Printer stops extruding with longer E values

-

Hey,

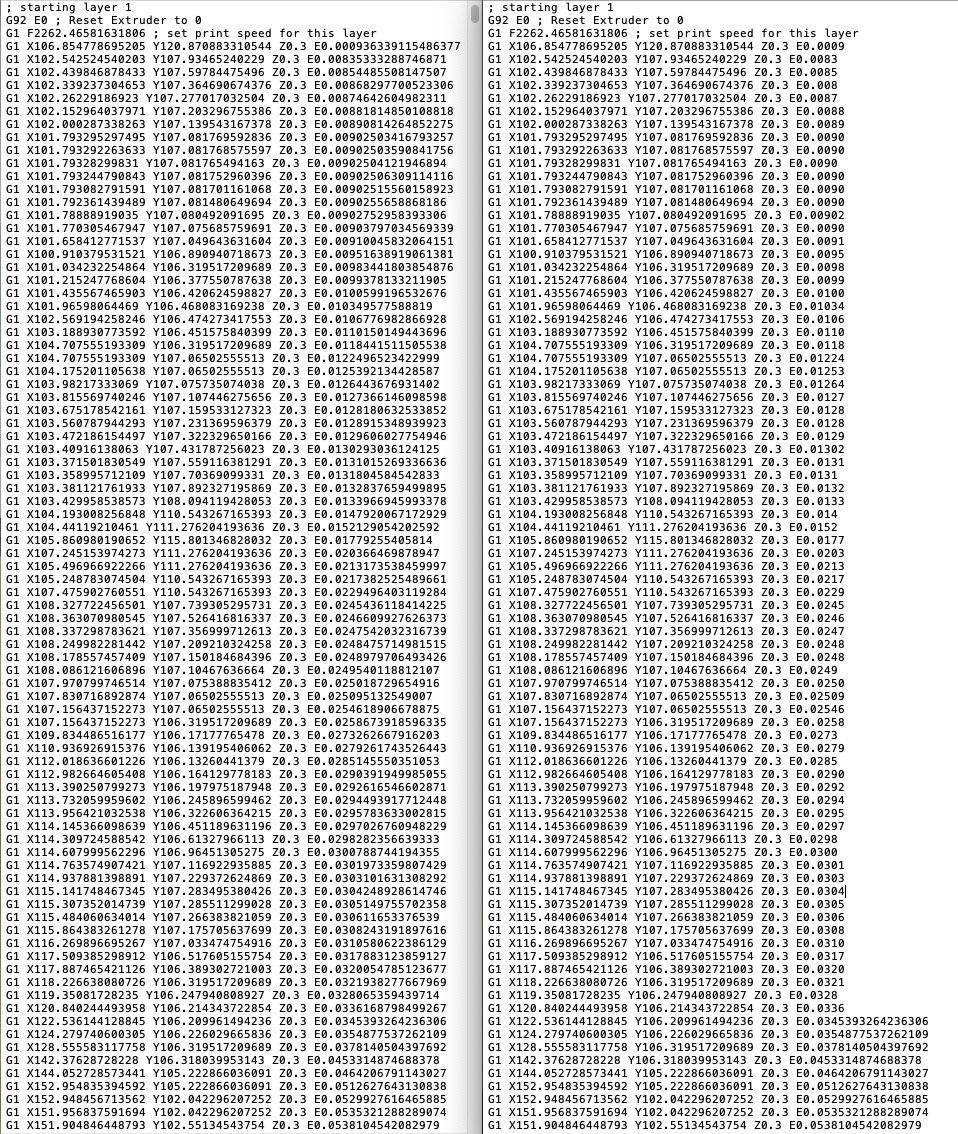

working on a custom slicer for my needs right now. Yesterday it output the following G-Code (the left one). Starting script went fine but, starting with the lines you see here, it stopped extruding. Even after stopping the print and starting a new and working one there were no more extruder moves. Unfortunately there was no error message like heater fault or anything alike.

To find the source of the problem I shortened the E-Values and it works just fine, even on the lines i didn't shorten.

Any ideas?Running RRF 3 RC9 (same problem on another machine running version 2

-

Please share the full G=code files.

-

-

@benecito, please upgrade to firmware 3.01-RC10 and test whether the issue is still present.

Which Duet are you using? Please share your config.g file too.

-

@dc42 I just tried, still the same thing.

-

@benecito Which Duet are you using? Please share your config.g file too.

-

-

I'm sorry, I can't reproduce this. The extrusion amounts commanded are tiny, so I had to set an extrusion factor of 8000% in order to get about the right amount of extrusion. With this set, I see no difference between the two files.

I changed the prologue of the files to suit my printer:

;WARMING UP G21 ; set units to mm G90 ; set to absolute positioning M80 ; turn on the power supply T0 ; tool 0 M140 S80 M104 S260 M116 G92 E0 ; reset extruder ;;G1 X70.0 Y0.0 Z10 F3000.0 ; move to start position ;;G1 E1.3 ; undo retraction ;;G1 X20.0 E1.8 F150 ; extrude and move ;;G92 E0 ; reset extruder ;;G1 X15.0 F900 ; move to side a little ;G4 S2 ; wait 2 seconds ;;G1 Z5 F5000 ; Move bed up a bit ;;G1 X10.0 ; move to side a little again ;;G1 Z2 F5000 ; Move bed up a bit ;;G1 Z2 F3600 ;;G92 E0 ; reset extruder M82 ; set extruder to absolute mode ; G10 L2 X-150 Y-100 ;;DC M221 S8000 ;;DC ; ; GO TO START POINT AND GET READY: ;;G92 E0 ; Reset Extruder to 0 ;;G1 F3600 E-1 ; retract at retraction speed G1 Z0.3 X108.576225238315 Y120.870883310544 F4800 ; move to first XY at rapid speed ;;G1 Z0.3 F3600 ; move to start Z at rapid speed ;;G1 E0 F3600 ; un-retract filament at retraction speed G4 P120; pause for a moment ; ; ; PRINTING OF ALL LAYER CURVES: ; starting layer 1 G92 E0 ; Reset Extruder to 0 G1 F2262.46581631806 ; set print speed for this layer G1 X106.854778695205 Y120.870883310544 Z0.3 E0.000936339115486377 G1 X102.542524540203 Y107.93465240229 Z0.3 E0.00835333288746871 G1 X102.439846878433 Y107.59784475496 Z0.3 E0.00854485508147507 G1 X102.339237304653 Y107.364690674376 Z0.3 E0.00868297700523306Here is the result of printing that file, at 45% complete:

If I don't set the extrusion factor to 8000% then the extrusion is too small to see; however the filament usage counts up just the same. So I believe RRF still processes the extrusion amount correctly when I don't increase the extrusion factor.

I have also checked the code, and verified that RRF reads values with high numbers of decimal places correctly and rounds or truncates them appropriately to fit in 32-bit floating format.

Perhaps you changed something else between the two prints?

Are you certain that you have the correct extrusion amounts? Before the print starts you retract filament by 1mm, then re-prime by 1mm. But the whole first layer uses only 0.4mm of filament!

-

Thanks a lot, great effort!

The extrusion factor is right, for sure but it's a completely different setup (printing chocolate by using a syringe like mechanism).Also I am sure I didn't change anything but shortened the E-values.

Thinking and working outside of standard use-cases often results in quite a bit of problems. So for now I'll keep experimenting and if a problem like this comes up again will have another look. Hopefully it is so many special things coming together it will not happen again.

Worst case I'll stick to repetier but I like RRF better by now.This it what it looks like when finished (if interested):

-

Nice!

One concern I have is that if your extrusion amounts are meant to be so small, then I suspect your retraction amount should be much less than 1mm. Also your retraction and repriming speeds should probably be very low in order to avoid missed steps. You have the maximum E speed set to 400mm/min, but that's still many orders of magnitude greater than your printing extrusion rates. Retracting and repriming 1mm at high speed and then expecting extrusion of 1/1000 that amount to be done accurately is asking a lot.

-

Thanks!

I wish retraction could be a lot smaller, but with the syringe based system I need it, at least for now. Obviously within the extrusion I need to go as fast as possible and Extrusion amounts within the print are given.

For now everything worked just fine and should it actually result into loosing steps rarely I guess there is no alternative for now. Probably it should not matter that much anyways as it is more like a flow rate I'm working with instead of actual small extrusion amounts.Do you see any alternative?