Robotic kinematics

-

@tony73 said in Robotic kinematics:

I have a lathe with modifications for manual cnc I could do the important pieces in aluminum.

This will be sufficient. It would be an advantage to already have a 3D printer, but I have a plan to start without. I will release all what I am doing to build the robot.

-

I have a 3d printer I took it for granted !!some pieces for my scara are created with 3d printing !

-

@tony73 I only ask because I have an idea to use 3D printed gears, and one needs a printer already to create it. But I'll explain in a few days.

-

ok! I look forward to hearing from you !

-

@JoergS5

good morning ! how is work on the robot going on? -

@tony73 hello, my first try was too flexible, I am currently building version 2. You'll see it in a few days.

-

@JoergS5

OK, see you soon! -

This post is deleted! -

@dc42 I have two short questions and hope you can easily answer them:

The M208 XYZ, are they cartesian coordinates, and when using U it is meant as a second X? For rotational actuators, I would use the result of the kinematics world coordinates for the M208 values, not the angles? Do I understand this correctly?

I have to inform the kinematics in advance before the G0/G1 move starts, what the complete movement will be. I added a seperate method for this in the kinematics. Where shall I add the call? (DDA/Move/...Init/Spin?) and are there additional parts where I have to add it (mesh compensation eg).

-

It's entirely up to you what you use the U axis for. In the CNC world, conventionally UVW behave like a second XYZ system, and ABC are rotational axes. But RRF doesn't require that.

-

@dc42 I meant are M208 values cartesian coordinates or stepper positions?

-

@JoergS5 said in Robotic kinematics:

@dc42 I meant are M208 values cartesian coordinates or stepper positions?

They are in whatever units your kinematics assumes for U parameters in G1 commands.

-

@dc42 ok thanks, I try to use it correctly.

-

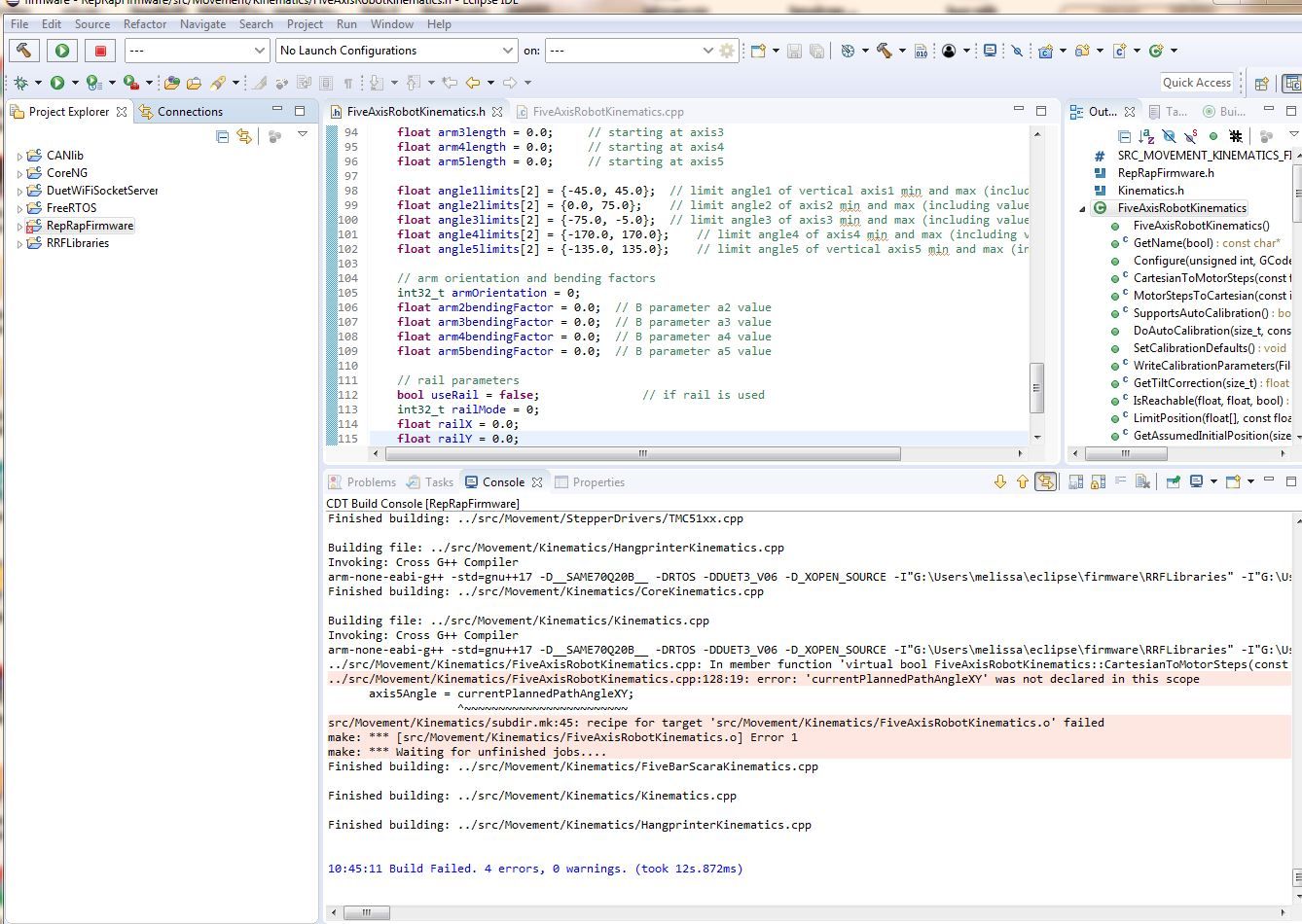

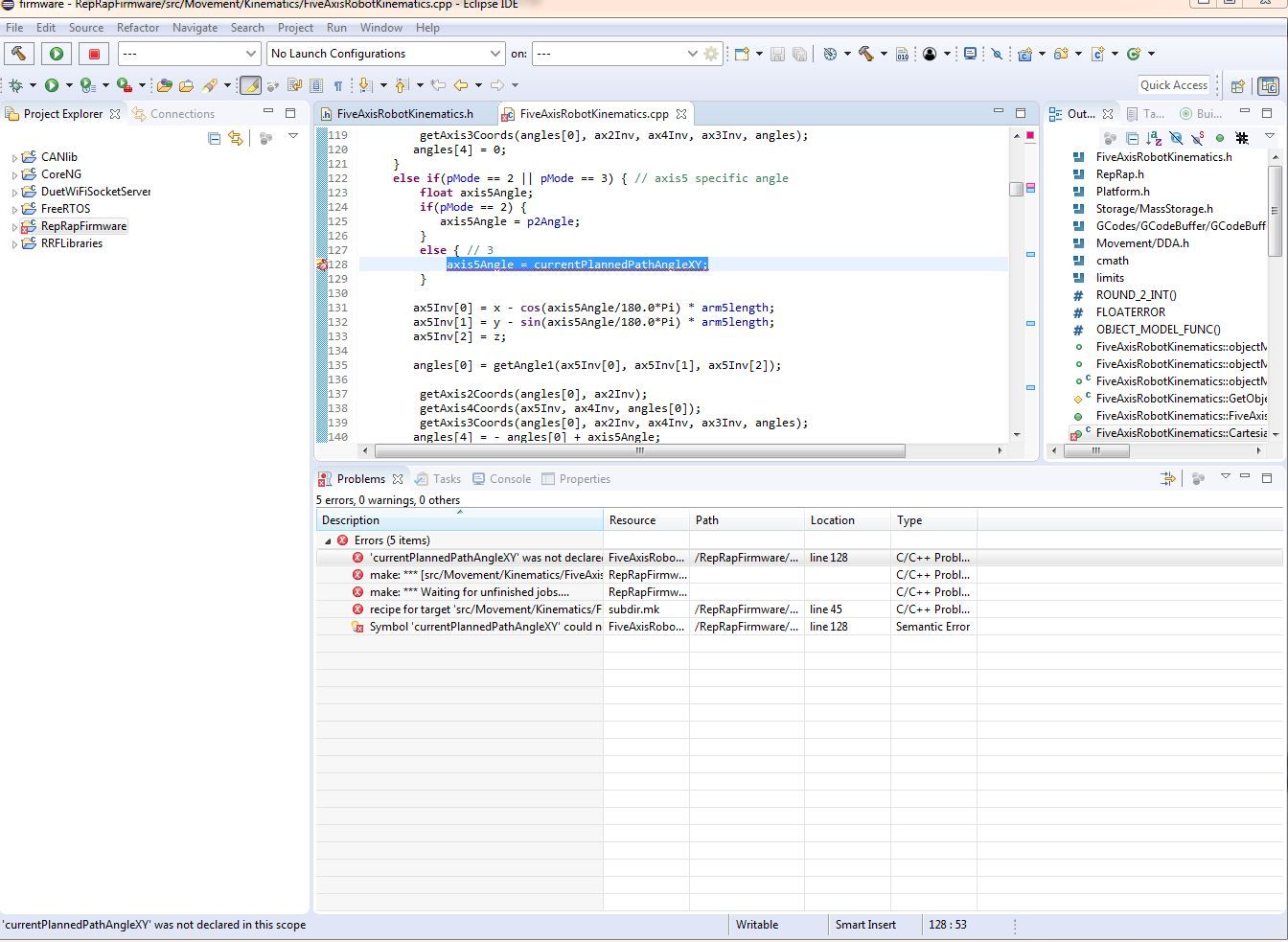

good morning ! I took the two files with the latest changes FiveAxisRobotKinematics.h and FiveAxisRobotKinematics.cpp I put them in rrf 3.1.0 as I always did, I tried to in eclipse to recompile the .bin gives me this error,

could you help me ? I don't know where I'm wrong!

-

@tony73 you're right, I missed checking it in into github. I'll do this in a minute. The variables are a prepration to support P3 (hotend in the direction of the movement) and a new P4.

Sorry that I overlooked it.

-

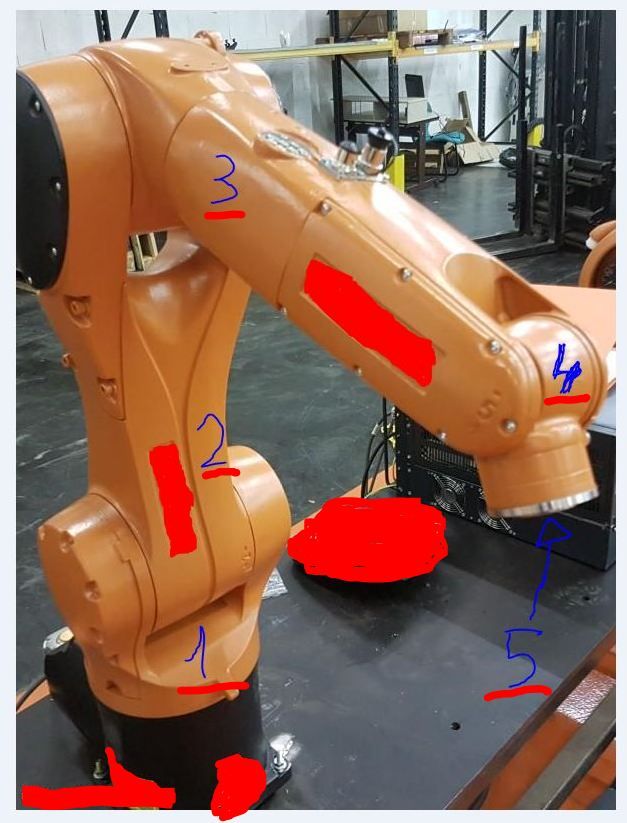

OK! eclipse firmware reloaded works! I would like to start building a robot that looks like this

with example link 1 /150mm, link 2/ 200mm, link 3/ 200mm, link 4/ 100mm, link 5/ 80mm

the (link 4 could be 100mm? considering that I don't know if link 2 can go to less than 0 degrees (type arm 2 max 75 degrees min -45 degrees? and could you say reduction ratio would serve on the basis of these arms, for the 5 engines?maybe I made a wrong speech!

if link 1 is 150mm, I can make link 4 of 100mm that is 50mm less than link 1, can there be a problem or can it be done? can create problems at link 2 for min angle 0? -

@tony73 I think you confuse some of the distances, What you mark as link 1 distance has no meaning. Only how much it can rotate is important.

=> to answer your question, different axis lengths are no problem. Longer will probebly be more stable. I will use between 100 and 200 also.Link 2 min angle 0 is no problem. You must calibrate the angle at a different angle (eg 90 degree).

Your question according reduction ratio: which ratio do you plan?

At the 5 you must assemble something horizontal to hold a hotend if you want to use it for 3d printing.

The robot as such looks very stiff and will be precise (if the ratio is ok) imho. In axis 5 could be a harmonic drive. A planetoid gear could have backlash, but you could run it in P0 mode.Axis 1 is very important to be precise (exactly horizontal rotation eg), you should consider making the rotating plate as big/good/stiff as possible.

-

This post is deleted! -

@JoergS5

ok! I take note of all the advice! and thank you for your help! if these were the lengths of the robot arms ((X0.0: 0.0 Y0.0: 0.0 Z100.0 L200.0: 200.0: 100.0: 80.0)) what reduction ratio would you use so that the 5 motors have excellent precision?about the second robot you are building how long do you need to finish it?

-

@tony73 I don't exactly know the best ratio, the commercial robots often have 1:30 for every axis. My approach will be to calculate mathematically which is the best ratio:

high ratio means higher precision and more torque, but slower. So there will be an optimal ratio for the desired speed. Regarding the maximal extruder speed, the robot has a maximum speed. More speed (= low ratio) is not necessary and would result in lower precision. High ratio would be slow. The arm lengths are also important.To calculate is on my long todo list...