Multiple Errors Duet3

-

@dk said in Multiple Errors Duet3:

Is it related to the firmware or is it a computer problem?

it happened because you re-imaged the sd-card, which generates new host keys on the pi - and the client keeps track of the hostname and fingerprint of the past keys to detect changes (or attacks). nothing to worry about as you did (unknowingly) change they keys on the pi

@dk said in Multiple Errors Duet3:

I also tried BOSSA, but it's freeze at 44-45%

from the pi or the computer? try the other one and try a different usb cable, seems to help for most cases.

did you make a not of what happened when trying to run M997 after downloading the 3.0 files?

-

If you skip the pi for now and setup in standalone mode you can probably get your firmware updated using this method.

https://duet3d.dozuki.com/Wiki/Getting_Started_With_Duet_3#Section_Running_in_standalone_mode

-

@bearer Bossa finally works! third cable!

Thank you very much for your help!

Now I trying to figure out how to get BL-touch on 1LC Tool board get to work. It can't be done through https://configurator.reprapfirmware.org isn't it? -

@dk said in Multiple Errors Duet3:

BL-touch on 1LC Tool board

https://duet3d.dozuki.com/Wiki/Duet_3_firmware_configuration_limitationsafaik thats not going to work until 3.3 is released, unless the toolboard is also controlling the z motor -

@bearer BLTouch on toolboard works fine for Z homing and bed levelling. Some people are having issues with intermittent comms or power supply, but we’re having difficulty replicating that to troubleshoot.

Ian

-

@dk said in Multiple Errors Duet3:

Now I trying to figure out how to get BL-touch on 1LC Tool board get to work. It can't be done through https://configurator.reprapfirmware.org isn't it?

For physical connections, see https://duet3d.dozuki.com/Wiki/Duet_3_Tool_Board#Section_Connecting_a_BL_Touch

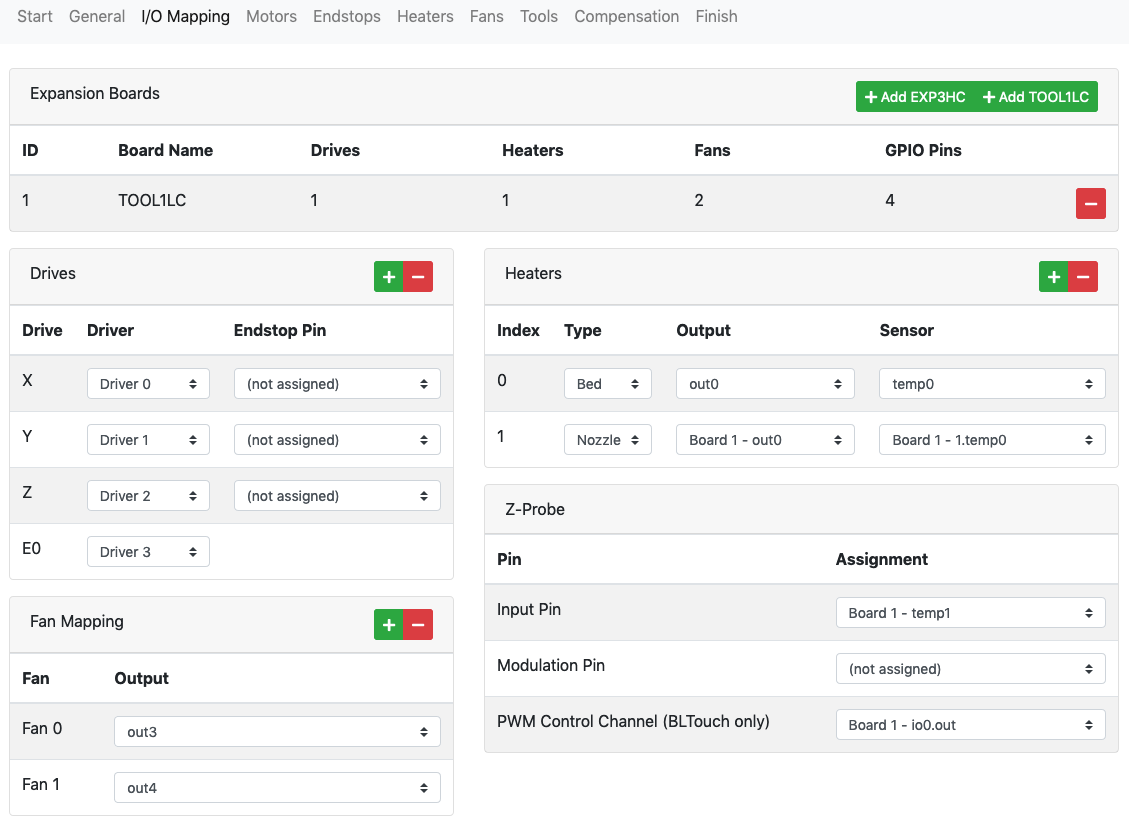

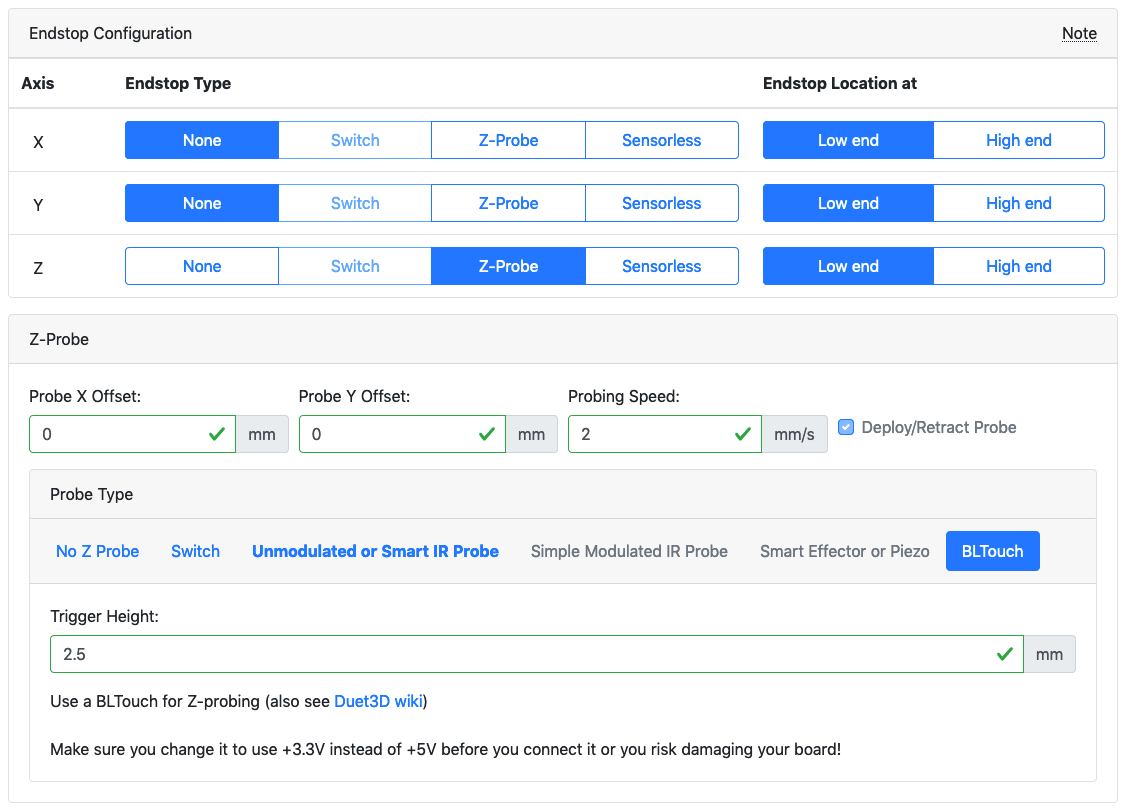

The configuration tool can produce the code, but doesn't set the CAN address, and I've noticed an error in the input pin drop down. So you'll need to edit config.g afterwards. Setting the following:

and

Produces:

; Z-Probe M950 S0 C"1.io0.out" ; create servo pin 0 for BLTouch M558 P9 C"^1.temp1" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger heightAssuming CAN address is 121, change this to:

; Z-Probe M950 S0 C"121.io0.out" ; create servo pin 0 for BLTouch M558 P9 C"^121.io0.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger heightNot sure if you actually need the pull-up resistor ^, but shouldn't hurt. Test and report back!

Ian

-

@droftarts said in Multiple Errors Duet3:

Not sure if you actually need the pull-up resistor ^, but shouldn't hurt. Test and report back!

All Duet 3 ioX.in ports have permanent pullup resistors, on the main board and on expansion boards. So you never need to use ^ in the name. We recommend that you do not, because enabling it reduces the noise margin..

-

@droftarts Unfortunately, this didn't help. I tried with and without ^. BL-touch lights up in red but does not extend.

Can I find somewhere configuration files for any real working Delta printer on Duet3 with Tool board? This would help me a lot in setting up my printer. -

@dk Please post your config files so we can see what you have now.

-

Every time after reboot I get Error messages :

Error: M950: Response timeout: CAN addr 1, req type 6027, RID=8

Error: M106: Fan number 0 not found

Error: M950: Response timeout: CAN addr 1, req type 6027, RID=10

Error: M106: Fan number 1 not foundAnd when I push Home all only one motor moves.

Config.g

; Configuration file for Duet 3 (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Tue Sep 01 2020 22:07:15 GMT-0400 (EDT); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Duet 3" ; set printer name

M665 R240 L460 B190 H750 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them; Drives

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M569 P0.1 S0 ; physical drive 0.1 goes forwards

M569 P0.2 S0 ; physical drive 0.2 goes forwards

M569 P1.0 S1 ; physical drive 1.0 goes forwards

M584 X0.0 Y0.1 Z0.2 E1.0 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X160.00 Y160.00 Z160.00 E415.00 ; set steps per mm

M566 X1200.00 Y1200.00 Z1200.00 E800.00 ; set maximum instantaneous speed changes (mm/min)

M203 X3000.00 Y3000.00 Z3000.00 E600.00 ; set maximum speeds (mm/min)

M201 X3000.00 Y3000.00 Z3000.00 E1000.00 ; set accelerations (mm/s^2)

M906 X1600 Y1600 Z1600 E900 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 Z0 S1 ; set minimum Z; Endstops

M574 X2 S1 P"io0.in" ; configure active-high endstop for HIGH end on X via pin io0.in

M574 Y2 S1 P"io1.in" ; configure active-high endstop for HIGH end on Y via pin io1.in

M574 Z2 S1 P"io2.in" ; configure active-high endstop for HIGH end on Z via pin io2.in; Z-Probe

M950 S0 C"121.io0.out" ; create servo pin 0 for BLTouch

M558 P9 C"121.io0.in" H5 F120 T1000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X20 Y25 Z3 ; set Z probe trigger value, offset and trigger height

M557 R160 S40 ; define mesh grid; Heaters

M308 S0 P"temp3" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp3

M950 H0 C"out1" T0 ; create bed heater output on out1 and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"1.temp0" Y"thermistor" T500000 B4723 C1.19622e-7 ; configure sensor 1 as thermistor on pin 1.temp0

M950 H1 C"1.out0" T1 ; create nozzle heater output on 1.out0 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit; Fans

M950 F0 C"1.out2" Q500 ; create fan 0 on pin 1.out2 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"1.out1" Q500 ; create fan 1 on pin 1.out1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

; homedelta.g

; called to home all towers on a delta printer

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Tue Sep 01 2020 22:07:15 GMT-0400 (EDT)

G91 ; relative positioning

G1 H1 X760 Y760 Z760 F1800 ; move all towers to the high end stopping at the endstops (first pass)

G1 H2 X-5 Y-5 Z-5 F1800 ; go down a few mm

G1 H1 X10 Y10 Z10 F360 ; move all towers up once more (second pass)

G1 Z-5 F3600 ; move down a few mm so that the nozzle can be centred

G90 ; absolute positioning

G1 X0 Y0 F3600 ; move X+Y to the centre; deployprobe.g

; called to deploy a physical Z probe

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Tue Sep 01 2020 22:07:15 GMT-0400 (EDT)M950 S0 C"121.io0.out"

M280 P0 S10 ; deploy BLTouch; retractprobe.g

; called to retract a physical Z probe

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Tue Sep 01 2020 22:07:15 GMT-0400 (EDT)

M950 S0 C"121.io0.out"

M280 P0 S90 ; retract BLTouch -

Can you send M122 and M98 P"config.g" and post the results?

-

@dk you have a Duet 3, and a Toolboard, correct? Did you follow the steps in this guide: https://duet3d.dozuki.com/Wiki/Duet_3_Tool_Board

Have you changed the CAN address of your Toolboard? And if so, what to? See https://duet3d.dozuki.com/Wiki/Duet_3_Tool_Board#Section_Set_the_CAN_addressWhatever it’s set to, at the moment you have some commands referring to CAN address 1 (extruder motor, hit end heater, fan etc), and some as CAN address 121, which is the default (BLTouch). Also, it may need a firmware update (further up in the document linked above).

Ian

-

@Phaedrux

M122

=== Diagnostics ===

RepRapFirmware for Duet 3 MB6HC version 3.1.1 running on Duet 3 MB6HC v0.6 or 1.0 (SBC mode)

Board ID: 08DJM-956L2-G43S4-6JTDJ-3SJ6S-986GH

Used output buffers: 1 of 40 (21 max)

=== RTOS ===

Static ram: 154604

Dynamic ram: 161404 of which 276 recycled

Exception stack ram used: 224

Never used ram: 76708

Tasks: NETWORK(ready,1972) HEAT(blocked,1248) CanReceiv(suspended,3424) CanSender(suspended,1488) CanClock(blocked,1436) TMC(blocked,204) MAIN(running,4528) IDLE(ready,76)

Owned mutexes:

=== Platform ===

Last reset 00:00:44 ago, cause: power up

Last software reset at 2020-09-22 22:34, reason: User, spinning module LinuxInterface, available RAM 76708 bytes (slot 0)

Software reset code 0x0010 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0444a000 BFAR 0x00000000 SP 0xffffffff Task MAIN

Error status: 0

MCU temperature: min 39.2, current 39.6, max 39.7

Supply voltage: min 23.9, current 23.9, max 23.9, under voltage events: 0, over voltage events: 0, power good: yes

12V rail voltage: min 12.2, current 12.2, max 12.3, under voltage events: 0

Driver 0: standstill, reads 24456, writes 0 timeouts 0, SG min/max not available

Driver 1: standstill, reads 24456, writes 0 timeouts 0, SG min/max not available

Driver 2: standstill, reads 24456, writes 0 timeouts 0, SG min/max not available

Driver 3: standstill, reads 24456, writes 0 timeouts 0, SG min/max not available

Driver 4: standstill, reads 24457, writes 0 timeouts 0, SG min/max not available

Driver 5: standstill, reads 24456, writes 0 timeouts 0, SG min/max not available

Date/time: 2020-09-22 22:34:11

Slowest loop: 4.22ms; fastest: 0.20ms

=== Storage ===

Free file entries: 10

SD card 0 not detected, interface speed: 37.5MBytes/sec

SD card longest read time 0.0ms, write time 0.0ms, max retries 0

=== Move ===

Hiccups: 0(0), FreeDm: 375, MinFreeDm: 375, MaxWait: 0ms

Bed compensation in use: none, comp offset 0.000

=== MainDDARing ===

Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1

=== AuxDDARing ===

Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1

=== Heat ===

Bed heaters = 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamberHeaters = -1 -1 -1 -1

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP* is ready with "M122" in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger* is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon* is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty.

=== Network ===

Slowest loop: 0.47ms; fastest: 0.01ms

Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions Telnet(0), 0 sessions

HTTP sessions: 0 of 8- Ethernet -

State: disabled

Error counts: 0 0 0 0 0

Socket states: 0 0 0 0 0 0 0 0

=== CAN ===

Messages sent 20, longest wait 0ms for type 0

=== Linux interface ===

State: 0, failed transfers: 3

Last transfer: 18ms ago

RX/TX seq numbers: 539/540

SPI underruns 3, overruns 3

Number of disconnects: 0

Buffer RX/TX: 0/0-0

=== Duet Control Server ===

Duet Control Server v3.1.1

Code buffer space: 4096

Configured SPI speed: 8000000 Hz

Full transfers per second: 0.02

M98 P"config.g"

Error: M569: Response timeout: CAN addr 1, req type 6018, RID=12

Error: M350: Response timeout: CAN addr 1, req type 6021, RID=13

Error: M906: Response timeout: CAN addr 1, req type 6017, RID=14

Warning: M307: Heater 0 appears to be over-powered. If left on at full power, its temperature is predicted to reach 365C

Error: M308: Response timeout: CAN addr 1, req type 6011, RID=19

Error: M950: Response timeout: CAN addr 1, req type 6026, RID=20

Error: M307: Heater 1 not found

Error: M950: Response timeout: CAN addr 1, req type 6027, RID=22

Error: M106: Fan number 0 not found

Error: M950: Response timeout: CAN addr 1, req type 6027, RID=24

Error: M106: Fan number 1 not found - Ethernet -

-

I have Duet3 and Toolboard with BMG and Mosquito Magnum + BL-touch

I have follow all speps frome this guide.

I did not changed the CAN address of ToolboardSending M115 B121 give me :

Board TOOL1LC firmware 3.1.0 (2020-05-15b1) -

@dk then you need to go through your config.g and change all references to CAN address 1 to 121, eg

M569 P1.0 S1 ; physical drive 1.0 goes forwards

Changes to:

M569 P121.0 S1 ; physical drive 121.0 goes forwardsIan

-

Changed. I still cant extrude

-

@dk said in Multiple Errors Duet3:

Changed. I still cant extrude

Are there any errors now if you run

M98 P"config.g"? You need to reset Duet for changes to config.g to take effect, or run M98 P"config.g". If there are still errors, please post your current config.g, along with the list of errors reported.Assuming everything is set correctly with no errors, to extrude you either need to heat up the hot end to a temperature above 160C, or allow cold extrusion with

M302 P1(see https://duet3d.dozuki.com/Wiki/Gcode?revisionid=HEAD#Section_M302_Allow_cold_extrudes).For the probe, you have already defined the servo pin with

M950 S0 C"121.io0.out" ; create servo pin 0 for BLTouchin config.g, so it's unnecessary (and may cause confusion if you change the configuration later) in deployprobe.g and retractprobe.g. Delete the M950 line in these files.Does the BLTouch do a self-test at startup? It should extend and retract the pin itself twice if it has power (which you say it does as the red LED comes on). If deployprobe.g and retractprobe.g still don't work, try inverting the input in config.g with '!', ie

M950 S0 C"!121.io0.out". You can either send this command in the gcode console (and add it to config.g if it works), edit config.g and reset Duet, or edit config.g and run M98 P"config.g" for the command to take effect. If it still isn't functioning, check the wiring, and post a picture of how it's wired.@dk said in Multiple Errors Duet3:

Can I find somewhere configuration files for any real working Delta printer on Duet3 with Tool board?

We don't have a machine with this configuration to share a working config with you. Many home-built printers are bespoke, and it's possible that you are the first with this combination! If there are any other users who see this and have a similar setup, please share your config files.

Ian

-

I have change Toolboard address to 20 following this procedure See https://duet3d.dozuki.com/Wiki/Duet_3_Tool_Board#Section_Set_the_CAN_address , and change M569 P20.0 S1

Now I can extrude.

I also change address for heater and Thermistor and gget them work to!

M308 S1 P"20.temp0" Y"thermistor" T500000 B4723 C1.19622e-7

M950 H1 C"20.out0" T1And I also change address for BL-touch (with and without ! ) and delete M950 line from deployprobe.g and retractprobe.g files. But it's still don't work.

; Z-Probe

M950 S0 C"20.io0.out" ; create servo pin 0 for BLTouch

M558 P9 C"20.io0.in" H5 F120 T1000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X20 Y25 Z3 ; set Z probe trigger value, offset and trigger height

M557 R160 S40 ; define mesh gridAnd BLTouch does not self-test at startup. Just steady red light. I connect it to Duet2 I have on another printer and it perform startup test as usual.

M98 P"config.g" give me just one warning (no Errors any more)

Warning: M307: Heater 0 appears to be over-powered. If left on at full power, its temperature is predicted to reach 365CSo I assume the problem is in Z-probe settings

-

Does the BLTouch power up if you connect it directly to the main board and change your pin names accordingly?

-

@Phaedrux

Yes, it does