature of a support forum - most users are looking for answers to questions or issues they are having (not always issues with firmware). Users who just get on with printing don't often post.

Given the large number of Duets we sell, it's not surprising that some customers need help with using them.

-

@NexxCat Fair comment. But should dissatisfied customers and those with genuine grievances simply shut up and go away? Would things improve if nobody was allowed to criticise?

Yes, I am looking at options - as I said in my last video. I'll either tear out the gen 3 stuff and put gen 2 back, or maybe replace it with something completely different, or just turn the machine into a simple, basic, single input hot end machine. All of which are a shame and could be avoided.

Sure my machine is advanced and complex. But it worked before with Duet gen 2. My grievance is not that the firmware won't do something "special", it's that it doesn't have the same functionality that it used to have. I just want the previous functionality restored (and without any new bugs creeping in).

It used to be that I could come up with an idea, bounce it off the Duet team, and we would move forward together. That's how firmware retraction of all filaments came about - I expressed the need for it with mixing hot ends and the Duet guys did the firmware (which I beta tested). Similarly, when I mounted the extruders on a separate gantry, I expressed the desire to home that gantry independently. That's how CoreXYUB kinematics came about. There are other numerous examples. I like to think that together, we moved 3D printing forward, for the benefit of the wider community. It's a shame that came to an end.

When the Duet guys announced gen 3, I happily agreed to "donate" my machine to the cause in return for them "donating" the hardware. I spent dozens of hours doing the hardware conversion, and hundreds of hours testing pre-production firmware. Then a week without pay on the stand at the TCT show (which was an embarrassment for all concerned because the firmware wasn't ready). Then hundreds more hours (and metres of filament) testing beta firmwares before the Duet guys threw me under a bus and decided to leave me with a partially functional machine.

It's true that recently, I've decided not to test Beta firmwares. Firstly because I think I've done more than my fair share over the years. Secondly because in many cases the firmware hasn't addressed the outstanding issues that I've had.

I'll shut up now and go away......

-

@dc42 said in Easier to use Software:

They already exist:

https://e3d-online.com/blogs/news/asmbl

https://www.diabasemachines.com/hseriesThis reminds me the long promised flying cars.

-

@zapta said in Easier to use Software:

This reminds me the long promised flying cars.

You mean you don't have one?

They're great!

Frederick

-

@deckingman said in Easier to use Software:

I'll shut up now and go away......

Don't do that - I just made a big batch of popcorn!

I just haven't wanted to deal with the problems of beta firmware.

I won't try a release candidate.

I even wait for the released version to generate some feedback before I install it.

I'm just too old.

Frederick

-

@zapta said in Easier to use Software:

@dc42 said in Easier to use Software:

They already exist:

https://e3d-online.com/blogs/news/asmbl

https://www.diabasemachines.com/hseriesThis reminds me the long promised flying cars.

What is interesting in that link is this - quote .......

" All parts are easily available and can be controlled directly by the Duet2."

Thank goodness they didn't mention controlling it with Duet 3

-

@deckingman, I'm having a hard time working out what you are complaining about regarding the current capabilities of Duet 3. Your machine has been working using Duet 3 right from the time that you first joined us on the Duet3D stand at TCT with your machine. There were some teething troubles, but far from being an embarrassment as you claim, it produced several good prints (as well as a few failed ones). The second year that you joined us, it produced lots of good prints.

I remember seeing you complain about the following items relating to firmware on Duet 3:

-

Endstops connected to the main board cannot yet control motors attached to expansion boards. Way back I think we asked you to connect your Z endstop switch to the expansion board instead of to the main board because of this. So your machine is working within this limitation. Are you really desperate to rewire the endstops?

-

Unable to run heater tuning on your hot end because its heater/thermistor are driven from an expansion board. In fact this facility has been implemented and is available in 3.3beta1 firmware.

-

Insufficient step rate on expansion boards to use high microstepping (although this did not stop you from doing good prints at TCT). This was fixed early in the RRF 3.2 development cycle. You chose not to install any beta or RC versions, so you had to wait until the 3.2 stable release to get the benefit.

-

Your homing script did not execute correctly when you installed RRF 3.2 stable. This turned out to be caused by the combination of using a M109 command in your homing file (which is highly unusual) and then calling another macro in your homing file (which is also on common, except for homeall.g calling other homing files). This is not a combination that I or any of our beta users tested with. Had you installed a 3.2beta or 3.2RC firmware version on your machine, it would have been found in time to fix it for the 3.2stable release. As it is, I spend half a day debugging this so that I could fix it in the 3.2.2 release.

I guess I must have missed something, because from your posts it appears that you still think that something is stopping you from using your machine as you want, and you wish that you were using Duet 2 to control it. What have I missed?

-

-

@dc42 There is something seriously wrong with your memory. I'm starting to get really worried about you.

The first time we did the TCT show was 2017 - I did a blog post about it at that time https://somei3deas.wordpress.com/2017/09/06/my-printer-and-i-will-be-at-the-tct-show/. This was with a Diamond 5 colour using Duet 2 (Ethernet plus Duex 5) and for sure, I produced some quite reasonable prints.

In 2018, my machine was not on your stand. Duet 3 was just announced and you had a display board driving various motors (you also had an M3D crane quad with a Maestro which was almost, but not quite producing some prints).

Then I converted my machine to gen 3 from June 2019 onwards when the first pre-production boards became available. I did a series of blog posts documenting that conversion. The first was this one

https://somei3deas.wordpress.com/2019/07/15/wiring-upgrade-duet-generation-3-and-tct-show-2019/

The second was this one https://somei3deas.wordpress.com/2019/08/28/duet-generation-3-upgrade-and-tct-show-part-2/. Note that it opens with these sentences

"Progress has been slow up until now because it have been waiting for the hardware to arrive. The expansion boards which are prototype boards, arrived on Monday 19th so I have now been able to fit them and wire them up. As I write this (Wednesday 28th August) I am awaiting the main board which should arrive in the post today. "

The third post was this one https://somei3deas.wordpress.com/2019/09/03/duet-generation-3-upgrade-and-tct-show-2019-part3/

It starts wit this with this

Captains log, StarDate 3rd September 2019. Things are hotting up and getting quite frantic so this will have to be very quick post.

and it ends with this

As I write this, there are various people throughout the UK and also in Germany who are working long days to get the firmware ready for the show. Many of us worked from 7.00 a.m. to past 10:00 pm on both Saturday and Sunday.

As of this moment, all 7 axes now move as they should, as do all 6 extruders and the bed heats but not the hot end. Homing switches on expansion boards do not yet currently work but these things should be resolved in the next couple of days or so.

So far, the only wiring issue was that I had stupidly connected the bed SSR the wrong way round, which was easily fixed and caused no damage. So I’m quite pleased about that.

Unfortunately, I will be going on holiday between 10th September and 19th so that leaves very few testing days between now and the TCT show.

I’ll have to finish this blog post now and it is unlikely that I’ll be able t find time to post any more updates before the show starts.

After the TCT show, I did a follow up blog post https://somei3deas.wordpress.com/2019/10/21/duet-generation-3-upgrade-part-4-and-post-tct-show/

That one starts with this

Despite all our best efforts, the Duet guys didn’t quite get all of the outstanding issues resolved with the prototype expansion board firmware in time for the TCT show. So we had to run with what we had. I wasn’t able to successfully complete a full demonstration print, but I did manage some partial prints. Fortunately, when I explained that the expansion boards were prototypes and so was the firmware, most people were quite understanding.

Maybe you weren't embarrassed by the lack of any functional printers on you stand. IIRC, Tony's delta didn't work either. But I was certainly embarrassed on you behalf with constantly making excuses for the non-functional firmware.

But how can you say quote "The second year that you joined us, it produced lots of good prints."? The reality is that it never produced a single decent print - just a few partial failures due to all sorts of issues. I couldn't even home the bloody thing, other than inching the bed up and using the "paper under the nozzle, G92 Z0" thing.

Sure the machine is now just about functional because I've managed to come up with numerous work-a rounds. But there are still these limitations

https://duet3d.dozuki.com/Wiki/Duet_3_firmware_configuration_limitationsOh and I can sort of produce some sort of parts providing I don't want to use pressure advance - as I stated here on 22nd Feb https://forum.duet3d.com/topic/21562/firmware-bundle-3-2-2-released/24?_=1614610750592

That last one has been met with the normal deathly silence that I've come to expect............

But what's the point? You don't read posts and seemingly moderators don't flag them for your attention as I suggested might be a good idea. That's bad enough but what's really worrying is that your recollection of events and flagged problems seems to be divorced from reality.

-

Thanks for refreshing my memory. I had forgotten that you were using Duet 2 at the first TCT show.

@deckingman said in Easier to use Software:

Sure the machine is now just about functional because I've managed to come up with numerous work-a rounds. But there are still these limitations

https://duet3d.dozuki.com/Wiki/Duet_3_firmware_configuration_limitationsWhich of those limitations actually affects your use of your machine, other than the ability to auto tune your hot end, which is implemented in 3.3beta1?

@deckingman said in Easier to use Software:

Oh and I can sort of produce some sort of parts providing I don't want to use pressure advance - as I stated here on 22nd Feb https://forum.duet3d.com/topic/21562/firmware-bundle-3-2-2-released/24?_=1614610750592

I'm sorry, that one seems to have slipped through the cracks. It's always better to start a new thread to describe a new issue, rather than mention it in a thread that has posts from different users about different things. I invite you to start a new thread describing that issue, which should include a photo of the faulty infill, the config.g file you were using at that time, and the pressure advance setting if it isn't in the config.g.

-

@dc42 I don't know how you keep your cool, You must have the patients of a saint.

As a developer, I'd most likely end up in a physical altercation, if I had to deal with some of the garbage people regularly throw your way.

-

@dc42 said in Easier to use Software:

Which of those limitations actually affects your use of your machine, other than the ability to auto tune your hot end, which is implemented in 3.3beta1?

TBH, it's more a complete lack of confidence in the firmware. I just don't trust it any more. When faults are obvious like homing failed messages, or extruders running backwards as per the 3.2 release, that's one thing. But when it's something like low step pulse frequency with no ability to look at hiccups (as was the case with expansion boards until recently) one has no way of knowing that the firmware is misbehaving.

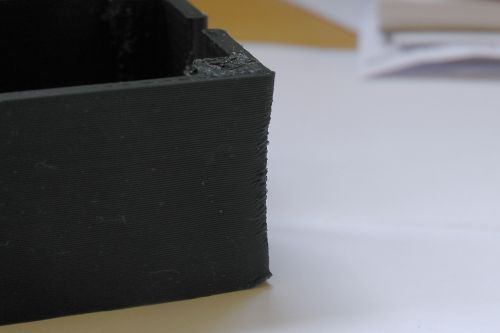

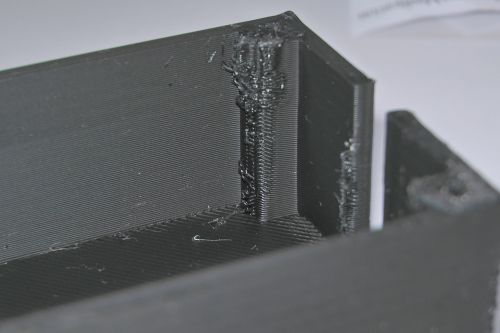

Here are some of pics of a little case I just printed using a simple single input hot end and with pressure advance disabled. It's bloody awful - like the first print ever produced on a crap machine by a rank amateur.

Look how the corner bulges out at the top.

Look at this mess on the corners

Look at this stringing on the inside as if retraction has stopped working

As I said, it's like the first print ever turned out by someone new to the hobby using a machine that cost less than two of my 6 extruders.

There is so much wrong with that print that I hardly know where to start and I'm struggling to believe that it''s all caused by my disabling pressure advance.

The last 18 months have destroyed any confidence I had in the firmware. I just can't trust it any more............

-

@deckingman said in Easier to use Software:

The last 18 months have destroyed any confidence I had in the firmware. I just can't trust it any more............

They why are you still using it?

-

@deckingman: Lack of thrust is for a large part gut-feeling-territory, there is little to nothing Duet3D can do about that. Sometimes it happens that products go in a direction which does not suit you. Vehicle manufacturers do that, coffee machine manufacturers do that, and so on.

If I were in your situation I threw out the Duet3 and went back to Duet2+DueX5 with RRF2.05 or investigate other controllers. Takes a lot less energy in the end.

-

I believe that one good strategy is to separate between a stable version, even if it's a year old, and a bleeding edge one that covers the big leap from a stable 2.x to a stable 3.x.

It will provide latest and greatest to users that want and can take risks, a pool of testers for the developers, and stability for the users that need it. It will also reduces the pressure on the developers to get it right and fast, and will bring peace and harmony to the Duet community.

My 2c.

-

@zapta said in Easier to use Software:

I believe that one good strategy is to separate between a stable version, even if it's a year old, and a bleeding edge one that covers the big leap from a stable 2.x to a stable 3.x.

It will provide latest and greatest to users that want and can take risks, a pool of testers for the developers, and stability for the users that need it. It will also reduces the pressure on the developers to get it right and fast, and will bring peace and harmony to the Duet community.

My 2c.

This will work for some people, but as a developer I can tell you it almost never works with those that complain the loudest. The ones that complain the loudest are usually the ones that want to be on the bleeding edge.

-

@DanS79 said in Easier to use Software:

@deckingman said in Easier to use Software:

The last 18 months have destroyed any confidence I had in the firmware. I just can't trust it any more............

They why are you still using it?

I'm not - other than the pile of crap I just produced because I needed a container in a hurry, my printer sits idle - as it has done for many weeks.

Longer term, I'm still weighing up my options and looking at alternatives.

-

@DanS79 said in Easier to use Software:

The ones that complain the loudest are usually the ones that want to be on the bleeding edge.

It's hard to complain about a version that is called 'nightly build'.

-

@DanS79 said in Easier to use Software:

............. The ones that complain the loudest are usually the ones that want to be on the bleeding edge.

Yes this accusation keeps getting levelled at me - basically it's all my fault for having a complex machine.

But let's explore that a little more (though I understand that you'd prefer a physical altercation - usually a sign that the arguiment has been lost IMO).

Firstly the machine is fundamentally the same as it was 3 years ago. I haven't been asking for anything new or special - simply the functionality that it had when I used gen 2. It's almost there now, but arguably that's because I have "screamed and shouted" as @dc42 put it. I suspect that had I kept quiet, it would have taken much longer than the 19 months it has taken so far.

Secondly, the complexity is mostly mechanical. Sure it's CoreXYUV with a mixing hot end but that's not desperately complex or wildly exotic. We can forget about the load balancing gantry - the only reason it's still on the machine is that I can't be bothered to remove it.

The Z axis is a simple as it gets - just a single motor driving 3 screws via a continuous belt. The complexity is making it such that it is mechanically flat, level and stays that way. It doesn't need, nor do I use any firmware levelling. Nor do I use and firmware flatness compensation. Nor does it need multiple motors.

The Z "probe" is the nozzle itself on a kinematic mount. Again, the complexity is making that mechanical mount such that the hot end is constrained from any XY movement but allowed to move in Z. The physical stop is also the switch - two metal parts that come together and make a circuit. It doesn't get any more basic than that. The firmware just has to react to an IO pin being pulled high or low. No probe to deploy, no IR or inductive sensor - nothing more than the simplest of switches.

All other end stops are simple micro switches.

The hot end is heavy and rigid. As such it has low resonant frequency so ringing just doesn't happen. So the machine does not need DAA.

The extruders are dual drive BMGs which do not slip. So the machine does not need non-linear extrusion.

All temperature sensors are simple NTC thermistors . So no need for thermocouples or PT100s.

I don't use any filament monitors.

Which brings me to the other accusation, that it's all my fault for not now testing beta firmwares. But as illustrated above, I don't use half the things that other users do, so their input is likely to be more relevant than mine.