Retraction... once more with FEELING!

-

I love my delta printer. I designed and built it myself from scratch. It's big, it's fast, it's versatile and it prints amazing. Surface finish is awesome, results are rock solid. There's nothing wrong with it...

...except of course for the oozing/stringing. I know, I know, this is covered ad nauseum all over this forum and the general Internet! There's a million guides out there to help solve this issue. And yet...

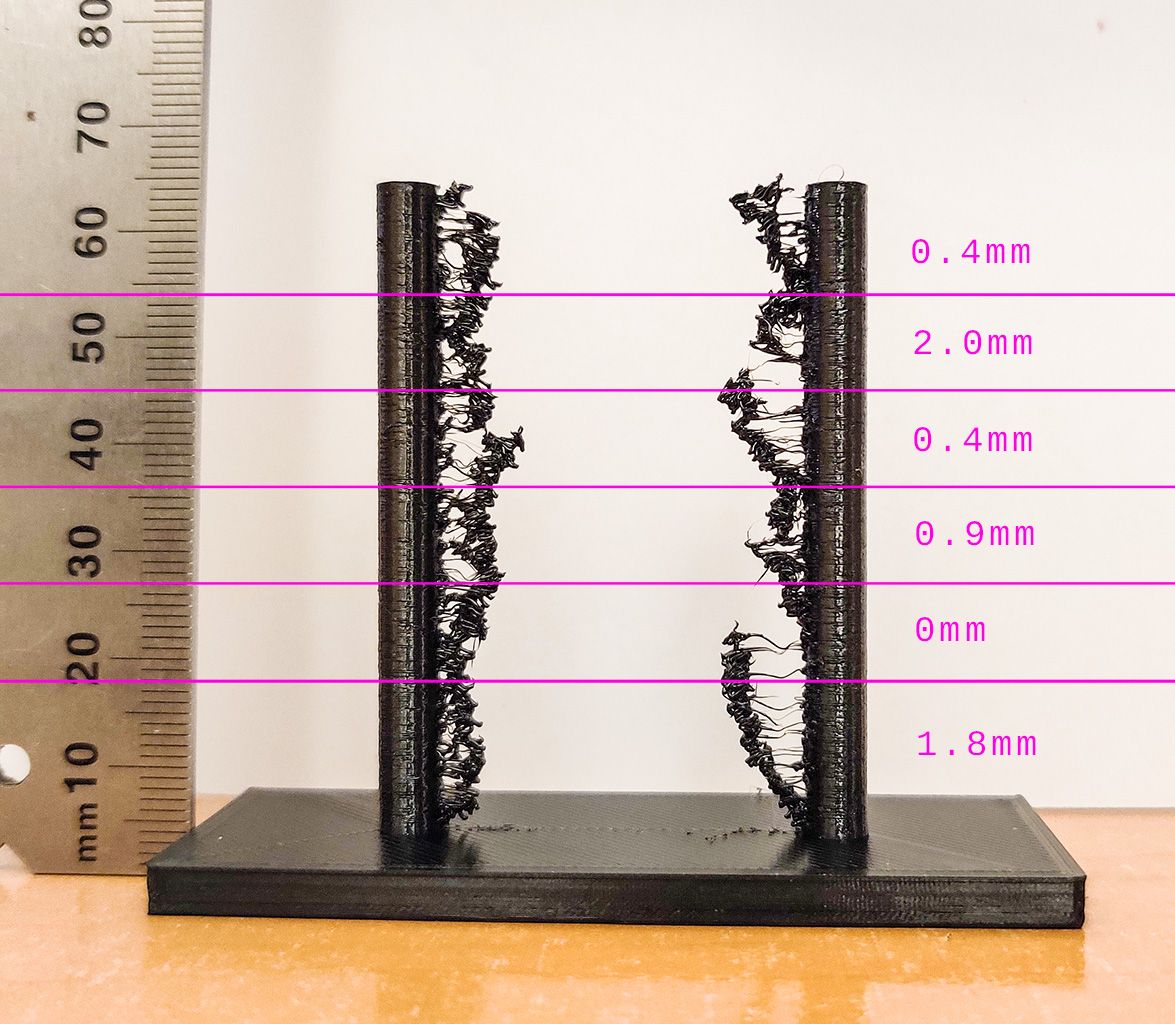

Today I decided to sit down and really work on it. Tune settings meticulously until I get it perfect. The best place to start is with retraction length, right? Here's my result:

Yes, I know it looks like I was leaping about randomly with the settings. But there's a method to my madness. The 1.8mm setting is what I've been running for months., so that's what I started with. After that, I wanted a dramatic difference. So I went with NO retraction! How tricksy! Except that made no difference...

So then I figured I'd split the difference with 0.9mm... except there WAS no difference...

Then I went with the Slice Engineering recommendation for direct drive extruders of matching retraction length to nozzle diameter (0.4mm). Still no difference...

Then I went to the other extreme, the max recommended for direct drive! Still no difference...

Finally I went back to the previous setting, because I was baffled by this complete lack of results. Seriously, this is a heck of a wide range of retraction lengths. Nothing ever made any difference. How is this even possible?

The extruder is an Orbiter sitting (almost) directly on top of a Slice Mosquito Magnum hotend with a plated copper 0.4mm nozzle. The mounting adapter on the Smart Effector requires 34mm of bowden tubing. The board is a Duet 3 with firmware 3.2 (though the same results were had with 3.1.1). Firmware retraction is defined as such:

M207 S1.8 F3600That retraction speed is the recommendation for an Orbiter extruder, however I've tried 2400 and 5400 with no obvious difference. The recommended retraction distance for the Orbiter is 1.2mm, though that hasn't helped my results.

The extruder is defined as follows:

M566 X1800.00 Y1800.00 Z1800.00 E300 M203 X12000.00 Y12000.00 Z12000.00 E3600 M201 X1500.00 Y1500.00 Z1500.00 E660All those numbers are directly pulled from the Orbiter recommendations. I've got pressure advance set to:

M572 D0 S0.03Though I've tried every value from 0 to 1.0. Results were much worse the closer I got to 1.0. The 0.03 value is the recommendation for this extruder.

I've confirmed that firmware retraction is enabled in Cura, and G10 is in fact what's used for retraction throughout generated gcode files. I've also tried enabling Z hop on retract, with disastrous results. Instead of small, easily-removable clumps, I ended up with countless cobwebs that were very difficult to remove. It was like a decades-old spider's nest. The filament I'm mostly printing with these days,, and that I've been expensively wasting for this tuning, is Polymaker PolyMide CoPa, which is a mix of Nylon 6 and Nylon 66.

HELP ME PLEASE!!! What am I doing wrong?!?

-

A couple of suggestions:

-

I recently stumbled upon an older blog post by Michael Hackney who recommends fast retract and slow unretract. That made oozing skid marks disappear on my Ultimaker

-

Try varying the temperature by 5C up or down

-

Super important: Make sure not to accidentally combine slicer and firmware retract. That happened to me in the past.

-

Check out KISS slicer's tuning wizard for PreloadVE.

-

just to complete the list, ensure that your Nylon is dry-dry whole printing. Actively heated filament box during printing and vacuum bag for long-term storage is what people recommended to me.

-

-

All good points, thank you!

@oliof said in Retraction... once more with FEELING!:

A couple of suggestions:

- I recently stumbled upon an older blog post by Michael Hackney who recommends fast retract and slow unretract. That made oozing skid marks disappear on my Ultimaker

I had tried making the retract slower while keeping unretract fast, but that did not seem to help. I had not considered doing the opposite. I'll try that tomorrow.

- Try varying the temperature by 5C up or down

My concern with that is that when 10c lower in temperature, the resulting parts are much more brittle. CoPa really seems to like being in the upper area of its suggested range (250-270c, I'm running at 260c), especially at its max recommended speed (60mm/s). But it's worth trying to drop 5c to see if it helps.

- Super important: Make sure not to accidentally combine slicer and firmware retract. That happened to me in the past.

There's definitely no slicer retract in the generated gcode files, it's only G10/G11

- Check out KISS slicer's tuning wizard for PreloadVE.

Will do! Looks interesting

- just to complete the list, ensure that your Nylon is dry-dry whole printing. Actively heated filament box during printing and vacuum bag for long-term storage is what people recommended to me.

Oh this filament is dry as dry can be. I dry it in a printdry box for 8 hours at 70c before I use it, and it's inside the heated printer enclosure during printing, along with a bunch of desiccant bags that change color when they absorb moisture. They're all bright orange (dry).

-

Is your Bowden tube firmly seated at both ends? When I used Bowden, I had similar issues. The tube itself was moving up and down with retraction, not the filament. The solution was to make sure the tube was seated fully, then wrap a wire or place a shim under the collar of the Bowden tube connector, to hold it firmly in the connected position.

-

@bot Hmm, that's a good question. I do know that the very short (34mm) bowden tube is tight at both ends because the extruder sits about 0.5mm proud of the adapter when it's not screwed down and screwing it down causes the bowden tube to be compressed lightly. There's no fitting holding it in place, it just sits within a channel inside the adapter between two holes in the hotend and extruder. However it does have wiggle room inside the adapter and the tube is constantly bent by the adapter due to the required angle to make the extruder fit on the effector and still retain the full range of motion. The tubing is well supported in the direction opposite the bend so it SHOULDN'T be flexing in any direction, but I'm using capricorn tubing at that point which is more restrictive on the filament and that might be causing the tubing to shift on retraction. I'll try switching to conventional 2mm PTFE tubing and see if that makes a difference. I'm starting to sour on capricorn tubing for very short distances anyways, it doesn't seem beneficial.

-

Hmm... You have a direct extruder, right? That small section of tube shouldn't matter so much (I was thinking you had a bowden tube, from the pictures alone).

How about the filament drive gear's tightness on the shaft that turns it? Motion can be lost if the grub screw isn't tightened firmly.

-

The fact that there is no difference apparent between settings suggests to me that retraction isn't happening, per @bot's suggestion. If you put a mark on the filament, can you see it jumping up during retractions?

-

I'm not familiar with nylon, but with other materials (PLA, PETG, ABS) I've found turning OFF a part cooling fan can reduce very thin stringing.

-

Something else to try...

Disclaimer: While I state it several times below, this post is based my beliefs mixed with facts. I'm not the kind of engineer that understands the "why" of stringing, and I don't want to represent myself as someone who actually knows what they're talking about in that regard...

Similar to typical configurations of remote direct drive extruders (such as the flex3drive and nimble), the "jerk" is pretty low at only 300mm/min (or 5mm/sec.) In the case of the remote extruders, they suggest a value as slow as 50 (but I'm using 250 on my nimble.)

I believe (without proof or any factual knowledge) that these very slow jerk settings make retraction less useful: If the extruder is extruding filament out at 1mm/sec and you retract at 60mm/sec (as per your m207), you're requesting an speed change of 61mm/sec - which is greater than the max of 5mm/sec specified in the M566 configuration.

While I won't pretend to know exactly how RRF handles this situation, it suggests that a retraction actually causes the nozzle to pause in place for some amount of time in order to "instantly" switch from +1mm/sec to -4mm/sec and then accelerate to a max of 60mm/sec (at a rate of 660mm/sec per sec) until it's retracted the set amount of filament. I don't know the exact amount of time that it would take to retract 2mm with a max of 60mm/sec with those values, but however long it takes is time that the nozzle is just sitting there against the most recently deposited filament, as well as oozing a bit, creating a recipe for stringing.

(Compare that with a direct drive extruder, such as a titan aero, where the jerk can easily be set as high as 3600 - which allows the extruder to go from 1mm/sec extruding to 59mm/sec retraction instantly.)

With all that typed (and hopefully it's accurate), the idea is that the configured values for E's accel and jerk don't allow QUICK retractions, which I suspect reduces the effectiveness of them.

Can you tinker with the jerk (M566) and accel (M201) to try and make them faster? I don't know how much abuse the orbiter's LDO stepper can take, nor the amount of abuse the gears in the orbiter can handle.

However, you can (at your own risk) tinker with the settings by printing your retraction test with retractions set to 2mm all the way through, and then modify the M566 E value (during the print from the DWC console) until the extruder starts skipping steps (clicking) or making unusual noises. While testing, also watch the filament feeding into the extruder to make sure it's actually retracting when it should.

Once you've reached your highest jerk, back it off a bit. Then start tinkering with the acceleration (M201) to raise it using the same method.

Are you able to reach higher values? Does it help?

-

I finally got my "boring work" done, so I've got time to run more tests. While I'm doing that, I'll answer some of the excellent suggestions that were contributed:

@oliof Thank you for suggesting Michael Hackney's blog posts, they've been very enlightening. He's more wordy than I am (which is saying something), but he has some good wisdom in there and I now have a much better understanding of how retractions (and a great many other things) work

@bot Yes it's direct drive. I've confirmed that the very short 34mm bowden tube is in fact tightly secured at all times and not bending or shifting in any direction, either while extruding or retracting. And yes, the set screws on the hobs are very tight. There doesn't appear to be any sloppiness in the filament movement from my inspection.

@whopping-pochard I just checked, and the filament is in fact moving during retraction. I can feel it with my hand while manually issuing G10/G11 commands, and the different retraction lengths are definitely having an effect. It's fairly easy to tell a difference between 0.4mm and 2.0mm of retraction.

@garyd9 For nylon, the part cooling fan is typically left off altogether except for bridging and such. I've been running all tests with it off. The Orbiter extruder I'm using is not remote direct drive, it has the motor right on the extruder. It is geared down like a remote direct drive extruder, but not as much. The Flex3Drive I used to run was geared at 40:1, the Orbitter I'm using now is about 7:1. You're totally right that these slow jerk settings tend to cause the nozzle to sit in one place for a bit wile the retraction is happening. That's probably a big part of what's happening here. Espeially with nylon at high temperature, which tends to get really runny and stringy. As long as the nozzle is moving fast, everything is great. But as soon as it pauses, the oozing happens. Unfortunately there's only so much jerk that de-geared extruders can manage, specifically because of that gearing. It's interesting that you mention the Titan extruder (3:1) can be set as high as 3600. That implies that my extruder (7:1) should be able to handle up to 1550, though the tiny Nema 14 motor I'm using may not be able to achieve that like a Nema 17 motor can. I'll try it out and see what kind of difference it makes

-

@whopping-pochard I just checked, and the filament is in fact moving during retraction. I can feel it with my hand while manually issuing G10/G11 commands, and the different retraction lengths are definitely having an effect. It's fairly easy to tell a difference between 0.4mm and 2.0mm of retraction.

Take it a step further and make sure it is happening during a test print.

-

I think I nailed it:

(note: the bottom is wavy because it's only 0.5mm thick and I just peeled it off the hot bed)

Ultimately, the solution was to minimize the amount of time that the nozzle stays in one place, and reduce the possibility of it moving across gaps immediately from the edge of a wall. I upped the speed (3600mm/s), acceleration (1500mm/s2) and jerk (1200mm/min) settings for the extruder, shortened the extrusion distance (1mm), fixed the "combing" setting in Cura (changed to "not in skin"), randomized the Z seam, and upped the outer wall wipe distance from 0.2mm to 0.4mm. Now all the stringing is gone. I still get some scarring on top skin from drooping filament, but it's minimal and literally the only minor blemish. Everything else prints so well, you'd think it was molded. Even tiny details that I used to struggle with now come out crisp and sharp.

Thanks all for the advice!

-

@goremanx What that 3600mm/sec or 3600mm/min?

-

@gorillamotors it's probably per minute since I can't imagine my extruder spitting out 10+ feet of filament per second

-

@goremanx said in Retraction... once more with FEELING!:

I've got pressure advance set to:

M572 D0 S0.03Though I've tried every value from 0 to 1.0. Results were much worse the closer I got to 1.0. The 0.03 value is the recommendation for this extruder.

As you have a 34mm Bowden tube between the extruder and the hot end, a higher value is almost certainly optimal. I would expect the optimum to be less than 0.1.

I've never printed nylon, but when printing PLA I found the best way to avoid stringing was to reduce print temperature - although that was before we had pressure advance..

-

I think the oozing is caused by the hotend staying too much on the place during retraction. If your printed is well calibrated and creates no irregular surfaces, i would set Z hop to 0mm for retraction and crank up the retraction speed and acceleration. With my direct extruder i use 0.03PA and 0.75mm retraction at 60mm/s and deretraction at 40mm/s.

Obviously the problem is higher with high flow hotends. That is why i would only use them if really needed. -

Ok so everyone realizes that this thread was solved months ago, right ?

-

@goremanx They must just be hooked on the feeling.