E0 Heater Fault problem

-

@gorf26 said in E0 Heater Fault problem:

M350 X32 Y32 Z32 E32 I0 ; configure microstepping without interpolation

unrelated. whats your reasoning for not wanting to run interpolation?

-

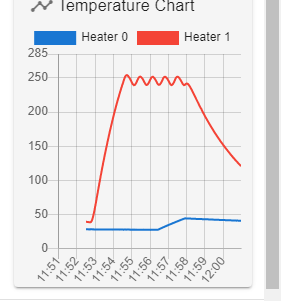

Here is a pic of the heat chart, i got to heat this time to run with no fault, i set the temp to 245C

and as you can see it is jumping around it over shoots to 251 and then drops to 239 and back up and back down..unrelated. whats your reasoning for not wanting to run interpolation?

never though about it would i be better off using?.

Thanks gary

-

yes x16 with interpolation is preferable and in most cases quieter. dont forget to adjust the steps/mm

the curve looks like one from a hotend without pid tuning

issue M307 H1 to see that the values have actually been applied

-

ran m307 h1 and the values are there..

also tried heatint to 245 a second time and now i get the heater fault it was at 40C.

I tried a third time and got same results, and this time i had my multi meter connected in the temp setting and that read 40C also so seems like the temp is close at least at low temps if i can get it go past 40 again i will see what the meter says at the higher temps..

thanks for the interpolation tip so you think i should drop down from x32 to x16 ok i will give it a shot when i get the heater working...

may try a new wire, don't know where to go from here..

Thanks gary

-

@gorf26 said in E0 Heater Fault problem:

also tried heatint to 245 a second time and now i get the heater fault it was at 40C.

can you share a picture of that?

-

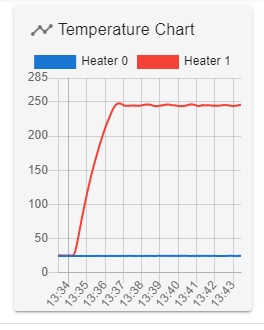

ran tune again got some different values, entered them into the config.g

and this is what i have now for a screen shot at 245C.. looks better, seems to be holding from 243.8 to 246.2 hits 246 drops to 243 then back to 246 keeps repeating that..

but ran 3 times after cooling and no heater fault.. will try a print later and see how that go's.not as good as the pt100 but i guess not bad or is it?.

Thanks gary

-

Seems reasonable.

How it looks during printing is much more important obvs.And while a PT100 is going to be more accurate, there's no reason why a thermistor can't provide a nice stable reading and PID loop.

-

Didn't go so good during print, the layers that were printed look fine, but print made it to layer 6 and then message heater fault, though i had captured the screen also but for some reason didn't get saved... haven't tried a new wire but looks like its next.. guess i go put one together..

Thanks gary

-

The fix for oscillating temperature is to increase the M307 D parameter.

-

Is the hotend assembled correctly? There should be a gap between the block and the heatsink.

Do you have a silicone nozzle sock on the block? They can help a lot with keeping a stable temp.

Does the cooling fan kick on at layer 6? Does it blow on the block more than it should?

Did you start tuning from room temp, or was it already warm?

Did you do the tuning with the part cooling fan on at an average level like you'd have on during a print? That can help it keep up during a print.

-

Is the hotend assembled correctly? There should be a gap between the block and the heatsink.

Yep been using as is for a couple months no problem, as i stated in the first message it was fine with the pt100 thern but the wire broke and only thing i had on hand was the therm that came with ed3 v6 hotend so till i can get a replacement pt100 thats what i'm tring to get working..

Do you have a silicone nozzle sock on the block? They can help a lot with keeping a stable temp.

no sock been printing with PETG and find it was to sticky and messy for the sock.

Does the cooling fan kick on at layer 6? Does it blow on the block more than it should?

No I have found at least for me the PETG sticks and prints better with no fan.

Did you start tuning from room temp, or was it already warm?

start at room temp.

Did you do the tuning with the part cooling fan on at an average level like you'd have on during a print? That can help it keep up during a print.

No cooling fan during tuning, i have the fan running that's cooling the heat sink only..

I did make a new wire and hooked it up, did another tune and added the new values to config.g

let cool down to room temp and the set the temp to 240C, it overshot by around 2%C

and about 20 or 30 seconds seemed to stabilize at 240C was running 239.5 to 240,5.Will try another test print tomorrow and see how that go's.

that's were i will find out if i get the fault, at least that's were i am now, no fault errors when tuning and none setting the temp in DWC..my D is set to 7.6 how high can that go, or should i bother with only about 1% oscillation?

Thanks gary

-

@gorf26 said in E0 Heater Fault problem:

my D is set to 7.6 how high can that go, or should i bother with only about 1% oscillation?

If you're stable within 1c I wouldn't bother trying to adjust any of the tuned parameters.