3D GCode Viewer integrated with DWC

-

@Sindarius what would be really helpful is being able to load a gcode for laser use and then jog the nozzle in x and y to ensure the scrap piece of wood you're going to use is in the correct position

-

@jay_s_uk said in 3D GCode Viewer integrated with DWC:

@Sindarius what would be really helpful is being able to load a gcode for laser use and then jog the nozzle in x and y to ensure the scrap piece of wood you're going to use is in the correct position

(

YEP! Also for CNC´s combined with sub-csys (so beside the standard-csys-G54 using sub-csys/"local-csys" like G55 and so on)

-> I think he is aware of it

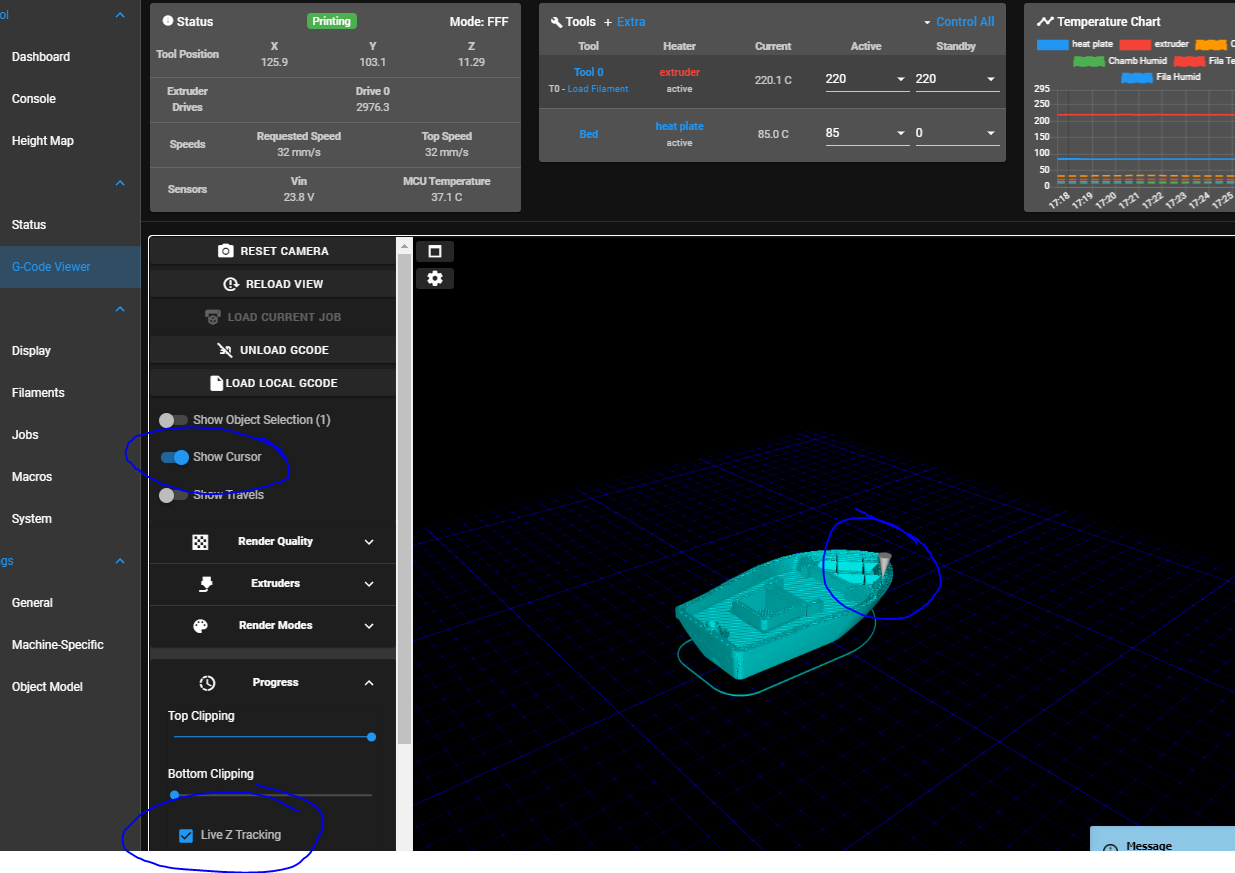

)BUT -> HEY HEY HEY, do you mean: AFTER the printer was homed -> THERE COULD BE A LIVE VIEW WITHIN THAT PLUGIN OF THE TOOL BY FETCHIN THE CURRENT TOOL POSITION FROM TEH OBJECT MODEL?

WOOAAAAAAAAHHHHHHHHHHHHHH

-

@LB I am looking at displaying each csys with an axes indicator and label at some point soon. I need to look at the code because I believe I am currently using machine position to drive the cursor.

-

@LB Feed rate has a lot of perks including being useful for looking at your movement. In line rendering mode it can help provide a nice color contrast on single material prints.

-

@PCR said in 3D GCode Viewer integrated with DWC:

@theruttmeister which slicer are you using? I never got the object Feature to Work!

Cura 4.4.0 iirc.

Not seen a 'label objects option' but then not ever looked for one. Not looked at the gcode either.

-

@Sindarius said in 3D GCode Viewer integrated with DWC:

@LB I am looking at displaying each csys with an axes indicator and label at some point soon. I need to look at the code because I believe I am currently using machine position to drive the cursor.

I understand. To not confuse people with more and more options (variables, conditions, etc.) it would be cool if it is consitet with DWC and PanelDue of course - I guess that is what you meant?

Cheers

-

Any chance this could be adapted for CNC milling,so instead of adding material, it works on removing material

-

@Sp00kie13 at this point it is just going to show the lines. To show actual carving is a different process. Most viewers I am aware of use voxels and remove them as they are traveled through. The other thing is without endmill information it would be inaccurate. Maybe some day it will be a project I work on but probably not anytime soon.

-

If duet is set up as a printer, are you already using M200 Dx and/or M404 Nx e.g. for a line-thickness (straight line) above the tool that is feeded to the dummy nozzle-cone-object for the live-view?

Also for the request to have a "live-view" of the "tool-position" one option would be to use M404 Dx as Tool cone lower hole? Just thinkin...

But I think as long as there is no m291 with keyboard input (e.g. only numbers for the M404 D_) changing it in config.g for having an update "tool-hole" in the 3D-viewer would be a bit odd?

Ah - I don´t know, just wanted to keep the discussion here goin

I like it - this is really amazing

:

:

-

@theruttmeister said in 3D GCode Viewer integrated with DWC:

@PCR said in 3D GCode Viewer integrated with DWC:

@theruttmeister which slicer are you using? I never got the object Feature to Work!

Cura 4.4.0 iirc.

Not seen a 'label objects option' but then not ever looked for one. Not looked at the gcode either.

Cura labels the objects automatically, however the labels are not ideal. For example, AFAIR all support material has the same label

-

@dc42

Interesting.I'm guessing that its not yet a widely enough used feature (per-object-cancel) that anyone has felt the need to fix that.

Hopefully that will change. Its a real value add, if I were selling printers to people its the kind of thing that would totally help win the sale.

For running a print farm, its now a hard requirement for me at least. -

@LB Currently the cone is simply using the current machine position coordinates from the object model to display its current position.

-

Would be great if the viewer stores the last settings. Obviously this is not the case?!

Thanks for your work!

-

@MartinNYHC Some of the settings should be getting stored in the local browser, such as the extruder color settings, which setting is not saving?

-

@Sindarius said in 3D GCode Viewer integrated with DWC:

@MartinNYHC Some of the settings should be getting stored in the local browser, such as the extruder color settings, which setting is not saving?

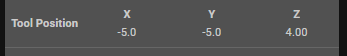

At least "Show Cursor" and "Live Z Tracking".

-

@MartinNYHC Yeah I don't think either of those are currently set to save. I'll look at adding them in 3.3

-

Do you think you could also "wipe" the "stage clean" if I simulated/printed one file and then start another (without loading it in the 3d-viewer before) and I still see the "old" model with was loaded to the 3d-viewer "last" time, but of course since "now" I am printing a different file:

I guess that is a bit more tricky to implement an automatic check if the current printed file is the same that is loaded/stored in the 3d-viewer and "if not" the stage is cleaned and only the cone is showed in live-tracking-mode?

(Hope you get what I´m writing here

and I am aware it would be more of a newbie or bomb-proof-comfort feature)

and I am aware it would be more of a newbie or bomb-proof-comfort feature)Edit:

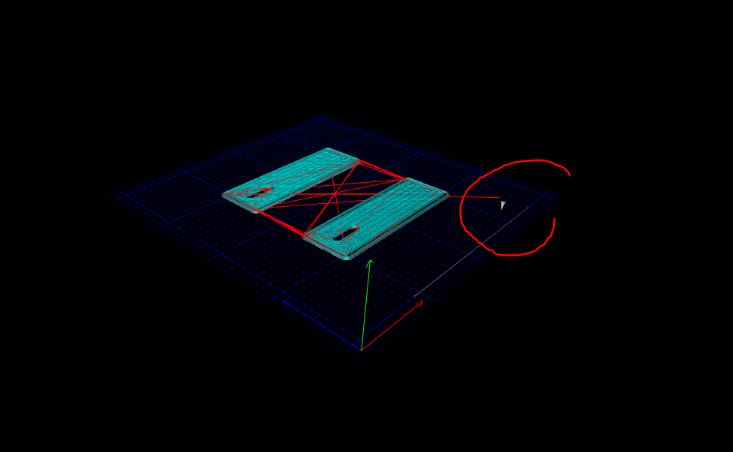

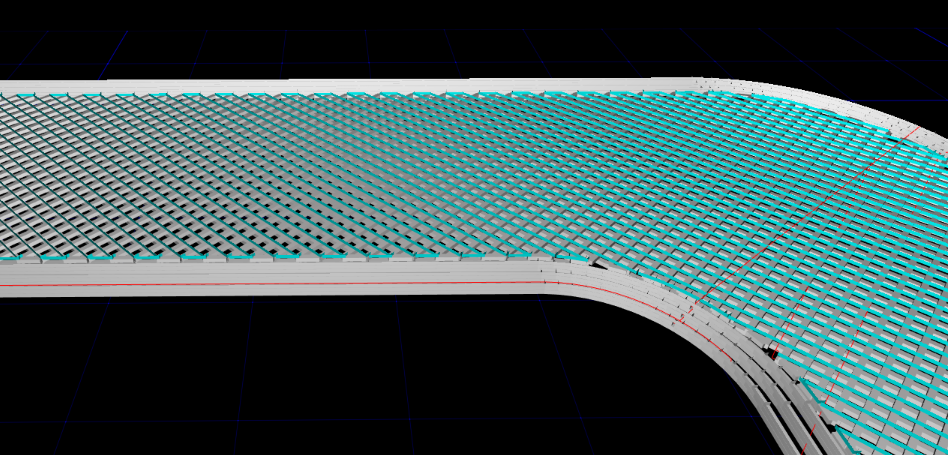

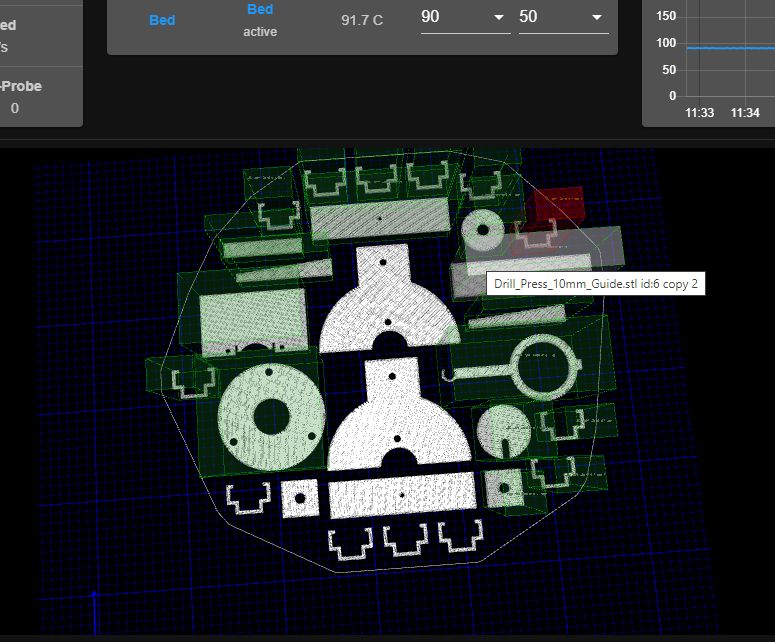

For each loaded layer you seem to use already 2 different colours for already-printed-on-current-layer and yet-to-be-printed-on-current-layer? Right? But depending on the view and rendering it is very hard to see and for me in most angles it looks like the two colours are kind of blurred or transition into each other so that it is hard to tell which is which.An example here of cyan to grey kind of:

Would be great if you can try to optimize line-thickness/width and render-light/shading to have the two colours easier to differentiate?Great work!

All the best -

@LB I'll double check the code but if you start a different job/simulation the load job button should light up to let you choose the new file. I'll double check it.

When you're printing/simulating a file there is a progress color in the progress tab where you can change the color for what has been printed. The light blue is the default extruders color for Tool 0. It may be worth while to experiment with some colors to see if you can find a set that work well for you. Some of what you are seeing is due to perspective.

As a print progresses it will use the progress color in the progress tab to change the tool color to the printed color.

I hope I am understanding the question/issue. Let me know

-

is there a limit to the number of objects which are counted by the plugin? I have a print bed where I added 28 or so objects and needed to cancel 3 of them. I could only cancel 1 as the other 2 and several others were not in the object list. The plugin also only reported 20 objects instead of the 28 that were being printed. Having the number user-configurable would be a nice thing if so

-

@Colten that limit is not on the viewer. The data comes from RRF