Cutting PTFE tube killed my board? What!?

-

I pulled one of my printers from the farm today to change out the hot end. While cutting the bowden tube off the hotend, I got a huge zap! Im talking almost the shock of my life. I felt a spark jump to my hand from the side cutters and off my other hand to the PCB on the head. Now my board doesn't boot! Who would have thought! I have seen the odd tiny spark when cutting used ptfe in the past, I assume the material is such a good isolator that it can store static within the walls of the tube, but enough to kill my board!?

-

@LeckieTech said in Cutting PTFE tube killed my board? What!?:

I assume the material is such a good isolator that it can store static within the walls of the tube

true story, and plastic rubbing against plastic adds up - never considered precautions for that though. then again with the whole frame grounded odds are it would dissipate to ground rather than my board.

odds are replacing the SD card won't help, but worth a try

-

@bearer its pretty crazy, everything is no go. When I turn on the printer all the heaters come on full blast and the motors are engaged. cant connect with the USB cable to pronter or program with bossa either. Im thinking this one is a lesson learned. Isolate your cutters when making that cut!

-

@LeckieTech said in Cutting PTFE tube killed my board? What!?:

Isolate your cutters when making that cut!

noooo! you want to discharge everything to common potential (normally ground)

Hard to say how much effort it would be to fix it, bit of luck and its just the atmel chip, but could also be pretty much all of the chips.

-

@bearer My best guess is that the jolt went to the logic side of the ARM. Ive got a probe and the hot end sensor up there there is really nothing else that goes to the processor directly. The output fets are not shorted. So I think you're right, I can just rework a new processor and it should be good to go.

-

Wow, bummer. Thanks for posting, I will remember that next time I'm trimming a tube on a printer.

-

I never considered the possibility of that happening! I did know that belts can build up static but for some reason, I never gave the Bowden tube/filament a thought.

Funnily enough, I used printed guides, bolted to the frame on the exit of my 6 filament reels to prevent them getting tangled up with each other, and I've just re-made them out of aluminium. The reason was that, over the years, the filament had started to wear grooves in the plastic guides but maybe running the filament over a grounded metal plate might have another benefit that I hadn't considered.

-

Apparently, (after some googling) PTFE static build up is a thing in industry to the point that carbon doped PTFE is available that is mildly conductive.

-

Hindsight being 20/20 those ESD wrist straps aren't just a gimmick even though most of could probably say I've done X for Y years without incident its a damn cheap insurance. Just don't get the wireless ones

Back in the real world, having the frame bonded to protected earth would accomplish 90%(?) the same thing when handling the printer while touching metaly bits. (i.e. keep one and on something metal while mandhandling things until you're confident any charge is dissipated but there is a reason the wrist straps have a 1M resistor or so)

-

@bearer I'm confident a static discharge strap would have saved the board in a passive operation as routine as swapping out a bowden tube. But now that I've been here, I will certainly take more care next time and clip a ground cable to my cutters or make sure there is no place for the discharge to arc to. Live and learn!

-

@LeckieTech it's surprising what can happen in the real world without you realising it. Static/Charge build up is one of the reasons we always stored our spare oil filled capacitors with the terminals shorted out. In the RF Fields we worked in they used to charge up to unreal levels if they weren't (high enough to blow a hole into body parts. Not nice).

-

It's advisable to ground both the extruder drive stepper motor casing and the hot end heatsink.

-

Old bitsfrombytes rapman users will remember strange reboots board had during winter dry air period that some ppl solved by attaching wet towels to the case of the printer

... the combo of acrylic corners and ptfe hotend made few kV of static reboot that pic32mx trough the adc input. the issue was finally solved by adding a small ceramic 100nF + 1uF tantalum + 2 diodes (to Vss and to Vdd) on the ADC line and grounding the whole machine. Arcol was even selling those carbon doped ptfe tubes that reduced the problem. What's interesting, it was only happening during winter when air inside would be dry. I don't remember actual numbers, should be available somewhere in the archives, but I measured 15 or 50kV of static between aluminium nozzle and the frame... but I didn't hear about any of those boards die from the static, they would just reboot ..

... the combo of acrylic corners and ptfe hotend made few kV of static reboot that pic32mx trough the adc input. the issue was finally solved by adding a small ceramic 100nF + 1uF tantalum + 2 diodes (to Vss and to Vdd) on the ADC line and grounding the whole machine. Arcol was even selling those carbon doped ptfe tubes that reduced the problem. What's interesting, it was only happening during winter when air inside would be dry. I don't remember actual numbers, should be available somewhere in the archives, but I measured 15 or 50kV of static between aluminium nozzle and the frame... but I didn't hear about any of those boards die from the static, they would just reboot .. -

@arhi that dry air really brings out the static here during Canadian winters. I get off my chair and I need to ground myself or I will hold a charge for 10 mins or more. I've got a few protos and testers that are usually running beside my computer with the boards just hardwired sitting on the bench. Static makes for a really detrimental situation! Although I've never had a board fry because of it until now, this is the first time with that PTFE jolt, but grabbing the nozzle purge off the bed a few times forgetting to ground yourself makes the printer hiccup every time. I should really wisen up and ground the chassis as good practice for those nights of experimenting. A simple gator clip is all it takes!

-

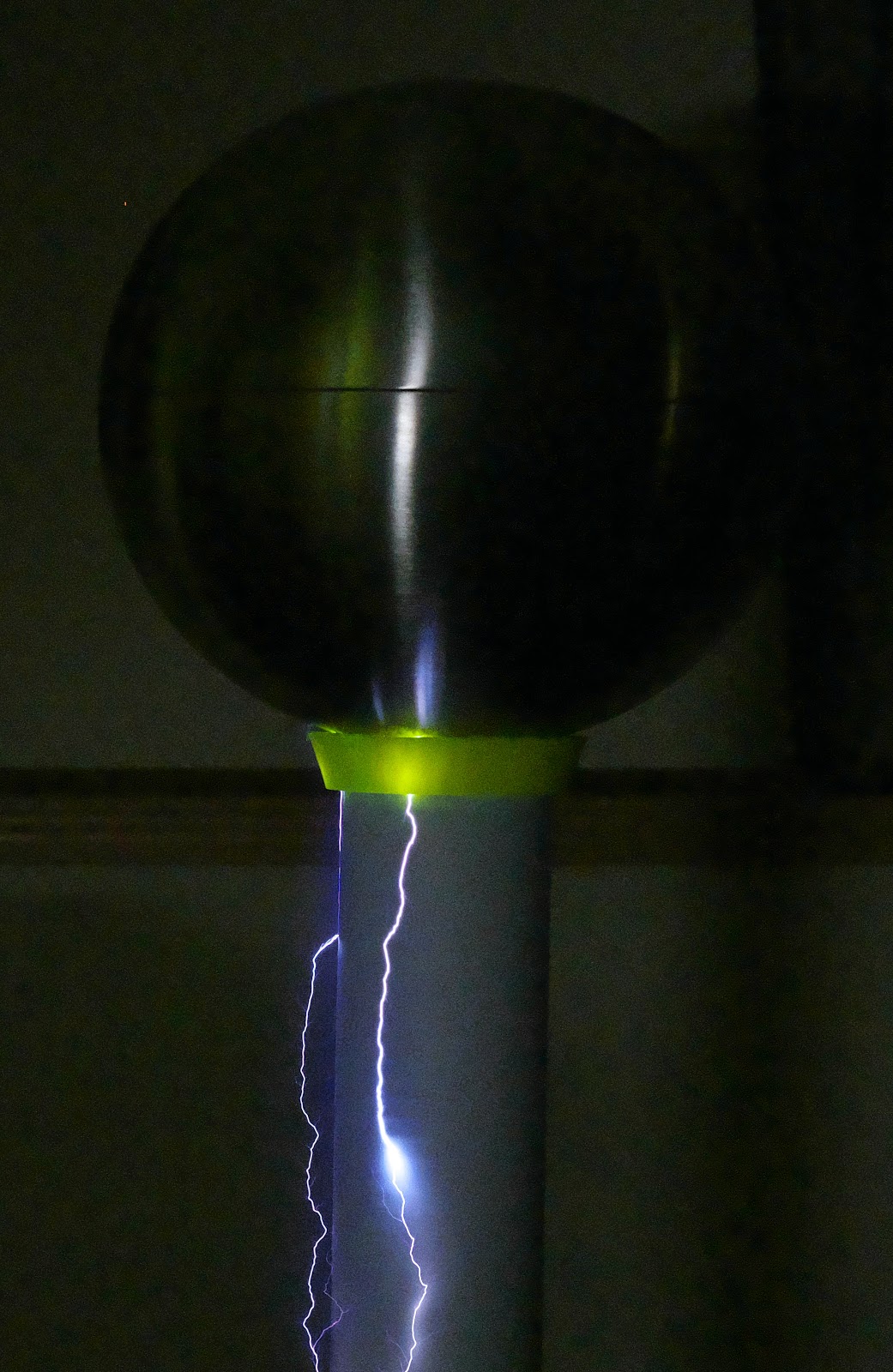

PTFE is on the extreme negative end of triboelectric series. That means almost anything (any kind of filament or anything else) that touches it is going to cause charge separation. Filament running through a long tube of PTFE will charge both the filament and the PTFE. Maybe the hotend is charging up- it will form a capacitor with the earth. A few kV on the hot-end jumps into the controller via the heater or thermistor leads (or extruder motor leads) and does the damage.

I built a Van de Graaff generator and used PTFE on one roller to maximize charging current.

Ground the hot-end, ground the printer's frame, and if motor mounts are printed plastic, ground all the motors, especially the extruder motor.

-

@LeckieTech said in Cutting PTFE tube killed my board? What!?:

@arhi that dry air really brings out the static here during Canadian winters. I get off my chair and I need to ground myself or I will hold a charge for 10 mins or more.

It is more / less same thing everywhere if you air your room as when outside air comes in and heats up the relative humidity drops big time. Colder the outside (or "bigger the temp difference), drier the air inside will be.

Now I'm renovating a house (while living in appt) from scratch and my new work area is pretty "safe" wrt static (grounded copper mesh on the floor covered with carbon filled "plastic/rubber" surface (like the antistatic soldering mat, only bit harder, not conductive but disipates static) and I hope this would help

but we'll see... I used to live in Cyprus, had a 1000m2 open space office with "laminate" flooring (compressed paper and some resin), we spent 5000$ for some antistatic system that had some fans blowing some "ionised air" over the floor.... Owner invested into that after we killed 250keur spectrum analyzer

but we'll see... I used to live in Cyprus, had a 1000m2 open space office with "laminate" flooring (compressed paper and some resin), we spent 5000$ for some antistatic system that had some fans blowing some "ionised air" over the floor.... Owner invested into that after we killed 250keur spectrum analyzer  (no clue why they could not replace the flooring).

(no clue why they could not replace the flooring).@mrehorstdmd I learned few lessons with bitsfrombytes rapman

- no acrylic parts that do anything "important" (darn thing is prone to rotting if it comes to contact with every day cleaning solutions + collects static like crazy)

- ground everything

- if you think you protected all the inputs on your mcu, you didn't. If you are sure you protected them from everything, no you did not