Robotic kinematics

-

@JoergS5 said in Robotic kinematics:

A problem is that the reporting output maximum length is limited and will abbreviate the output of the parameters. I'll search where it' s handled and will make it larger for Duet3, but this would be a request for David.

It's likely that I will change the output mechanism to remove the limitation on output length in 3.2beta3. I have already done the preparatory work.

-

@dc42 thank you, then I don't need to change it and use the workaround.

-

@tony73 said in Robotic kinematics:

is it now possible to make the robot assume any position in the homing phase, and he will know that he is at a certain degree from his min and max limits of each actuator

I am not sure whether we have a common understanding.

When the printer powers up, the following procedure is made for each axis:

- he doesn't know where the position of the stepper and hence the angle is

- he needs to rotate the stepper/angle to find the endstop

- when he found the endstop, he now knows through the A endstop position at which angle it is. The firmware stores the stepper position as liveCoordinates/motorPos and can calculate the cartesian coordinates when all home angles are set by homing all axes.

- through the A angle limits he knows how much he is allowed to rotate to min and max

Step 2 is difficult because the angle could be anywhere, so the printer doesn't know whether he should rotate left or right. One strategy would be to rotate left a bit, then right a bit more etc. until found. This could be a strategy for axis 1. Another strategy is to have the arm in a defined position when power off, so the printer can find the endstop by rotating in a specific direction. This could be a good strategy for axis 2 and 3. A third strategy could be that an external solution like a camera can tell the firmware where the arms are roughly and in which direction the printer can find the endstops. (I'll make a proposal in the homing document when I have a good solution. Maybe strategy 2 is best, because when power off, the arms could fall down. It is good to have a secure "parking position" anyway).

The endstops can be defined at high or low end, it doesn't matter for the M669 setting (but in config you must use one). For finding the angle, it would be good to approach the endstop always from the same direction, most endstops will differ with direction.

I have to test whether when using G1 H1 while homing needs a dummy M208, it may produce an error message when there is no M208.

-

Hello! I'm sorry but sometimes it is not easy to explain a concept, I think I understand the new A parameters you added I did these tests with a 3d program that I use like fusion 360, I only have the motors and the end stops, but it seems that the things are fine, there are small differences of hundredths or tenths, but it could be normal, except actuator 5 which continues to mark V 5.005 after homing, before homing and V 0.0

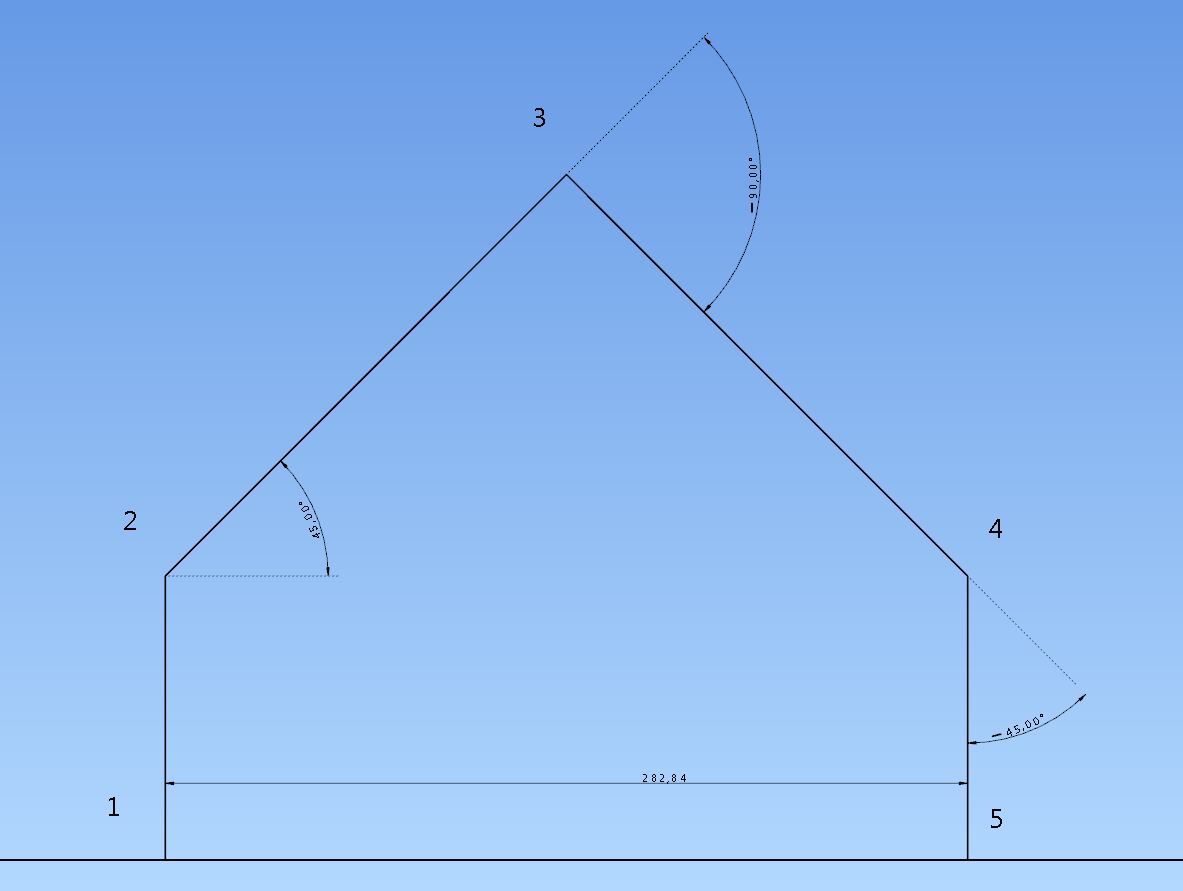

in both cases I can move in the X Y Z coordinates, always respecting the MIN MAX degree limits of the actuators, for the famous reachable area like gianbella!M669 K13 X0.0:0.0 Y0.0:0.0 Z100.0 L200.0:200.0:100.0:0.0 R0 P2:45 C0 A-45.0:0.0:45.0:0.0:45.0:90.0:-110.0:-90.0:0.0:-170.0:-45.0:0.0:-225.0:0.0:225.0:0.0:0.0:1000.0

this and M669 used for the graph below

height Z should be 0 after homing and X 282.84

M114 I from Z-0.002 and X 282.843 Y0.0 U-45 V5.005

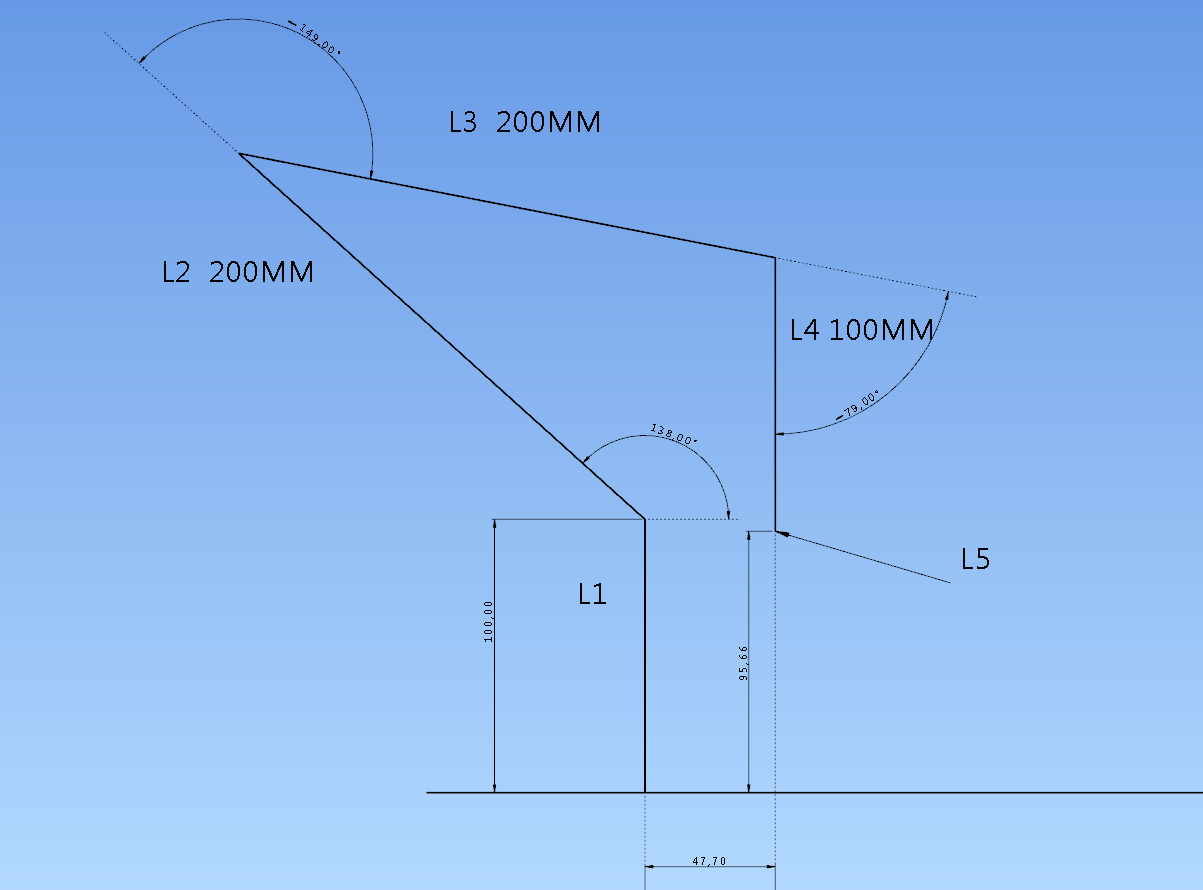

M669 K13 X0.0:0.0 Y0.0:0.0 Z100.0 L200.0:200.0:100.0:0.0 R0 P2:45 C0 A-45.0:0.0:45.0:0.0:138.0:150.0:-160.0:-149.0:0.0:-170.0:-79.0:0.0:-225.0:0.0:225.0:0.0:0.0:1000.0this is the second M669 test

height Z should be 95.66 after homing and X 47.70

M114 I from Z95.666 and X 47.717 Y0.0 U-78.989 V5.005the images are along the X axis

when I send M114 before homing the axes are all at zero X 0.0 Y0.0 Z0.0 U0.0 V0.0 after homing the only strange thing is V which becomes V5.005 -

@tony73 I am glad that there is some progress. Some of the angle errors may be from the trigonometric function being not exact, but I will check with my calculations. The V value is strange, I will analyze it separately. One reason could be that arm 5 length is 0, so the angle 5 doesn't play a role for the position calculation. But of course for the hotend direction it's important.

-

@tony73 could you please test the M114 results if you set M92 values to values with .0, e.g.

M92 X779.0 Y838.0 Z1067.0 U420.0 V71.0

This should diminish the Z error. If you can confirm it, I will try to find a solution.=> I tested a bit, changing all float to double in internal calculations. This halfes the errors, but not to 0. The G-Code stepsPerMm are read in as float always, changing it to double would yield this halfing, but this is deep intern of the firmware, changing has some effort.

-

@JoergS5

Hello! later I try M92 with .0 I'll let you know! I'm sorry but I have little time to devote these days! -

@tony73 no problem, no hurry. I myself am proceeding building the new version of the prototype, concentrating on a good design for the gears.

-

here are the results!

M92 X778.0 Y838.0 Z1066.0 U71.0 V71.0 : M92 CALCULATION WITH .0

M92 X778.67 Y838.10 Z1066.67 U71.11111111 V71.11111111 :M92 NORMAL CALCULATION THAT I HAD IN CONFIG.G

M669 K13 X0.0:0.0 Y0.0:0.0 Z100.0 L200.0:200.0:100.0:0.0 R0 P2:45 C0 A-45.0:0.0:45.0:0.0:45.0:90.0:-110.0:-90.0:0.0:-170.0:-45.0:0.0:-225.0:0.0:225.0:0.0:0.0:1000.0

: X 282.84 Y0.000 Z 0.000 U-45.000 V ? : FIRST GRAPH RESULT OF THE REQUIRED CALCULATION

: X 282.843 Y 0.000 Z-0.002 U-45.000 V 5.005 : FIRST OLD TEST

: X 282.843 Y 0.000 Z 0.000 U-45.000 V 5.000 : FIRST NEW TEST

M669 K13 X0.0:0.0 Y0.0:0.0 Z100.0 L200.0:200.0:100.0:0.0 R0 P2:45 C0 A-45.0:0.0:45.0:0.0:138.0:150.0:-160.0:-149.0:0.0:-170.0:-79.0:0.0:-225.0:0.0:225.0:0.0:0.0:1000.0

: X47.70 Y 0.000 Z 95.66 U-79.000 V ? : SECOND GRAPH RESULT OF THE REQUIRED CALCULATION

: X 47.717 Y0.000 Z95.666 U-78.989 V5.005 : SECOND OLD TEST

: X 47.696 Y 0.000 Z 95.664 U-79.000 V 5.000 : SECOND NEW TEST

in the first new test Z becomes 0.000 as calculated by the graph, in the second new test U becomes -79.000 as calculated by the graph, removing the decimals from M92 the result improves!

I see that V from 5,005 becomes 5,000

-

@tony73 thanks for testing, this is similar to my test result in the windows based tests. It seems to be rounding errors, I didn' t find another reason. btw z0.002 error is not so much, only 2 micrometer. But I would prefer exact results.

=> the inexactness comes from the converting float to motor position integers, using .0 doesn't produce such converting error. This error of Z0.002 will be unavoidable sometimes, because the motor cannot be positioned to the exact position in any constellation.When I change all calculations to double inclusive the stepsPerDegree, the errors are halved, but not zero. But there is no function to read G-Code values as double.

I tested multiplying the steps by 10 with .0 each, y8381.0 e.g., but the errors reappear then.

The V should be 45 because of axis 1 being 0 and P2:45, and my tests give back this angle also. I will find the reason!

I analyzed M114 a bit. The values after Count are the motorPos values. They are integer values and are angle*stepsPerDegree. (stepsPerDegree = m92 values)

-

@JoergS5

good morning! to use P3 mode, just put P3 in M669 or should I add something to the firmware? could you explain to me? -

@tony73 just use P3 instead of P2:45.

-

@JoergS5

I asked you this because I tried to put P3 and I saw a strange behavior of motor 5 when I send G1 XY commands, considering that I only look at a motor that moves its axis and not having set an offset between the motor shaft and extruder L5 = 0.0, what should I see if I move the robot (motors!) With G1 or simulating a print with a g.code? I would like to understand how the P3 command behaves -

@tony73 when you make a G1 move, you should see the arm 5 in the direction of the move. If you move a diagonal, arm 5 should be in the direction of this diagonal e.g. It takes into account the position of axis 1. If axis 1 has 10 degree, axis 5 is 10 degree less, so that arm 5 is still in the direction of the move.

-

@tony73 said in Robotic kinematics:

add something to the firmware?

I understand your question now, this is an incorrectness in documentation: I found a solution without changing the core of the firmware. It is not necessary to change anything in the firmware. I will correct the documentation.

-

@JoergS5

ok! a few days ago, I had already tried P3 when you finished implementing it, and it looked good to me, now in weird behavior! for example at every G1 the motor changes angle!

complicated to explain! -

@tony73 I will need a few days to complete the new prototype, then you can tell me which G1 commands you use and we can discuss the behaviour.

But I think it's normal that at every new G1 the angle changes, because the different G1s will have different print paths with different angles. Even while being on one G1, the angle will change, because axis 1 's angle will change and axis 5 must take it into account.It is of course possible that there hides a bug somewhere, because you have this strange V5 value.

What I am more afraid of is that there is anywhere a jerk in the movement: an axis 1 or axis 5 big change, making it difficult to print a nice line. I will simulate stl prints to find those critical situations. (probably at the edges of the printable areas)

-

@JoergS5

hello I wait for you to be ready with your robot! I would like to try to make a reducer, but i would need to know which maximum interpolated micro step (I1) supports duet 3 6ch, or which one is better to use (x8, x16, x32 ........) and which reduction ratio and better to use (1/10, 1/30, 1/50, 1/100 ......) I have an idea for how to build a reducer, which also acts as a supporting joint for the arms -

@tony73 Duet 3 supports all modes for interpolation. I would recommend x16, higher would mean more steps to generate for the Duet and has no advantage. (It does not mean more precision, as microsteps are not precise. Good gears can give more precision).

I am currently testing gear ratios and I'll tell you the result.

-

@JoergS5

good morning! how is the robot project going? were you able to try the reduction ratios?