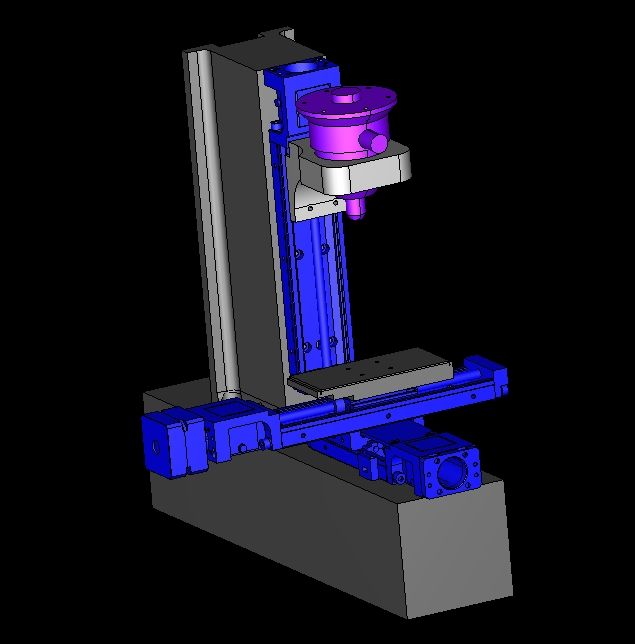

Duet controlled micro mill

-

Hey Tony. The selling point for this build, to my wife, was to make custom charms (think Alex and Ani) to peddle but I was mainly thinking of 2nd ops for parts made on my Duet controlled FFF (.1 mm extrusion width squirting PEI and PEKK).

-

Username checks out.

-

@3dpmicro next you need to build a tiny robot arm to lift the parts from the FFF printer to the micro mill!

-

I was able to get the motors to run over 1200 RPM (1200 mm/m travel speed) but while using my test program they stuttered when interpolating corners below a certain radius (G2/G3) with 16x ms, interpolated. Still almost silent and smooth at 8x Ms w/o interpolation. I went all over the place with Accel, and jerk with no apparent effect on the stuttering until down, around 600 mm/m. This 2.3 mm thick part took 14 minutes using a .81 mm end mill including interpolating the 6, 1 mm mounting holes. .1 mm axial DOC and 400 mm/m feed.

The demensions I can measure easily came out within .02 mmp.s. for the record i was not actually using the bathroom when I took the picture

-

@3dpmicro said in Duet controlled micro mill:

my Duet controlled FFF (.1 mm extrusion width squirting PEI and PEKK).

I saw your old thread about the probing in a hot chamber.

How is your heated build chamber printer coming along? Can you share some pictures of that? -

@nitrofreak The chamber is working well. 200 - 210c for Ultem 1010. The machine is an IDEX, has a fairly small work envelope of 100 mm cubed and is very stable mechanically and thermally so manual leveling is all that is needed. I would like to post pictures but decided not to until the Stratasys patent has expired. That was supposed to happen this year but could be extended. I am uncertain of the current status.

-

My little micro Mill has been working great. No hicups other than the PanelDue touch screen not always working right (too lazy to investigate). I make high precision machined parts at my job using $500k equipment and it still amazes me how accurate and repeatable this $800 machine is. Latest project was a gift I made for my parents 50th wedding anniversary. Using a 20 deg engraving bit with a .1mm tip the machine was consistently able to ablate the thin aluminum film from the backside of the mirror with only minor signs of etching the glass in a few places. This was after surfacing the spoil plate and verifying flatness within .005 mm. This tells me at least the Z is hitting the theoretical .003 mm resolution and doing it pretty darn consistently.

-

-

Pull-pull control horns machined from glass composite sheet on my micro mill. Concept to finished parts in less than an hour

-

Triskele charm for my lovely wife. Machined on the Duet Micro Mill of course

-

@3DPMicro said in Duet controlled micro mill:

...not to until the Stratasys patent has expired. That was supposed to happen this year but could be extended. I am uncertain of the current status.

You have a great mill, you motivate me to build one too. Very nice!

The patent you mentioned expires Feb 2021 and was discussed in https://www.reddit.com/r/3Dprinting/comments/d1bxy4/did_the_heated_build_chamber_patent_just_get_a/

-

JoergS5,

Thanks for the info on the patent.

How big are you going to build your mill? -

@3DPMicro It's in the idea project phase, so no detailed plans yet. But my highest priority will be precision with a small build space (maybe 50 mm in each direction).

-

@3DPMicro My special interest would be to mill small parts like

- nozzles like matchless nozzles or SuperVolcano and hotends/heatbreaks for them

- milling tools/cutters for bigger wood or metal CNC spindles

- bigger parts like harmonic drive splines

- producing ball bearing DIY would be nice too (just for fun)

- parts for my Märklin Z trains (they are 1:220 train models)

My general tought is to combine addititive with subtractive manufacturing and make a quality iteration: e.g. 3D print/metal casting/injection molding, then finish by routing/honing/sandblasting. Control product by comparing with the original model and iterate until the goal is reached.

-

@JoergS5 it's ,for sure, a good thing we have the Duet along with the work of David and Tony (and whoever else contributes). Now our imaginations aren't so much constrained by money. With the 2 and now the Duet 3 the sky is the limit on functions. Sounds like many of your projects will require turning as well as 4th axis milling. I'm in the process of retrofitting a pretty good-sized manual lathe to CNC using a Duet 2.

-

@3DPMicro Would be nice if you create threads about your lathe rebuild here also, as I am sure you have a lot of experience with precision production.

I agree that the Duets are great. I bought them primarily not because of the properties of the board, but because of the good support of firmware and nice, friendly, helpful forum.

-

@JoergS5 said in Duet controlled micro mill:

@3DPMicro Would be nice if you create threads about your lathe rebuild here also, as I am sure you have a lot of experience with precision production.

I agree that the Duets are great. I bought them primarily not because of the properties of the board, but because of the good support of firmware and nice, friendly, helpful forum.

I will probably do something similar with the lathe as I have done here with the mill. There doesn't appear to be much in the way of Duet controlled lathes so maybe I will be a bit more thorough with the steps involved. Should be relatively simple since it's only 2 axis but live tooling and/or tool changes will be something I want to incorporate

-

@3DPMicro This build looks really great! Is there any chance I could take a peak at a BOM or exploded view? I've been wanting to build something like this for machining watch cases / main plates but I haven't found the time.

Thanks!

-k -

@kzamani said in Duet controlled micro mill:

@3DPMicro This build looks really great! Is there any chance I could take a peak at a BOM or exploded view? I've been wanting to build something like this for machining watch cases / main plates but I haven't found the time.

Thanks!

-kI didnt create a BOM because it was fairly simple. Each axis is a self contained Misumi linear actuator. They are designed to stack to create a cartesian motion system. Mine are LX2001-100 (38mm travel) for the Y axis and LX2001-150 (88mm travel) for X, Z axis'. All are 1mm lead ball screws "P" precision grade for no backlash. The LX2005 would still provide high resolution (5mm lead ball screws) with .9 nema 17 steppers and afford faster rapids. Mine are 1.8 nema 14's on the X and Y and a .9 nema 17 on the Z. LX25's or 30's would also be a good choice as well as THK/NSK equivalents. The frame is made from 3" square steel bar machined to 75mm square. There is a decent amount of machine work to get them in a suitable state for a square and accurate CNC machine. I surface ground the critical surfaces but that isnt totally necessary. I also designed in some versatility to allow longer Y travel and separate linear rails and ball screw for the Z axis. End stops are OMRON E2EC-CR5C1 proximity switches which are deadly accurate.

If you want to duplicate exactly what I did I will put the CAD model up.

This temporary solution for keeping the machine clean has worked well so I doubt I'll change it

-

@3dpmicro Sorry to reply to this old thread but I find this build to be awesome, so simple yet super high precision, I wonder if is posible to see a video of it in action? I am a watchmaker student doing research for building a cnc mill and this one has to be the best approach I have ever seen, thanks in advance!