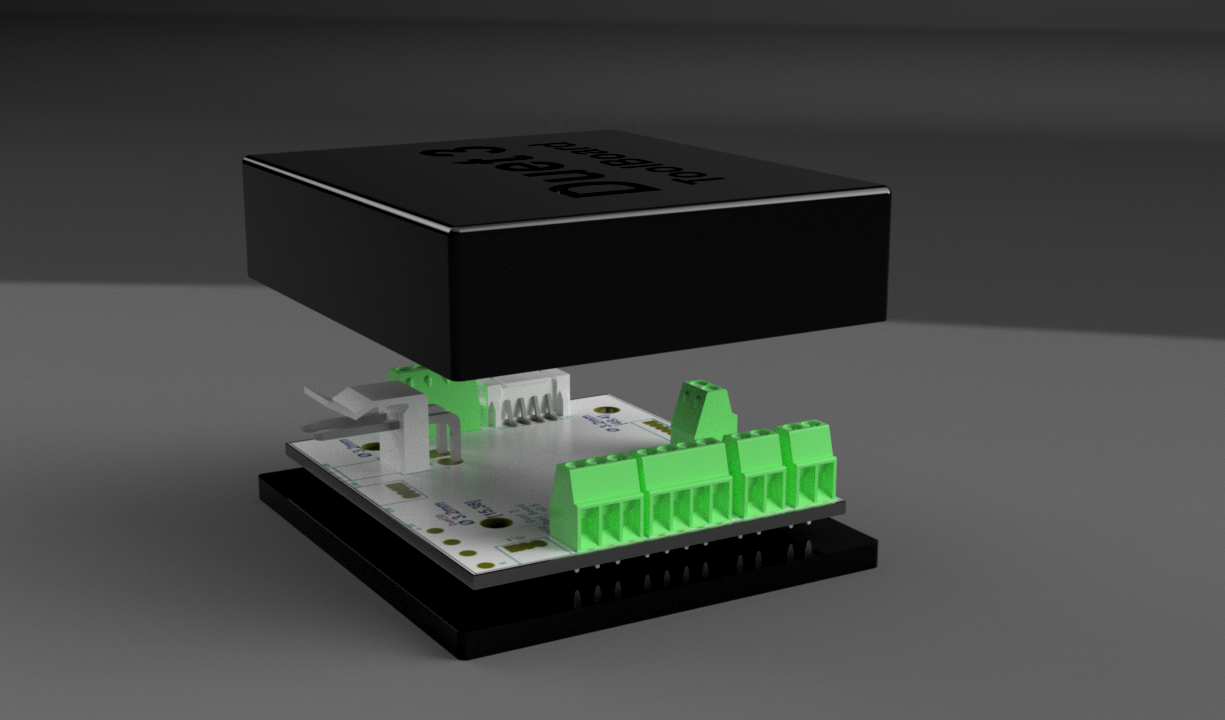

Duet 3 Tool Board

-

@timcurtis67 you never worked PDP11's then? Mind I can go back even further to the times of an IBM 1130 which used EBCDIC punched cards or a frantic Argos 500 with handlers and punched tape.

-

Anyone having the stp files for the 3 and 4 pin JST ZH + the 6 pin (stepper output) + the button?

I`m making a simple (not 100% accurate) ToolBoard 3D model that I can use in my designs + when designing a housing for it

-

@timcurtis67 said in Duet 3 Tool Board:

@tekkydave said in Duet 3 Tool Board:

Anyone old enough to remember SCSI hard disk? They had a SIP resistor pack in the last drive on the 50w ribbon cable.

I must be old, I remember the IDE drives and even 5 1/4" floppies...

But I never used the big 8" stuff...

I did! [Cue "You were lucky!" spoken with a Yorkshire accent].

I also remember when we asked one of our customers for a copy of their backup disks (this was before email) so we could diagnose the issue they reported. Next day it arrived by post... a perfect photocopy of a pair of 8" floppy disks!

-

@dc42 said in Duet 3 Tool Board:

a perfect photocopy of a pair of 8" floppy disks!

A page with pixels and a 8"" floppy represent about the same number of bits.

Seriously, I may missed it, what are the dimension of this board?

-

@zapta said in Duet 3 Tool Board:

Seriously, I may missed it, what are the dimension of this board?

As shown at https://duet3d.dozuki.com/Wiki/Duet_3_Tool_Board.

-

@dc42 https://www.dropbox.com/s/eh33zxsda53bvhv/2020-02-21 13.56.06.jpg?dl=0 look familiar?

https://www.dropbox.com/s/oamu8uhdz134qj6/2020-02-21 13.55.32.jpg?dl=0 from our antique computing pile at work

-

@daavery said in Duet 3 Tool Board:

@dc42 https://www.dropbox.com/s/eh33zxsda53bvhv/2020-02-21 13.56.06.jpg?dl=0 look familiar?

https://www.dropbox.com/s/oamu8uhdz134qj6/2020-02-21 13.55.32.jpg?dl=0 from our antique computing pile at work

Double sided 8 inch floppy? Luxury!

-

@dc42 double sided double density 1.2M

-

@dc42 Although I don't see a statement to the effect, I'm assuming IO0 is meant for the Z probe and IO1 the filament sensor yeah? Can IO1 be used as an X endstop instead?

-

Am I understanding correctly that having 4 tool boards would allow up to 10 stepper motors to be controlled (6 from the Duet3 and 4 additional from the tool boards)?

-

@blarbles said in Duet 3 Tool Board:

Am I understanding correctly that having 4 tool boards would allow up to 10 stepper motors to be controlled (6 from the Duet3 and 4 additional from the tool boards)?

I'd say that is correct - providing those additional 4 motors are all extruders. Funnily enough, @dc42 has just posted something on his WordPress site to that effect https://miscsolutions.wordpress.com/2020/03/02/converting-the-e3d-tool-changer-to-duet-3-with-hemera-tools-part-1/

-

@gtj0 said in Duet 3 Tool Board:

@dc42 Although I don't see a statement to the effect, I'm assuming IO0 is meant for the Z probe and IO1 the filament sensor yeah? Can IO1 be used as an X endstop instead?

afaik the only special function is IO0 needs to be used if connecting a PanelDue, beyond that you can configure any input to be a end stop or z probe or whatever.

-

@bearer said in Duet 3 Tool Board:

@gtj0 said in Duet 3 Tool Board:

@dc42 Although I don't see a statement to the effect, I'm assuming IO0 is meant for the Z probe and IO1 the filament sensor yeah? Can IO1 be used as an X endstop instead?

afaik the only special function is IO0 needs to be used if connecting a PanelDue, beyond that you can configure any input to be a end stop or z probe or whatever.

Yeah, that's on the main board but I know in the past there have been restrictions around having an axis's endstop on the same board as the stepper driver(s) so I wanted to make sure that if the axes motors were on the main board that the tool board's IO1 could be used as an X endstop.

-

@gtj0 said in Duet 3 Tool Board:

axes motors were on the main board that the tool board's IO1 could be used as an X endstop.

Verify by trying it, but reading all the release notes, this should work.

-

@Danal said in Duet 3 Tool Board:

@gtj0 said in Duet 3 Tool Board:

axes motors were on the main board that the tool board's IO1 could be used as an X endstop.

Verify by trying it, but reading all the release notes, this should work.

I don't have one and can't use one if it doesn't work

@Dougal1957 said in Duet 3 Tool Board:

@timcurtis67 you never worked PDP11's then? Mind I can go back even further to the times of an IBM 1130 which used EBCDIC punched cards or a frantic Argos 500 with handlers and punched tape.

I have fond memories of the 1130. I can still remember the great sounds the card reader and line printer made in unison when a coldstart card was read.

I just remembered the sound of cash registers of that era as well. Things are so damn quiet now.

-

@gtj0 said in Duet 3 Tool Board:

I don't have one and can't use one if it doesn't work

I have one main board (6HC), two expansions (3HC) and four tool boards (1HC). I'd be happy to give it a try for you. If you don't mind, could you describe the "test cases" you wish to see?

-

@Danal said in Duet 3 Tool Board:

@gtj0 said in Duet 3 Tool Board:

I don't have one and can't use one if it doesn't work

I have one main board (6HC), two expansions (3HC) and four tool boards (1HC). I'd be happy to give it a try for you. If you don't mind, could you describe the "test cases" you wish to see?

That would be great! In my case, I have all of my motion (CoreXY) motors on the main board and while the Y endstop is fixed on the frame, the X endstop (actually it's a dc42 IR sensor) is on the tool carriage and senses when the tool carriage approaches the far left.

Right now it's wired back to the main board along with the Z probe, temp sensor, and extruder heater. I just want to make sure that if the IR (or any) sensor was connected to IO1 on a tool board (actually it's just an "I" since there's no "out" pin) that it will work as an X endstop.

-

-

To work for me would need to connect a BLTouch, Duet Magnetic Filament Sensor, 50w heater, PT1000 RTD and an endstop. Curious to know if this is possible. Thanks!

-

@gtj0 said in Duet 3 Tool Board:

That would be great! In my case, I have all of my motion (CoreXY) motors on the main board and while the Y endstop is fixed on the frame, the X endstop (actually it's a dc42 IR sensor) is on the tool carriage and senses when the tool carriage approaches the far left.

I have a fairly similar setup, so I truly understand the 'test case'. I won't be able to get to it tonight; should only be a day or two... he said...