Core-XY based on Rat Rig V-Core and Duet 2 Ethernet

-

I just finished my upgrade to the V2 hardware and three Z motors. I drive them separately so that I can use the Duet firmware's auto levelling. Of course, I needed to get a Duex expansion board so that I had enough stepper drivers.

Before, when I had two Z motors, I could also drive them separately and keep the bed level on the X axis.Any reason why you don't use this feature?

Fitting the Orion to my V-Core was simple. I created a custom hot end mount which was designed to fit with the parts that Idris has made available on Thingiverse: Precision Piezo Orion Parts

Basically, I used the E3D groove clamp for the hot end and incorporated the essential elements of the corresponding top into the design of my hot end mount. The essential elements are simply four 3mm holes arranged on 26mm centres for the screws which go into the clamp and a 15mm wide conical depression above the Orion board which allows it to flex when the clamp transmits pressure on the nozzle to the board.

I'm currently working on a new design for the mount so that the clamp for the hot end can be screwed on from below. As it is now, I need to use 50mm long M3 screws which go all the way through the mount from the top and that's not exactly ideal.

-

@grizewald , thanks for the suggestion. The reason I don't use independent motor drives is that I am convinced once the belts are in place on the lead screws like in @deckingman's printer there is simply no need to drive them separate. I am using a (or will be once I have it machined) 10mm aluminium plate as heated bed and 5mm float glass. I think it will be very rigid. The maximum height difference would come from the pitch of the lead screw over one notch of the belt. I am very confident that can be dealt with with the mesh bed levelling. Also now that I have seen they will have a linear rail version of the RatRig soon (November / December apparently) I don't want to spend any money on the extension board, I rather build the new version once I have this one done.

Re piezos, I am not using a E3D V6, I have a Titan Aero, my mount would be very different. The reasons behind that choice have been mainly the gain in build height and less leverage on the nozzle due to the shorter compacter design. My next build will NOT have a Titan Aero again, in fact I probably go away from E3D and look at the BMG-M with the Mosquito hotend. I had issues with clogging (had the fan speed to low) and the extruder is often missing steps at higher speeds (not a pancake motor). So for now I am OK with the piezo cowboy style mount cause it works. I will revisit that once I have the print bed finished. I am not happy with my hotend mount anyway, its very hard to service. I would love a modular (possibly magnetic) mount.

Anyway, optical end stops 1st, proper bed next.

Regards

Jan P. -

@snoozer said in Core-XY based on Rat Rig V-Core and Duet 2 Ethernet:

The maximum height difference would come from the pitch of the lead screw over one notch of the belt.

Not even that. To get the bed level, simply slacken the grub screws on the pulleys and turn each individual screw. Once level, tighten the grub screws and that's it until you take the printer apart. Built correctly (and it's not difficult or expensive to do) there is no need for any flatness or level compensation - ever.

-

I have just put all parts for the print bed on my bench here. I can't remember what I have read re isolation now. Looking from top down what would be the best order of layers:

- Aluminium plate (bed)

- Heater

- Glass fiber reinforced aluminium foil

- mineral wool

- Cork

- Mechanical layer to keep it all in place.

I am not clear about the aluminium, would that be 1st after the heater or last before the mechanical layer ? I would use the original old RatRig print bed as mechanical layer to close of the bottom I think.

Thanks

Jan P.PS: I would use the aluminium 1st after the heater to reflect heat back rather than absorb in the other materials. Just my logic which may be wrong ofc.

-

@snoozer said in Core-XY based on Rat Rig V-Core and Duet 2 Ethernet:

I would use the aluminium 1st after the heater to reflect heat back rather than absorb in the other materials. Just my logic which may be wrong ofc.

I concur with your logic. My bed is, from top to bottom:

PEX sheet.

Spring steel sheet.

Magnet sheet.

4mm aluminium bed.

Silicone heating pad.

Aluminium tape.

2mm cork sheet.With high temperature double sided adhesive between the various layers.

It heats up quickly and the temperature at bottom of the cork surface is less than half thar of the top of the spring steel sheet.

-

@snoozer said in Core-XY based on Rat Rig V-Core and Duet 2 Ethernet:

Re piezos, I am not using a E3D V6, I have a Titan Aero, my mount would be very different.

Ah... very different indeed.

I have a Mosquito hot end which has just arrived. Once I have printed various parts, I'll be replacing the E3D V6.

My reason for getting the Mosquito is the ease and simplicity of nozzle changes. It's just a one handed operation and can be done with the hot end cold.

Changing nozzles on a V6 is such a fraught process that I just don't want to do it. Sadly, there are many times when a different sized nozzle would be much more appropriate than a generic 0.4mm one and I was getting to the point of contemplating building a quick change carriage and have three of four complete assemblies to swap in and out. A crazy expensive solution just to work around the horrors of wielding an adjustable wrench in one hand, a spanner in the other and trying to avoid serious burns, a cracked heat break, damaged sensor wires and a host of other traps!

Maybe this is E3D's master plan? We all need to buy five hot ends so we can swap nozzles easily!

-

@grizewald , yes, quick change hotend was on my list as well but its for now way to complex to get done nice with 3d printed parts. If I ever get a little milling machine maybe but not for now. I agree re the Mosquito, the nozzle is only one aspect, the mechanical build just seems much better quality and I am totally off the titan extruder, BMG M and Mosquito is my next bigger plan (Probably for the linear rail RatRig coming in December)

Anyway, I have finally my nice and heavy (maybe to heavy) aluminium bed mounted. I am still running on 2 steppers and it does work quiet OK but I had to increase the motor current to 2A and cant let it drop below 50% in idle to maintain position reliable. The glass plates are a dream to work with, SO easy to have a few of them, let cool down, print off, clean and ready to go while the next print is already on the way. I do have to tweak a few things by the looks of it. In compare to the Prusa PEI plate the lines of filament don't seen to blend into each other that well. I am at the very beginning now on glass, so I am sure I get there. Mesh bed levelling is MUCH better now, the piezo seems to respond very well to the hard glass on the solid mounted aluminium plate, much better than the spring loaded thin old bed with the Prusa surface. With the weight of this bed now I really need to have the lead screws linked. The bed drops when I switch of the printer and its does not drop quiet equal on both sides. For now I have a mechanical support where I drive the bed to before I power down so it rests on that instead of uncontrolled dropping.

I have done a few more iterations of a new hotend mount for piezo use. Also includes the Andromeda piezo in one of the designs but all of them have in common that they dont react to gradual pressure application. Sudden pressure yes but not if I drive Z to slow. I am not sure yet how to overcome that.

So the next on the list is:

- 3rd lead screw RatRig upgrade

- Belt drive for Z axix

- Improvements to bed insulation and glass hold down clamps

- learn printing on glass

Have Fun !

Jan P. -

I have that RatRig upgrade ordered along with longer lead screws and bearings, 3GT pulleys, idlers etc..... Have to find thrust bearings now and closed loop belts of suitable length.

Also just noticed as a very nice side effect of having a 230V AC bed heater now I can use a fanless 24V PSU. But I have to find a way to attach as thermistor to the glass surface. It does take a lot of time for the heat to come trhough the 10mm aluminium plate and the 5mm glass. Maybe just a "puck" style thing with the termistor embedded that I wire up to another termistor input to wait till its warm enough before starting the print. Was considering a small embedded termistor in the aluminium plate but that would still be way off.

Jan

-

My bed is only 4mm thick, but on top of that I now have a Wham Bam flexible build system, so the magnet layer and the spring steel sheet do tend to add a little delay before the top of the print bed stack gets to the same temperature as the thermistor embedded in the heating mat. It's not really a problem though as I pre-heat before doing my initial Z probing, so by the time I actually print, the surface isn't far behind. I'm certainly not getting any adhesion problems and like your solution, if I'm impatient to start the next print, I can simply swap spring steel sheets and get printing again with the minimum of delay.

I don't know how you can best deal with your bed assembly. The one disadvantage of glass is that it's a terrible conductor of heat, but I fear that if you put your thermistor on the glass that it might make it hard for the firmware to maintain good temperature control when the delay between applying heat and the thermistor registering it is so long.

A piezo sensor is never going to react properly to a slow increase in pressure as it won't generate a spike of electricity from the sudden compression that it gets when the bed is driven at a decent speed. If you increase the sensitivity until even a slow press will trigger it, you'll just end up getting false positives from even things like talking or the noise from the steppers as they drive the bed up. I probe at 6mm/s, which isn't exactly fast, but it's reliable every time. If you can't drive the bed fast enough because it's so heavy, then it sounds like you need NEMA 23 steppers for the bed and a Duet 3 to be able to drive them with enough current.

When I used to print on glass, it was very good for most types of filament. The only thing I didn't enjoy was having to spray the glass regularly with some kind of adhesive. It's important to do that away from the printer or otherwise the adhesive gets onto the lead screws and into the electronics. Not good for either!

I've been using fanless supplies on my V-Core from the start. One 480W 24V unit just to drive the bed heater and a smaller 120W 24V unit to drive the rest of the printer. As I've recently added another stepper, the Duex 5 board and a 50W hot end heater, I decided to upgrade my smaller supply to a 240W 24V unit. That arrived today and the great thing about having the supplies mounted on a DIN rail was that it took me all of two minutes to swap the 120W supply for the new one. That really confirmed to me that it was a good idea to mount them that way.

I'm still working with the Mosquito. My first mount (which has the Orion sensor on top) wasn't holding the Mosquito as well as it should, so I had to use my other printer to make a new one which makes use of the same mounting pattern as the one used on the BMG-M. The other problem is that it would print fine for the first 20 or so layers, but then it would jam due to heat creep in the heat break. The last one was with PLA and was such a bad jam that I had to dismantle the entire hot end so that I could put the block and heat break in the oven to cook out the PLA which had bonded to the walls of the heat break.

After that, I needed to polish the inside of the heat break to bring it to a mirror finish with very low friction. The problem seems to be due to the puny 25mm fan which they supply for cooling the heat break. I have no idea how they came up with the suggestion of running the fan at 70% as even when I'd put it back to 100%, it still resulted in my final PLA jam after just 40 layers.

Consequently, I've printed an adapter so that I can use an E3D 30mm fan instead. Once the boron nitride paste has fully set this evening, I'll be putting it all back together and testing again.

-

@snoozer said in Core-XY based on Rat Rig V-Core and Duet 2 Ethernet:

Sudden pressure yes but not if I drive Z to slow. I am not sure yet how to overcome that.

That's part and parcel of the piezo system. The trigger needs to be sharp and distinct. Going to slow and it can fail to register.

The best way to combat the bed dropping at power down is to use lead screws with a finer pitch thread.

-

Thanks @Phaedrux and @grizewald for your comments. Re z drive, I will use a single NEMA 23. I have received the V-Core 3 screw upgrade. They originally use it with 3 NEMA 17 and also suggest to drive them independent for bed levelling. I have decided against that. I have received my trust bearings now as well and have started to make up bearing blocks that mount instead of the steppers on the metal mounts. See pic.

So the lead screw goes through the bottom of that prototype black block, next radial bearing and on top of the outer ring rests the thrust bearing which again takes the load from the clamp on belt pulley. So I will have two on the forward side and one centered in the back. All three lead screws then joined by a loop belt plus one idler for tensioning.. I am not yet sure if a triangular belt drive has enough engagement on the teeth of they pulleys, if not I have to add a few idlers that wrap the belt around the pulleys more for better engagement of teeth. I intend to drive the rear single lead screw from a top mounted NEMA 23 or if that is not practical use a very short belt loop to drive the lead screw from a separate pulley and the motor in the base of the printer, not yet sure which I do. When I bought the pulleys I assumed its easy to get 3mm pitch belt but turns out that is not really the case, I have to make a mock up 1st now to see what length I need. Also forgot to order the NEMA 23 and motor mount (silly me).

Re piezo, guess that was kind of clear just I did not cop on to that, it needs a sharp impulse. Now with the glass bed it has never missed. Works very reliable now and wile bed levelling never probes on point more than 2 times, before it could take 4-6 times cause of the flexing nature of the flimsy light aluminium bed with the spring steel sheet. So for now I am all happy with the precision of the piezo. I will try again the other hotend mount with the build in Andromeda piezo.

Oh that sounds bad with the Mosquito, are you working in hot environment ? What you write re cooling issues would suggest issues will come up in an enclosed printer. I would not mind a 40 or 50mm fan as long as they can run silent. Or even a blower could them be a compacter, less noisy option. For an enclosed printer it may even make sense to have some sort of light weight duct with external fan to get cool air from outside the enclosure. Just thinking out loud, not there yet. The Linear Rail version will get the BMG M and Mosquito.

Have Fun.

JanPS: Re the termistor on top, that would not to control the heater but to delay the print start till the heat has gone through the materials. I find some way to implement that in the "Start G-code" section of the Slicer. IDK yet how I best implement that practically with a pocket cut in glass or whet ever, I probably have to experiment a bit.

My 2 NEMA 17 can drive Z WELL fast enough to trigger the z-probe. I just don't want to have huge inertia behind it with high speed if I can avoid it and go slower.

-

@grizewald, about the glue spray. I always apply that in the shower. I usually wash the glass in the kitchen sink with hot water and dry it. Then apply the glue in the shower to prevent glue mist on all the surroundings. The fact float glass is super cheap and can be got in any size combined with the ease of printing so far I don't think I go back to anything else to be honest. Have not yet tried ABS and PA. I did PC, PLA, PETG. Carbon filled XT-CF20 all work great.

Sorry I keep going on about this glass printing, I don't even bother sometime to wash the surface. I can see exactly where I printed before and just position the next part different in the Slicer, it is really so easy. For fun I just print one of my bearing blocks in ABS to give that a shot. I don't want to open my PA just now cause I have no dry box and its wet season here now......

Jan P.

-

I'm looking forward to see how you finally implement your Z belt drive, it sounds like it will be ultra stable!

I found out the major cause of my problems with the Mosquito. Even though I'd bought the filament I was using to test from a respected manufacturer who boasts "the smallest variance in the industry" for their filament diameter, I discovered that the new spools that I'd bought were anything but accurately manufactured!

I discovered the problem when I was going to change filament. I asked the printer to unload the filament and when it started to retract the filament from the hot end, the extruder motor started skipping. My initial thought was that I'd got another jam with the filament bonded to the heat break, but when I removed the feed tube and pulled the filament up by hand, there was no resistance at all. It was when I then attempted to pull the filament back through the feed tube to the spool I discovered that it was almost completely jammed inside the tube. The feed tubes that I use from my dry box to the printer are standard 2mm internal diameter PTFE tubes. For it to jam in those means a significant size error.

When I'd finally extracted the filament and got my calipers to it, it turned out that parts of the filament were 1.75mm in one direction and more than 1.9mm in the other! Needless to say, I'm having a conversation with the filament manufacturer.Having removed the out of tolerance filament from the equation, I'm now finding the Mosquito to be a rather exceptional hot end. I would never have imagined only needing 0.4mm of retraction to print PLA and even PETG with no oozing! The filament path through the entire hot end is very tightly constrained, much more so than in an E3D V6, even with Capricorn tubing. This leads to exceptional feed and retract accuracy, but also means that even slightly out of spec filament has the possibility to jam the hot end solid, as it did to cause the jam I mentioned earlier which forced me to dismantle the hot end to clear it.

I think what's needed is a laser filament diameter monitor to stop out of spec filament getting as far as the hot end!

-

@grizewald said in Core-XY based on Rat Rig V-Core and Duet 2 Ethernet:

I think what's needed is a laser filament diameter monitor to stop out of spec filament getting as far as the hot end!

or a 1.76mm hole in something that wont wear too quickly before the hotend.

-

@T3P3Tony That's an interesting idea! Maybe a small block of PTFE with a 1.76mm hole somewhere in the feed to the extruder, coupled to a spring loaded lever and microswitch.

When oversized filament tries to make it through the size check, it would cause the block to move on its lever and trigger the microswitch which could be connected to an end stop input.

I can think of a few ways to design the mechanism. Next time I take the hot end apart, I'll make an accurate measurement of the inside diameter of the heat break and see what the limit actually is.

Certainly, something to prevent out of spec filament getting as far as the hot end would save considerable frustration in the future.

-

@grizewald .....or how about a thin but hard metal plate just before the hot end with a hole that has a very sharp edge, so that if the filament is slightly over sized, it would "shave" a bit off ?

-

@deckingman @grizewald I love the two engineering approaches here, one to pause and alert the user, the other to fix it as its going!

-

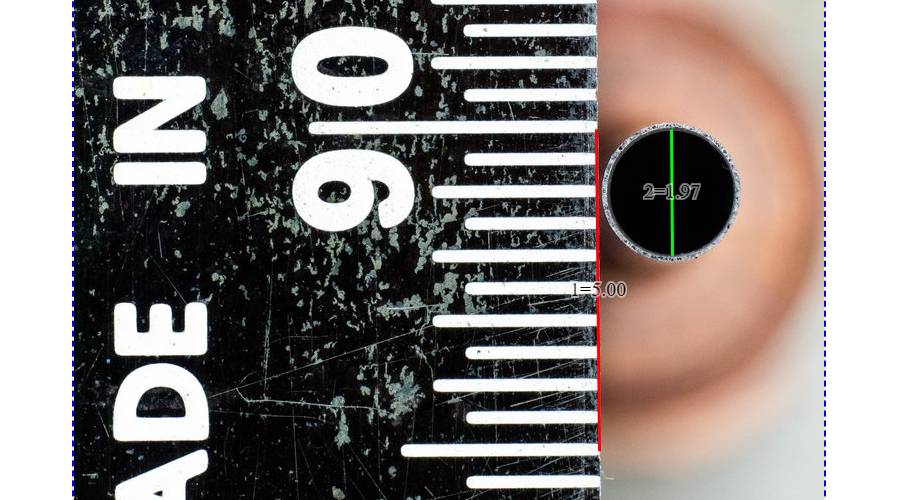

@grizewald I checked the STEP file from the Mosquito documentation and it measured at 1,95 mm

I also measured it from a picture where it is 1,97 mm (see below). Ignore the IN, it just says MADE IN U.S.A., scale is in mm

-

@deckingman That could work, but I have my doubts about being able to create a sharp enough edge on a piece of stainless steel tubing and the ability of my extruder to exert enough force to shave PLA filament without skipping.

I just tried shaving some PLA with a fresh scalpel blade and the hardness of the filament was a significant obstacle.

-

@OBELIKS Thanks for the measurement. I guess my filament must have been really out of spec!