@pcr NC, US.

Posts made by warbunnies

-

RE: Vivedino Troodon Control Board questionposted in Other control boards

@dc42 Thanks! I'll read more into that but it certainly does look like it. Would explain why the low voltage is getting no power.

-

RE: Vivedino Troodon Control Board questionposted in Other control boards

I'm definitely going through the process of getting a new board from them BUT the main issue there is international shipping, there are crazy delays right now. I'm asking if they can do any sorta overnight shipping but my guess it that it will probably take a while and running the prototyping shop on one printer is going to be rough.

-

Vivedino Troodon Control Board questionposted in Other control boards

Never rush things right? Sigh... Well I rushed things and mixed up the wires going to a new extruder I was installing on a troodon. When I turned it on after installing the extruder, it did not turn on. I'm only getting the blue vin light on the control board.

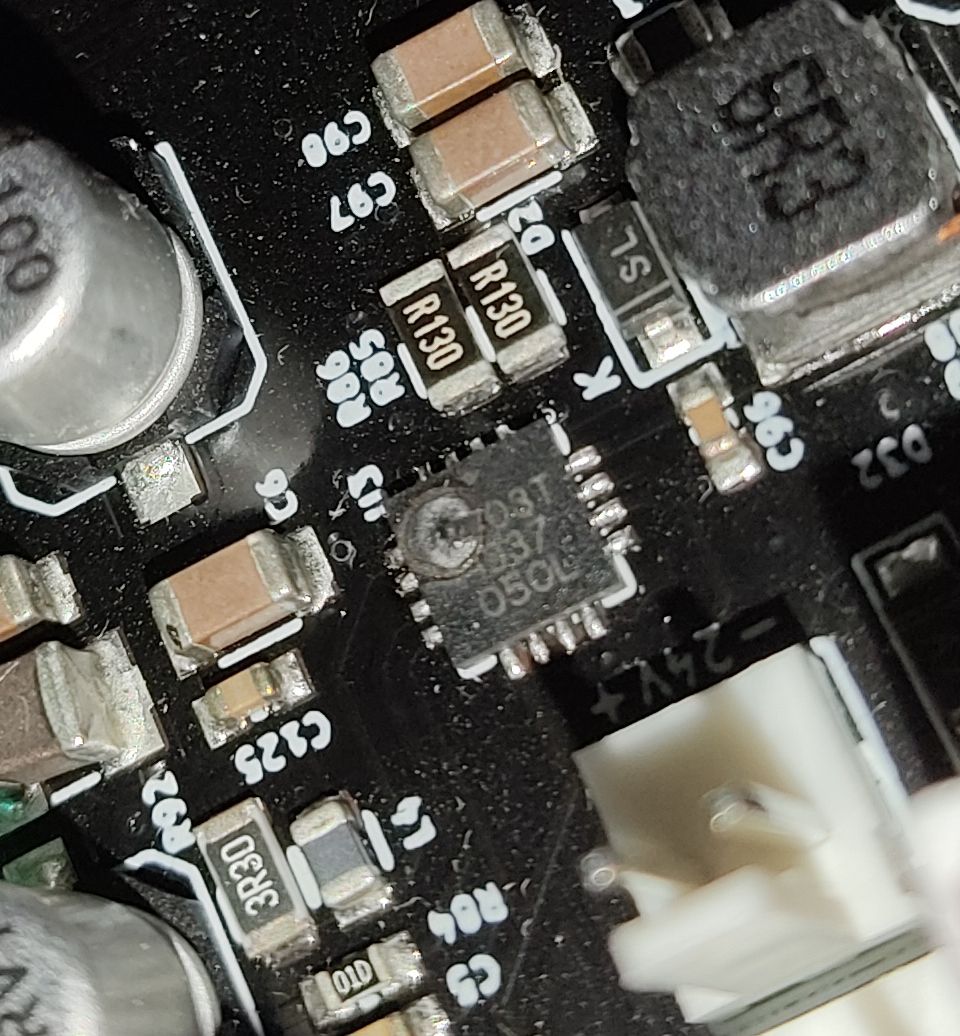

I tried replacing the fuses, nothing changed. And I've moved on to looking for damage on the board. The only thing I can find is this one chip looked burnt/melted, I cleaned it off with alcohol to read the numbers but I cannot seem to find it through google.

The numbers I can read are:

03T

1937

050L

Does anyone know what this is & do you think replacing it might fix the issue? I'm gonna order another board but with global shipping in the toilet... I was kinda hoping to try some fixes in the mean time.

-

RE: Second Layer Off & Offsets Questionposted in Tuning and tweaking

@Veti okay the ssh instructions seem clear enough. i should be fine pulling that off.

-

RE: Second Layer Off & Offsets Questionposted in Tuning and tweaking

@Veti honestly cause that seemed like it was the suggested way of doing it... the instructions as i understood them made standalone sound like a dated alternative.

-

RE: Second Layer Off & Offsets Questionposted in Tuning and tweaking

@Veti Will do.... as soon as i figure out how. I've never actually used a pi before and I don't really understand how to send the "sudo apt update

sudo apt upgrade" commands. is there a way to initiate that from the duet ui or do i have to find a way to plug in the pi to a screen and keyboard? -

RE: Second Layer Off & Offsets Questionposted in Tuning and tweaking

@Veti I'll look into the thermistors... they are performing great though and not really an issue... if i was printing anything but pla on this machine for work it'd probably be more critical.

the firmware is: RepRapFirmware for Duet 3 MB6HC 3.01-RC9 (2020-04-21b1)

-

RE: Second Layer Off & Offsets Questionposted in Tuning and tweaking

thanks... hows that work? do i upload the file then put it in like this: "<download link>" or do i copy past the text in "<text>"?

-

Second Layer Off & Offsets Questionposted in Tuning and tweaking

So I've had a few interesting troubles getting my idex going with the duet 3.

The first is that my offsets only seem to allow for a negative offset and not a positive one. No error happens when I start a print with a positive offset on an axis, but it pretends like they don't exist. I've managed to make it work but it is a bit of a pain and I wonder why that would be?

The second problem is that my second layer height is printing too high above the print bed. I kind of wonder if it is related to my babystepping or if it is related to my z offset.

The third problem is that if I pause and then restart a print, the z height seems to change. not by a lot... probably less than .5mm but it definitely does change. and happens every time I pause then start the print again on the first layer.

-

RE: Second layer jumpposted in Tuning and tweaking

I'm having this same issue with my printer. The second layer is definitely printing well above were it is suppose to.

-

RE: IP address works but duet3.local/ doesn't?posted in Firmware installation

@bearer

Looks like I got some reading to do.

-

RE: IP address works but duet3.local/ doesn't?posted in Firmware installation

@Veti thank you! i will admit that network stuff is not my area.

@bearer thank you! those 2 suggestions did not produce results but hopefully that is enough information to get our IT guy on the right track.

-

IP address works but duet3.local/ doesn't?posted in Firmware installation

I have a duet 3 with a pi4 hooked up. Just got it. The only thing I have done so far is change the wpa_supplicant file to match networks being used.

Everything worked perfectly on my home network, then I took it in to work and ran into problems. I thought it wasn't working period but we got our IT guy involved and apparently it did connect after like 4 minutes but you could only connect with the ip address and the duet3.local/ did not work. It would be nicer if it did.

I'm curious if anyone has any ideas on why this would happen?

-

RE: Ceramic hotend...?posted in General Discussion

they are a full metal. the ptfe stops up in the cold end. the nozzle & heatblock are separate. the ceramic heater encloses a metal core that threads into the heatbreak & the nozzle threads into the metal core.

-

RE: Ceramic hotend...?posted in General Discussion

Nope I'm talking about these: https://www.deltaprintr.com/product/mini-hotend/

they even have a damn picture labled "micro nozzles coming soon" bunch of lies.

-

RE: Ceramic hotend...?posted in General Discussion

Okay ya that is a fair point. they are more delicate, proper wire constraint is a MUST. It could be offset by a good supplier. The heater itself isn't that expensive to make. Along with a good design of the metal parts. The nozzles need to be easier to remove & the temp sensor should be close to but not in the nozzle. Combine a decent design with that heater & you got a winning hotend.

-

RE: Ceramic hotend...?posted in General Discussion

I will let the world know! Good lord I want them to catch on. I'm probably gonna try making my own at some point. It is just nichrome & a non conductive, high heat material after all...

Alibaba seems to be the only place which kinda sucks cause i cannot buy bulk at the volume they want to make me custom parts.

-

RE: Ceramic hotend...?posted in General Discussion

Just to clear up any misunderstanding about how well these things heat. The ceramic hotends heat up much faster than e3d hotends. Usually pass 200 after 30 seconds with the deltaprintr one. Though I wouldnt suggest using their mini hotend. Originally they said they would be coming up with different nozzle sizes & 3 years later, nothing. emailed them last year and they pretended not to know anything about it & had no plans to do it. But it was a very very good hotend for the period of time i used it. The heater is so strong that it seems to react much faster to changes than the normal heating method.

I've been trying to find a good source of ceramic heaters myself and hopefully they will catch on. The fast heating/ cooling time is great for tool changing.

-

RE: Pt1000 Helpposted in Duet Hardware and wiring

ah... that would have been my mistake. I thought I had a later fw than I did. that seems to have fixed it.