Mesh bed Levelling with BLTouch. Am I doing something wrong?

-

One possible issue is that you are doing g32 and g29 before the printer is up to temp. Recommend moving the g32 after the nozzle and bed heating commands.

Most likely your printer and bed dimensions are slightly changing due to probing before everything up to temp. Try to probe as close as possible to printing so things don’t change from where the printer thinks thing are to where they actually are now.

-

@gloomyandy said in Mesh bed Levelling with BLTouch. Am I doing something wrong?:

Is there a reason why your probe points for the lead-screws do not share the same Y values? One is 165 the other 160.

Also looking at the two meshes that you provided there is something odd going off. The first (lower resolution) mesh shows part of the bed to be "above zero" with the rest below, the second (higher resolution) mesh shows pretty much all of the mesh "below zero". That does not seem correct to me.

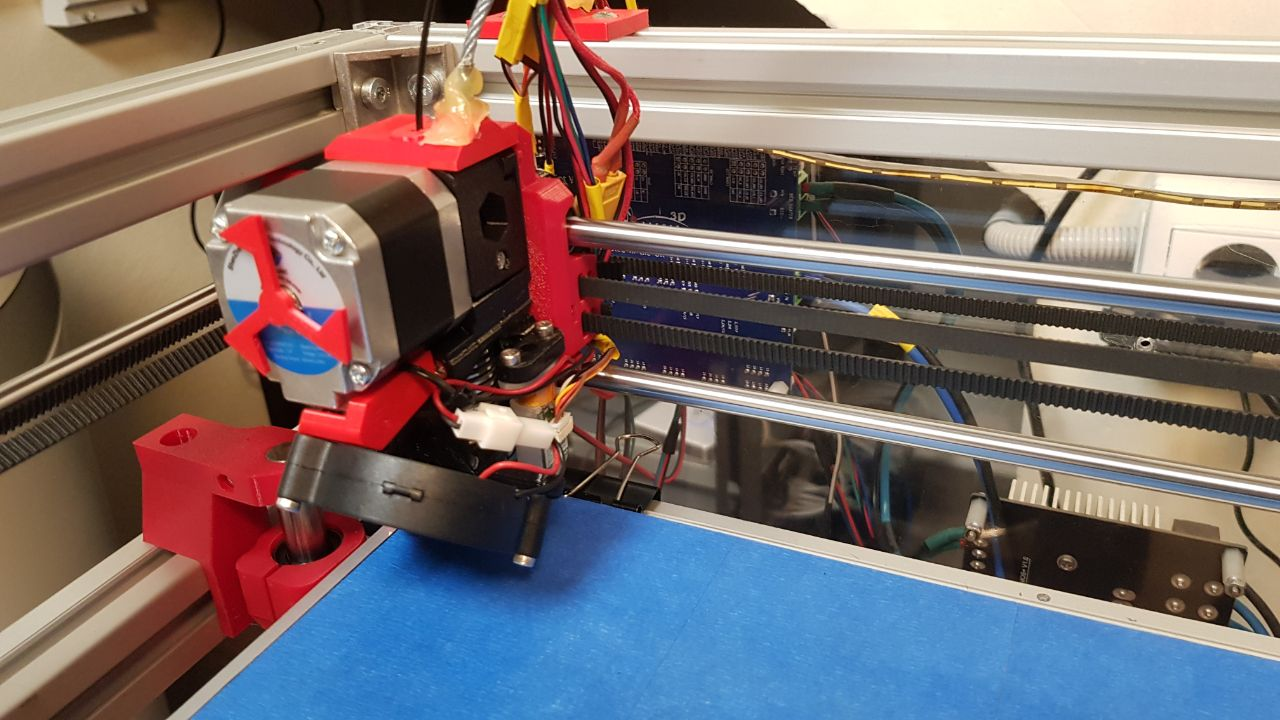

Regarding the different Y, the printer is a CoreXY with 2 lead-screws. When I checked for the Y position for the G32, I discovered that the motors were not perfectly aligned, and that's reflected in the bed file.

About the image, the bed is magnetic, is an aluminum heated bed, with a glass on top that has the magnets on it (Buildtak) and the steel sheet on top. I'm assuming that even though I put the sheet always the same way, the measurements changes. I'm doing always a G32 and a G29 after removing and installing the sheet, and if I repeat the G29 (without removing the sheet), results are consistent.

Regards

-

@mwolter said in Mesh bed Levelling with BLTouch. Am I doing something wrong?:

One possible issue is that you are doing g32 and g29 before the printer is up to temp. Recommend moving the g32 after the nozzle and bed heating commands.

Most likely your printer and bed dimensions are slightly changing due to probing before everything up to temp. Try to probe as close as possible to printing so things don’t change from where the printer thinks thing are to where they actually are now.

I'm not always using the heated bed. When I do, I put the bed on, wait for it, and then home Z and perform the G29, as I´ve noticed, as you said, that bed expands (and as I've several "layers", it needs more time to reach the temp on top).

Regarding the nozzle temp, as I'm using a BLTouch, the nozzle temperature is not "important", I just have it into account for the G31 command.The problem is that, checking the raft, it doesn't seems to be applying the compensation... even though as per the heightmap, the printer is aware of it :S.

Regards

-

An easy way to check if the mesh is applied is to watch the z steppers for the first layer. They should move slightly if mesh compensation is enabled.

-

@mwolter said in Mesh bed Levelling with BLTouch. Am I doing something wrong?:

An easy way to check if the mesh is applied is to watch the z steppers for the first layer. They should move slightly if mesh compensation is enabled.

I did... I can see the left side still more squashed and I cannot see the motor moving (I've put a bit of tape and I´ve been observing it, and I think it didn't move at all...)

-

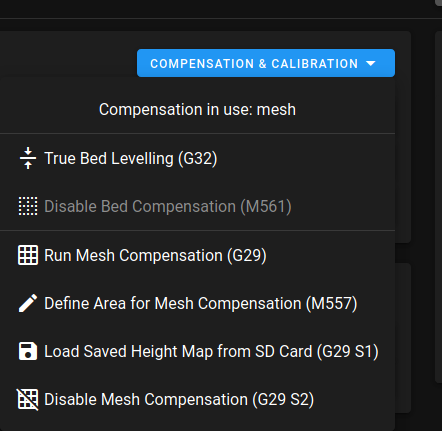

@okercho When you are printing, if you go to the 'Dashboard' and click the 'Compensation & Calibration' button, what does it say at the top of the dropdown?

If mesh compensation is enabled it should look like this.

Compensation in use: meshP.

-

@PaulHew I posted before :), yes, it says "mesh" in use

image url)

image url)I'm thinking about doing the difference between left/right quite obvious on purpose, to see if it actually works or not, as I think mesh is applied even if you're not printing but moving the head around...

Regards

-

I find the best way to test the success of mesh compensation is to print a test file like this twice, once with it enabled and once without.

bedlevel_nozzle_0.4_200x200-0.3-0.8.stl

Also ensure that your taper height isn't set too low with M376

https://duet3d.dozuki.com/Wiki/Gcode#Section_M376_Set_bed_compensation_taper

-

@okercho said in Mesh bed Levelling with BLTouch. Am I doing something wrong?:

I'm thinking about doing the difference between left/right quite obvious on purpose, to see if it actually works or not, as I think mesh is applied even if you're not printing but moving the head around...

You height map is actually very flat, so it will be difficult to see the Z axis moving due to bed compensation being active.

It's not uncommon for the height map not to match what you see when printing, which may be the case here. This happens when you use a Z probe with a large offset from the nozzle, and the print head doesn't stay in exactly the same plane as it moves over the bed. For example, some printers have an X carriage that moves on 2 smooth rods. If there is a slight twist between those rods, then the print head will rotate slightly about the X axis as it moves in X. If the Z probe is offset from the nozzle in the Y direction, that will cause the relative heights of the nozzle and the Z probe to change.

-

I tried bed leveling with different probes, ir probe and bltouch.

My Problem was different trigger heights at different locations on the bed with both probes.

Check that. Trigger height should be the same, no matter where you probe on the bed.

I think the printhead is somehow twisting.

Good luck!

-

@dc42 said in Mesh bed Levelling with BLTouch. Am I doing something wrong?:

@okercho said in Mesh bed Levelling with BLTouch. Am I doing something wrong?:

I'm thinking about doing the difference between left/right quite obvious on purpose, to see if it actually works or not, as I think mesh is applied even if you're not printing but moving the head around...

You height map is actually very flat, so it will be difficult to see the Z axis moving due to bed compensation being active.

It's not uncommon for the height map not to match what you see when printing, which may be the case here. This happens when you use a Z probe with a large offset from the nozzle, and the print head doesn't stay in exactly the same plane as it moves over the bed. For example, some printers have an X carriage that moves on 2 smooth rods. If there is a slight twist between those rods, then the print head will rotate slightly about the X axis as it moves in X. If the Z probe is offset from the nozzle in the Y direction, that will cause the relative heights of the nozzle and the Z probe to change.

Actually that makes a lot of sense... I'm using 8mm rods for a 300mm bed, and I was thinking that maybe is just not sturdy enough...

I'm gonna see how can I replace the 8mm rods by 10mm... wish me luck!

I'll report back.

Cheers

-

I'm dealing with this same type of issue. I've been having problem with my z-offset floating around and having to constantly change it. So I with some advice from @Phaedrux im modifying my probe parameters and getting my BL Touch and nozzle tip closer for a smaller z-offset.

@Phaedrux said in Mesh bed Levelling with BLTouch. Am I doing something wrong?:

I find the best way to test the success of mesh compensation is to print a test file like this twice, once with it enabled and once without.

bedlevel_nozzle_0.4_200x200-0.3-0.8.stl

Also ensure that your taper height isn't set too low with M376

https://duet3d.dozuki.com/Wiki/Gcode#Section_M376_Set_bed_compensation_taper

Man. There is so much to learn when you take off your training wheels and start really learning about gcode, reprap firmware, and all the things you can do. Never even heard of taper height. Adding it to the list of things to learn.

-

Hey, i had the same issue for a long time. Maybe this can help you

Link to the issue:

Strange BLTouch issue -

Hi,

while this is an older thread, the problem itself is very current, unfortunately

While I had it for an Anycubic Mega S printer, it was basically the same root cause. I solved it w/o having to replace any hardware, but with some additional mathematics to compensate for the rod twist. I wrote something up explaining the issue and also provide there a little online tool to create appropriate compensation GCode commands. This works great for me and I have no more issues with the bent hardware, so maybe it is a proper resolution for some of you also...

Regards, habitoti