Homing issues on 2 delta printers after upgrading to 3.1.1

-

- Are your M665 and M666 commands the same as before?

- If you remove the last two G1 lines, do you still get the error; and what XYZ position does DWC then report after homing?

- Please post your config.g file.

-

Thanks David.

I am using the same M666 and M665.

Ok - when I comment out the last 2 G1 lines I do not get the error. (If I comment them out 1 at a time I get the error) It reports X 3.1 Y-0.3 Z454.29

Config:

; Configuration file for UltiBots D300 V-Slot 3D Printer ; version 1.0 for firmware version 3.0 ; Communication and general M111 S0 ; Debug off M550 PThing-2 ; Machine name and Netbios name (can be anything you like) M551 XXXXX ; Machine password (used for FTP) ;*** If you have more than one Duet on your network, they must all have different MAC addresses, so change the last digits ;*** Wifi Networking M552 S1 ; Enable WiFi M555 P2 ; Set output to look like Marlin M575 P1 S1 B57600 ; Communication parameters for the PanelDue G21 ; Work in millimetres G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves ; Axis and motor configuration M569 P0 S0 ; Drive 0 goes forwards (X tower) M569 P1 S0 ; Drive 1 goes forwards (Y tower) M569 P2 S0 ; Drive 2 goes forwards (Z tower) M569 P3 S0 ; Drive 3 goes forwards (extruder 1) M574 X1 S1 P"xstop" ; X min active high endstop switch M574 Y1 S1 P"ystop" ; Y min active high endstop switch M574 Z1 S1 P"zstop" ; Z min active high endstop switch ;*** The homed height is deliberately set too high in the following - you will adjust it during calibration M665 L376.890 R209.670 H450.462 B140.0 X0.114 Y0.283 Z0.000 ; set delta radius, diagonal rod length L380.31, printable radius and homed height M666 X0.107 Y-0.648 Z0.542 ; put your endstop adjustments here, or let auto calibration find them M350 X64 Y64 Z64 E16 I1 ; Set microstepping to 32 for X, Y and Z and 16 for extruder stepper with interpolation M92 X640 Y640 Z640 ; Set axis steps/mm M906 X1000 Y1000 Z1000 E500 ; Set motor currents (mA) M201 X1000 Y1000 Z1000 E1000 ; Accelerations (mm/s^2) M203 X20000 Y20000 Z20000 E3600 ; Maximum speeds (mm/min) M566 X1200 Y1200 Z1200 E300 ; Maximum instant speed changes mm/minute ; Fans M950 F2 C"fan2" M950 F1 C"fan1" ; This fan is the Heatsink Fan M106 P1 T50 S255 H1 ; Set hotend heatsink FAN1 thermostatic control at 50°C ; Thermistors M308 S0 P"bed_temp" Y"thermistor" T100000 B3950 ; define bed temperature sensor ;M308 S1 P"e0_temp" Y"thermistor" T100000 B4725 C7.06e-8 ; define E0 temperature sensor M308 S1 P"spi.cs1" Y"rtd-max31865" R395 F5 ; Heater configuration M950 H0 C"bed_heat" T0 ; heater 0 uses the bed_heat pin, sensor 0 M140 H0 M950 H1 C"e0_heat" T1 ; heater 1 uses the e0_heat pin and sensor 1 ; Tool definitions M563 P0 D0 H1 ; Define tool 0, the extruder G10 P0 S0 R0 ; Set tool 0 operating and standby temperatures ;M92 E415 ; Bondtech BMG steps per mm M92 E822 ; Titan Aero steps per mm old: 837 ; Z probe and compensation definition ; Change "H25" to "H3" AFTER commissioning your printer M558 P5 C"!e0stop" X0 Y0 Z0 H4 F60 ; FSRs with JohnSL board Z probe behaves as a switch and is not used for homing any axes ;G31 X0 Y0 Z-0.15 P500 ; More (-) Z is less smooshed, more (+) Z is more smooshed G31 X0 Y0 Z-0.25 P500 ; More (-) Z is less smooshed, more (+) Z is more smooshed T0 ; Select tool 0, the hot end M501 ; Load config-override.g -

Does it work if you replace this line:

G1 Z-5 F6000 ; move down a few mm so that the nozzle can be centred

by this:

G1 H2 X-5 Y-5 Z-5 F6000 ; move down a few mm so that the nozzle can be centred

or alternatively by:

G1 Z-10 F6000 ; move down a few mm so that the nozzle can be centred

-

Thank you David. I changed to

G1 H2 X-5 Y-5 Z-5 F6000 ; move down a few mm so that the nozzle can be centredAnd that did the trick.

-

But it did not work for my friend's machine. IO asked him to post here.

-

Hi David, I am also having this issue which is why I got help from Michael, it seems even after changing the lines you recommend I am still getting that error.

Config.g

; Configuration file for UltiBots D300 V-Slot 3D Printer ; version 1.0 for firmware version 3.0 ; Communication and general M111 S0 ; Debug off M550 PVader ; Machine name and Netbios name (can be anything you like) M551 XXXXX ; Machine password (used for FTP) ;*** If you have more than one Duet on your network, they must all have different MAC addresses, so change the last digits ;*** Wifi Networking M552 S1 ; Enable WiFi ;M587 S"Epcot" I"192.168.1.102" M555 P2 ; Set output to look like Marlin M575 P1 S1 B57600 ; Communication parameters for the PanelDue G21 ; Work in millimetres G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves ; Axis and motor configuration M569 P0 S0 ; Drive 0 goes forwards (X tower) M569 P1 S0 ; Drive 1 goes forwards (Y tower) M569 P2 S0 ; Drive 2 goes forwards (Z tower) M569 P3 S0 ; Drive 3 goes forwards (extruder 1) ;M574 X2 Y2 Z2 S1 ; set endstop configuration (all endstops at high end, active high) M574 X1 S1 P"xstop" ; X min active high endstop switch M574 Y1 S1 P"ystop" ; Y min active high endstop switch M574 Z1 S1 P"zstop" ; Z min active high endstop switch ;*** The homed height is deliberately set too high in the following - you will adjust it during calibration M665 L376.890 R209.421 H448 B140.0 X1.000 Y0.329 Z0.000 ; set delta radius, diagonal rod length L380.31, printable radius and homed height M666 X-0.44 Y-1.37 Z1.81 ; put your endstop adjustments here, or let auto calibration find them M350 X64 Y64 Z64 E16 I1 ; Set microstepping to 32 for X, Y and Z and 16 for extruder stepper with interpolation M92 X640 Y640 Z640 ; Set axis steps/mm M906 X1000 Y1000 Z1000 E500 ; Set motor currents (mA) M201 X1000 Y1000 Z1000 E1000 ; Accelerations (mm/s^2) M203 X20000 Y20000 Z20000 E3600 ; Maximum speeds (mm/min) M566 X1200 Y1200 Z1200 E300 ; Maximum instant speed changes mm/minute ; Fans M950 F2 C"fan2" M950 F1 C"fan1" ; This fan is the Heatsink Fan M106 P1 T50 S255 H1 ; Set hotend heatsink FAN1 thermostatic control at 50°C ; Thermistors M308 S0 P"bed_temp" Y"thermistor" T100000 B3950 ; define bed temperature sensor M308 S1 P"e0_temp" Y"thermistor" T100000 B4725 C7.06e-8 ; define E0 temperature sensor M950 H0 C"bed_heat" T0 ; heater 0 uses the bed_heat pin, sensor 0 M950 H1 C"e0_heat" T1 ; heater 1 uses the e0_heat pin and sensor 1 ; Heater configuration M140 H0 ; Tool definitions M563 P0 D0 H1 ; Define tool 0, the extruder G10 P0 S0 R0 ; Set tool 0 operating and standby temperatures ;M92 E415 ; Bondtech BMG steps per mm M92 E822 ; Titan Aero steps per mm old: 837 ; Z probe and compensation definition ; Change "H25" to "H3" AFTER commissioning your printer M558 P5 C"!e0stop" X0 Y0 Z0 H4 F60 ; FSRs with JohnSL board Z probe behaves as a switch and is not used for homing any axes ;G31 X0 Y0 Z-0.15 P500 ; More (-) Z is less smooshed, more (+) Z is more smooshed G31 X0 Y0 Z-0.25 P500 ; More (-) Z is less smooshed, more (+) Z is more smooshed T0 ; Select tool 0, the hot end M501 ; Load config-override.gHere is my current homedelta.g

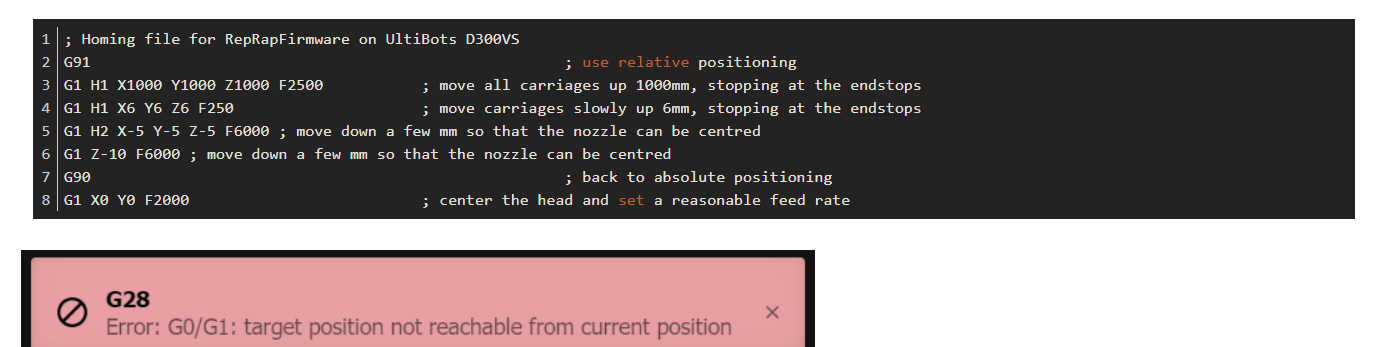

; Homing file for RepRapFirmware on UltiBots D300VS G91 ; use relative positioning G1 H1 X1000 Y1000 Z1000 F2500 ; move all carriages up 1000mm, stopping at the endstops G1 H1 X6 Y6 Z6 F250 ; move carriages slowly up 6mm, stopping at the endstops G1 H2 X-5 Y-5 Z-5 F6000 ; move down a few mm so that the nozzle can be centred G1 Z-10 F6000 ; move down a few mm so that the nozzle can be centred G90 ; back to absolute positioning G1 X0 Y0 F2000 ; center the head and set a reasonable feed rate

-

sLpDhaWK and my config.g and other files are nearly identical. The only difference is that I have a PT100 setup on an E3D Titan Aero and he has a V67 hot end with Ultibots microstruder. Otherwise I used the exact config files that we edited together yesterday.

-

@sLpFhaWK said in Homing issues on 2 delta printers after upgrading to 3.1.1:

G1 Z-10 F6000 ; move down a few mm so that the nozzle can be centred

Can you try more than 10mm?

-

@sLpFhaWK , your homedelta.g file is very significantly different, and wrong in at least one important respect. Please take a closer look and work out what it is doing, and what you want it to do instead.

-

@dc42 said in Homing issues on 2 delta printers after upgrading to 3.1.1:

@sLpFhaWK , your homedelta.g file is very significantly different, and wrong in at least one important respect. Please take a closer look and work out what it is doing, and what you want it to do instead.

David, I've been messing with it for a good part of the morning. I even used the configurator to see what a clean homedelta.g would look like, and I've used the exact same one as Michael and I am still getting the issue.

Our printers are nearly identical aside from his hotend/extruder setup.

-

I can, and will. This is my homedelta.g now.

G91 ; relative positioning G1 H1 X1200 Y1200 Z1200 F2500 ; move all towers to the high end stopping at the endstops (first pass) G1 H2 X-6 Y-6 Z-6 F2500 ; go down a few mm G1 H1 X7 Y7 Z7 F360 ; move all towers up once more (second pass) G1 Z-5 F6000 ; move down a few mm so that the nozzle can be centred G90 ; absolute positioning G1 X0 Y0 F6000 ; move X+Y to the centre -

That homedelta.g file looks better than the one you pstes earlier. But if you refer to my earlier post, I suggested to @mhackney that he change the line:

@sLpFhaWK said in Homing issues on 2 delta printers after upgrading to 3.1.1:

G1 Z-5 F6000 ; move down a few mm so that the nozzle can be centred

-

@dc42 said in Homing issues on 2 delta printers after upgrading to 3.1.1:

@sLpFhaWK said in Homing issues on 2 delta printers after upgrading to 3.1.1:

G1 Z-5 F6000 ; move down a few mm so that the nozzle can be centred

If you refer to my earlier post, I suggested to @mhackney that he change that line.

David you are correct, and I did change that and even though it worked for Michael it did not work for me.

-

@sLpFhaWK said in Homing issues on 2 delta printers after upgrading to 3.1.1:

@dc42 said in Homing issues on 2 delta printers after upgrading to 3.1.1:

@sLpFhaWK said in Homing issues on 2 delta printers after upgrading to 3.1.1:

G1 Z-5 F6000 ; move down a few mm so that the nozzle can be centred

If you refer to my earlier post, I suggested to @mhackney that he change that line.

David you are correct, and I did change that and even though it worked for Michael it did not work for me.

So why did you post the old homedelta.g instead of the modified one? How do you expect me to help you if it appears to me that you have ignored my suggestions?

-

@dc42

David, with all due respect I haven't ignored your suggestions. I am unsure why the homedelta.g I posted didn't have your change in it, at the time I copied and pasted what Michael had sent to me in a messenger chat.But I am also confused, is that line supposed to be in the homedelta.g twice? If you look at my original code it is in there on line 5. Do I delete line 6?

This is what I have now, and even now I'm not sure it's correct.

G91 ; relative positioning G1 H1 X1200 Y1200 Z1200 F2500 ; move all towers to the high end stopping at the endstops (first pass) G1 H2 X-6 Y-6 Z-6 F2500 ; go down a few mm G1 H1 X7 Y7 Z7 F360 ; move all towers up once more (second pass) G1 H2 X-5 Y-5 Z-5 F6000 ; G1 Z-20 F6000 ; move down a few mm so that the nozzle can be centred G90 ; absolute positioning G1 X0 Y0 F6000 ; move X+Y to the centre -

@dc42 So, this is odd and probably related to his issue too...

As I reported above, when I made the one line change you suggested, homing worked fine. Then I homed, jogged down in Z by 200mm and reset the Duet. Now I am getting the same error - and even odder - even issuing G28 (or clicking home) multiple times, the printer does the home cycle and then generates the target not reached error.

Here is my homedelta.g after making your change:

; Homing file for RepRapFirmware on UltiBots D300VS G91 ; use relative positioning G1 H1 X1000 Y1000 Z1000 F2500 ; move all carriages up 1000mm, stopping at the endstops G1 H2 X-5 Y-5 Z-5 ; move all carriages down 3mm G1 H1 X6 Y6 Z6 F250 ; move carriages slowly up 6mm, stopping at the endstops G1 H2 X-5 Y-5 Z-5 F6000 ; move down a few mm so that the nozzle can be centred G90 ; back to absolute positioning G1 X0 Y0 F2000 ; center the head and set a reasonable feed rateI have not touched my scripts and after I made your change earlier today I tested homing and jogging in Z and X-Y many (>10) times with no issues. But now after a reboot it is failing.

-

And removing the last 2 G1 lines as you originally requested, the error is not generated.

-

I've tried lowering 15 mm in the G1 H2 line third from the bottom to give a bit more room. That fails too.

If I only comment the last G1 X0 Y0 F2000 no error is generated but any jog move in Z generates this error:

M120 G91 G1 Z-5 F6000 G90 M121 Error: G0/G1: target position not reachable from current position -

I'm not really a delta guy, but from past instances of that error it was usually enough to drop all carriages in Z to resolve the error, which from what I understand means that the requested move would require one of the carriages to raise above the endstop to be reached.

-

Thanks Phaedrux. Mechanically, nothing has changed on these printers and mine are workhorses. The error message seems logical and your first post above made sense so I tried -15mm drop in Z on my machine but still getting this error.

It is true that a movement in XY on a delta causes at least 1 carriage to move up the tower and that does seem to be what this error message is telling us. But at 15mm down from the home switches there should be enough room for small X-Y movements. So as a test I did the final downward move to:

G1 H2 X-100 Y-100 Z-100 F6000 ; move down a few mm so that the nozzle can be centred

So now I see the home sequence, the slow descent of 100mm, then a final X-Y adjustment presumably for the M666 endstop offset adjustments and THEN the error is raised.

David, you asked about my M665 and M666 before, they are copied from my 2.x config.g. They seem correct. Hmm, this got me thinking, maybe my config-override.g has some bad stuff in it. I commented out the M665 and M666 in it and now homing seems to be working again. Here is what I commented out in config-override:

;M665 L376.890:376.890:376.890 R209.670 H450.462 B140.0 X0.114 Y0.283 Z0.000 ;M666 X0.107 Y-0.648 Z0.542 A0.00 B0.00