@Phaedrux Actually that article you listed very well may be the correction I need. I will make these adjustments and see if it sticks. Thanks!

Posts made by sneakyferret

-

RE: Issues starting AP Modeposted in General Discussion

-

RE: Issues starting AP Modeposted in General Discussion

; Configuration file for Duet WiFi (firmware version 2.03) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2.0.3 on Thu Sep 05 2019 15:50:44 GMT-0400 (Eastern Daylight Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Tall Printer" ; set printer name M665 R180 L160 B130 H580 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them M575 P1 S1 B57600 ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S0 ; physical drive 0 goes backwards M569 P1 S0 ; physical drive 1 goes backwards M569 P2 S0 ; physical drive 2 goes backwards M569 P3 S1 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z80.00 E410.00 ; set steps per mm M566 X1200.00 Y1200.00 Z1200.00 E1200.00 ; set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z18000.00 E1200.00 ; set maximum speeds (mm/min) M201 X1000.00 Y1000.00 Z1000.00 E1000.00 ; set accelerations (mm/s^2) M906 X1100 Y1100 Z1100 E900 I50 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 Z0 S1 ; set minimum Z ; Endstops M574 X2 S1 P"!xstop" ; X active low and disabled endstop M574 Y2 S1 P"!ystop" ; Y active low and disabled endstop M574 Z2 S1 P"!zstop" ; Z active low and disabled endstop ; Z-Probe M558 P5 C"zprobe.in+zprobe.mod" R0.4 H5 F1000 T6000 B1 ; set Z probe type to effector and the dive height + speeds G31 P100 X0 Y0 Z-.15 ; set Z probe trigger value, offset and trigger height M557 R130 S20 ; define mesh grid ; Temperature Sensors M308 S0 P"bed_temp" Y"thermistor" T100000 B3950 ; define bed temperature sensor M308 S1 P"e0_temp" Y"thermistor" T100000 B4725 C7.06e-8 ; define E0 temperature sensor ; Heaters M950 H0 C"bed_heat" T0 ; heater 0 uses the bedheat pin, sensor 0 M950 H1 C"e0_heat" T1 ; heater 1 uses the e0_heat pin and sensor 1 M307 H0 B0 S1.00 M140 H0 ; Fans M950 F2 C"fan2" Q500 ; Hot end fan M106 P2 T45 H1 M950 F0 C"fan0" Q500 ; Part Cooling fan M106 C"PartFan" P0 S0 H-1 B1 M307 H0 ; report the process parameters for heater 0 M307 H0 R2.186 K0.17:0.11 D5.67 S1.00 V24.0 ; set the process parameters for heater 0 ; Tools M563 P0 H1 F0 D0 T0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined M501 ; recall last used parametersI see there is M552 S1 in my config, silly me. Mainly, what I was doing was accessing the printer through USB to give it the command

M588 S"*" (to delete all known networks)

then using

M552 S0 (networking idle mode)

M589 S"TallBoyPrinter" P"Kaoken123" I192.168.10.1 (To set it to AP mode and assign it a static IP)

then

M552 S2 (to set it as access point)

I will then disconnect USB and power the printer

But, like you showed me, I think that was all for nothing since the other M552 command is in config. Do I just need to set M552 S2 in my config instead? -

Issues starting AP Modeposted in General Discussion

Hi. I have a Duet2 wifi I would like to run in AP mode. When I connect via USB, delete its known networks, swap it to AP mode and assign it an IP to use it will not hold these settings when I try to start up printer. It always reverts back to my old wifi network and seems to always remember it even when I clear the known networks. Suggestions? Can post any configs you need. Firmware installed is currently the latest stable, 3.4.6.

-

Want to do a clean install on a fresh SD card, need guidanceposted in Firmware installation

Hello! I have worked hard to configure my Duet2 wifi printer and have it printing effectively. I have a question though.

I received this printer from someone and it had VERY old firmware on it. When I was much dumber about this, I upgraded it from a 2.x version to 3.4.4 when I was much less educated about the entire Duet3D system. Basically, I want to install the newest firmware available on a new SD card, update all of the firmware on my board, then transfer over the configs and such that make my printer run like it should. This section took me so long to figure out back in the day and I don't want to lose it.

I have a hard copy of my old firmware backed up just in case but what files need transferring from old install to fresh install so my 3D printer runs? I am assuming the config.g, bed.g, homedelta.g. Is there anything else I am missing?

-

RE: Bloob on printposted in Tuning and tweaking

@claustro not sure if applicable but a YouTuber was having the exact same problem with a different printing software and found that it was the resume after power loss feature causing the issue. Maybe give this a look? Video here about their problem

-

RE: Thanks to this forum, my Duet3D printer is functional!posted in My Duet controlled machine

@sneakyferret Now to fight the never ending fight of drum roll bed level mesh compensation! Love you guys.

-

Thanks to this forum, my Duet3D printer is functional!posted in My Duet controlled machine

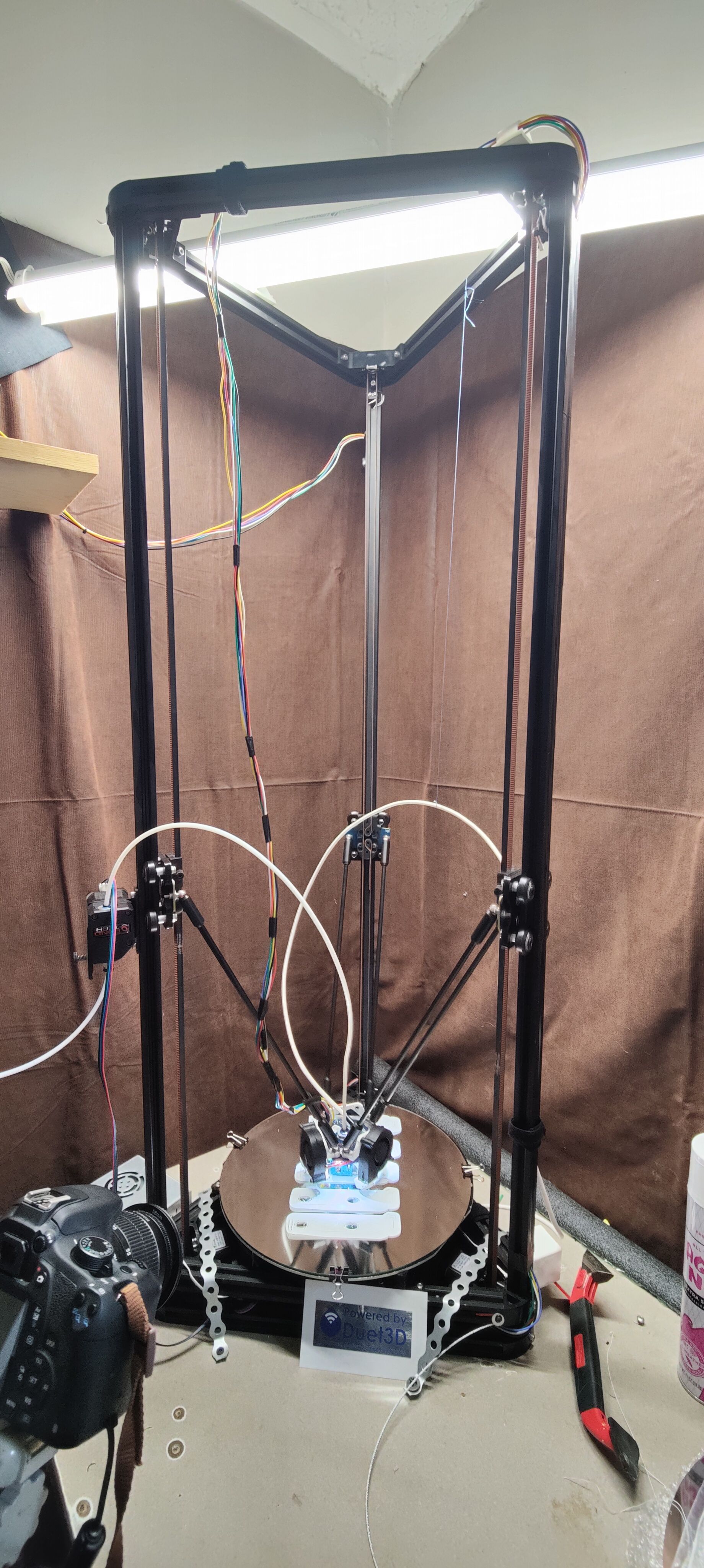

Thanks everyone who actively helps out on the forum. I couldn't have done it without you and the patient support of those here. My printer is a HE3D K280 running on a Duet2 wifi board and Smart effector v4. I made a twitch stream to watch long prints from anywhere so if you want to watch it go, head to www.twitch.tv/synthsnprints .

I make no money from this stream and it's purely for fun so hop in, give some recommendations, chat, and visit while listing to relaxing music.

Thanks again everyone!

-

RE: (wasn't sure if allowed) Selling my HE3D Duet3d hardware printerposted in General Discussion

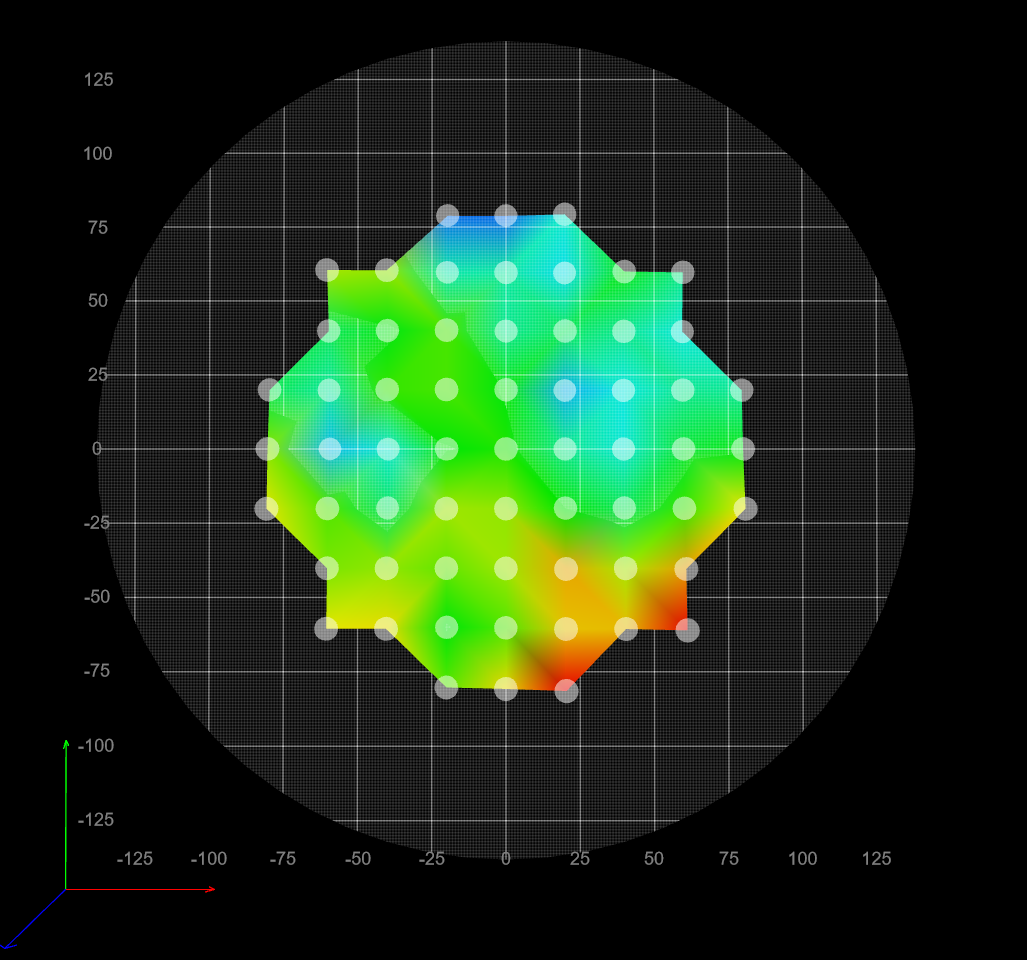

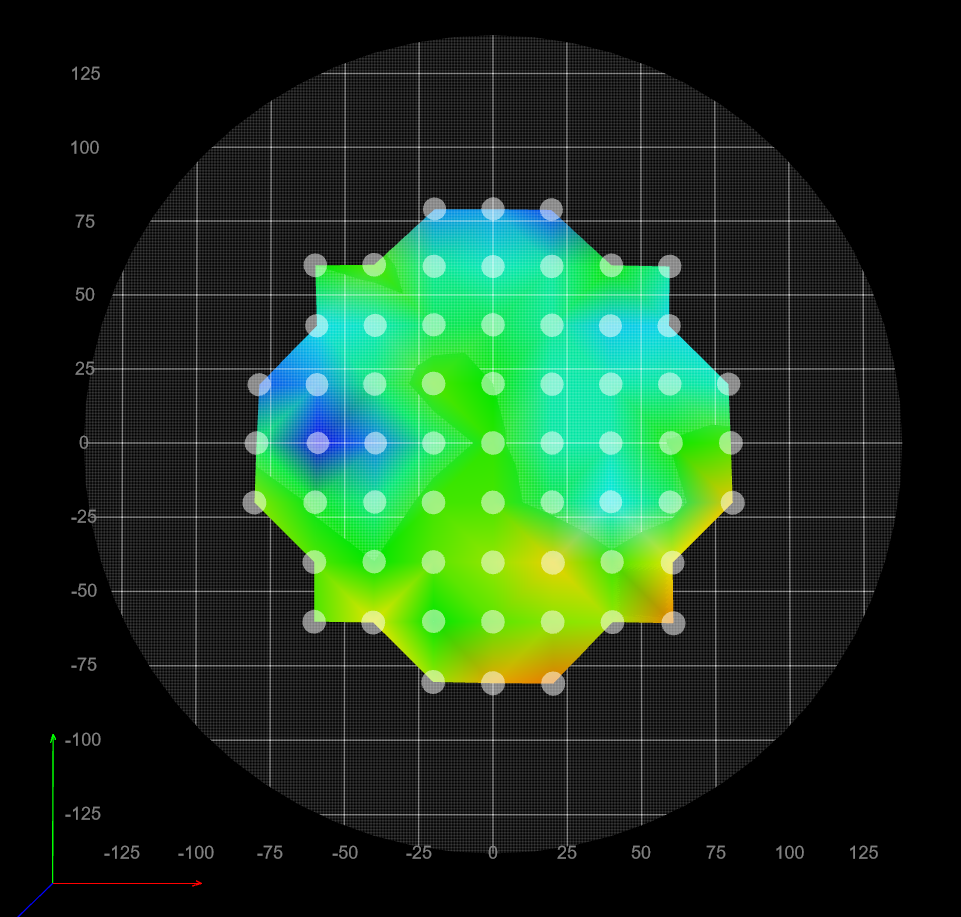

@leprint Funny you should mention that because I have adjusted the tension and lubricated these things many times but what I find curious is the height map DOES change when I adjust the tension of any of them. I have made a spreadsheet of how I adjusted each tower and recorded the height map afterwards. Then, I would save that height map screenshot, adjust another tower, then record the results to see if I could find out what's causing it but I could never find a clear answer for the cause of those dips and peaks you see in the heightmap. I even lubricated the channels they move up and down through and made sure every bearing was not seizing or clicking with no avail.

-

RE: (wasn't sure if allowed) Selling my HE3D Duet3d hardware printerposted in General Discussion

@leprint I'll give these suggestions a go when I return home from work. The cables are long enough to not cause pull on the effector when fully at the bottom and they don't sag to much off the side to cause tilt so far as I can tell. I will rewire the effector data cables but all I have is Cat6e. Think that's shielded enough?

I appreciate the tip with getting a proper z level but unfortunately I have already done this about 3 or 4 times with no change in behavior. Thank you for reaching out. I really don't want to get rid of this.

-

RE: (wasn't sure if allowed) Selling my HE3D Duet3d hardware printerposted in General Discussion

@Surgikill It has load detection so the entire effector detected when it makes contact with the bed.

-

RE: (wasn't sure if allowed) Selling my HE3D Duet3d hardware printerposted in General Discussion

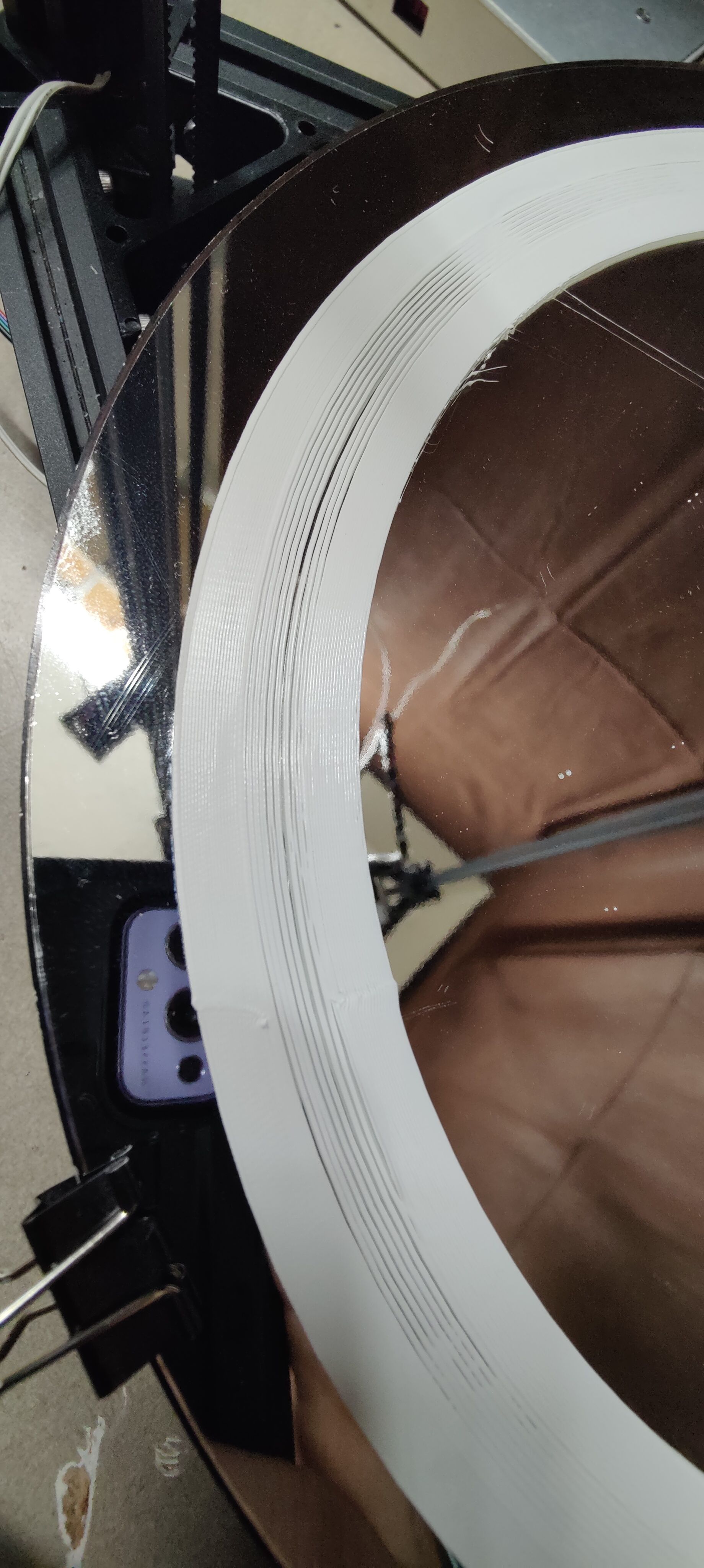

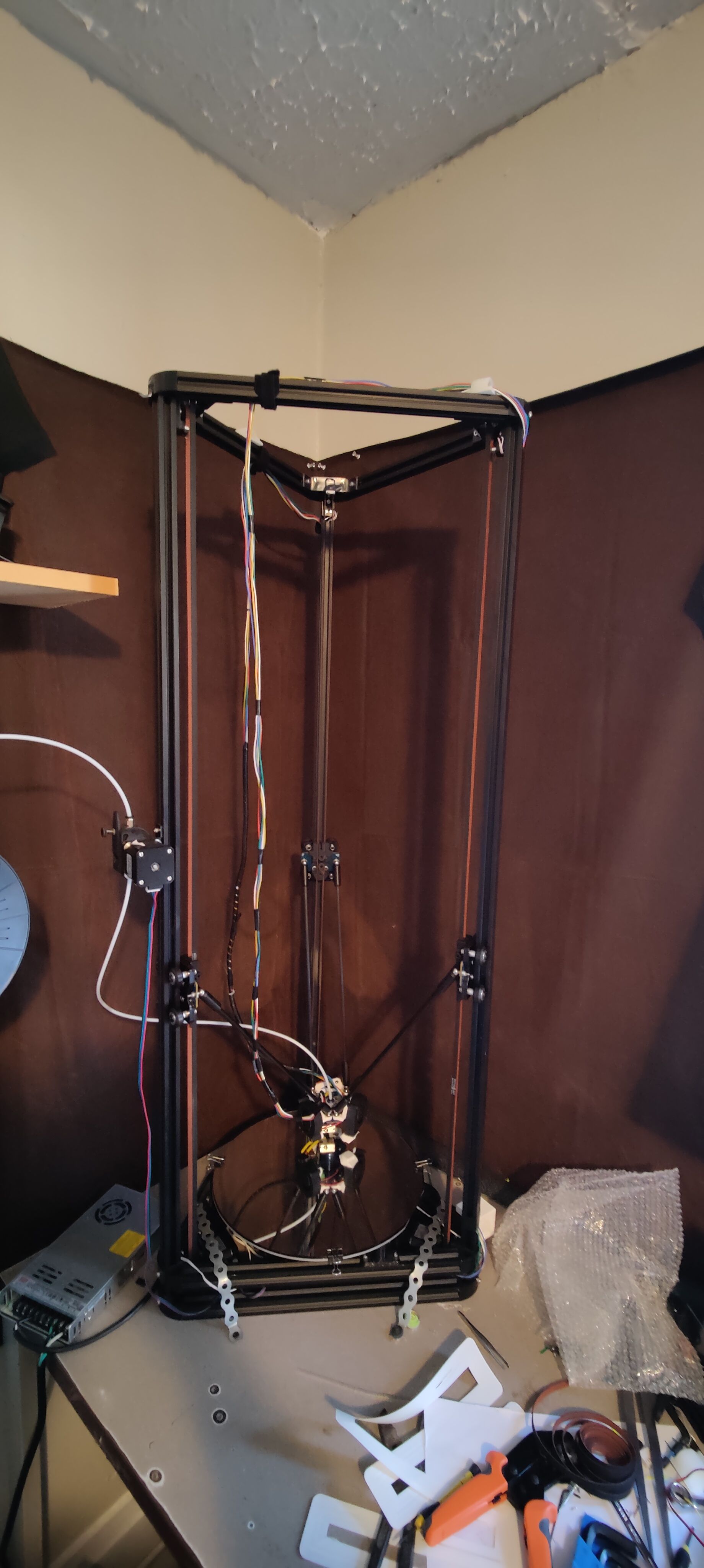

@sneakyferret a few pictures but can take better ones for anyone who needs to see more.

-

RE: (wasn't sure if allowed) Selling my HE3D Duet3d hardware printerposted in General Discussion

@dc42 I definitely do not want to sell but I have posted a few times and done as people have suggested with no results sadly. Short of replacing the main board and all stepper motors and HOPING thats the fix, I am not sure what else to do. Basically, I cannot get a good first layer due to some sort of possible mechanical trouble. No matter what I do I cannot get a decent height map and the height map changes slightly every time I run a fresh delta calibration and mesh compensation . I am running a Duet2wifi with a Duet3d Smart Effector v2. Here's what I have done so far:

- Squared up all towers to within a few mm.

- Replaced all belts.

- Had someone print me adjustable carriers to make sure all belts are tight but not overly so.

- Measured and checked all rods making sure they're all equal length.

- Rewired and crimped wire ends twice to make sure of no fouled connections between main board and smart effector.

- Replaced smart effector from v1 to v2 (previous effector had a metal nut with no fiber washer so the delicate circuits were damaged).\

- Set the effector to turn off/on during mesh compensation/delta calibration to prevent the bed heater from interfering with touch detection.

- Checked stepper motors and their set screws multiple times.

- Tightened every possible bolt I could find.

- Literally, strapped the printer down to the table its on to prevent it from walking/moving too much.

For the longest time I had the printer doing quite well but then I wanted to lengthen the effector wire harness due to cables sagging off the side and getting caught on things. I rewired the effector so the wires go from under the heat bed where there is a 3d printed container holding the main board. Those wires then run up the back side of two towers (voltage separated from the other sensor wires) and then back town to the effector through the center of the printer. The only things I have not replaced that are mechanical are the top idlers (i checked them and they did not seem bad at all. Smooth, no grinding or resistance, stepper motors, and main board.

Here are all my configs:

config.g

; Configuration file for Duet WiFi (firmware version 2.03) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2.0.3 on Thu Sep 05 2019 15:50:44 GMT-0400 (Eastern Daylight Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Tall Printer" ; set printer name M665 R180 L160 B130 H580 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them M575 P1 S1 B57600 ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S0 ; physical drive 0 goes backwards M569 P1 S0 ; physical drive 1 goes backwards M569 P2 S0 ; physical drive 2 goes backwards M569 P3 S1 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z80.00 E410.00 ; set steps per mm M566 X1200.00 Y1200.00 Z1200.00 E1200.00 ; set maximum instantaneous speed changes (mm/min) M203 X18000.00 Y18000.00 Z18000.00 E1200.00 ; set maximum speeds (mm/min) M201 X1000.00 Y1000.00 Z1000.00 E1000.00 ; set accelerations (mm/s^2) M906 X1100 Y1100 Z1100 E900 I50 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 Z0 S1 ; set minimum Z ; Endstops M574 X2 S1 P"!xstop" ; X active low and disabled endstop M574 Y2 S1 P"!ystop" ; Y active low and disabled endstop M574 Z2 S1 P"!zstop" ; Z active low and disabled endstop ; Z-Probe M558 P8 C"zprobe.in+zprobe.mod" R0.4 H5 F1000 T6000 B1 ; set Z probe type to effector and the dive height + speeds G31 P100 X0 Y0 Z-.15 ; set Z probe trigger value, offset and trigger height M557 R85 S20 ; define mesh grid ; Temperature Sensors M308 S0 P"bed_temp" Y"thermistor" T100000 B3950 ; define bed temperature sensor M308 S1 P"e0_temp" Y"thermistor" T100000 B4725 C7.06e-8 ; define E0 temperature sensor ; Heaters M950 H0 C"bed_heat" T0 ; heater 0 uses the bedheat pin, sensor 0 M950 H1 C"e0_heat" T1 ; heater 1 uses the e0_heat pin and sensor 1 M307 H0 B0 S1.00 M140 H0 ; Fans M950 F2 C"fan2" Q500 ; Hot end fan M106 P2 T45 H1 M950 F0 C"fan0" Q500 ; Part Cooling fan M106 C"PartFan" P0 S0 H-1 B1 M307 H0 ; report the process parameters for heater 0 M307 H0 R2.186 K0.17:0.11 D5.67 S1.00 V24.0 ; set the process parameters for heater 0 ; Tools M563 P0 H1 F0 D0 T0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined M501 ; recall last used parametersbed.g

; bed.g file for RepRapFirmware, generated by Escher3D calculator ; 16 points, 7 factors, probing radius: 130, probe offset (0, 0) G28 G30 P0 X0.00 Y130.00 Z-99999 H0 G30 P1 X83.56 Y99.59 Z-99999 H0 G30 P2 X128.03 Y22.57 Z-99999 H0 G30 P3 X112.58 Y-65.00 Z-99999 H0 G30 P4 X44.46 Y-122.16 Z-99999 H0 G30 P5 X-44.46 Y-122.16 Z-99999 H0 G30 P6 X-112.58 Y-65.00 Z-99999 H0 G30 P7 X-128.03 Y22.57 Z-99999 H0 G30 P8 X-83.56 Y99.59 Z-99999 H0 G30 P9 X0.00 Y65.00 Z-99999 H0 G30 P10 X56.29 Y32.50 Z-99999 H0 G30 P11 X56.29 Y-32.50 Z-99999 H0 G30 P12 X0.00 Y-65.00 Z-99999 H0 G30 P13 X-56.29 Y-32.50 Z-99999 H0 G30 P14 X-56.29 Y32.50 Z-99999 H0 G30 P15 X0 Y0 Z-99999 S7homedelta.g

; homedelta.g ; called to home all towers on a delta printer ; ; generated by RepRapFirmware Configuration Tool v2.1.8 on Sun Feb 02 2020 21:40:18 GMT-0500 (Eastern Standard Time) G91 ; relative positioning G1 H1 X605 Y605 Z605 F1800 ; move all towers to the high end stopping at the endstops (first pass) G1 H2 X-5 Y-5 Z-5 F1800 ; go down a few mm G1 H1 X10 Y10 Z10 F1800 ; move all towers up once more (second pass) G1 Z-10 F6000 ; move down a few mm so that the nozzle can be centred G90 ; absolute positioning G1 X0 Y0 F6000 ; move X+Y to the centreIf anyone can find anything and help me out I would be very much appreciated. If not, I will sell to someone who knows more about these.

-

(wasn't sure if allowed) Selling my HE3D Duet3d hardware printerposted in General Discussion

I have a HE3D K280 delta printer with duet2 wifi, smart effector V2, 24v power supply that I just can't figure out so was wondering if anyone here would be interested in it. Wasn't sure if this was allowed or not. Can post pics of interested

-

RE: Diagnosing poor print quality (wits end please!)posted in General Discussion

@o_lampe Interesting development. I did what you said and identified a single rod that was more loose than all the others. I swapped them around, no difference. Turns out, its that rod position that is more loose no matter which rod is in that place.

-

RE: Diagnosing poor print quality (wits end please!)posted in General Discussion

@sneakyferret One thing I have recently noticed: When doing a mesh calibration run, some coords the smart effector makes a very audible but normal 'tap' sound as it contacts. Other spots, its either very muffled (like its tapping cloth) or not audible at all. THE PLOT THICKENS.

-

RE: Diagnosing poor print quality (wits end please!)posted in General Discussion

@o_lampe That's brilliant. Thank you! Doing that now.

-

RE: Diagnosing poor print quality (wits end please!)posted in General Discussion

@Phaedrux Not from anything I can tell. I have ordered new belts that I will be installing hopefully Friday and I hopefully will be finding someone local to 3d print better carriage adapters so I can properly adjust belt tension because the stock ones included with my K280 are, ahem, garbage.

-

RE: Diagnosing poor print quality (wits end please!)posted in General Discussion

@Herve_Smith Thanks for the insight. I am still looking into this but I have tightened every bolt, leveled every tower, and made sure every rod is mounted correctly that I know of. The only result changes I get are adjusting the tower guide wheel tensions but it never truly improves and the heightmap only changes when I change tensions but probes the same every time. How do I interpret the height map when I see, seemingly random with no pattern, spikes and dives in the heightmap?

-

RE: Diagnosing poor print quality (wits end please!)posted in General Discussion

Very poor bed adhesion due to, I am assuming, an improper mesh compensation. I have already done both of those twice over with the same results. The config I have now was what was printing well then I started making slight changes after the effector rewiring and now I can't seem to get it to stabilize. I will post more tomorrow when I can.