Predator Project - The Mjolnir -

-

@dc42

"I presume you have read https://duet3d.dozuki.com/Wiki/Calibrating_a_delta_printer." Yes sorry I forgot... it was the first one when I start installing duet board on my predator

Honestly I thought the BL touch was not the best, also because as you can see, it has a great offset from the effector center axis (46mm), I thing by the geometry this can be one of the reasons it is not a good solution.

Nozzle contact probe (I think you're speaking about piezo probe) was one of the first solution i thought but i was scared about the mechanical application on my effector, especially looking forward for the double extruder mod...

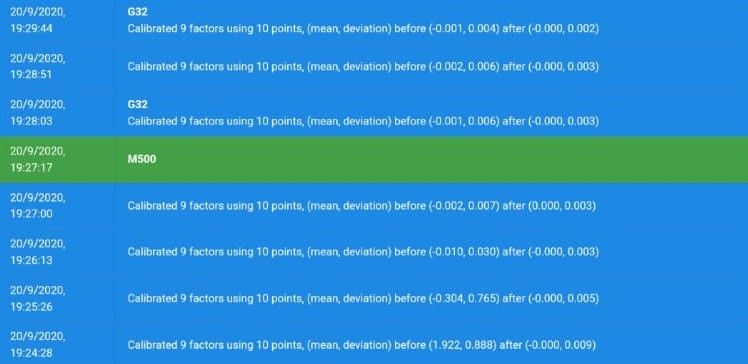

Here the promised update i've done today:

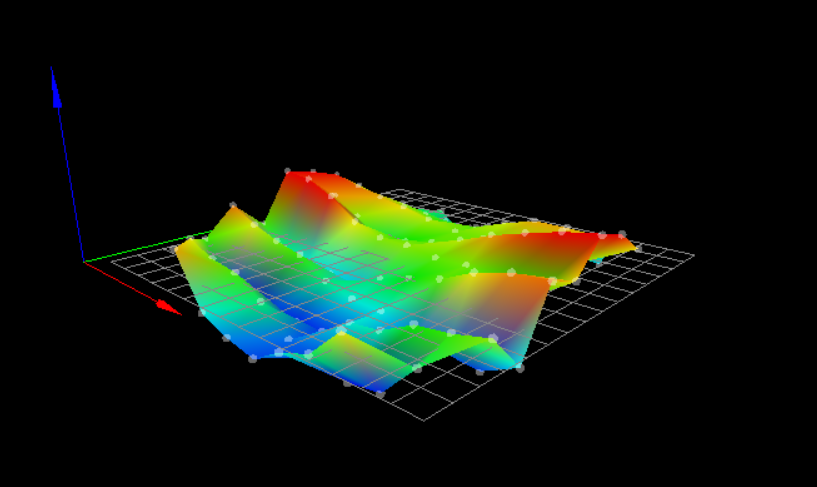

As you can see here, the printing is quite well in the center of the bed, become far in negative Y cordinates and too closer on positive Y cordinate...

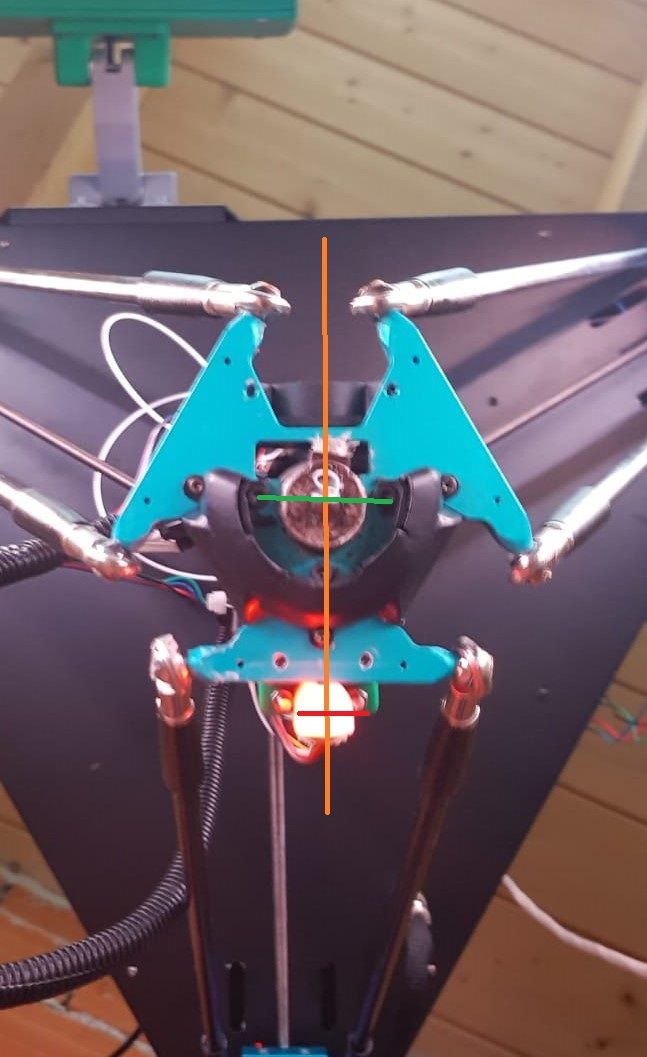

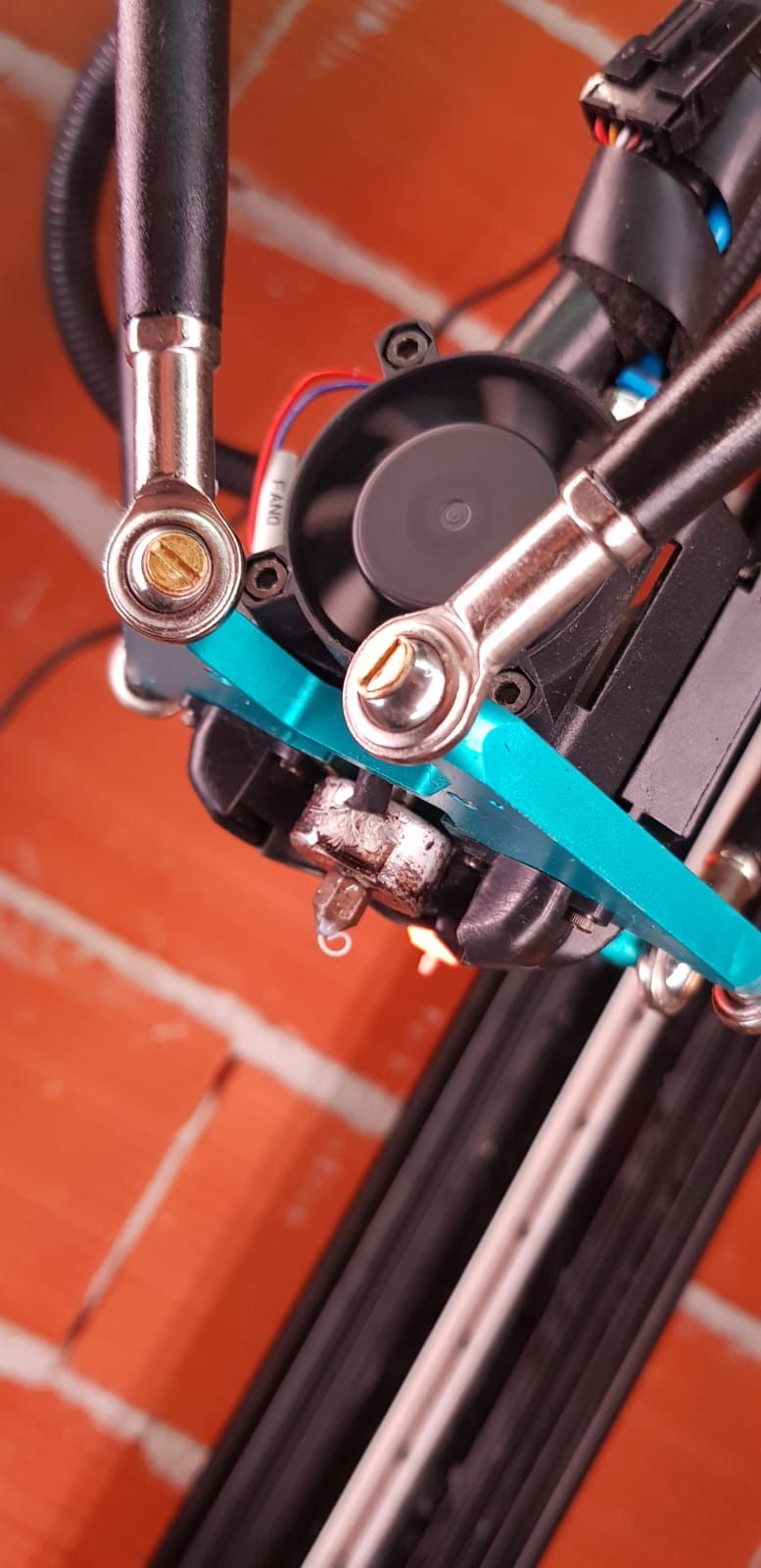

Here the actual effector configuration:

... Next step: design new effector for Piezo probe.

You think guys it'll need other mod, due to this new design?

-

I forgot the other option, Piezo on bed. Here I think we have 2 roads:

Piezo under the bed (but i'm scared when i need to probe for ABS (bed @90/100°C, i think piezo suffer at that temperature.

Piezo under the bed support... but how many and where on ultrabase shape?

suggestions?

thanks again guys

-

Piezo in the print head mounting or on the effector may be another possibility.

-

Smart effector is also an elegant solution, but with the dual extruder you pretty much have to eliminate effector tilt and in that case bltouch should also work reasonably well?

-

@bearer said in Predator Project - The Mjolnir -:

but with the dual extruder you pretty much have to eliminate effector tilt

My experience with dual nozzles is that it's very difficult to prevent one from interfering with the printing by the other.

I wonder if the 'tiltability' of delta printers can be used to address it. E.g. on tool change, tilting the non active nozzle up such that it is not interfering with piezo measurement or printing by the other nozzle.

-

Hi Everybody, thank you for the suggestions and sharing your experiences.

what I learned is to say bye bye to my BLtouch (i will recycle it on my ender 3

)

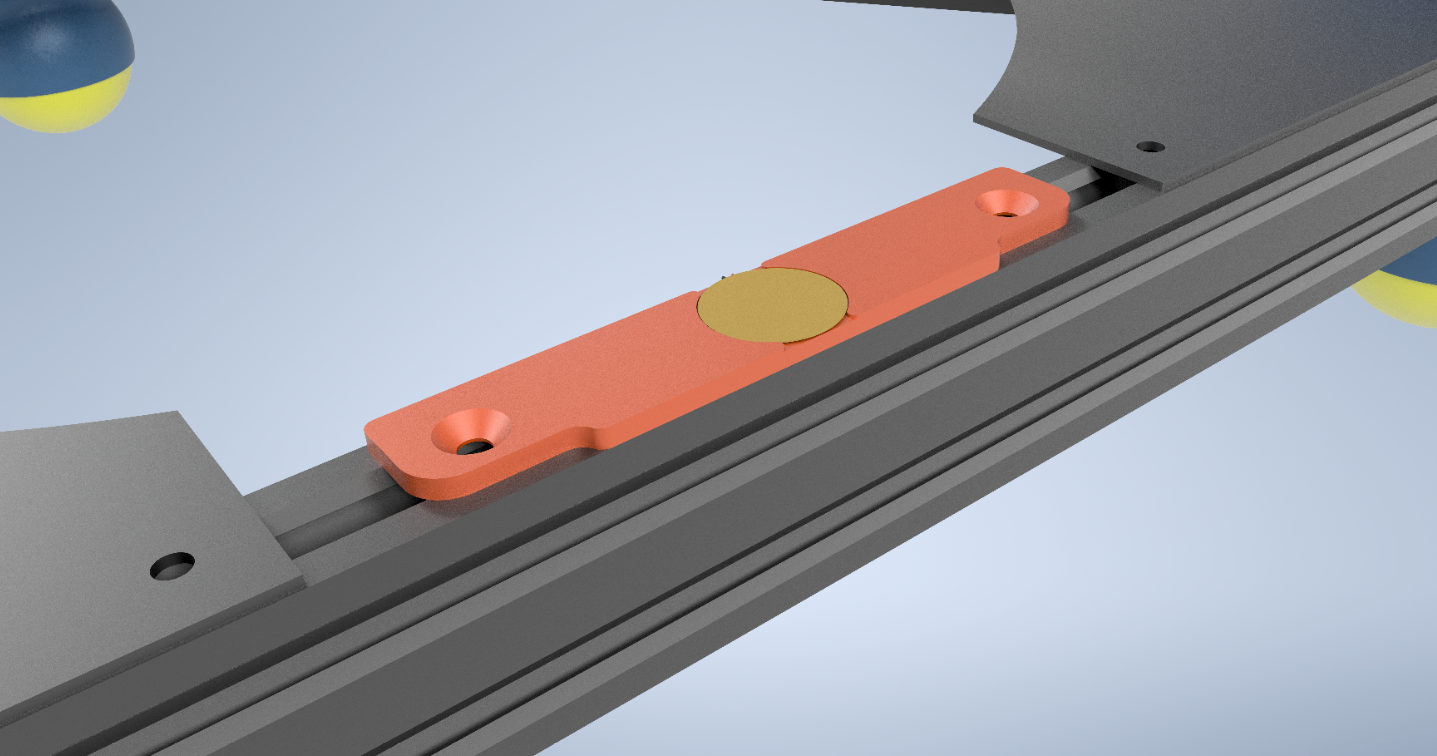

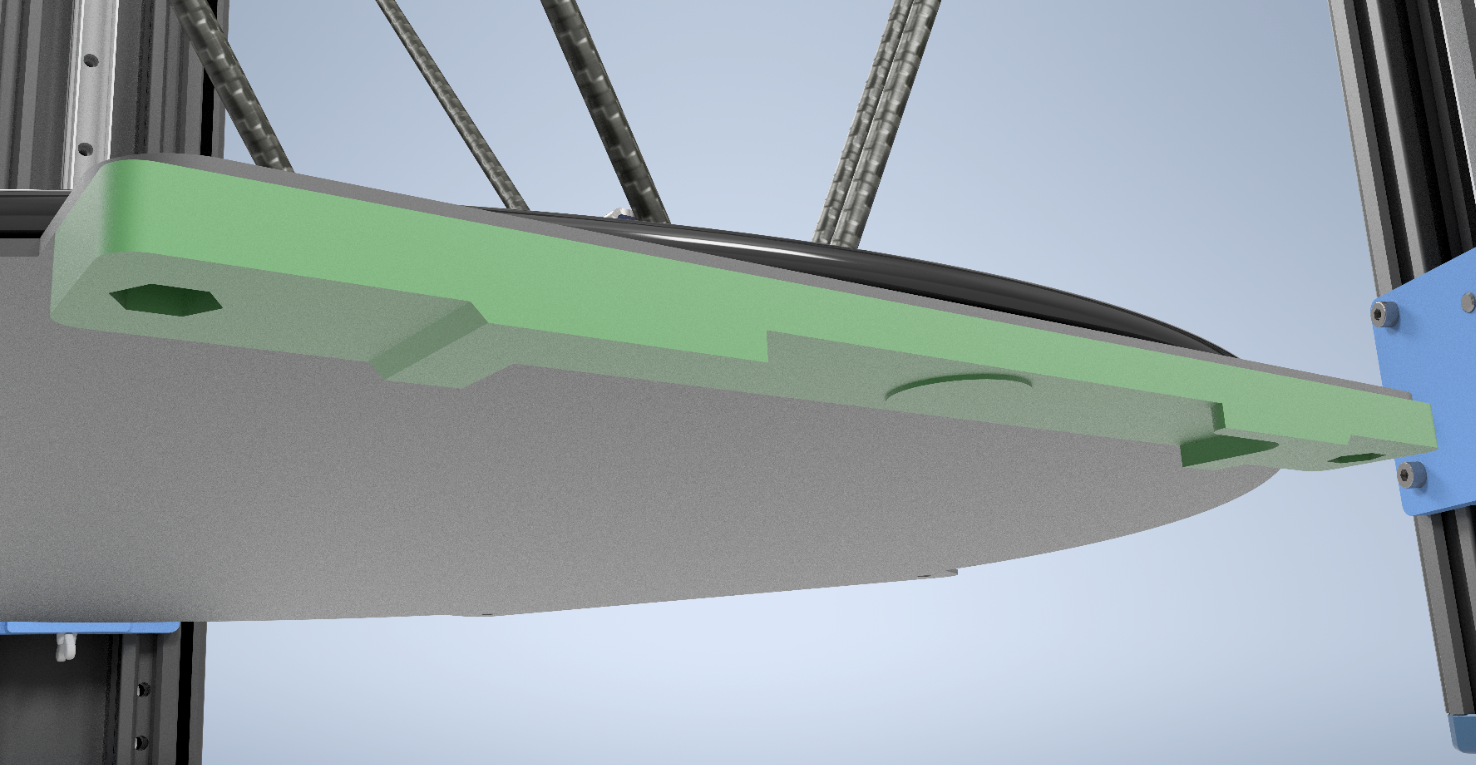

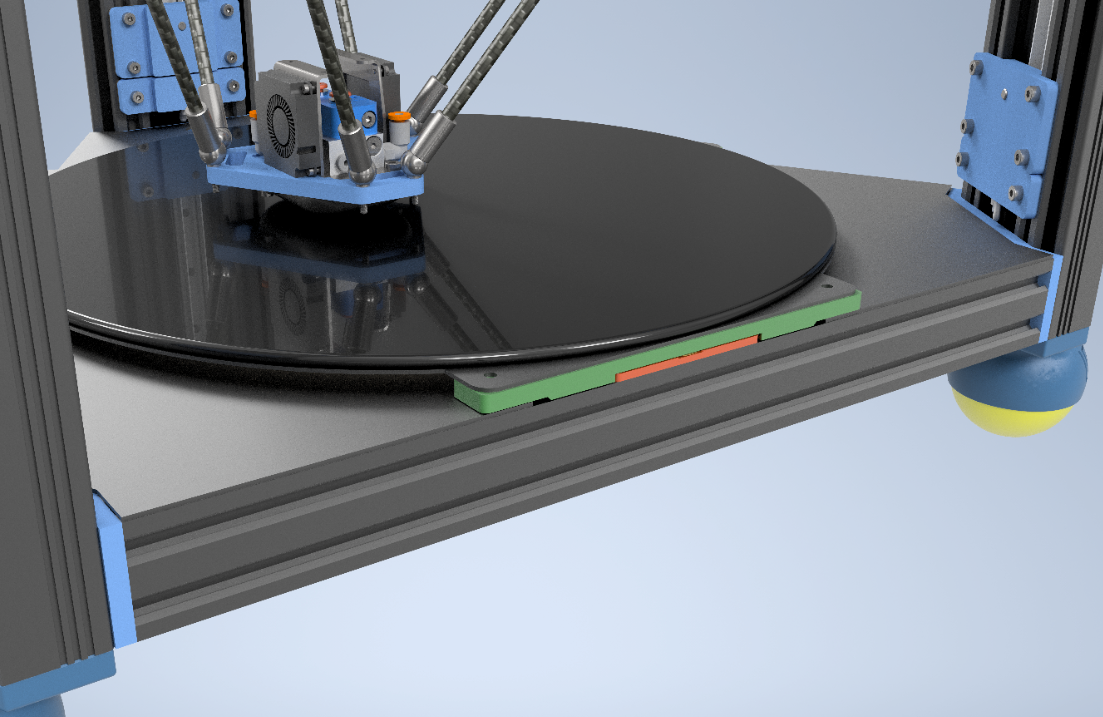

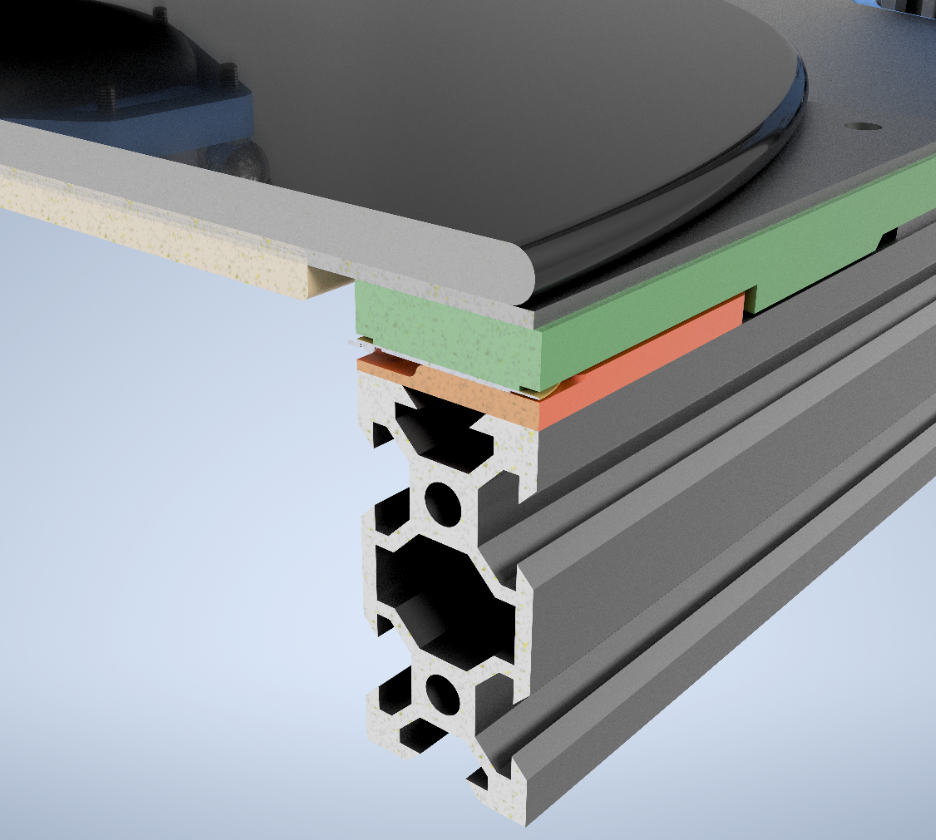

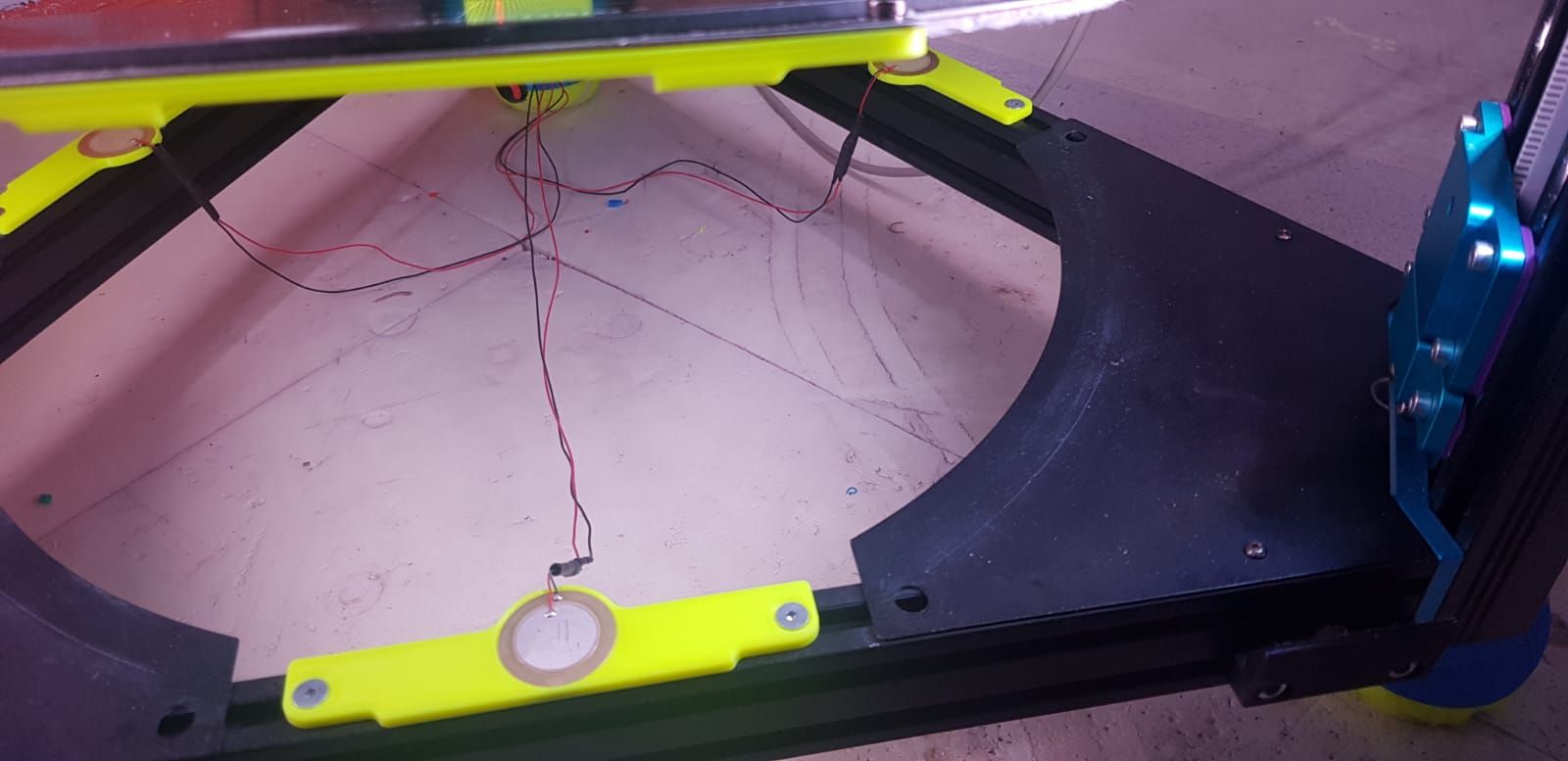

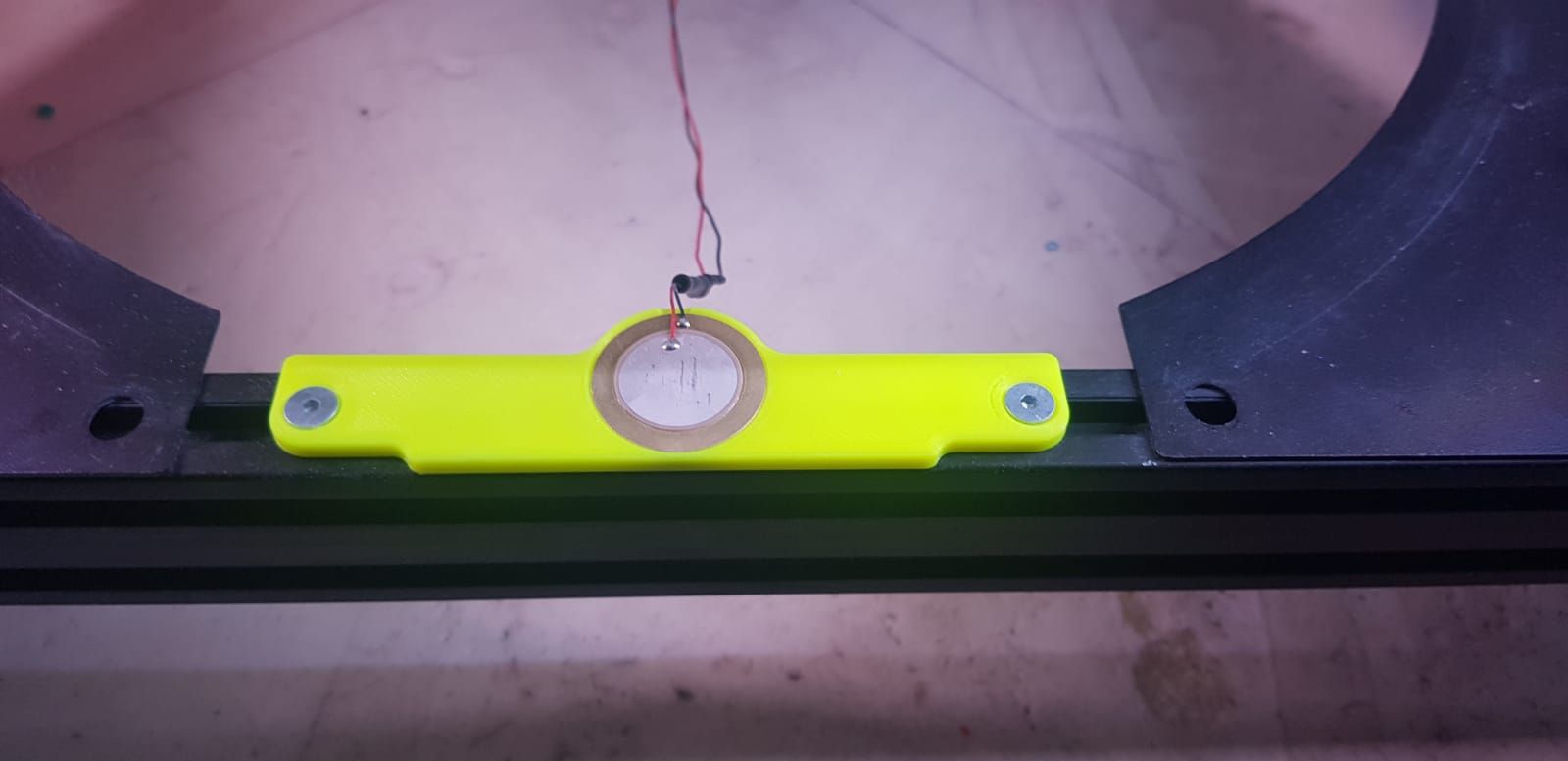

)I designed new bed support to place piezo (Precision piezo kit Ø20mm):

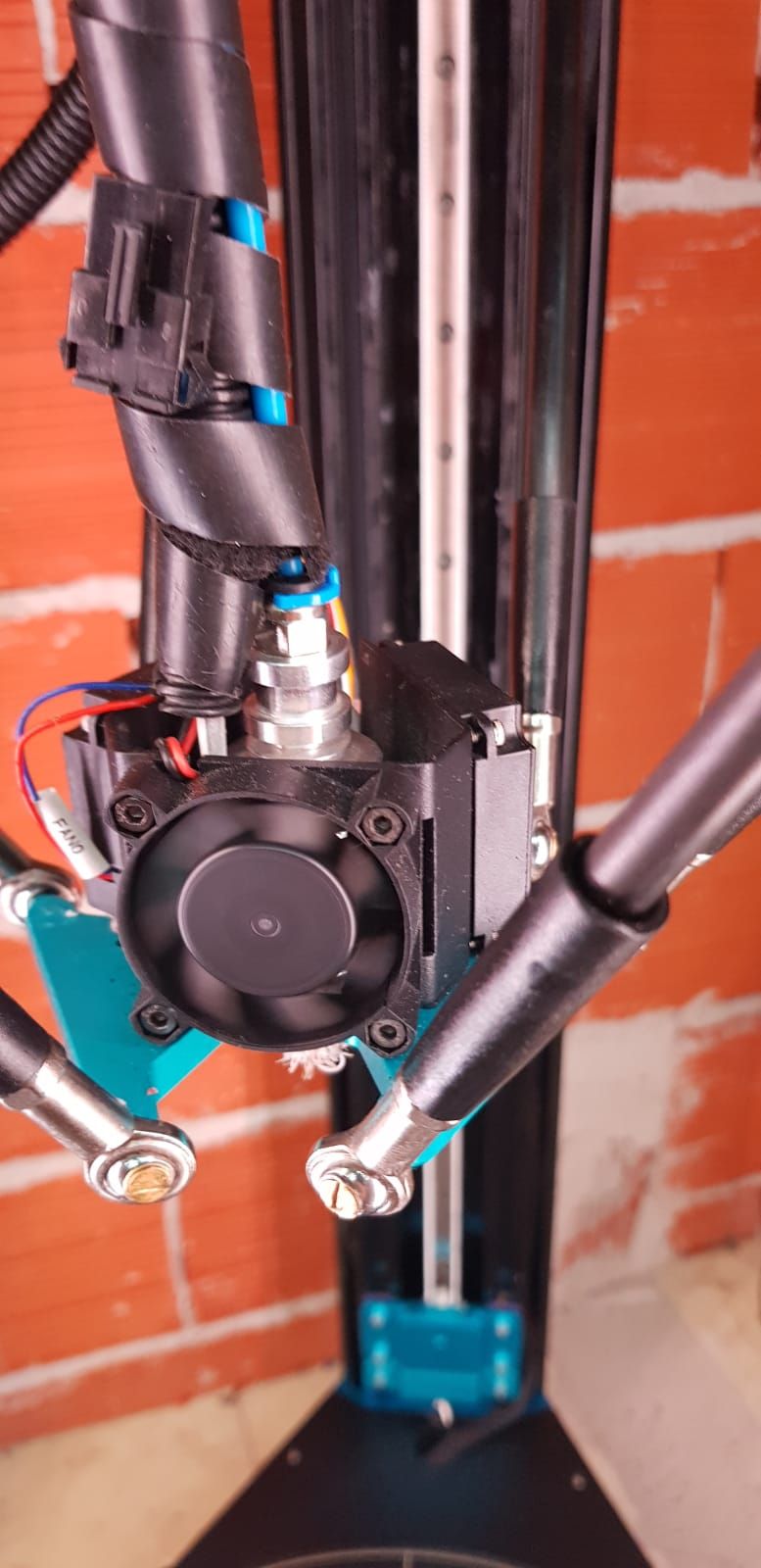

...and problably i will move to a new print head solution to prevent tilt issues:

i will design a special cooler to proceed with my liquid cooling idea and create a compact effector...

hope you like it and i'm on the right way now..

thanks guys!

thanks guys! -

I am waiting for the day when our 3D printers will be as pretty as their CAD renderings.

-

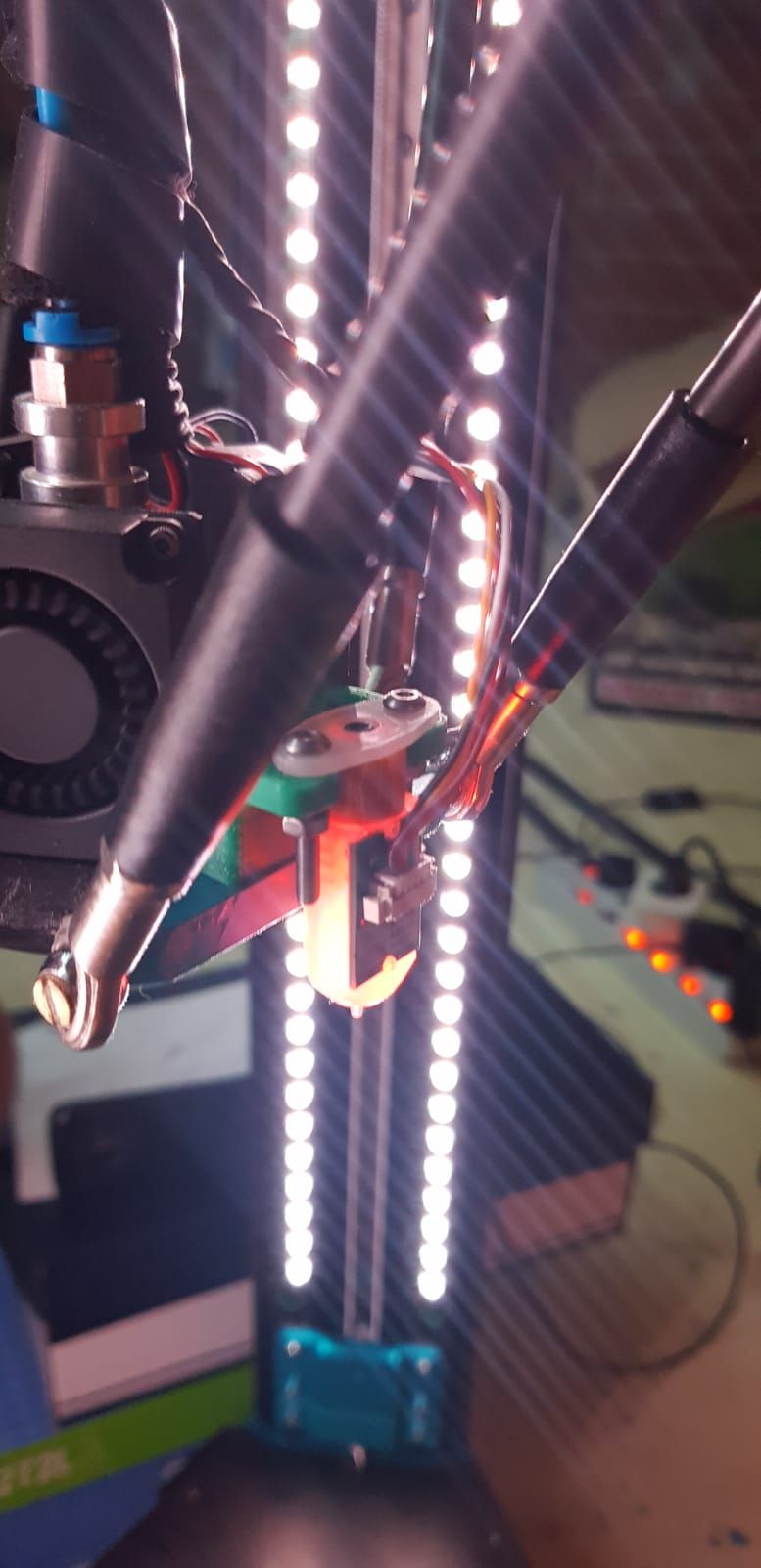

here we go....!

instead of what drawed before, I made (due to supplier wrong shipment) the Ø27 piezo support, probably more sensitive

here a short preview,

https://youtu.be/zSb38aC-XgElooks good:

But unfortunatelly I don't understand this mesh... really don't...

I will check again geometry and road lenght with a caliber...

wait for your comments

-

@thor3k, that height map with ridges at one end of the X direction turning into valleys at the other end is a beautiful example of the effects of backlash in the joints of a delta printer.

Try lubricating the joints.

-

Thank you dc42, I thought it depend of bad geometries.. is something I saw on first tests, I remember (se my first post) it goes better when I goes back from magnetic joints to the original ball eye rod joints..

I will check the lubrification on my mag balls...

-

Btw sticktion in the carriage or belts too loose would also cause that pattern in the height map.

-

Hi, how's this project going? I'm interested in the piezo mounts. Does the heated bed float on them or is it screwed down? Do you have a place you are putting the files as I would really like something similar for mine.

Thanks

-

@thor3k hi , I would make this mod too on my predator , can you share the stl file for mount the piezo Undermath ?

-

@thor3k I'd be interested in the mounts - would you mind sharing them?