3 mm (2.85) vs 1.75 mm filament

-

Hello all, I'm not sure if this is allowed or not on here but I'm looking for peoples thought and experiences with the two common filament sizes. I have printers that use both filament types, and I've been fighting with the one that uses 3mm the most. I recently rebuilt it/customized it by adding the Duet 3 board and fitted it with the E3D titan aqua extruders (in 3mm) with volcano hotends. I did this because it was a 3mm machine before and I had a large supply of 3mm filament. It is also a large format printer with build volume of 334mm x 374mm x 588mm and I like to use 0.mm up to 1.2mm nozzles.

One of the things that I have been fighting with is the mass flow of filament. I'm using a print speed calculator to help me figure out how quickly I should print, and I'm finding that I can't print anywhere near the limits that this calculator shows. I find that I'm okay to print upto a filament extrusion speed of about 2.5mm/s which is about 33% of what that site tells me a Volcano should be capable of.

There is an interesting page that give a good explanation and seems to be consistent with what I have observed when it comes to the flow rate and extruder pressure.

I'm leaning towards converting the machine to 1.75mm filament in hopes that I will be able to get closer to 75% of the theoretical limit of the volcano. I would really like to be able to lay down a 1.2mm x 0.6mm tool path at a speed of 40-60mm/s but to do that I need to extrude close to 5mm/s with 3mm filament or 15mm/s with a 1.75mm filament.

Anyone have similar experience? Would I be better off staying with 3mm filament and using a super volcano?

Thanks for thoughts.

-

At 1.2 mm line width with 0.6 mm layer height, you would extrude roughly 29 mm3 at 40 mm/sec.

A Volcano is limited to just below 20 mm3.

You are asking too much for the Volcano and should try the super volcano. I do not know the expected melt rate of the Super Volcano.

Keep in mind that larger melt chambers have drawbacks ....The expected flow rate on the print speed calculator seems way too high.

For example, I assume 10 mm3/s for a regular E3D V6 -

@baird1fa said in 3 mm (2.85) vs 1.75 mm filament:

I'm not sure if this is allowed or not on here

Absolutely allowed, but I have moved to the 3D printing general chat area.

-

@jens55 I think you are correct. I took that calculator at face value but now that you pointed it out (20mm3/s) I did more digging and it appears even that might be a bit on the high side. I found a document that E3D published and the most they pushed it to was 18.3mm3/s for a fleet of benchy’s when they first tested the super volcano. On that same document it showed test data for the super volcano up to 73mm3/s.

Hmm....

-

@baird1fa There are a couple of other things to note. Firstly, the filament itself is a relatively poor conductor of heat. The filament is heated from the outside, so it takes a bit of time for that heat to find it's way through to the core and the larger the filament diameter, the longer that time is. Somewhat conversely, larger diameter filament has a larger surface area in contact with the hot block. So if you try to print too fast, you may find that there is a gradient through the cross section and the core might not be fully melted. Secondly, because the cross sectional area of the filament is very much greater with 2.85mm diameter, then for a given volume of extruder material, the linear movement will be greatly reduced - less micro steps needed. This may be problematic for small moves, especially if the extruder does not have enough resolution. 0.9 degree extruder motors would help but higher gearing would be better IMO.

-

I have a Wanhao D5S Mini which originally came with 3mm filament support. I have since upgraded it to use the E3Dv6 hotends, and have a bunch of hotends (3mm and 1.75mm versions), allowing me to switch out for different nozzle sizes and filament diameters (for 3mm I use the original geared extruder, and for 1.75mm I have a Bondtech QR extruder, also geared). Having the nozzles and everything ready makes switching out a lot easier (though it still take 20+ minutes for a switch - but no hot parts as would be the case when switching only nozzles).

Ultimately I find using 1.75mm more convenient. Other things that helped with my decision to get 1.75mm capability is the fact that 3mm in my country is getting phased out (no new printers use it, the companies that sell 3mm have very little options in colors - and there is only PLA). I still have many 3mm spools, and if I need something printed in a color I have in 3mm, I will use it until it is done.

The 3mm filament becomes brittle a lot easier than the 1.75mm (and removing the short pieces from a Bowden setup is bad).

-

@baird1fa I started with 3mm and I still use 3mm for some projects, my dual head is 3mm + 1.75mm.

One interesting fact that Vik Olivier from NZ explained is that for the same price / amount of involvement / class of machinery 3mm filament is order of magnitude more precise than 1.75mm filament. If I understood correctly the "absolute size of the filament" is what's hard to get so for one level of gear (one price range) you get for e.g. .1mm error irrelevant if your filament is .5, 1, 1.5, 3 or 5mm thick. So the absolute error is the same, but relative error, what is actually important, is much greater for 1.75 than for 3.0mm as volume error for 1.75mm filament with .1mm error is much greater in % than volume error for 3.0mm filament with same .1mm error. I never made my own filament myself so maybe something changed in the meantime but I guess Vik knows what he's talking about being the guy who made the first clone with dr. Adrian and who AFAIK introduced PLA to the 3D printing world

Extruding 3mm filament vs 1.75 out of the same nozzle requires lot more force. Even with much more powerful heating block the force is increased, that's why, if you look at the old extruders, they were all geared. Also, as @deckingman mentioned you need precision in the extruder movement as you are making smaller movements due to larger cross cut surface.

I myself use 3mm filament only with 1.5 and 2mm nozzle. I gave up using 3mm filament for the "normal" nozzle as the price of the 1.75mm filament and accessibility of the 1.75mm filament is now even better than one of the 3.0 filament. Only 2 3mm filaments I push out of "normal" nozzle are Kai's

- moldlay (let's say wax)

- claylay (clay)

as I don't have them in 1.75 variant at all, but I use these filament so rarely that it can be considered statistical error.

Using 3mm filament for years with my own hotends and extruders I can say

- 100W heater for the hotend is not something I consider "too much"

- 60W heater for the hotend is something I consider "barely adequate"

- if you are running nema17 motor on the extruder you must have geared extruder and 1:3 is usually not enough

- I have 3mm titan aero and I'm not happy with it, even with nice 80W heater on the hotend it's not capable of pushing filament trough, I did make it work ok with the biggest nema17 I could find but that makes extruder rather heavy

-

@arhi thanks for the info. I’m using the Titan aqua which has a 3:1 gear reduction and a nema 17 motor. I do find that I don’t get the best details on small prints using a 0.4mm nozzle but it’s not awful. I’m torn as I would like to print larger thing faster so using the 1mm and 1.2mm nozzle. And that sounds like I’m not even close to what you are extruding.

Should I try the super volcano? Or just change to 1.75mm filament and keep the volcano hot end? I see dyze makes the typhoon which looks like the cats meow of extruders but at 2600USD it a tad expensive For my current needs.

-

@baird1fa said in 3 mm (2.85) vs 1.75 mm filament:

@arhi thanks for the info. I’m using the Titan aqua which has a 3:1 gear reduction and a nema 17 motor. I do find that I don’t get the best details on small prints using a 0.4mm nozzle but it’s not awful. I’m torn as I would like to print larger thing faster so using the 1mm and 1.2mm nozzle. And that sounds like I’m not even close to what you are extruding.

details are related to extruder precision and nozzle size, assuming you are not skipping any steps, 1:3 with 400step/rev motor on titan should be enough wrt precision, but I doubt it's enough wrt torque if you are not using the heavy 60mm long motor there.

Should I try the super volcano?

Dunno really. I think you should ping E3D support and ask them why what you already have don't work as they designed the 3mm heatbreak for 3mm filament so it should work, they maybe have idea how to make it work.

I never tried those long melt zone hotends as I never believed that possible and with big nozzles oozing is a serious problem. I'm more for powerful heater on the short melt zone. It is not safe (as it can melt the aluminium if something goes terribly wrong) but works for me. I don't know if there's a commercial system that work like this. I know some PRC manufacturers sell barrel type ceramic heaters that are very close to what I design for myself.

Or just change to 1.75mm filament and keep the volcano hot end?

I'm not 100% sure but I think 1.75 and 3mm heatbreak for titan are not the same on the heatsink size so to get 1.74mm titan you need a whole new thing, not just a new heatbreak, but I might be wrong.

Should you move to 1.75 from 3mm ... when I started 3mm was the norm so I became used to it and that's the only real reason I still have 3mm hotends. I use the 3mm only for nozzle size 1.5mm and bigger as with 1.75mm filament you can't do 1.5+ really as the filament don't melt, it just go trough so you really need a 3mm filament and you need to crank up the heat. I have 2 zones on these nozzles, basically 2 heaters next to each other, first is wound longer and is set to temp you would normally use to print with that plastic, second is closer to the orifice, 2 coils of khantal only, set 20-30C over the printing temperature, everything coated in fire-cement. TBH I never tried this e3d combination with heatblock and nozzle crewing from one side, heatbreak from other side for 3mm that I liked the performance, the only commectially awailable hotend for 3mm that I tried and that worked ok were 1730 and hexagon and the "wound" stuff still work better. I stil have makergear hotend (like this one https://youtu.be/OgvX7L2bGCw not the v2/v4 stuff original v0

) that works awesome

) that works awesome

I see dyze makes the typhoon which looks like the cats meow of extruders but at 2600USD it a tad expensive For my current needs.

there's probbly a reason why they make it and why it cost that much but if you ask you don't need it

that's my take on it.

that's my take on it. -

looking at typhoon

4.6:1 transmission and NEMA23 motor

dual melt zone, 400W heater

this is where filament enter

this is where it exit

notice the mesh between melt zone and the nozzle

This is some seriously engineered and not easy to manufacture device so it is priced accordingly

... but you can take a lot of info from it

... but you can take a lot of info from it

-

@arhi thanks for the info. I got frustrated today and swapped in my 1.75mm Titan aqua. I kept the volcano block as that is the same. But I changed out the whole extruder, heat break, and nozzle as those are all specific to the filament diameter in the Titan aqua.

So far I’m much happier with it. I’m now printing at 120mm/s with a 0.4mm nozzle and 0.2mm layer height and 0.48mm width. With 3mm I was barely able to get printing at 40-60mm/s with the same setup.

I don’t think torque was a problem nor precision (837steps/mm) as there was plenty of power to just shred the filament. I think the other part of the equation is the ability to grip the filament and transfer the power to it. The Titan seems to lack that ability.

I don’t intend to go over 1.2mm nozzles so I think I’ll be happier with the 1.75mm filament. The only downside I see is I’m going to be stuck with lots of 3mm filament for a while. My secondary extruder is still 3mm for now so I can still use it, but that will also change eventually.

The typhoon uses a quad drive similar to some wire feed welders.

-

@baird1fa said in 3 mm (2.85) vs 1.75 mm filament:

I think the other part of the equation is the ability to grip the filament and transfer the power to it. The Titan seems to lack that ability.

Yes, I think titan uses same hobbed gear for 3 and 1.75 so might not be optimal for 3mm.

I don’t intend to go over 1.2mm nozzles so I think I’ll be happier with the 1.75mm filament.

There's no need to use 3mm then, except if you have bunch on stock so want to use it up.

The only downside I see is I’m going to be stuck with lots of 3mm filament for a while. My secondary extruder is still 3mm for now so I can still use it, but that will also change eventually.

use the 3mm with huge nozzle for the infill and you will use it up quickly

-

@arhi I’m rather old school, and have a pretty slow bed slinger with Prusa i2 style horizontal X axis, with Greg’s extruder and X carriage, using direct extruded 3mm filament. Hot end is a genuine J head With 0,4 nozzle. I print up to 60mm/s usually 0.2mm layer height, and this works well for functional prints with not too obvious layers.

However, the hobbed bolt on my Greg’s extruder has been a weak point for a long time. Having fitted a (cloned) BMG for 1.75mm filament on my Delta, I really liked the dual hobbed bolts, and it always has good grip, with no noticeable drop in extrusion as speed increases. I looked for a similar direct drive replacement for the 3mm Greg’s, but there’s only the Bontech QR (with stepper driver gearbox) or DDG (Ultimaker upgrade) 3mm extruders, neither suitable for mounting direct drive.

So I’m currently hacking on the OpenSCAD code to put Bondtech gears from the QR in the Greg’s extruder. 3mm filament may be passé in the 3D printing world, but those of us who still use it deserve better gripping extruders!

I’m trying to do 2 versions, one using the Greg’s layout, and one using the Ultimaker geared setup, which would be closer in size and layout to the BMG and Titan, hopefully. I’ll let you know how I get on!

Ian

PS if anyone in the UK wants to donate their old, unused 3mm filament to me, I’m more than happy to take it off your hands!

-

@droftarts said in 3 mm (2.85) vs 1.75 mm filament:

@arhi I’m rather old school, and have a pretty slow bed slinger with Prusa i2 style horizontal X axis, with Greg’s extruder and X carriage, using direct extruded 3mm filament. Hot end is a genuine J head With 0,4 nozzle. I print up to 60mm/s usually 0.2mm layer height, and this works well for functional prints with not too obvious layers.

I was pushing 80mm/sec .5mm "line" .35mm layer with .4mm jhead and wade's extruder so it should work ok

However, the hobbed bolt on my Greg’s extruder has been a weak point for a long time.

IIRC Greg's extruder is slightly modified Wade's right, uses same hobbed bolt? I think I have one of the Arcol.hu hobbed bolts for Wade's extruder cnc'ed and quenched lying around unused, lemme check if I can find it and if you want it I can ship it for free :), They have awesome grip. I used it 99.9999% with ABS but Arcol was using them on PLA so both should work ok.

So I’m currently hacking on the OpenSCAD code to put Bondtech gears from the QR in the Greg’s extruder. 3mm filament may be passé in the 3D printing world, but those of us who still use it deserve better gripping extruders!

I ordered some original gears from Bondtech while back in order to design extruder similar to wade/greg that uses Bondtech drive gears. The gears are in the original packaging for over two years

I never found time/inspiration to even start that project

I never found time/inspiration to even start that project  so if you do it, please share

so if you do it, please share

-

@arhi said in 3 mm (2.85) vs 1.75 mm filament:

IIRC Greg's extruder is slightly modified Wade's right, uses same hobbed bolt?

Yes, Greg's extruder is a modified Wade's. I'm actually using this one which is further refined: https://www.thingiverse.com/thing:18379 and there's a lovely history article about extruder development here: https://reprap.org/wiki/Genealogy_/_Archeology_of_the_Greg's_Wade's_Geared_Extruder

I think I have one of the Arcol.hu hobbed bolts for Wade's extruder cnc'ed and quenched lying around unused, lemme check if I can find it and if you want it I can ship it for free

My hobbed bolts are all home made, which probably explains the slipping! Thank you very much for the offer, but generally my extruder is reliable so long as I don't print too fast and there is no inconsistency in the filament. My J Head is the other weak point, as it has the original 5.6ohm heater resistor (at 12V = 25W!). I think I'll only want to rebuild it again with the Bondtech gears and one of the 3mm E3D v6 hot ends I have kicking around.

So I’m currently hacking on the OpenSCAD code to put Bondtech gears from the QR in the Greg’s extruder.

...so if you do it, please share

Will do!

Ian

-

@droftarts said in 3 mm (2.85) vs 1.75 mm filament:

My hobbed bolts are all home made, which probably explains the slipping!

I was also making them myself with M3 and M4 thread cutter. Arcol was doing some testing with both what I and he made manually and with some of the one sold commercially (makergear and some others) and shown that they do not properly grab filament so he worked with his local machinist and they made a rig that was cutting them "straight" and not under angle (what thread cutter does) and the teeth were shaped differently too - dunno how the tool looked exactly never seen it myself. But the difference in "grabbing" is huge

If you change your mind ping me via IM .. I believe the "screw" can go into a simple envelope and will cost nothing to ship so ..

-

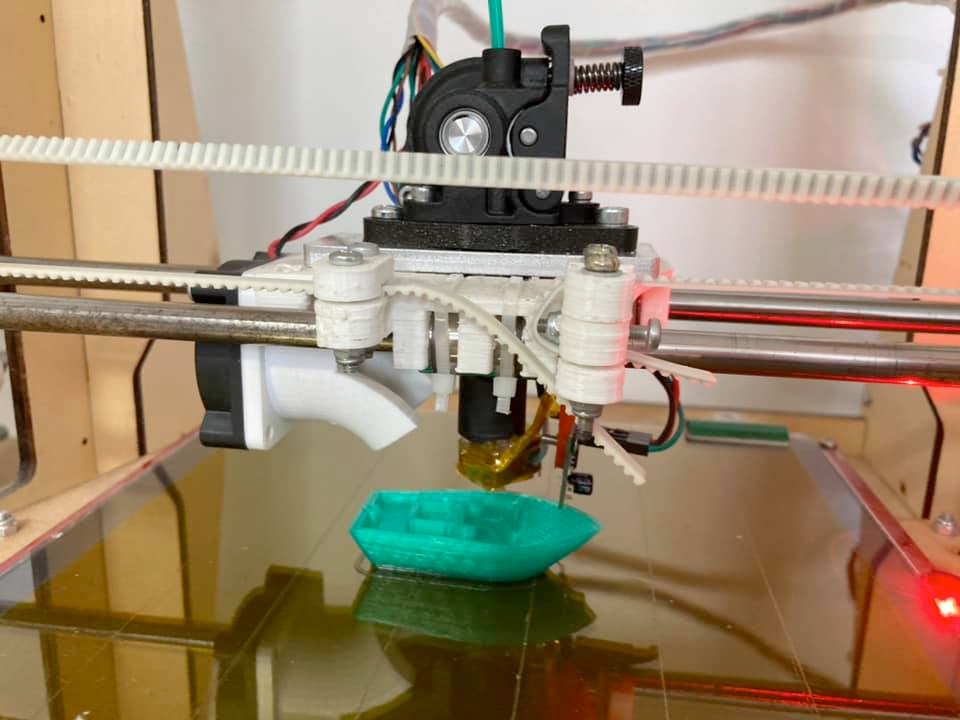

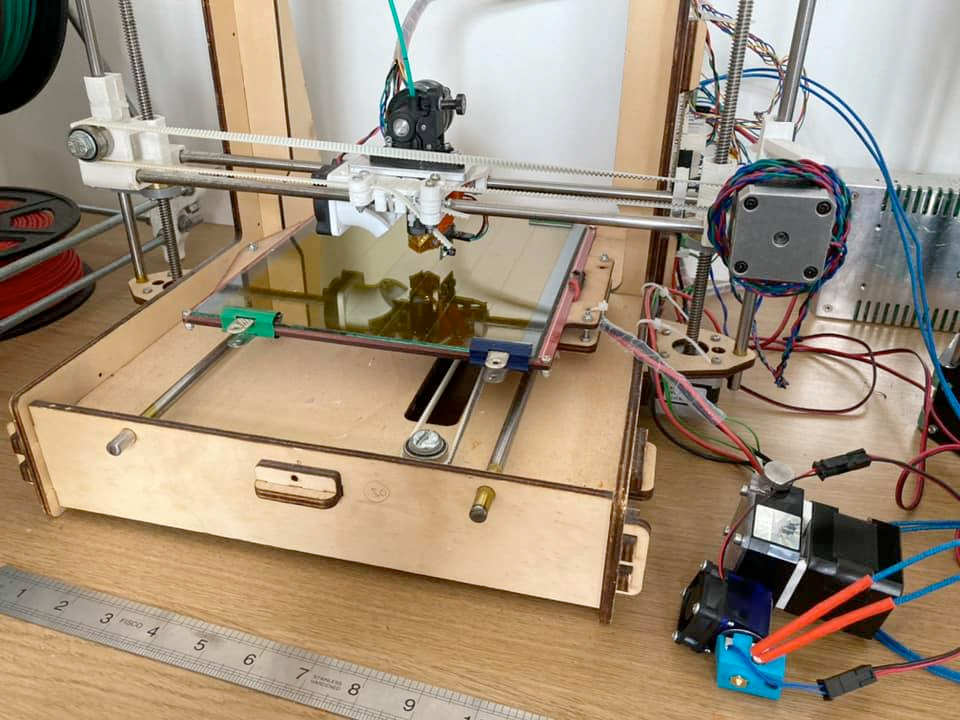

After a long time not managing to finish off my version of a 3mm extruder using Bondtech gears, I ended up buying a Orbiter v1.5 and modifying it for 2.85/3mm filament. This was pretty easy, just drilled out the filament path to 3.5mm and fitted the hobbed gears from a Bondtech DDG (available separately, too). Works well and is tiny! Here it is printing a Benchy on my old-school bed-slinger.

And yes, I should probably clean up the rusty rails and bearings...

Ian