RepRapFirmware 3.0 is released!

-

@Adamfilip said in RepRapFirmware 3.0 is released!:

I keep running into error when homingall

G28 SetPosition called when DDA ring not empty

Please confirm that you are running version 3.0 (not beta or RC), and post your config.g file, homeall.g file, deployprobe.g and retractprobe.g files if you have them, and any other files that homeall.g calls.

-

@deckingman: I think RRF3 is a lot more generalised / has a lot less notion of specific pin functions than RRF2. It would not surprise me that a 'create heater output' M950 does not differentiate between different kind of heaters. Which is, IMHO, a good thing.

But the flipside is that the PWM frequency is also default, and probably quite high. Which does not work well for SSR's and especially the zero-crossing types; you can turn them on or off 100 times a second maximum (in the 50Hz EU). Thus, if one uses a 10Hz PWM frequency, the power can be regulated in 10% increments only, which is already not very high resolution. With a 500Hz PWM frequency the triggering of the SSR becomes a statistical function; a higher duty cycle makes it more likely that the SSR triggers at the zero crossing. It will regulate, but more in a bang-bang like fashion than a nicely controlled proportional fashion.

Since the thermal time constant of my heated bed is so large, I could easily get away with a 0.1Hz PWM frequency, but that increases thermal stress (wires in the heater heating up - cooling down - heating up - cooling down...), so 2-5Hz is a better option.

Which made me search for the limits on PWM frequency, which I did not find.

@Adamfilip : I got those 'G28 SetPosition called when DDA ring not empty' messages too after upgrading to RRF3, and in my case it had something to do with the endstop switches being setup in the wrong polarity. They were already triggered when the homing move started.

After fixing this, the message went away. -

@DaBit said in RepRapFirmware 3.0 is released!:

@Adamfilip : I got those 'G28 SetPosition called when DDA ring not empty' messages too after upgrading to RRF3, and in my case it had something to do with the endstop switches being setup in the wrong polarity. They were already triggered when the homing move started.

After fixing this, the message went away.I still want to find out exactly what is causing this, so that I can fix it.

-

In case it helps: here is my config bundle, or at least the latest backup: https://nextcloud.icecoldcomputing.com/s/YQo7Z7iEqfzDcXF

When I invert the endstop polarity in de M574's at line 40-41 of config.g so that they are triggered when the printhead is nowhere near them, I also get this DDA ring error. It also shows up in the eventlog (also included in the ZIP), but no more information is logged there.

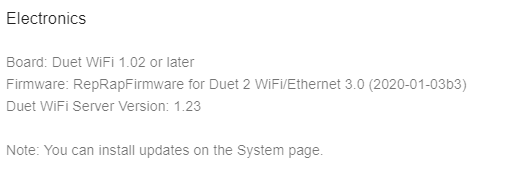

RRF is the stable release ((2020-01-03b3), board is Duet2Wifi 1.02 or later, DWC is 2.0.4If you want access to the board to run tests or do some debugging, just ask and I will setup temporary SSH access that allows you to tunnel to the Duet.

-

Yes running 3.0 not beta

Here are config and homeall

I dont have the others at the momentConfig.------------------------------------------------------------

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2.1.5 on Wed Jan 08 2020 19:38:55 GMT-0500 (Eastern Standard Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"TitanXY" ; set printer nameM667 S1 ; select CoreXY mode

; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S0 ; physical drive 1 goes backwarsa

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S0 ; physical drive 3 goes backwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X32 Y32 Z32 I0 ; configure microstepping without interpolation

M350 E16 I1 ; configure microstepping with interpolation

M92 X400 Y400 Z1593 E409 ; set steps per mm

M566 X600 Y600 Z20 E800 ; Set maximum instantaneous speed changes (mm/min)

M203 X9000 Y9000 Z1500 E10000 ; Set maximum speeds (mm/min)

M201 X1000 Y1000 Z250 E5000 ; Set accelerations (mm/s^2)

M906 X1200 Y1200 Z1500 E1100 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

M572 D0 S0.15 ; Pressure Advance ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X270 Y270 Z300 S0 ; set axis maxima; Endstops

M574 X1 S3 ; configure sensorless endstop for low end on X

M574 Y1 S3 ; configure sensorless endstop for low end on Y; BLTouch

; Z-Probe

M950 H3 C"nil" ; Disable heaters h7 to free up pins

M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H10 F800 T2000 ; set Z probe type to bltouch and the dive height + speeds

G31 X20 Y0 Z3.3 P25 ; Z probe trigger value, offset in relation to nozzle. And trigger height adjustment

M557 X15:215 Y15:195 S20 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M307 H0 A61.9 C160.5 D1.3 B0 S0.5 v24.4 ; disable bang-bang mode for the nozzle heater and set PWM limit

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M143 H1 S285 ; set temperature limit for heater 1 to 280C

M307 H1 A583.7 C261.1 D3.9 B0 S1.0 v24.3 ; disable bang-bang mode for the nozzle heater and set PWM limit; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on

M950 F2 C"fan1" Q500 ; create fan 2 on pin fan1 and set its frequency

M106 P2 S1 H1 T45 ; set fan 2 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings are not defined

Homeall ----------------------------------------------------------

; homeall.g

; called to home all axes

;

; generated by RepRapFirmware Configuration Tool v2.1.5 on Wed Jan 08 2020 19:38:55 GMT-0500 (Eastern Standard Time)M913 X75 Y75 Z100 ; reduce motor power

M400 ; make sure everything has stopped before we make changes

M915 H400 X Y S0 R0 F0 ; set X and Y to sensitivity 0, do nothing when stall, unfiltered

M574 X1 Y1 S3 ; set endstops to use motor stallG91 ; use relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current positionG4 P500 ; wait 500msec

G1 H1 X-285 F2000 ; move quickly to X axis endstop and stop there (first pass)

G4 P500 ; wait 500msec

G1 X5 ; move away from home

G4 P500 ; wait 500msec

M400 ; make sure everything has stopped before we make changesG4 P500 ; wait 500msec

G1 H1 Y-285 F2000 ; move quickly to Y axis endstop and stop there (first pass)

G4 P500 ; wait 500msec

G1 Y5 ; move away from home

G4 P500 ; wait 500msec

G1 H1 Y-285 F2000 ; move quickly to Y axis endstop and stop there (first pass)G1 H2 Z10 F6000 ; lift Z relative to current position

G1 X150 Y150 F1200 ; Centre Print head

G1 H1 Z-305 F1800 ; move Z down until the endstop is triggered

G92 Z0 ; set Z position to axis minimum (you may want to adjust this)G1 H2 Z10 F6000 ; lift Z relative to current position

M400 ; make sure everything has stopped

M913 X100 Y100 ; XY motors to 100% current

G90 ; back to absolute positioning -

-

This is the config;

; Endstops

M574 X2 S1 P"xstop" ; Set active high endstops

M574 Y2 S1 P"ystop"

M574 Z2 S1 P"zstop"; Z-Probe

M558 P5 C"zstop" R0.4 H1 F120 T6000 ; Set Z probe type to effector and the dive height + speeds

G31 P100 X0 Y0 Z-0.252 ; Set Z probe trigger value, offset and trigger height

M557 R85 S20 ; Define mesh grid; Heaters

M308 S0 P"bed_temp" Y"thermistor" T100000 B4138 C0 R4700 ;

M950 H0 C"bed_heat" T0 ; heater 0 uses the bed_heat pin, sensor 0

M308 S1 P"spi.cs1" Y"rtd-max31865" ; define E0 temperature sensor

M950 H1 C"e0_heat" T1 ; heater 1 uses the e0_heat pin and sensor 1; Fans

M950 F0 C"fan0" ;

M106 P0 S0 Q500 H-1 ;

M950 F1 C"fan1" ;

M106 P1 S1 Q500 H1 T45 ;

M950 F2 C"fan2" ;

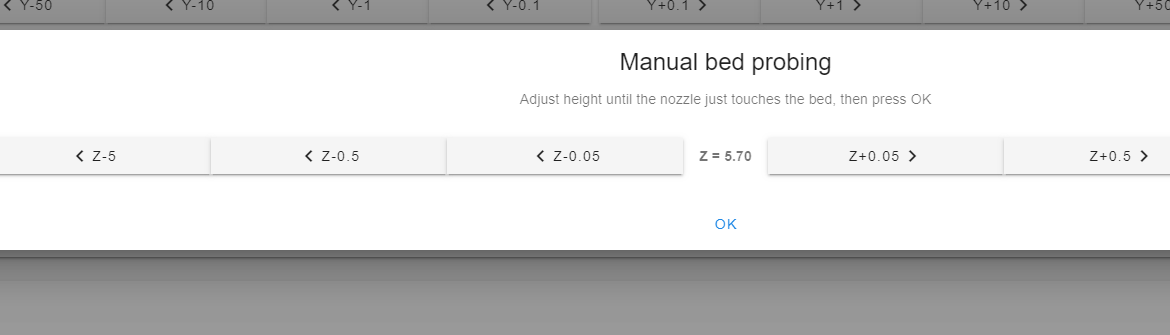

M106 P2 S1 Q500 H1 ;added the bold part as you suggest but if try to run Delta calibration start on Manual calibration

-

@bulka said in RepRapFirmware 3.0 is released!:

M558 P5 C"zstop" R0.4 H1 F120 T6000 ; Set Z probe type to effector and the

added the bold part as you suggest but if try to run Delta calibration start on Manual calibration

This depends on where you have the probe plugged in, if it's the Smart Effector and plugged into the z endstop connector, that would be correct. But, usually it's plugged into the probe connector next to the expansion header. In that case what you put would be incorrect.

If the probe connector, it should be

M558 P5 R0.4 C"zprobe.in+zprobe.mod" H1 F120 T6000

-

-

@bulka is this a Duet Wifi or Duet3? and Am I right in thinking it is a smart effector?

-

-

@bulka ok here is my config file using the same hardware.

; Configuration file for Duet WiFi (firmware version 1.17) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool on Fri Jul 07 2017 14:49:07 GMT+0100 (BST) ; General preferences M111 S0 ; Debugging off G21 ; Work in millimetres G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves M555 P2 ; Set firmware compatibility to look like Marlin ;*** The homed height is deliberately set too high in the following - you will adjust it during calibration. M665 L450.570 R239.241 H400.083 B175.0 X0.081 Y0.091 Z0.000 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0.315 Y0.808 Z-1.123 A0.20 B0.02 ; Put your endstop adjustments here, or let auto calibration find them ;M665 L450.570 R239.403 H400.898 B175.0 X0.191 Y0.213 Z0.000 ; Set delta radius, diagonal rod length, printable radius and homed height ;M666 X0.392 Y0.645 Z-1.037 A0.12 B-0.07 ; Put your endstop adjustments here, or let auto calibration find them M208 Z0 S1 ; Set minimum Z ; Endstops M574 X2 Y2 Z2 S1 ; Define active high microswitches M558 P5 C"^zprobe.in" X0 Y0 Z0 H5 R0.4 F1200 T6000 ; Set Z probe type to unmodulated, the axes for which it is used and the probe + travel speeds G31 P100 X0 Y0 Z-0.05; Set Z probe trigger value, offset and trigger height M557 R160 S20 ; Define mesh grid ; Drives M569 P0 S0 ; Drive 0 goes forwards M569 P1 S0 ; Drive 1 goes forwards M569 P2 S0 ; Drive 2 goes forwards M569 P3 S1 ; Drive 3 goes forwards M92 X200 Y200 Z200 E1667 ; Set steps per mm M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation M566 X900 Y900 Z900 E40 ; Set maximum instantaneous speed changes (mm/min) M203 X18000 Y18000 Z18000 E2400 ; Set maximum speeds (mm/min) M201 X1000 Y1000 Z1000 E120 ; Set accelerations (mm/s^2) M906 X1000 Y1000 Z1000 E500 I30 ; Set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Heaters M143 S300 ; Set maximum heater temperature to 300C ;M305 P0 X201 ; Set thermistor + ADC parameters for heater 0 and remap it to channel 201 ;M305 P1 X200 ; Set thermistor + ADC parameters for heater 1 and remap it to channel 200 M308 S0 P"spi.cs2" Y"rtd-max31865" F50 M308 S1 P"spi.cs1" Y"rtd-max31865" F50 M950 H0 C"bed_heat" T0 M950 H1 C"e0_heat" T1 ;M307 H0 A199.0 C962.6 D5 B0 ;M307 H1 A409.7 C232.2 D4.5 B0 ;M307 H0 A161.6 C1109.8 D5.8 S1.00 V24.4 B0 M307 H0 A449.1 C783.3 D9.8 S1.00 V24.4 B0 M307 H1 A544.9 C280.1 D4.2 S1.00 V24.4 B0 ; Tools M563 P0 D0 H1 F2; Define tool 0 G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C ; Network M550 PDelta ; Set machine name M552 S1 ; Enable network ; Access point is configured manually via M587 by the user M586 P0 S1 ; Enable HTTP M586 P1 S1 ; Enable FTP M586 P2 S0 ; Disable Telnet ; Fans M106 P0 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off ;M106 P1 S1 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on ;M106 P2 S1 I0 F500 H-1 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned off M563 P0 D0 H1 M564 H0 ; Custom settings are not configured T0 G28 ;G29 S1 ;M572 D0 S0.05 ; set pressure advance M501This works I am on RRF 3.0 on my Wifi board

Hopefully this will help you

note the probe settings for the smart effector

M558 P5 C"^zprobe.in" X0 Y0 Z0 H5 R0.4 F1200 T6000 ; Set Z probe type to unmodulated, the axes for which it is used and the probe + travel speeds

G31 P100 X0 Y0 Z-0.05; Set Z probe trigger value, offset and trigger height -

@DaBit I'll check my settings when I get back home in 8 days or so. I suspect that I'm using 10Hz because that is what I've always used. IIRC that figure of 10Hz was chosen specifically to suit SSRs. However, do not confuse the PWM frequency with the mark-space ratio that is PWM itself. And also, don't forget that the thermal mass of the aluminium plate acts as a huge damper to the conduction of heat through the plate, which makes the PWM frequency largely irrelevant.

-

You have a bed.g file?

-

-

@bulka Glad to be of help

Doug

-

The documentation for converting M558 to RRF3 is a bit confusing in regards to the "I" parameter. In particular, it doesn't say anything about it (in that section)

https://duet3d.dozuki.com/Wiki/RepRapFirmware_3_overview#Section_M558

As well, the gcode wiki page also seems to imply that "M558 I1" is valid (https://duet3d.dozuki.com/Wiki/Gcode#Section_M558_Set_Z_probe_type)

"All of the above for RepRapFirmware 2.x relates to RepRapFirmware 3, except the following:" (and nothing that follows makes mention of the I param.)

Yet, from reading this thread, I get the impression that RRF2:

M558 P8 I1 R0.4 F300 H3does not work in RRF3 as:

M558 P8 R0.4 I1 C"zprobe.in" H3 F300and instead should be written as:

M558 P8 R0.4 C"!zprobe.in" H3 F300 ; I1 removed, ! prepended to zprobe.in

Edit: I accidentally left the "I1" in my 558 after converting, and had the ! before the pin. The result apparently was a double inversion. Removing the I1 and leaving the "!" made everything seem to work.

So ... which is the proper way?

-

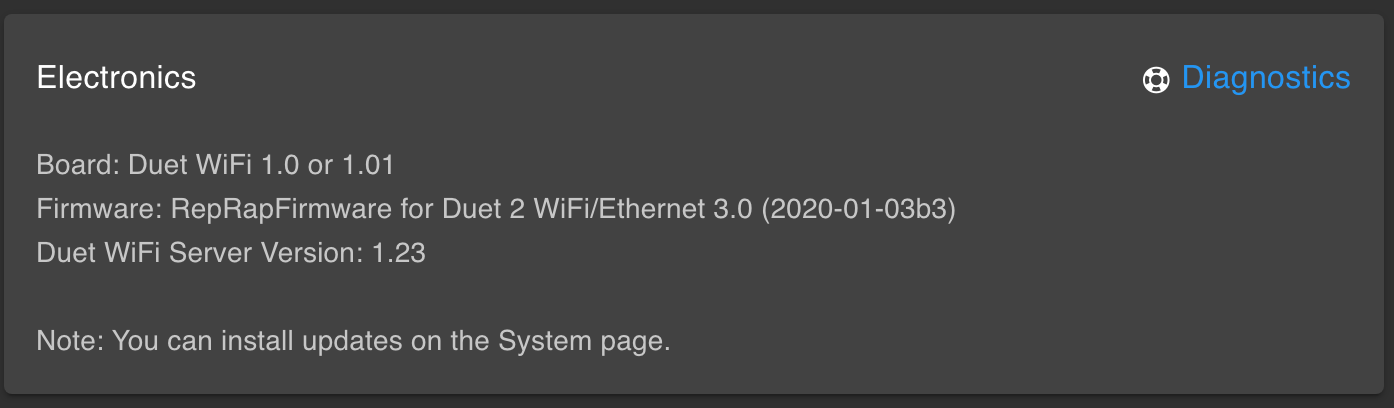

Duet2 wifi h/w version 1.04

Printer is a normal delta (with 0.9 degree steppers)

Firmware is the first general release of RRF3After starting my first print with RRF3 on a Duet2 WiFi, I'm seeing a LOT of hiccups using an identical configuration to what I used with RRF2 (where I only rarely saw a hiccup.)

For example, 45 seconds after sending "M122", I sent M122 again and saw "Hiccups: 423(0)"

Measuring it at one point, I got 161 hiccups for a travel move of around 80mm.

The hiccups seem to be only after travel moves which are configured at 200mm/sec in my slicer. Yes, I could slow this down and probably get rid of the hiccups, but the point is that I did NOT get hiccups with RRF2.0.5 with the exact same gcode file.

The speed related lines in my config.g are directly copied from my RRF2 config.g, as well as the stepper config. I've included them below:

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X199.50 Y199.50 Z199.50 E837.50 ; set steps per mm M566 X1200.00 Y1200.00 Z1200.00 E2400.00 ; set maximum instantaneous speed changes (mm/min) M203 X21000.00 Y21000.00 Z21000.00 E10000 ; set maximum speeds (mm/min) (severely limited by slicer) M201 X1500.00 Y1500.00 Z1500.00 E1000.00 ; set accelerations (mm/s^2) (limited by M204) M204 P500 T1200The delta parameters are:

M665 L360.260:360.260:360.250 R215.476 H415.377 B140.0 X0.426 Y0.176 Z0.000 M666 X0.298 Y-0.635 Z0.337 A-0.31 B0.33A random M122 is also shown in case there's some information that might diagnose an issue:

M122 === Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 3.0 running on Duet WiFi 1.02 or later Board ID: 08DGM-9T6BU-FG3SN-6JKD6-3S46P-KUYVD Used output buffers: 3 of 24 (23 max) === RTOS === Static ram: 30516 Dynamic ram: 91248 of which 96 recycled Exception stack ram used: 544 Never used ram: 8668 Tasks: NETWORK(ready,640) HEAT(blocked,1240) MAIN(running,104) IDLE(ready,156) Owned mutexes: === Platform === Last reset 01:32:22 ago, cause: software Last software reset time unknown, reason: User, spinning module GCodes, available RAM 8940 bytes (slot 1) Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0xffffffff Task 0x4e49414d Error status: 0 Free file entries: 9 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest block write time: 14.1ms, max retries 0 MCU temperature: min 36.0, current 36.6, max 37.0 Supply voltage: min 23.3, current 23.5, max 24.5, under voltage events: 0, over voltage events: 0, power good: yes Driver 0: ok, SG min/max 0/990 Driver 1: ok, SG min/max 0/267 Driver 2: ok, SG min/max 0/403 Driver 3: ok, SG min/max 0/1023 Driver 4: standstill, SG min/max not available Date/time: 2020-01-09 22:39:36 Cache data hit count 4294967295 Slowest loop: 13.92ms; fastest: 0.10ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Move === Hiccups: 621(0), FreeDm: 153, MinFreeDm: 101, MaxWait: 0ms Bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves: 119268, completed moves: 119228, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 === AuxDDARing === Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 === Heat === Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1 -1 -1 Heater 0 is on, I-accum = 0.3 Heater 1 is on, I-accum = 0.5 === GCodes === Segments left: 1 Stack records: 2 allocated, 0 in use Movement lock held by null http is idle in state(s) 0 telnet is idle in state(s) 0 file is doing "G1 X-14.161 Y69.007 E0.00898" in state(s) 0 serial is idle in state(s) 0 aux is idle in state(s) 0 daemon is idle in state(s) 0 queue is idle in state(s) 0 autopause is idle in state(s) 0 Code queue is empty. === Network === Slowest loop: 200.45ms; fastest: 0.09ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(1) HTTP sessions: 1 of 8 - WiFi - Network state is running WiFi module is connected to access point Failed messages: pending 0, notready 0, noresp 23 WiFi firmware version 1.23 WiFi MAC address 84:f3:eb:83:42:fc WiFi Vcc 3.41, reset reason Turned on by main processor WiFi flash size 4194304, free heap 24224 WiFi IP address 192.168.7.10 WiFi signal strength -50dBm, reconnections 0, sleep mode modem Socket states: 2 0 0 0 0 0 0 0 -

I am totally confused ( not hard to do)

I have a part fan connected to board Fan0

I have an extruder fan connected to board Fan1

I have a system fan connected to board Fan2I have made changes to the config file for RRF3 but the fans are not working properly, the extruder fan is on all the time, the system fan is not working and the part fan comes on if I move the sliders on part or system.

Very frustrating.RepRapFirmware 2 settings

; Thermistors and heaters

M305 P0 R4700 B3950 S"Bed Heater" ; bed thermistor R and B values

M305 P1 R4700 B4388 H23 S"Hot end" ; nozzle 1 thermistor R and B values

M307 H0 A104.6 C986.0 D1.9 ;B0 ; Auto tune PID for bed heater

M307 H1 A669.8 C253.0 D4.5 ;B0 ; Auto tune PID for extruder 0

; Fan settings

M106 P1 T45 H1 ; Fan 1 to run when H1 is above 45Celsius

M106 P2 H100:101 T35:50 L0.3 ; electronics cooling fanall of the above works correctly.

RepRapFirmware 2 settings

; Thermistors and heaters

M950 H0 C"bed_heat" T0 ; create bed heater output on bedheat and map it to sensor 0

M308 S0 P"bed_temp" Y"thermistor" T4700 B3950 ; configure sensor 0 as thermistor on pin bedtemp

M143 H0 S70 ; set temperature limit for heater 0 to 70C

M307 H0 A104.6 C986.0 D1.9 B0 S1.00 ; Auto tune PID for bed heaterM950 H1 C"e0_heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M308 S1 P"e0_temp" Y"thermistor" T4700 B4388 ; configure sensor 1 as thermistor on pin e0temp

M143 H1 S230 ; set temperature limit for heater 1 to 230C

M307 H1 A669.8 C253.0 D4.5 B0 S1.00 ; Auto tune PID for extruder 0M308 S100 Y"mcu-temp" A"CPU" ; CPU temp sensor

M308 S101 Y"drivers" A"Duet_drv" ; drivers temp sensor; Fan settings

M950 F0 C"fan0" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P0 C"PartFan" ; set Part fan.

M950 F1 C"fan1" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P1 S0 H1 T45 C"Extruder" ; set Extruder Fan. Thermostatic control is turned on

M950 F2 C"fan2" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P2 H100:101 T35:55 L40 C"System" ; set System fan. Thermostatic electronics cooling fan -

Hello @dc42

why i get G28 error when i want to home my locking actuator?; Home U Axis G91 ; Set relative mode G1 U-360 F9000 H1 ; Big negative move to search for home endstop G1 U4 F600 ; Back off the endstop G1 U-10 F600 H1 ; Find endstop again slowly G90 ; Set absolute modeHere is code from homeu.g

and here is from homeall.g

; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v2.0.4 on Sat Oct 12 2019 15:44:24 GMT+0200 (Srednjeevropski poletni čas) T-1 ;remove tool befor probing G91 ; relative positioning G1 Z5 F3000 H2 ; lift Z relative to current position G1 H1 X-435 Y-388 F1800 ; move quickly to X or Y endstop and stop there (first pass) G1 H1 X-435 ; home X axis G1 H1 Y-388 ; home Y axis G1 X5 Y5 F3000 ; go back a few mm G1 H1 X-435 F360 ; move slowly to X axis endstop once more (second pass) G1 H1 Y-388 ; then move slowly to Y axis endstop G90 ; absolute positioning G1 X210 Y200 F3000 ; go to first bed probe point and home Z G30 ; home Z by probing the bed M98 P"homeu.g" ; Uncomment the following lines to lift Z after probing ;G91 ; relative positioning ;G1 H2 Z5 F50 ; lift Z relative to current position ;G90 ; absolute positioningMatej