@testpro

100mm_Rounded_Cube.gcode BB.gcode

Sorry this is the latest and best print file i have at this time. the one above is an older version of this file.

@testpro

100mm_Rounded_Cube.gcode BB.gcode

Sorry this is the latest and best print file i have at this time. the one above is an older version of this file.

@phaedrux

100mm_Rounded_Cube.gcode 1_MAKE_Robot_V6.gcode

ok i have gave you the gcode for the Cube which printed very well and then the make robot which is not printing so well at this time.

at this point the objects are now printing in the center of the bed. so that is cleared up for now.

i have found the reason why the Z axis was bit incrementing. in the slicer Prusa 2.3.3 under print settings. Custom G code i had the following:

G28 ;home all axes

G29 S1 ;allows bed compensation

G1 Z5 F5000 ; lift nozzle

this would not let the Z axes increment while printing but i changed it to this :

G28 ;home all axes

G1 Z5 F5000 ; lift nozzle

G29 S1 ;allows bed compensation

and it now works just fine. why is this an issue? or did i just stumble on to a bug?

@testpro

after doing the manual bed leveling several times my height map is -0.22 to 0.021.

so pretty even at this point.

the file format is not allowed. and no more offsets for the tools at this time.

still can not figure out why z will not increment with the bed compensation working.

ok first test print incremented as it should while printing the first layer and fine tuning it.

once i confirmed the Z was incrementing for the steps of adjustments and for the second layer. i did another test print but this time i added in the bed compensation and now it will not let the Z axis increment and will not increment on second layer either.

[0_1629147063561_100mm_Rounded_Cube.3mf](Uploading 100%)

ok at this point i have cleaned out all the slicer files from the last month of trying to get this to work.

I also took out the slicer completely from my machine and reinstalled a new fresh copy of the Prusa slicer 2.3.3.

i did mover the origin back to the front front left corner in the slicer as well. so this is where it homes for now. i would like it to home in the center but this is not practical at this time.

now i have ran through the slicer again with the factory settings and put the basic information in and now the Z works pushing the nozzle closer or away with the touch screen baby steps. Plus the printer now increments for the layers where before it did not.

what part of the slicer settings you need to see?

@fcwilt

yes it does and that is done my end. except my Y = 200. and the print never comes out in the center of the bed at all. if i have this way as you have it shown it will print front left hand side and if i move the item to the far back right and then slice it still comes up front to the right but not as far. but if i move the item to far back right in slicer it is off the bed in slicer and will not slice.

so at this time i have the origin set to x=0 y=0 just so i can get it on the board. still not right at this point.

@phaedrux

ok yes a little more detail on my part would help.

I don't understand what you mean here.

1A) in the Prusa slicer i have set the origin of E0 to X= 150 Y= 100, this will put the Print dead center of the of build plate. but when it prints there is only a fraction of the Print Cube on the front left corner of the print bed.

I don't understand what you mean with this either.

2A) This is stating when i print the print is in the front left of the print bed in reality but in Prusa slicer it is dead center of the build plate.

@testpro

Yes i defiantly have something wrong with the set up of the Duet board in software or in the slicer Prusa.

i went over the slicer setting and basically have the bare minimum setting i think, the slicer is set to 15 x, 100y for the center of the bed and the machine homes close to it 170 x, 85 y.

i set this cube up for printing dead center of the board but when it runs it the back right corner around y= -80 & x= -100 to -150. which it the front left corner of the board. wired.

@phaedrux

I put those in when we first set up the new hot ends. I have only adjusted E0 because that is the only one we are using at present.

on the other question yes it will move up manually while printing using baby steps on touch screen 0.02 or on Net 0.5.

when i home it will lower the bed and when x & Y are done, the bed raises and stops like it should.

Could this have something in my slicer settings doing this?

@phaedrux

ok i had to reprint the bottom hot end piece due to the fact the one my boss printed actual broke because it was printed wrong.

so i printed a new one with my resin 3d printer and it worked good and now have it installed. the height map is much more even now and the first layer prints great now. the more robust lower hot end helps alot.

now it seems the Z axis will not increment as it prints for some reason. the Z axis stays at 3.96 the whole time printing. i have not idea what i have done but that is what i got. any ideas on this one?

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Tue Jul 06 2021 10:19:08 GMT-0400 (Eastern Daylight Time)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Big Box 1" ; set printer name

; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M569 P4 S1 ; physical drive 4 goes backwards

M584 X0 Y1 Z2 E3:4 ; set drive mapping

M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

M92 X160.47 Y361.26 Z1599.10 E179.0:291.30 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z300.00 E1200.00:1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z60.00 E250.00:250.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E1200:1200 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S120 ; Set idle timeout

; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X280 Y180 Z300 S0 ; set axis maxima

; Endstops

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z2 S1 ; configure Z-probe endstop for high end on Z

; Z-Probe

;M558 P1 C"zprobe.in+zprobe.mod" H5 F120 T6000 ; set Z probe type to unmodulated and the dive height + speeds

;G31 P500 X-16.1 Y26 Z0.297 ; set Z probe trigger value, offset and trigger height

;M557 X16.1:300 Y5:174 P20 ; define mesh grid

M558 P5 C"e0stop" H5 F120 T3000 ; Z probe connected to E0 endstop input

;M558 H30 ;*** Remove this line after delta calibration has been done and new delta parameters have been saved

G31 P500 X16.1 Y26 Z1.600 ; set Z probe trigger value, offset and trigger height

M557 X10:250 Y10:200 S40 ; define mesh grid

; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S285 ; set temperature limit for heater 1 to 285C

M308 S2 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin e1temp

M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S285 ; set temperature limit for heater 2 to 285C

; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H1:2 T45 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1:2 T45 ; set fan 1 value. Thermostatic control is turned on

M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency

M106 P2 S1 H1:2 T10 ; set fan 2 value. Thermostatic control is turned on

; Tools

M563 P0 S"Ron 0" D0 H1 F0 ; define tool 0

G10 P0 X-16.1 Y26 Z5 ; set tool 0 axis offsets

G10 P0 R160 S220 ; set initial tool 0 active temp 220 and standby temperatures to 160C

M563 P4 S"Ron 1" D1 H2 F0 ; define tool 1

G10 P4 X16.1 Y26 Z5 ; set tool 0 axis offsets

G10 P4 R160 S220 ; set initial tool 0 active temp 220 and standby temperatures to 160C

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

; homeall.g

; called to home all axes

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Tue Jul 06 2021 10:19:08 GMT-0400 (Eastern Daylight Time)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 X-235 Y-215 F1800 ; move quickly to X or Y endstop and stop there (first pass)

G1 H1 X-235 ; home X axis

G1 H1 Y-215 ; home Y axis

G1 X5 Y5 F6000 ; go back a few mm

G1 H1 X-235 F360 ; move slowly to X axis endstop once more (second pass)

G1 H1 Y-215 ; then move slowly to Y axis endstop

G90 ; absolute positioning

G1 X10 Y10 F6000 ; go to first bed probe point and home Z

G30 ; home Z by probing the bed

; Uncomment the following lines to lift Z after probing

;G91 ; relative positioning

;G1 Z5 F100 ; lift Z relative to current position

;G90 ; absolute positioning

; homex.g

; called to home the X axis

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Tue Jul 06 2021 10:19:08 GMT-0400 (Eastern Daylight Time)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 X-305 F1800 ; move quickly to X axis endstop and stop there (first pass)

G1 X5 F6000 ; go back a few mm removed H2 at beginning

G1 H1 X-305 F360 ; move slowly to X axis endstop once more (second pass)

G1 H2 Z-5 F6000 ; lower Z again

G90 ; absolute positioning

; homey.g

; called to home the Y axis

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Tue Jul 06 2021 10:19:08 GMT-0400 (Eastern Daylight Time)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G1 H1 Y-205 F1800 ; move quickly to Y axis endstop and stop there (first pass)

G1 Y5 F6000 ; go back a few mm removed from front H2

G1 H1 Y-205 F360 ; move slowly to Y axis endstop once more (second pass)

G1 H2 Z-5 F6000 ; lower Z again

G90 ; absolute positioning

; homez.g

; called to home the Z axis

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Tue Jul 06 2021 10:19:08 GMT-0400 (Eastern Daylight Time)

G91 ; relative positioning

G1 H2 Z5 F6000 ; lift Z relative to current position

G90 ; absolute positioning

G1 X10 Y10 F6000 ; go to first probe point

G30 ; home Z by probing the bed

; Uncomment the following lines to lift Z after probing

;G91 ; relative positioning

;G1 Z5 F100 ; lift Z relative to current position

;G90 ; absolute positioning

i just turned the machine on and homed all and it done just fine.

then i went to move screen and and hit +5 and the bed moved down.

on the height map i got a really low map using IR probe and a really high map using manual. so i am going to say it does not matter witch i use. or the Z axis operating backwards has something to do with it.?

@phaedrux

ok i have done the manual bed leveling. then i cycled power on the unit and everything seems to be good.

so then i redo the Z = 0 over again because i know it is off. My height map is way above the grid.

so i run down the codes and manually adjust the nozzle to the bed and then tell to lower 5 mm. then i put in G30 S-1 and bed moves down away from the nozzle but never goes up and the console states "The Z probe never triggered". so something is wrong somewhere.

anyideas? ```

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.2.3 on Tue Jul 06 2021 10:19:08 GMT-0400 (Eastern Daylight Time)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Big Box 1" ; set printer name

; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M569 P4 S1 ; physical drive 4 goes backwards

M584 X0 Y1 Z2 E3:4 ; set drive mapping

M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

M92 X160.47 Y361.26 Z1599.10 E185.0:291.30 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z300.00 E1200.00:1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z60.00 E250.00:250.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E1200:1200 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S120 ; Set idle timeout

; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X280 Y180 Z300 S0 ; set axis maxima

; Endstops

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z2 S1 ; configure Z-probe endstop for high end on Z

; Z-Probe

;M558 P1 C"zprobe.in+zprobe.mod" H5 F120 T6000 ; set Z probe type to unmodulated and the dive height + speeds

;G31 P500 X-16.1 Y26 Z0.297 ; set Z probe trigger value, offset and trigger height

;M557 X16.1:300 Y5:174 P20 ; define mesh grid

M558 P5 C"e0stop" H5 F120 T3000 ; Z probe connected to E0 endstop input

;M558 H30 ;*** Remove this line after delta calibration has been done and new delta parameters have been saved

G31 P500 X16.1 Y26 Z3.000

; set Z probe trigger value, offset and trigger height

M557 X10:250 Y10:200 S40 ; define mesh grid

; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S285 ; set temperature limit for heater 1 to 285C

M308 S2 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin e1temp

M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S285 ; set temperature limit for heater 2 to 285C

; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H1:2 T45 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1:2 T45 ; set fan 1 value. Thermostatic control is turned on

M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency

M106 P2 S1 H1:2 T10 ; set fan 2 value. Thermostatic control is turned on

; Tools

M563 P0 S"Ron 0" D0 H1 F0 ; define tool 0

G10 P0 X-16.1 Y26 Z5 ; set tool 0 axis offsets

G10 P0 R160 S220 ; set initial tool 0 active temp 220 and standby temperatures to 160C

M563 P4 S"Ron 1" D1 H2 F0 ; define tool 1

G10 P4 X16.1 Y26 Z5 ; set tool 0 axis offsets

G10 P4 R160 S220 ; set initial tool 0 active temp 220 and standby temperatures to 160C

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

ok done a manual bed leveling. but now how do i turn this off.

the thing will not home on z i have to adjust it.

@testpro

ok so i put the above code in one line at a time and the M557 will set the grid.

so when the extruder moves to a location it will let me know to lower the nozzle until it cripsa sheet of paper and then it ok or whatever it will state and it will move to next point and do it again?

if this what you are saying.

@phaedrux

yes i have done the paper on the top taped down and get the same result of a very lumpy height map. the sensor has been cleaned as well. Several times.

i am thinking this is so frustrating because it reads rights a few times then goes and does something else for readings. the reading are consistent only for 3 to 4 times thin it changes .

i would like not to put more money into this project but if the Z is not consistent, i do not have a choice.

the one with the blue cover is E0, E1 is not being used at this time and nozzle is removed.

the link you have is what i have been following this whole time calibrate the Z probe. i can not get a consistent result when repeating the read out. two or three times it reads one thing and then it just goes and comes back with something totally different. From project to project and from day to day i have go back over things and reset them because it will not do what is supposed to.

if anyone have a better idea i am all ears because right now it is not consistent. i am getting tired chasing the same issue around.

so what other options are there?

@fcwilt

ok at this point i am calling this a loss.

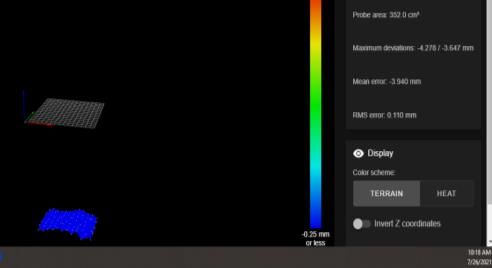

i have adjusted the Z probe to be 1 mm higher than the extruder nozzle. and ran a new height map and here is what I got.

this makes no sense to me. so i ran two more height maps and now they like the old Hight maps.

i readjusted the z = 0 point and i get a neg. number and i put that in and cycle power and reset software twice.

ran new height map and it looks like the old one except i am within 0.3 mm across the bed. go to print base of the curve file and the nozzle 1/2" off the bed so we readjusted the z =0 again and the same thing happens. so then i changed the neg. number to positive number and go to print and the nozzle is being pushed into the bed.

it seems i am getting consistent numbers then out of now where everything changes. so guess there is something wrong with the probe.

So BL Touch is all i am hearing about so will it work with the board board (Duet 2 wifi) or is there something else i need to do.

it is either this or i just throw the printer away. very frustrating.