Is there already a documentation about the new plugin system? I'm interested to know how to implement a new plugin.

Best posts made by MartinNYHC

-

Third party plugin documentationposted in Duet Web Control wishlist

-

RE: Issues with pressure advance since RRF 3.4posted in General Discussion

After synchronizing with @Argo what already has been tested and what not I wanted to rule out that the problem is caused by the 1LC toolboard.

Top: E stepper comnnected to a Duet3 3HC

Bottom: E stepper connected to 1LCSo at least we are now sure that it is not related to the 1LC.

My setup:

Same printer as @Argo

Duet3 6HC with 1LC and SBC running RRF 3.4.3

LGX extruder with Rapido HF hotend.config.g

; General preferences M111 S0 ; Debugging off G21 ; Work in millimetres G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves M669 K1 ; Select CoreXY mode M564 S1 H1 ; Forbid axis movements when not homed G4 S1 ; wait for expansion boards to start ; Drives ; --- Z Drive map --- ; _______ ; | 3 | 4 | ; | ----- | ; | 2 | 5 | ; ------- ; front ; ; Drive directions M569 P0 S1 ; A (X) M569 P1 S1 ; B (Y) M569 P2 S1 ; Z1 M569 P3 S0 ; Z2 M569 P4 S1 ; Z3 M569 P5 S0 ; Z4 M569 P121.0 S1 ; E ; Motor mapping and steps per mm M584 X1 Y0 Z2:3:4:5 E121.0 M350 X16 Y16 Z16 E16 I1 ; Use 1/16 microstepping with interpolation everywhere M92 X80 Y80 Z400 E414.92683 ; Drive currents M906 X1500 Y1500 Z1500 E650 ; XYZ and E current M906 I30 ; Idle current percentage M84 S300 ; Idle timeout ; Accelerations and speed ;M566 X600 Y600 Z60 E8000 ; Set maximum instantaneous speed changes (mm/min) M566 X400 Y400 Z60 E8000 ; Set maximum instantaneous speed changes (mm/min) M203 X30000 Y30000 Z3000 E15000 ; Set maximum speeds (mm/min) M201 X10000 Y10000 Z250 E1800 ; Set maximum accelerations (mm/s^2) M204 P4000 T5000 ; Accelerometer ;M955 P121.0 I05 ; set address and orientation of tool board ; PA, DAA ;M572 D0 S0.05 M572 D0 S0.035 M593 P"zvdd" F35.2 ; Axis travel limits M208 X5 Y-5 Z0 S1 ; Set axis minima M208 X350 Y350 Z375 S0 ; Set axis maxima ; Endstops M574 X2 S1 P"^io1.in" ; Xmax endstop M574 Y2 S1 P"^io2.in" ; Ymax endstop ;M574 Z1 S1 P"^io3.in" ; Z endstop switch M574 Z1 P"nil" ; No endstop ; Z probes ;M558 K0 P8 C"121.io0.in" I1 H2.5 F250 T18000 A31 S0.0035 R0.2 ; set Z probe type to switch and the dive height + speeds ;G31 K0 P500 X0 Y25 Z8.74 ;M558 K1 P8 C"io3.in" I1 H2 F240 T18000 A31 S0.0035 R0.2 ; set Z probe type to switch and the dive height + speeds ;G31 K1 P500 X0 Y0 Z0 ; set Z probe trigger value, offset and trigger height -0.8 ; Filament Sensor ;M591 D0 P7 C"121.io2.in" S1 ; Bed leveling M671 X-53:-53:400:400 Y-5:420:420:-5 S20 ; Define Z belts locations (Front_Left, Back_Left, Back_Right, Front_Right) ;M557 X20:335 Y20:330 P5:5 M557 X120:235 Y120:230 P2:2 ; Bed heater M308 S0 P"temp0" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor M950 H0 C"out1" T0 ; create bed heater output M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater ; Hotend heater ;M308 S1 P"121.temp1" Y"pt1000" M308 S1 P"121.temp1" A"Heater 1" Y"thermistor" T100000 B4725 C7.06e-8 M950 H1 C"121.out0" T1 ;M950 H1 C"out2" T1 M307 H1 B0 S1 ; disable bang-bang mode for heater and set PWM limit M143 H1 S300 ; Set temperature limit for heater ; Chamber Thermistor M308 S2 P"temp1" A"Chamber" Y"thermistor" T100000 B3950 ; configure sensor 2 as thermistor ; MCU sensors M308 S3 Y"mcu-temp" A"MCU" M308 S4 Y"drivers" A"Drivers" M912 P0 S-13 ; MCU temp calibration ; Fans ;M950 F0 C"121.out1" Q10000 ; part cooling fan # old Sunon M950 F0 C"121.out1" ; part cooling fan # new Gsdtime M106 P0 C"Bed" S0 H-1 ; part cooling fan M950 F1 C"121.out2" ; hotend fan M106 P1 C"Hotend" L0.70 X0.70 H1 T70 S0.70 ; hotend fan M950 F2 C"out7" Q10 ; air filter fan M106 P2 C"Filter" S0 H-1 B0.2 ; air filter fan M950 F3 C"out4" Q24000 ; electronics bay left side M106 P3 S0.75 H-1 B1 C"Bay" ; electronics bay left side ;M950 F4 C"1.out3" Q24000 ; electronics bay right side ;M106 P4 S0.75 H-1 B1 C"Bay Right" ; electronics bay right side M950 F5 C"out5" ; sbc fan M106 P5 S0.2 H-1 C"SBC" ; sbc fan M950 F6 C"out6" ; chamber light M106 P6 S1 H-1 C"Light" ; chamber light ; Tools M563 P0 S"Hotend" D0 H1 F0 ; define tool 0 ;G10 P0 X0 Y0 Z-2.75 G10 P0 X0 Y0 Z0 G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Enable debugging via USB ;M111 S1 P0 ; Platform ;M111 S1 P1 ; Network ;M111 S1 P2 ; Webserver ;M111 S1 P3 ; GCodes ;M111 S1 P4 ; Move ;M111 S1 P5 ; Heat ;M111 S1 P6 ; DAA ;M111 S1 P7 ; Roland ;M111 S1 P8 ; Scanner ;M111 S1 P9 ; PrintMonitor ;M111 S1 P10 ; Storage ;M111 S1 P11 ; PortControl ;M111 S1 P12 ; DuetExpansion ;M111 S1 P13 ; FilamentSensor ;M111 S1 P14 ; Wifi ;M111 S1 P15 ; Display ;M111 S1 P16 ; LinuxInterface ;M111 S1 P17 ; CAN ; Neopixel M150 X3 Q3000000 ; set LED type to NeoPixel and set SPI frequency to 3MHz M150 W255 P255 Y255 S3 F0 ; Misc M575 P1 S1 B115200 ; enable support for PanelDue M501 ; load config-override.g M302 P0 ; disallow cold extrudes T0 ; select tool 0 ; Auto Z M98 P"/macros/autoz/edit_me.g" ; load your settings for autoz with klicky probe M400 M98 P"/macros/autoz/scripts/autoz_globals.g" ; load autoz framework for klicky probe M400 ; ERCF ;M98 P"0:/macros/sys/ercf/lib/init.g" -

RE: Duet3 Neopixel Wiringposted in Duet Hardware and wiring

@Nuramori said in Duet3 Neopixel Wiring:

I have mine working on my BLV with the duet3. It’s actually easier than it was with the duet2. I can share details and pictures in a bit if you’re interested.

Yes please

-

RE: Issues with pressure advance since RRF 3.4posted in General Discussion

@gloomyandy My extruder is clogged

Will do the test prints tomorrow.

Will do the test prints tomorrow. -

RE: Duet/RRF Mosaic Palette and Octoprintposted in 3D Printing General Chat

@Phaedrux Yes, my final way for the future is definitely a tool changer.

At least I got it to run. I'm doing the pre gcode via DWC and then start the main print via Octoprint. I had to block M503 in Octoprint otherwise it stucks in status "starting".

The "slow down during splices" plugin feature seems to work. I printed @100mm and during splices @50mm without any problems.

-

RE: Question for Nodejs guysposted in DSF Development

That's what I was looking for. Very useful. Thx mate!

-

RE: RRF 3.2: Failed to start Duet Control Serverposted in Firmware installation

My fault. I still had an empty SD card inserted into the Duet 3

Sorry for that.

-

RE: Duet 2 or 3 for Corexyposted in General Discussion

Thanks for pointing out, but I bought a Duet 3 6HC today

Now I need to wait for the ordered frame parts. Did I mention that I hate waiting at all?

Latest posts made by MartinNYHC

-

RE: Issues with pressure advance since RRF 3.4posted in General Discussion

@gloomyandy My extruder is clogged

Will do the test prints tomorrow.

Will do the test prints tomorrow. -

RE: Issues with pressure advance since RRF 3.4posted in General Discussion

@Argo I also had this issue before I switched from a Mosquito Magnum to Rapido

-

RE: Issues with pressure advance since RRF 3.4posted in General Discussion

@gloomyandy I already tried lots of different settings within the last few months but that doesn't change anything. The same applies to the RRF version - same results as @Argo starting with 3.4.

-

RE: Issues with pressure advance since RRF 3.4posted in General Discussion

After synchronizing with @Argo what already has been tested and what not I wanted to rule out that the problem is caused by the 1LC toolboard.

Top: E stepper comnnected to a Duet3 3HC

Bottom: E stepper connected to 1LCSo at least we are now sure that it is not related to the 1LC.

My setup:

Same printer as @Argo

Duet3 6HC with 1LC and SBC running RRF 3.4.3

LGX extruder with Rapido HF hotend.config.g

; General preferences M111 S0 ; Debugging off G21 ; Work in millimetres G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves M669 K1 ; Select CoreXY mode M564 S1 H1 ; Forbid axis movements when not homed G4 S1 ; wait for expansion boards to start ; Drives ; --- Z Drive map --- ; _______ ; | 3 | 4 | ; | ----- | ; | 2 | 5 | ; ------- ; front ; ; Drive directions M569 P0 S1 ; A (X) M569 P1 S1 ; B (Y) M569 P2 S1 ; Z1 M569 P3 S0 ; Z2 M569 P4 S1 ; Z3 M569 P5 S0 ; Z4 M569 P121.0 S1 ; E ; Motor mapping and steps per mm M584 X1 Y0 Z2:3:4:5 E121.0 M350 X16 Y16 Z16 E16 I1 ; Use 1/16 microstepping with interpolation everywhere M92 X80 Y80 Z400 E414.92683 ; Drive currents M906 X1500 Y1500 Z1500 E650 ; XYZ and E current M906 I30 ; Idle current percentage M84 S300 ; Idle timeout ; Accelerations and speed ;M566 X600 Y600 Z60 E8000 ; Set maximum instantaneous speed changes (mm/min) M566 X400 Y400 Z60 E8000 ; Set maximum instantaneous speed changes (mm/min) M203 X30000 Y30000 Z3000 E15000 ; Set maximum speeds (mm/min) M201 X10000 Y10000 Z250 E1800 ; Set maximum accelerations (mm/s^2) M204 P4000 T5000 ; Accelerometer ;M955 P121.0 I05 ; set address and orientation of tool board ; PA, DAA ;M572 D0 S0.05 M572 D0 S0.035 M593 P"zvdd" F35.2 ; Axis travel limits M208 X5 Y-5 Z0 S1 ; Set axis minima M208 X350 Y350 Z375 S0 ; Set axis maxima ; Endstops M574 X2 S1 P"^io1.in" ; Xmax endstop M574 Y2 S1 P"^io2.in" ; Ymax endstop ;M574 Z1 S1 P"^io3.in" ; Z endstop switch M574 Z1 P"nil" ; No endstop ; Z probes ;M558 K0 P8 C"121.io0.in" I1 H2.5 F250 T18000 A31 S0.0035 R0.2 ; set Z probe type to switch and the dive height + speeds ;G31 K0 P500 X0 Y25 Z8.74 ;M558 K1 P8 C"io3.in" I1 H2 F240 T18000 A31 S0.0035 R0.2 ; set Z probe type to switch and the dive height + speeds ;G31 K1 P500 X0 Y0 Z0 ; set Z probe trigger value, offset and trigger height -0.8 ; Filament Sensor ;M591 D0 P7 C"121.io2.in" S1 ; Bed leveling M671 X-53:-53:400:400 Y-5:420:420:-5 S20 ; Define Z belts locations (Front_Left, Back_Left, Back_Right, Front_Right) ;M557 X20:335 Y20:330 P5:5 M557 X120:235 Y120:230 P2:2 ; Bed heater M308 S0 P"temp0" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor M950 H0 C"out1" T0 ; create bed heater output M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater ; Hotend heater ;M308 S1 P"121.temp1" Y"pt1000" M308 S1 P"121.temp1" A"Heater 1" Y"thermistor" T100000 B4725 C7.06e-8 M950 H1 C"121.out0" T1 ;M950 H1 C"out2" T1 M307 H1 B0 S1 ; disable bang-bang mode for heater and set PWM limit M143 H1 S300 ; Set temperature limit for heater ; Chamber Thermistor M308 S2 P"temp1" A"Chamber" Y"thermistor" T100000 B3950 ; configure sensor 2 as thermistor ; MCU sensors M308 S3 Y"mcu-temp" A"MCU" M308 S4 Y"drivers" A"Drivers" M912 P0 S-13 ; MCU temp calibration ; Fans ;M950 F0 C"121.out1" Q10000 ; part cooling fan # old Sunon M950 F0 C"121.out1" ; part cooling fan # new Gsdtime M106 P0 C"Bed" S0 H-1 ; part cooling fan M950 F1 C"121.out2" ; hotend fan M106 P1 C"Hotend" L0.70 X0.70 H1 T70 S0.70 ; hotend fan M950 F2 C"out7" Q10 ; air filter fan M106 P2 C"Filter" S0 H-1 B0.2 ; air filter fan M950 F3 C"out4" Q24000 ; electronics bay left side M106 P3 S0.75 H-1 B1 C"Bay" ; electronics bay left side ;M950 F4 C"1.out3" Q24000 ; electronics bay right side ;M106 P4 S0.75 H-1 B1 C"Bay Right" ; electronics bay right side M950 F5 C"out5" ; sbc fan M106 P5 S0.2 H-1 C"SBC" ; sbc fan M950 F6 C"out6" ; chamber light M106 P6 S1 H-1 C"Light" ; chamber light ; Tools M563 P0 S"Hotend" D0 H1 F0 ; define tool 0 ;G10 P0 X0 Y0 Z-2.75 G10 P0 X0 Y0 Z0 G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Enable debugging via USB ;M111 S1 P0 ; Platform ;M111 S1 P1 ; Network ;M111 S1 P2 ; Webserver ;M111 S1 P3 ; GCodes ;M111 S1 P4 ; Move ;M111 S1 P5 ; Heat ;M111 S1 P6 ; DAA ;M111 S1 P7 ; Roland ;M111 S1 P8 ; Scanner ;M111 S1 P9 ; PrintMonitor ;M111 S1 P10 ; Storage ;M111 S1 P11 ; PortControl ;M111 S1 P12 ; DuetExpansion ;M111 S1 P13 ; FilamentSensor ;M111 S1 P14 ; Wifi ;M111 S1 P15 ; Display ;M111 S1 P16 ; LinuxInterface ;M111 S1 P17 ; CAN ; Neopixel M150 X3 Q3000000 ; set LED type to NeoPixel and set SPI frequency to 3MHz M150 W255 P255 Y255 S3 F0 ; Misc M575 P1 S1 B115200 ; enable support for PanelDue M501 ; load config-override.g M302 P0 ; disallow cold extrudes T0 ; select tool 0 ; Auto Z M98 P"/macros/autoz/edit_me.g" ; load your settings for autoz with klicky probe M400 M98 P"/macros/autoz/scripts/autoz_globals.g" ; load autoz framework for klicky probe M400 ; ERCF ;M98 P"0:/macros/sys/ercf/lib/init.g" -

RE: Issues with pressure advance since RRF 3.4posted in General Discussion

Same bulging here.

6HC + 1LC with RRF 3.4.3 and PA 0.035.

-

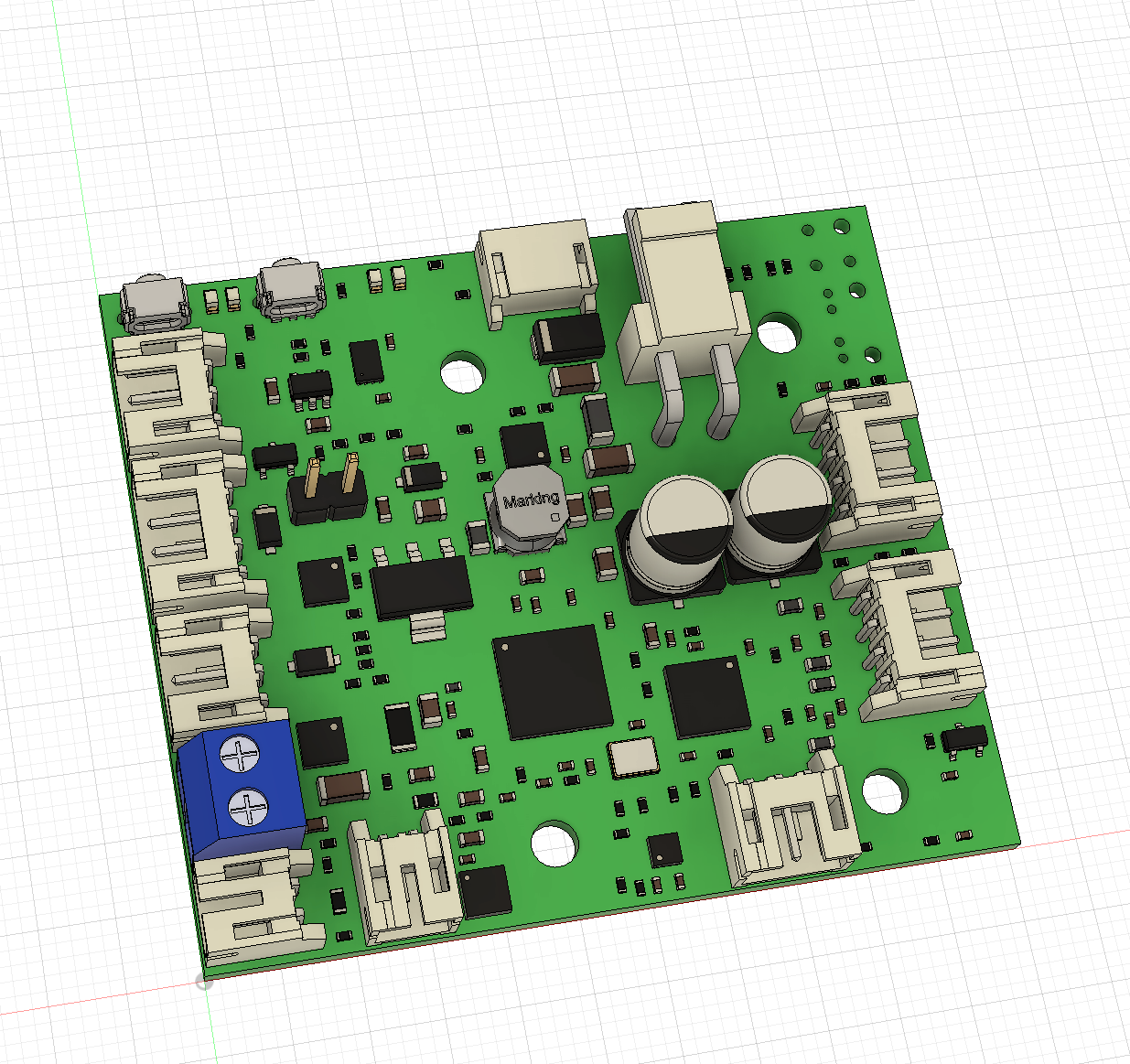

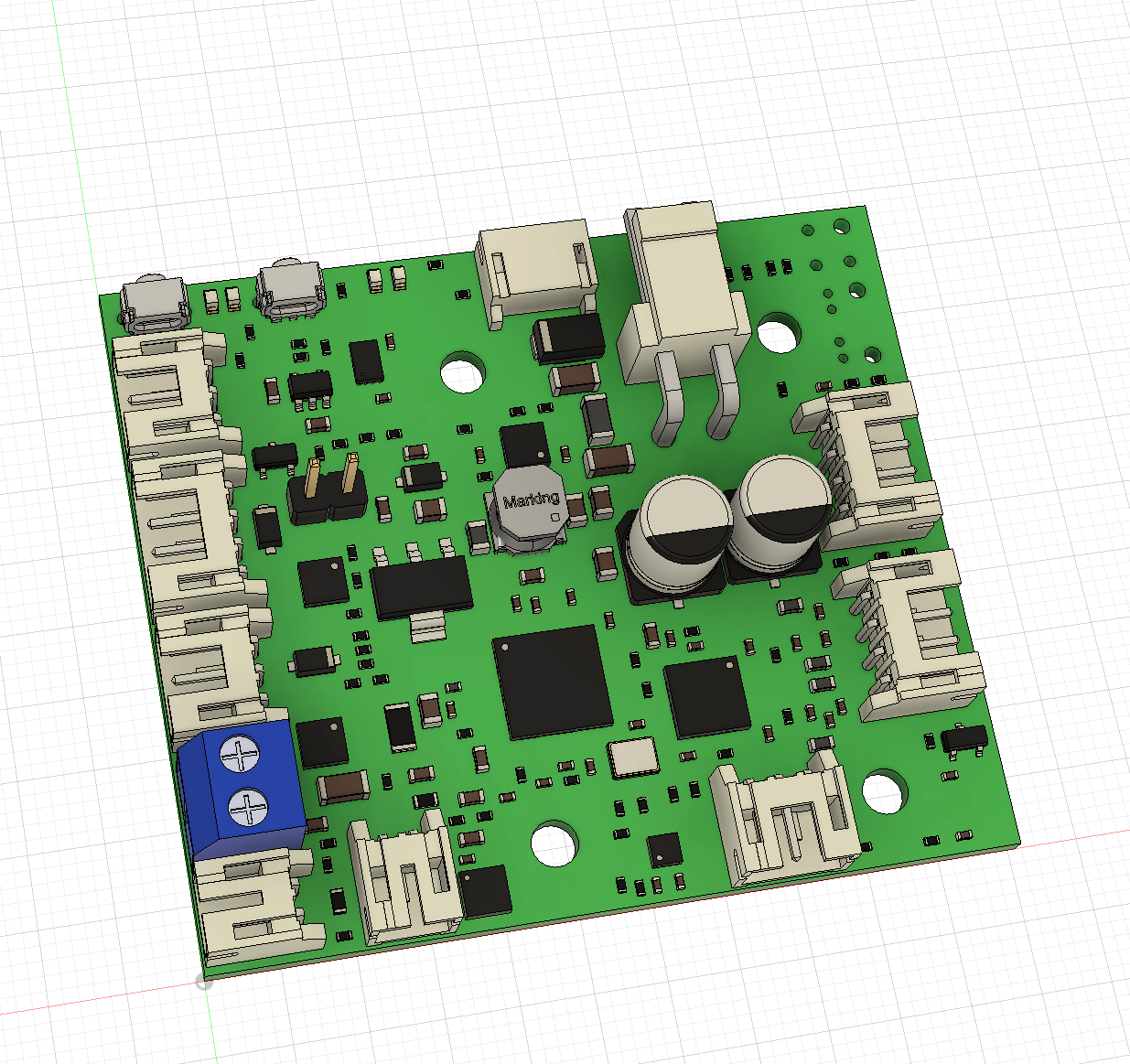

Duet 1LC STEP file not matching v1.3posted in General Discussion

The step file for 1LC version 1.3 doesn't match.

-

RE: 1LC toolboard no longer foundposted in Duet Hardware and wiring

Just connected a brand new 1LC toolboard v1.2 and getting the same error.

-

1LC toolboard no longer foundposted in Duet Hardware and wiring

When I switched on one of my printers this morning, all of a sudden the 1LC toolboard is no longer recognized.

Already did a factory default reset of the toolboard and checked the cabling. Yesterday evening it still was working and there are no changed to the configuration.

Duet3 6HC --CAN--> Duet3 3HC --CAN--> 1LC. All running RRF 3.4.0.

Any ideas please?

-

RE: Duet2 + SBC + Additional driversposted in Duet Hardware and wiring

@jay_s_uk NOW i got it

I think that's the way for me.

I think that's the way for me.