Heater Error with Dual Thermistors

-

What firmware version and DWC are you using?

-

@Phaedrux said in Heater Error with Dual Thermistors:

What firmware version and DWC are you using?

I just updated the firmware to the latest stable release 2.05.1 and that didn't make a difference, DWC is at 1.22.6

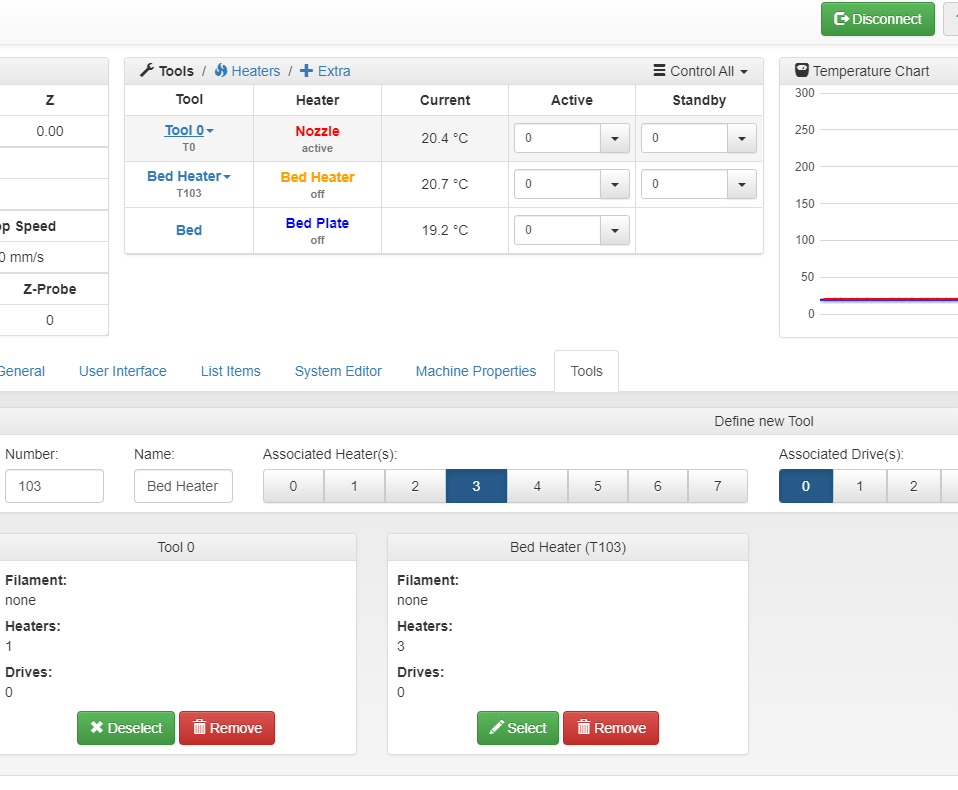

I did change the following (bold) in the code below and I'm not getting the error but still cannot see the other heater in the tools or the chart so not sure if it's working:

M305 S"Bed Heater" P3 R4700 T100000 B3950........; Beta3950 thermistor inside the Keenovo heater

M143 P100 H0 X3 A2 C0 S110......................................; make sure silicone heater stays below 110°C

M143 P101 H0 X3 A1 C0 S125......................................; make sure silicone heater shuts down at 125°C

M143 H0 S110.....................................................................; maximum bed temperature -

I would suggest updating your DWC to 2.0.7 to see if you can get the heater showing up in the Extra section.

P103 should work for an additional heater, but maybe try a higher number.

I also have a feeling that this may work better in general in RRF3.

In fact, looking at the wiki entry for M143 it looks to be missing it's description for RRF2 at the moment. So I can't even verify if your syntax is actually correct for RRF2. Seeking some clarity on that.

If you do decide to switch to RRF3 there will be some additional changes required.

-

It's interesting, found this while trying different things. I went into settings and then over to the tool tab and I can add another heater and it shows up fine in my tools however it's gone as soon as I reboot DWC, I don't see 2.07 available here: link text what changes would I need to make to go to RRF 3?

-

-

@Phaedrux Thanks and Wow! That new look is going to take a little to get used to! That upgrade alone didn't change the tool setting to allow me to see my other thermistor but I'll take some more time to look through the code. I'm sure it's something I'm just not seeing.

-

Can you post your full config?

I think it might have something to do with the order of heaters and assumptions about bed heaters in RRF2.

In RRF3 it's a bit simpler to do something like this because instead of having predefined pins and roles, you define them yourself.

-

Certainly, I got this config from another user that has the same machine and have tweaked it to make it work for me. Mine does not have a PanelDue but I didn't think the code in there would affect anything (it's a Core XY machine):

; Configuration file for Duet WiFi (firmware version 2.03 or newer)

; executed by the firmware on start-up; General preferences

M111 S0 ; Debugging off

G21 ; Work in millimetres

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M555 P2 ; Set firmware compatibility to look like Marlin

M575 P1 B57600 S1 ; Comms parameters for PanelDue

M564 S1 H1 ; Forbid axis movements when not homed; General setup

M667 S1 ; Select CoreXY mode (2.03RC1 and below)

M669 K1 ; Select CoreXY mode (2.03 and up); Network

M550 Voron ; Set machine name

M552 S1 ; Enable network

M586 P0 S1 ; Enable HTTP (for DWC)

M586 P1 S1 ; Enable FTP (for remote backups)

M586 P2 S0 ; Disable Telnet; --- drive map ---

; _______

; | 6 | 7 |

; | -------|

; | 5 | 8 |

; -------

; front; Drive directions

M569 P0 S1 ; A

M569 P1 S1 ; B

M569 P3 S1 ; Extruder #1

M569 P4 S0 ; Extruder #2

M569 P5 S0 ; Z1

M569 P6 S1 ; Z2

M569 P7 S0 ; Z3

M569 P8 S1 ; Z4; Motor mapping and steps per mm

M584 X0 Y1 Z5:6:7:8 E3:4

M350 X16 Y16 Z16 E16:16 I1 ; Use 1/16 microstepping with interpolation everywhere

M92 X80 Y80 Z400 ; Set XYZ steps per mm (1.8deg motors)

;M92 X160 Y160 Z800 ; Set XYZ steps per mm (0.9deg motors)

M92 E560:560 ; Set Extruder steps per mm (Mobius 3);M350 Z16 I0 ; disable Z interpolation

; Drive currents

M906 X1200 Y1200 Z1200 E1000 ; XYZ and E current

M906 I30 ; Idle current percentage

M84 S120 ; Idle timeout; Endstops

M574 X2 Y2 Z0 S1 ; Set NC endstops for X and Y, no Z endstop (we have multiple probes instead)

M208 X0.1 Y0.1 Z0 S1 ; Set axis minima

M208 X299.8 Y309 Z275 S0 ; Set axis maxima; Bed leveling

M671 X-65:-65:365:365 Y-20:380:380:-20 S20 ; Define Z belts locations (Front_Left, Back_Left, Back_Right, Front_Right)

M557 X25:275 Y25:275 S25 ; Define bed mesh grid (inductive probe, positions include the Z offset!)

;M557 X25:275 Y25:275 S50 ; Define bed mesh grid (bed piezo); Accelerations and speed

M98 P"/macros/print_scripts/speed_printing.g"; Bed Heater

;M305 P0 R4700 T100000 B3950 ; Set thermistor + ADC parameters for heater 0

;M307 H0 A90.0 C700.0 D10.0 S1.00 B1 ; Bang-bang bed

;M143 H0 S110 ; Set temperature limit for bed heater to 110C; Bed heater, dual thermistor setup (one for the heater + one for the bed)

M305 S"Bed Plate" P0 R4700 T100000 B4725 ; Stud thermistor on the edge of the plate

M307 H0 B1 S1 ; 100% PWM, bang-bang modeM305 S"Bed Heater" P3 R4700 T100000 B4725 ; thermistor inside the Keenovo heater

M143 P100 H0 X3 A2 C0 S110 ; make sure silicone heater stays below 110°C

M143 P101 H0 X3 A1 C0 S125 ; make sure silicone heater shuts down at 125°C

M143 H0 S110 ; maximum bed temperature; Hotend #1 heater

M305 S"Nozzle" P1 X501 R4700 ; Set thermistor Configure PT1000 for heater 1

M143 H1 S300 ; Set temperature limit for heater 1 to 300C; Hotend #1 heater

; M307 values are for reference only, RRF stores them in config-override.g via M500 after a PID calibration.

;M305 P1 R4700 T100000 B4725 C0.0000000706 ; Set thermistor + ADC parameters for heater 1

;M307 H1 A454.1 C235.9 D4.5 S1.00 B0 ; 104GT2 PID, 30W heater; Chamber temperature sensor via temperature daughterboard pins on Duex

;M305 S"Ambient" P104 X405 T21 ; Set DHT21 for chamber temp

;M305 S"Humidity [%]" P105 X455 T21 ; Set DHT21 for chamber humidity; Disable unused heaters (so they are hidden on the PanelDue)

M307 H2 A-1 C-1 D-1

;M307 H3 A-1 C-1 D-1

M307 H4 A-1 C-1 D-1

M307 H5 A-1 C-1 D-1

M307 H6 A-1 C-1 D-1

M307 H7 A-1 C-1 D-1; Select inductive Z probe on powerup

M98 P"/macros/print_scripts/activate_z_probe.g"; Fans

M106 P8 S1 I0 H1 T50 ; E3D V6 Hotend fan, turns on if temperature sensor 1 reaches 50 degrees

M106 P7 S0 I0 H-1 ; Part cooling fan, no thermostatic control

M106 P6 T45:65 F50 H100:101:102 ; Electronics bay fan, turn on gradually if MCU is over 45C or any TMC driver is over temp

M106 P5 S1 H0 T50 ; Chamber filter fan, turn on when bed is hotter than 50C

M106 P2 S1 I0 H1 T50 ; LED, turns on if temperature sensor 1 reaches 50 degrees; Tools

M563 P0 D0 H1 F4 ; Define tool 0, use fan #4 for M106

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C; Pressure advance

M572 D0 S0.2M501 ; load config-override.g

T0 ; select tool 0 -

@p40whk said in Heater Error with Dual Thermistors:

M305 S"Bed Plate" P0 R4700 T100000 B4725 ..............; Stud thermistor on the edge of the plate

M307 H0 B1 S1 ..................................................................; 100% PWM, bang-bang mode

M305 S"Bed Heater" P103 R4700 T100000 B3950........; Beta3950 thermistor inside the Keenovo heater

M143 P100 H0 X103 A2 C0 S110......................................; make sure silicone heater stays below 110°C

M143 P101 H0 X103 A1 C0 S125......................................; make sure silicone heater shuts down at 125°C

M143 H0 S110.....................................................................; maximum bed temperatureIn the command shown in bold, you haven't specified which thermistor port you are using (X parameter).

-

Hmm, I thought that was what the P103 was for (I'm still learning RRF). My thermistor is on the Duex5 "E2_Thermistor3" pins so would I need to add an X-command in that line like this:

M305 S"Bed Heater" P103 X3 R4700 T100000 B4725 ..........; thermistor inside the Keenovo heater

Edit: That fixed it! The bed heater now shows up under + Extra.

Thanks you so much for the help!