@OwenD Thank you so much! That's what I needed!

Posts made by webdes03

-

RE: [Solved] What filament is loaded?posted in Gcode meta commands

-

[Solved] What filament is loaded?posted in Gcode meta commands

After power cycling, DWC remembers what filament is loaded in a tool, however I cannot find anywhere in the object model where that loaded filament is referenced?

Today, I use the filament loading macros to set a global variable of the filament name, but it doesn't work after a power cycle without unloading and reloading the filament. I must be missing something because I can't find a command or anywhere in the object model that says what the currently loaded filament is.

-

RE: Is DuetPrintFarm still in development?posted in Duet Web Control

@T3P3Tony I did look through the code. Unfortunately, .NET is where I'm least proficient... I can somewhat interpret what's going on, but I'd probably need to do it in React/TS/Node if I was going to be remotely productive. If I do something I'll open source it though so maybe I can try and fill that void if you guys aren't sure if you'll further mature the existing solution. I can't imagine the demand is that high--I actually wanted it less for full blown farm management and more for queuing for a single printer.

-

RE: Is DuetPrintFarm still in development?posted in Duet Web Control

@T3P3Tony Thanks for following up. I may work on my own solution, and will share if it comes to anything!

-

Is DuetPrintFarm still in development?posted in Duet Web Control

I'm not sure if this is the right section to raise this, but is the DuetPrintFarm (https://github.com/Duet3D/DuetPrintFarm) project still in active development? I set out this morning to start whipping up something to queue prints, and then came across this in the Duet3D Github, but it looks like the last update was a couple years ago so I'm not sure if anyone is still working on it. @dc42 @chrishamm @T3P3Tony

If it's still being worked on, and there's a feature request list somewhere, it'd be great to get a Docker image option for deployment, instead of having to download and run manually.

-

RE: Is duet the right option for laser cutterposted in Laser Cutters

I'm currently building a CNC using a Duet3 and most of what you describe is already available. I've got air/mist cooling, vacuum, etc all setup via the onboard IO, so all of your cooling, air, extraction, etc is absolutely doable today just by wiring it up and putting together the right gcode and/or macros.

VFD/Laser is also supported via a dedicated PWM port specifically for that use. Where you'll potentially fall short is more in the UI since the DWC UI is very much designed for 3D printing, there's the Ooznest "theme" for DWC that gives more/better UI for CNC purposes, so you can certainly try that.

Duet seems to be pretty committed to advancing these boards both from an IO and firmware perspective. I'm positive you can make everything work today, and the support and feature set will only improve over time if their past performance and attitude is an indicator of what's to come.

-

RE: Duet 3 cnc, how to start? Make stepper motor turn?posted in CNC

@Tsolsi A gross oversimplification, but idle current is needed to prevent the motor from moving due to outside forces when not commanded to move. If you tell your machine to move to 100,100, it should move and hold 100,100 and you shouldn't be able to move it by hand once it's there.

-

RE: Building a 600x600 MPCNC: Good settings to start with?posted in CNC

@dgrat the CNC build I’m working on now is based on a Duet3. Pretty excited to start making chips!

-

RE: Building a 600x600 MPCNC: Good settings to start with?posted in CNC

I built a MPCNC last year and am currently building an OpenBuilds machine to replace it. The MPCNC is great if you just want to cut soft wood or acrylic, or if you're just looking to learn the basics. The only way you're cutting anything harder than that is to build a very short machine, which makes it almost unusable (think Z capacity of 3-4cm), and even then the machine design is way too flexible for anything very hard. Unless your use case specifically matches the capabilities of the MPCNC then you'll probably quickly outgrow it. I struggled to mill any sort of hardwood without using painfully slow speeds.

-

RE: Fan Outputs for 24V Relays?posted in CNC

@bonjipoo, I did. I'm just using a 24V Solenoid air valve (specifically this one: https://amzn.to/35cxang). It's connected to out9 and defined as P3...

M950 P3 C"out9" ; define P3 as misterThen simply create M7.g and M9.g to turn it on and off...

M7:

M42 P3 S1 ; enable mister

G4 P2000 ; wait for 2 secondsThe 2 second wait just ensures that there's active mist/air before the machine moves on.

M9:

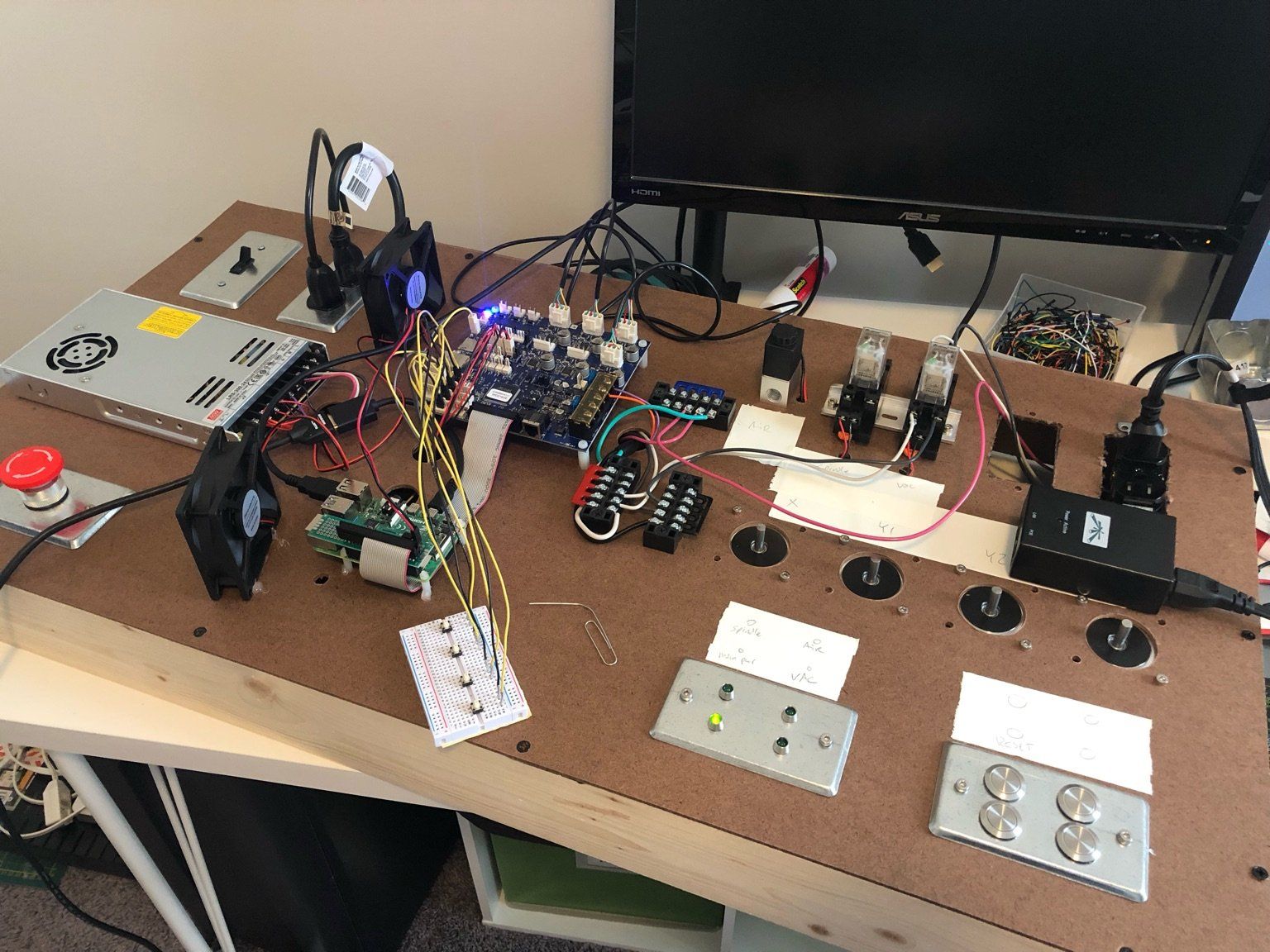

M42 P3 S0 ; disable misterIt should be noted that I haven't actually built my machine yet, but I've mocked up all of the electronics and relays on a test bench to prove out my design, and the mister does work (at least in a test setting).

-

RE: Get Output Pin States for Conditional GCodeposted in Gcode meta commands

Ahh awesome, thanks guys!

-

RE: Get Output Pin States for Conditional GCodeposted in Gcode meta commands

Just in case the full dump helps diagnose anything:

I am running RC7 if that makes a difference.

-

RE: Get Output Pin States for Conditional GCodeposted in Gcode meta commands

And by "I only see inputs", I mean endstops...

{ "key": "sensors", "flags": "v", "result": { "analog": [], "endstops": [ { "triggered": false, "type": "inputPin" }, { "triggered": false, "type": "inputPin" }, { "triggered": false, "type": "inputPin" }, { "triggered": false, "type": "inputPin" } ], "filamentMonitors": [], "inputs": [], "probes": [ { "calibrationTemperature": 25.0, "deployedByUser": false, "disablesHeaters": false, "diveHeight": 5.0, "maxProbeCount": 1, "offsets": [ 0, 0 ], "recoveryTime": 0, "speed": 2.0, "temperatureCoefficient": 0, "threshold": 500, "tolerance": 0.030, "travelSpeed": 100.0, "triggerHeight": 0.700, "type": 0, "value": [ 1000 ] } ] } } -

RE: Get Output Pin States for Conditional GCodeposted in Gcode meta commands

Hmmm... let me poke around. I only see inputs, not outputs... but maybe it's staring me in the face and it's just not "clicking".

-

Get Output Pin States for Conditional GCodeposted in Gcode meta commands

I have relays connected to "out8" and "out9" on my Duet 3, for the purpose of powering a mister and vacuum.

;Set up vacuum and misting outputs M950 P2 C"out8" ; define P2 as vacuum M950 P3 C"out9" ; define P3 as misterEverything works correctly, and I added M7/9/10/11.gfiles to enable those functions):

# M7.g M42 P3 S1 ; enable mister G4 P2000 ; wait for 2 seconds # M9.g M42 P3 S0 ; disable mister G4 P2000 ; wait for 2 secondsNow, I'm trying to create macros to toggle the mister and vacuum on and off, but I can't figure out how to read the outputs to determine if they're on or not so I can do the appropriate action of the toggle (turn it on of it's off, or off if it's on).

Presumably I can do something like the following, I just can't seem to master the right solution to make it work:

# ToggleMister.g if P3 EQ 0 M7 else M9 -

RE: M7/M9/M10/M11 Implementation (Coolant and Vacuum) [CNC]posted in Firmware wishlist

@T3P3Tony Works exactly as you described, thanks!

-

RE: M7/M9/M10/M11 Implementation (Coolant and Vacuum) [CNC]posted in Firmware wishlist

@T3P3Tony Whaaaaaat! I guess we can close this request then

-

M7/M9/M10/M11 Implementation (Coolant and Vacuum) [CNC]posted in Firmware wishlist

It'd be fantastic to see M7/9 for Coolant and M10/11 for Vacuum implemented, even if they simply executed a macro, simply so that the native output from a post processor could control vacuum and coolant.

-

Fan Outputs for 24V Relays?posted in CNC

Hey everyone, I'm brand new to the Duet ecosystem and RepRap, but experienced in the world of 3D printers and home CNC's (Marlin-based).

I'm in the process of designing and building a new CNC machine using a Duet 3 and I have some questions surrounding relays.

I've successfully connected and configured hardware E-stop and reset buttons, and am currently working on external events/triggers to control relays for vacuum, spindle on/off and misting, but I'm not super clear on where to connect those relays. I bought 24V relays, expecting to set the the jumper for Out 7-9 to "V_FUSED" (I'm using a 24V power supply). I believe this is correct, but wanted to validate before wiring anything up.

For context, the spindle and vacuum, relays are 24V relays to switch mains (110) power to standard outlets to enable the router and vacuum. The air/mister is a 24V (200mA draw) solenoid-controlled valve that connects to a shop air supply.

Being new to RepRap, I'm also a little lost on how to define those pins for these functions, ie Spindle for Out 7, Vacuum for Out 8 and Air/Mister for Out 9, as I intend to connect hardware buttons as triggers to enable these outputs in addition to/in lieu of GCode. Do these simply get defined as fans from the controllers perspective?

Any help or guidance is appreciated. The forum and documentation has been great so far, I just want to sanity check myself to make sure I don't burn up my new $200 controller.