Pressure Advance: Discussion for Future Development

-

That's exactly what i ended up doing to (well i setteled on 0.4), even though i would get the most consistent pressure somewhere close to 2, but it sounded like my BMG was one nudge away from exploding at that point

Designed new extruder mounts so i could move the extruders over the build area (corexy machine) and shorten the bowdens down to 300mm ish, so 0.4 isn't that much off.

-

@QuintBrand said in Pressure Advance: Discussion for Improvement in Bowden Printers:

Seems little interest CCS...

Were you waiting on my feedback? It sounded like you were generally agreeing with me and not asking questions.

I don't think "length" is a better parameter to use for filtering over "time". We are dealing with time based phenomenon, ie lag between extruder drive motion > nozzle pressure > nozzle flow rate. How fast the print head is traveling doesn't impact these things.

-

I have resorted to printing without PA now. In my case I observed that the extruder reverse motion gets skipped on consecutive small segments, thus all my over-extrusion issues ensued.

I also dug in the Firmware and at some point it just stopped being fun as there are multiple approximations related to step generation which smell bad. Having no handy HW simulation tools it just took too long to debug with all the variables.

I saw Klipper implements "smoothing" for PA, so I started moving to it to test it out. While there are pros and cons between Duet and Klipper (I still like the Duet), but at least in Klipper the CPU basically only runs the step pulses, so no need to deal with interrupts being late or whatnot.

Not finished yet, tho.

-

Hey, no I was not trying to push you in any way, but actually trying to support this tread from sliding away as I think it is an excellent idea to get the "gun" effect out of the printing with PA

.

.I think bit time and length would be nice. I agree that if we'd "need to choose" time is probably better, but when printing at (quite) different speeds for infill, walls etc I think length is also nice.

I also went from 0.4-0.5 found from testing to 0.2 to ease the printing somewhat and get good results anyways too.

-

@Exerqtor said in Pressure Advance: Discussion for Improvement in Bowden Printers:

That's exactly what i ended up doing to (well i setteled on 0.4), even though i would get the most consistent pressure somewhere close to 2, but it sounded like my BMG was one nudge away from exploding at that point

Designed new extruder mounts so i could move the extruders over the build area (corexy machine) and shorten the bowdens down to 300mm ish, so 0.4 isn't that much off.

Answers like this make me not feel alone in the world.

-

@RyanP said in Pressure Advance: Discussion for Improvement in Bowden Printers:

@Exerqtor said in Pressure Advance: Discussion for Improvement in Bowden Printers:

That's exactly what i ended up doing to (well i setteled on 0.4), even though i would get the most consistent pressure somewhere close to 2, but it sounded like my BMG was one nudge away from exploding at that point

Designed new extruder mounts so i could move the extruders over the build area (corexy machine) and shorten the bowdens down to 300mm ish, so 0.4 isn't that much off.

Answers like this make me not feel alone in the world.

Aye me too... Most calibration things I can see the difference and select a good balance (although often having to run multiple parameter ranges to get a matrix of options - stringing control being a good example here, move speed, retraction length, retraction rate wipe etc.) but this one feels like black magic hah

-

Just saw this tutorial pop up, note that it is for klipper-fw, but it should be translateable for RRF to i think. Gonna try it tomorrow and see what numbee i end up with this time

https://www.lpomykal.cz/anycubic-kossel-klipper-pressure-advance/

-

@dc42, any thoughts on this?

-

@dc42 I was really hoping you would weigh in here!

-

-

I'm sorry, I don't have time to look at improving PA until I've implemented input shaping. But I've bookmarked this thread so that I can return to it. Pressure advance smoothing is something I was already thinking about.

-

while we're at it, is there any impact using DAA (Dynamic Acceleration Adjustment: M593 with F != 0) during PA calibration process? DAA is related to acceleration where PA is jerk related, technically one shouldn't alter the other result but... heavy doubt

or is it better to turnOFF DAA, calibrate PA, then calibrate/turnON DAA ?

-

DAA might reduce acceleration, so it may affect PA - but only because in reality, PA should not be applied linearly. I think I would be inclined to calibrate DAA first followed by PA, however I haven't tested doing it both ways so I may be wrong.

-

Forgive the reference, but that's the way Klipper does it. First you do input shaping and only then PA.

Speaking of input shaping - since you are looking at it - are you also considering the option of using an accelerometer (like adxl345) to get the measurements?

-

@pkos said in Pressure Advance: Discussion for Future Development:

Speaking of input shaping - since you are looking at it - are you also considering the option of using an accelerometer (like adxl345) to get the measurements?

Yes.

-

Awesome!

-

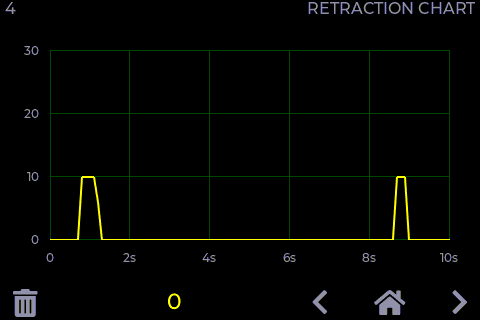

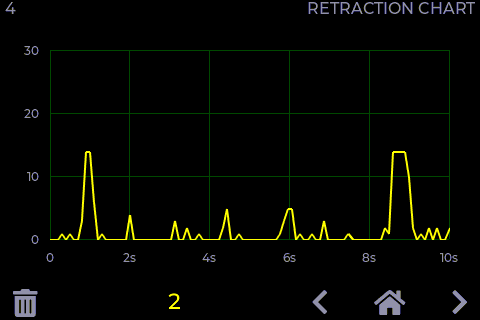

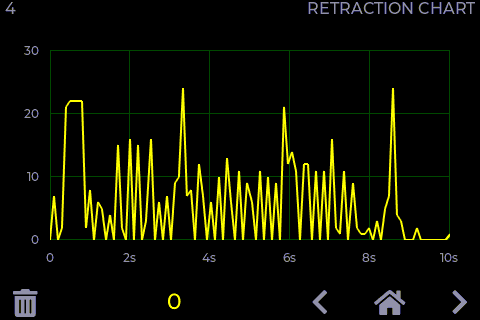

I run a small experiment, printing calicat at 50mm/s with different PA values while watching the retraction graph on the stepper analyzer.

(my printer uses esteps=830 with 1/16 microsteps, such that 10 full steps on the vertical axis represent (10 * 16) / 830 = 0.193mm).

With PA = 0 it looks very very clean with normal 0.2mm retractions as set in my slicer (using BMG direct):

Increasing the PA to 0.08 (my normal, BMG, direct) introduced small intermediate retractions, I presume because of the PA:

Increasing to PA=0.2 made it really loud and wilde:

With very rapid shot direction changes such as these ones:

-

I generally make parts where the seam ends up on a radiused corner. And something i've noticed is that the seam will look really good for one sized radius and bad for another of a substantially larger or smaller radius.

I assume this is because the PA value was tuned for angular acceleration similar to that encountered while traversing the corner radius.

Can anything be done to take X & Y acceleration and jerk into account?

-

-

@dc42 said in Pressure Advance: Discussion for Future Development:

I'm sorry, I don't have time to look at improving PA until I've implemented input shaping. But I've bookmarked this thread so that I can return to it. Pressure advance smoothing is something I was already thinking about.

Thanks for the reply. It's good to know that it is on the radar.

I'm wondering if one of my suggestions: not allowing PA to change the print head acceleration, might be developmentally cheap enough to try in a beta release?

I still believe that when PA reduces print head acceleration, it could be adding to the issue of mismatched extrusion rate.