Duet 3 Tool Board

-

@gtj0 said in Duet 3 Tool Board:

That would be great! In my case, I have all of my motion (CoreXY) motors on the main board and while the Y endstop is fixed on the frame, the X endstop (actually it's a dc42 IR sensor) is on the tool carriage and senses when the tool carriage approaches the far left.

I have a fairly similar setup, so I truly understand the 'test case'. I won't be able to get to it tonight; should only be a day or two... he said...

-

@mwolter said in Duet 3 Tool Board:

To work for me would need to connect a BLTouch, Duet Magnetic Filament Sensor, 50w heater, PT1000 RTD and an endstop. Curious to know if this is possible. Thanks!

I'm about to convert my tools from thermistors to PT100s (like a PT1000, but no amp board needed). And I have a BLt. I can test this as well. Filament sensor will work on an IO port, and heater will work, those are pretty inherent to a tool board. Again, may be a day or two.

Would the BLt be your Z Probe? The switch endstop, for what axis is this?

-

@gtj0 said in Duet 3 Tool Board:

@dc42 Although I don't see a statement to the effect, I'm assuming IO0 is meant for the Z probe and IO1 the filament sensor yeah? Can IO1 be used as an X endstop instead?

Yes to all.

-

@mwolter said in Duet 3 Tool Board:

To work for me would need to connect a BLTouch, Duet Magnetic Filament Sensor, 50w heater, PT1000 RTD and an endstop. Curious to know if this is possible. Thanks!

It should be possible to use the temp1 pins to connect a switch-type endstop, but I'll need to check whether the firmware supports that.

-

@Danal said in Duet 3 Tool Board:

@gtj0 said in Duet 3 Tool Board:

axes motors were on the main board that the tool board's IO1 could be used as an X endstop.

Verify by trying it, but reading all the release notes, this should work.

The combination that doesn't yet work is using an endstop switch connected to the main board to stop a motor connected to an expansion or tool board, when the same axis doesn't also have a motor connected to the main board. This will be fixed in firmware 3.02.

-

@dc42 said in Duet 3 Tool Board:

@Danal said in Duet 3 Tool Board:

@gtj0 said in Duet 3 Tool Board:

axes motors were on the main board that the tool board's IO1 could be used as an X endstop.

Verify by trying it, but reading all the release notes, this should work.

The combination that doesn't yet work is using an endstop switch connected to the main board to stop a motor connected to an expansion or tool board, when the same axis doesn't also have a motor connected to the main board. This will be fixed in firmware 3.02.

Ah, the reverse case. Thanks David.

@Danal If you still have time to test that'd be great but not so urgent, for me anyway.

-

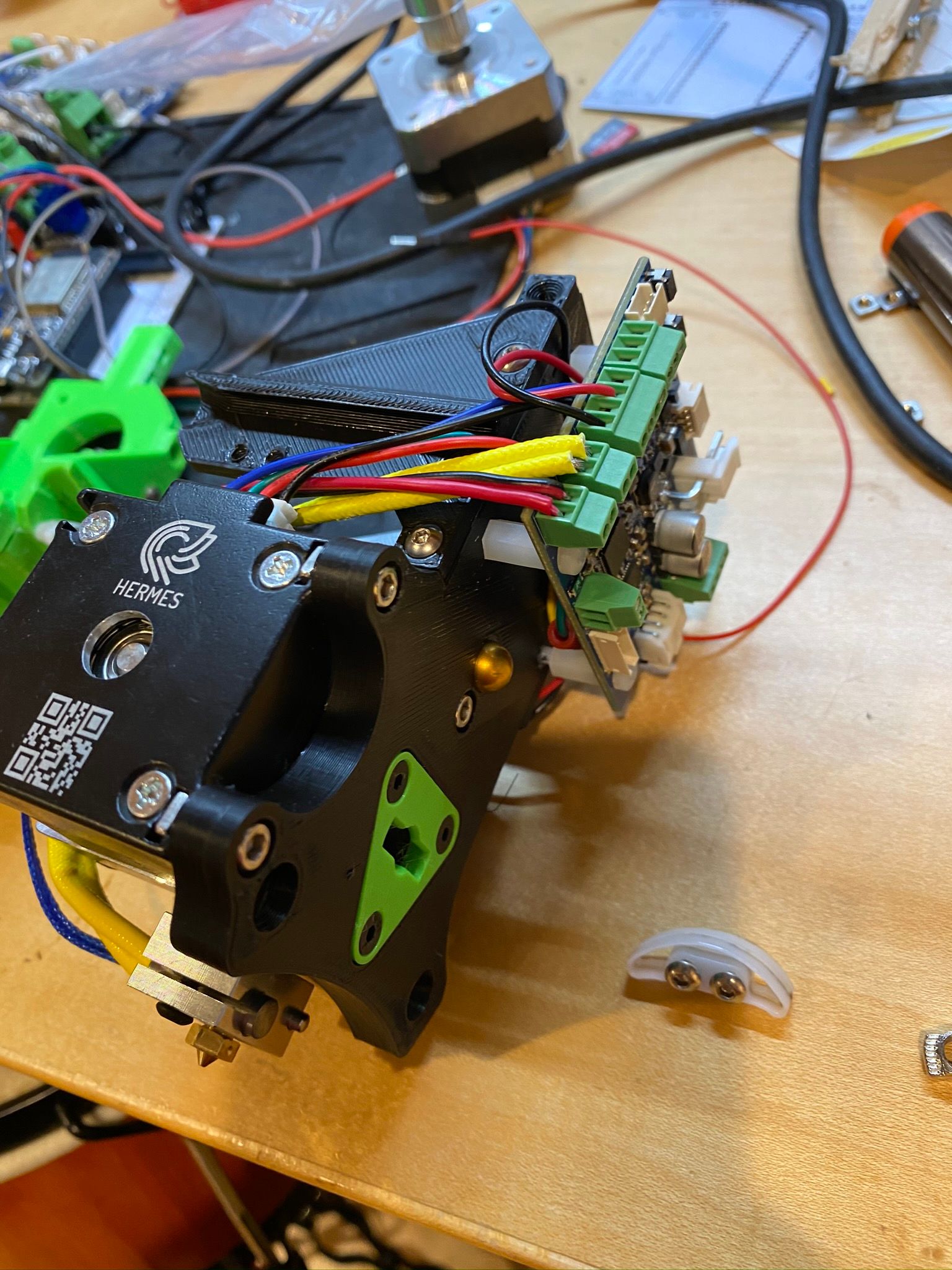

Designed and printed mount for the tool board on my core xy - wireing next!

-

Looks nice.

We are working on mounts for the tool board on a Hermera on a toolchanging printer, over on the Jubilee discord. I'll cross post when we have something working.

We plan to mount it on the open bosses opposite the tool lock plate, and protect it so it won't get crushed if the tool is accidentally "overparked".

-

the hole pattern on the tool board matches the Hemera mount points by the way, so you could just mount it to the front of the Hemera if you are not using that space. Photographic evidence on dc42's blog.

-

@Danal said in Duet 3 Tool Board:

We plan to mount it on the open bosses on the hermera opposite the tool lock plate

@oliof said in Duet 3 Tool Board:

the hole pattern on the tool board matches the Hemera mount points

Perhaps I should have included the words in italics... we are saying the same thing. One side of the Hemera mounts are occupied by the kinematic tool plate; the other by the tool board.

-

Early effort, we may change this. Decided NOT to mount on the hermera itself, because it is already pushing "thickness" on that axis for "parking row" on this printer.

At the moment, this little test article is on my Jubilee, being slung around, it it seems OK.

-

@Danal said in Duet 3 Tool Board:

Early effort, we may change this. Decided NOT to mount on the hermera itself, because it is already pushing "thickness" on that axis for "parking row" on this printer.

At the moment, this little test article is on my Jubilee, being slung around, it it seems OK.

I too was encountering "Packaging" issues with the tool board mounted on the extruder, my solution.