Error: Attempting to extrude with no tool selected

-

hello everyone every time a part prints my filament stops outputting and i have an error but the printer keeps printing

thank you advance

advance -

Do you have a tool selection in your code?

i.e

T0 in your config.g or your start.g code? -

M80 ; Turns on the ATX power supply

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"sgk008" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable TelnetM669 K1 ; select CoreXY mode

; Endstops

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y2 S1 P"ystop" ; configure active-high endstop for high end on Y via pin ystop

M574 Z1 S2 ; configure Z-probe endstop for low end on ZM575 P1 S1 B57600 ; Set things up for the PanelDue

; Filament sensor

M591 D0 P1 C"e0stop" S1 ; Set Filament sensor Simple type (High) for extruder drive 0, connected to endstop input 3 (E0; Drives

M569 P0 S0 ; Drive 0 goes backwards blv: its was S1

M569 P1 S0 ; Drive 1 goes backwards blv: its was S1

M569 P2 S0 ; Drive 2 goes forwards

M569 P3 S1 ; Drive 3 goes backwards WAS 0

M569 P4 S0 ; Drive 4 goes forwards

M584 X0 Y1 Z2:4 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X200 Y200 Z400 E415.178 ; Set steps per mm for Bondtech.

M566 X600 Y600 Z1000 E200 ; Set maximum instantaneous speed changes (Jerk) (mm/min)

M203 X20000 Y20000 Z600 E2000 ; Set maximum speeds (mm/min)

M201 X1000 Y1000 Z100 E5000 ; Set accelerations (mm/s^2)

M906 X1000 Y1000 Z1000 E1000 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X-23 Y0 Z0 S1 ; Set axis minima

M208 X320 Y321 Z350 S0 ; Set axis maxima; Z-Probe

M558 P1 C"^zprobe.in" H5 F200 T9000 I0 R0.5 ; Set Z probe type mini ir sensor

G31 P500 X-2 Y-16.4 Z0.310 ; Set Z probe trigger value, offset and trigger height

M557 X20:270 Y20:270 S240 ; Define mesh grid; Heaters

M307 H0 R0.277 C337.2 D9.55 S1.00 V23.7 ; Set PID for heated bed values

M307 H1 R2.105 C132.8 D9.06 S1.00 V23.6 ; Set PID for hotend values

M308 S0 P"bedtemp" Y"thermistor" A"Bed" T100000 B4725 C0.0000000706 R4700 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" A"Hotend" T100000 B4725 C0.0000000706 R4700 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M143 H1 S260 ; set temperature limit for heater 0 to 260C

M308 S2 P"mcu-temp" Y"mcu-temp" A"Duet Board" ; Configure MCU sensor; Tools

M563 P0 S"T0" D0 H1 F1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C; Access point is configured manually via M587 by the user

;M586 P0 S1 ; Enable HTTP

;M586 P1 S1 ; Enable FTP

;M586 P2 S1 ; Enable Telnet;Hot End fan tool

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 C"HE Fan" S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on 100% at 45deg;Tool Fan/ Layer Fan

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S1 H-1 ; set fan 0 value. Thermostatic control is turned off;MB cooling fan layer

M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency

M106 P2 C"MB Fan" S1 H2 T35:55 ; set fan 2 value. Thermostatic control is turned on Temp Range of 35 - 55 deg; Custom settings

M572 D0 S0.275 ; Set bowden extruder elasticity compensation for E0

M572 D1 S0.275 ; Set bowden extruder elasticity compensation for E1

M207 S4.0 F2400 Z0.075 ; Set firmware retraction parameters; Scanner support (debug)

;M750; Set up DHT sensor on channels 101-102

;M305 P101 X405 S"DHT temperature" T11

;M305 P102 X455 S"DHT humidity [%]" T11; Automatic power saving

M911 S21 R22 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; Set voltage thresholds and actions to run on power loss; Custom settings are not configured

M564 H0 ; Let the Jog buttons work blv: added to allow jog buttons

; Miscellaneous

M501 ; load saved parameters from non-volatile memory

T0 ; select first tool -

@sgk said in Error: Attempting to extrude with no tool selected:

M575 P1 S1 B57600 ; Set things up for the PanelDue

try disconnecting the paneldue.

also post the output of M98 P"config.g"

-

@Veti said in Error: Attempting to extrude with no tool selected:

M98 P "config.g"

12:47:21M98 P"config.g"

HTTP is enabled on port 80

FTP is disabled

TELNET is disabled

Error: Invalid extruder number '1'

Warning: Macro file config-override.g not found

12:47:15Message Log cleared! -

@sgk said in Error: Attempting to extrude with no tool selected:

Error: Invalid extruder number '1'

M572 D1 S0.275 ; Set bowden extruder elasticity compensation for E1i think it might be that statement

-

I must put 0

M572 D0 S0.275; Définir la compensation d'élasticité d'extrudeuse Bowden pour E1 -

you already have a line like that in your config

-

@Veti oh yes

I understood I have a double line

thank you very much -

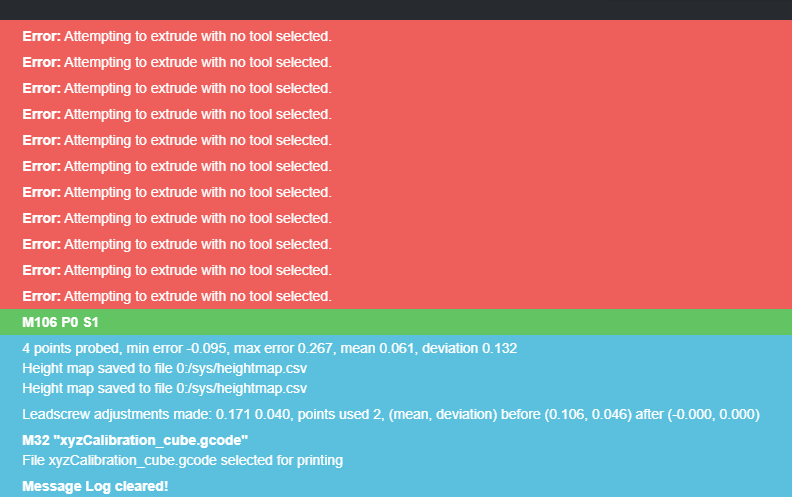

I still have the same error

14:29:50Error: Attempting to extrude with no tool selected.

14:29:46Error: Attempting to extrude with no tool selected.

14:29:42Error: Attempting to extrude with no tool selected.

14:29:38Error: Attempting to extrude with no tool selected. -

@sgk post the gcode file you're printing with. My guess is that you have a rogue T-1 or T1 command in there.

Did you also try Veti's suggestion of disconnecting the Panel Due? I've seen before where interference in the wires to the Panel Due corrupts the data flow and gives similar issues.

-

-

it does it to me since the update of 2.03 2.05 3.0 3.1 3.2

with all files from all slicers

-

@sgk upload the sliced gcode file, not the stl.

Did you try disconnecting the panel due?

-

yes the same

-

it's crazy since I was in 3.2 I have this problem

-

did you disconnect the paneldue?

-

@Phaedrux or @T3P3Tony (or one of the other moderators), it seems @sgk has been blocked from posting (getting flagged as spam by Akismet.com). Can you help with this please?

-

@engikeneer thanks for the heads up. this is the first time i have seen it with someone who is already posting successfully. Akismet is a bit of a black box, can you ask him to email info@duet3d.com and we can try and trouble shoot through this.

-

@sgk You must post the sliced gcode file so we can see what the slicer is adding.