One more thought/question: should the lead screws be fixed only at the bottom (or top?), or on both ends? I think only fixing one end would be better (don't want them overconstrained), but I'm not sure.

Best posts made by RS

-

RE: Choosing a Z axis styleposted in 3D Printing General Chat

-

Choosing a Z axis styleposted in 3D Printing General Chat

Hello everyone,

I found that I have too much time on my hands, and decided to design and build a 3D printer myself

. Not because there aren't any good ones to buy, but to learn something and have fun doing so.

. Not because there aren't any good ones to buy, but to learn something and have fun doing so.Details most relevant to this post:

- Heated chamber (around 70 °C)

- Print bed heatable up to 150 °C

- Print bed size: around 30cm x 30cm

- Frame built from aluminum extrusions (2020, 2040 or 4040; not sure yet)

- Most parts will be 3D printed (including the bed mounts). Yes, I know, PLA will not work in a heated chamber

- And of course: driven by a Duet board!

I did some research and looked around how other printers handle their print bed / Z axis, and came up with three alternatives that I like:

-

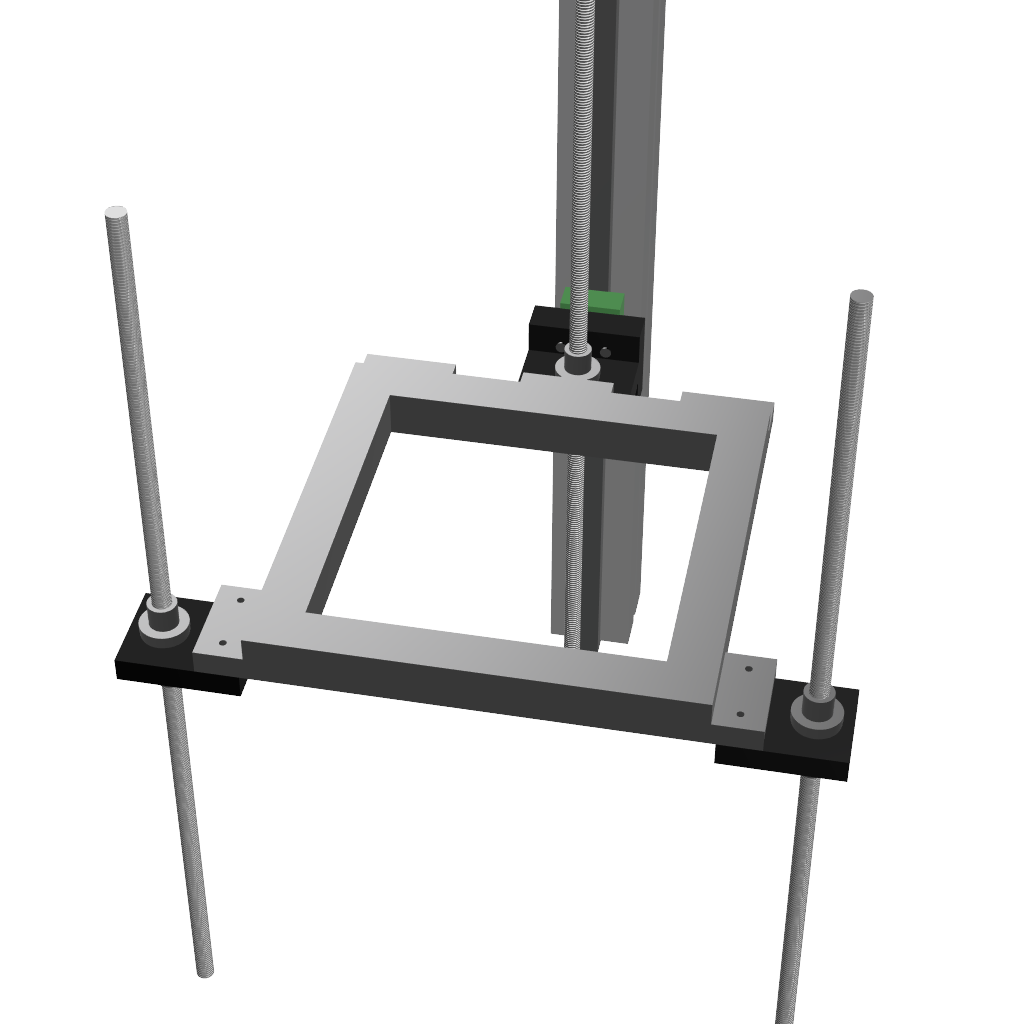

A single linear guide to restrict movement of the bed to strictly up/down, and three lead screws for lifting it:

-

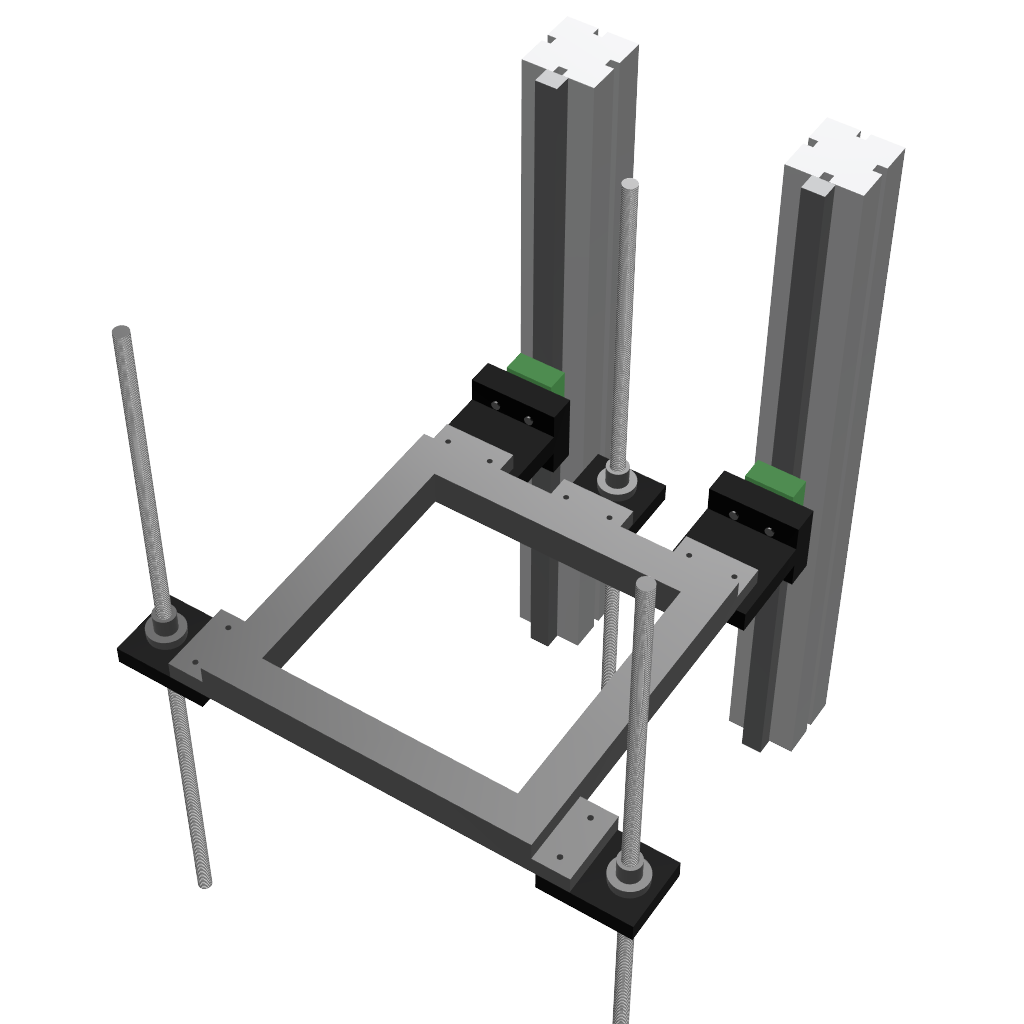

Similar to option 1, but with two linear guides:

-

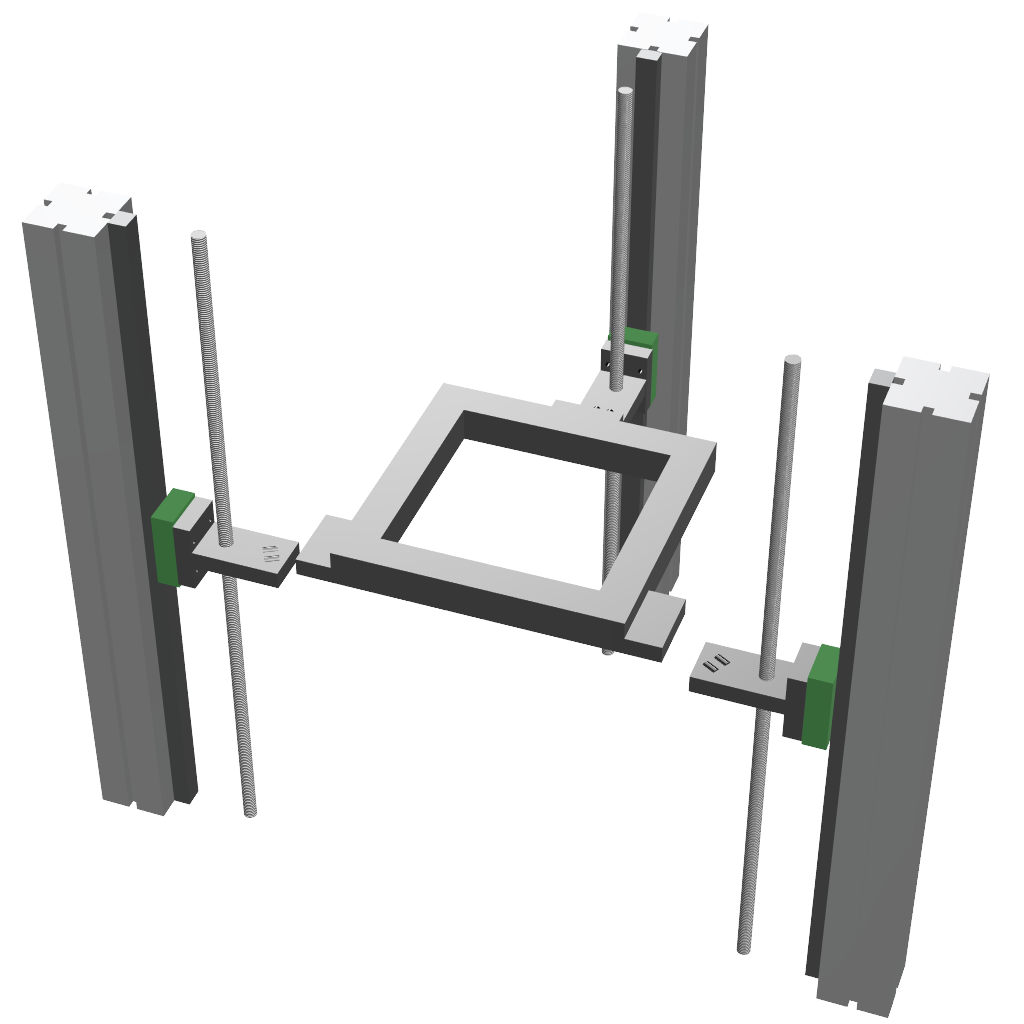

A kinematic mount with three linear guides, each with a lead screw for lifting. This is the mechanism used by the Jubilee printer:

(The bed frame is shown as 'levitating'; in reality, it would sit on the dowel pins.)

(Models are just quick-and-dirty, with little details. Also, print bed is not shown (just the frame); bed will probably be mounted on the frame using a kinematic mount as described here:

https://drmrehorst.blogspot.com/2017/07/ultra-megamax-dominator-3d-printer-bed.html)Now I'm trying to decide which of these options I like most. Here are my thoughts:

- Single linear guides:

- Pro: cheapest solution; easiest to align.

- Con: might not have enough resistance against rotation around Z axis (but not sure; I have no experience with linear guides)

- Unsure: what about thermal expansion? If the bed frame expands differently than the main frame, will the lead screws be bent a little bit to "make room"? Is this a problem?

- Two linear guides:

- Pros: better resistance against Z-rotation

- Cons: harder to align, as the two linear guides must be perfectly parallel

- Unsure: If the bed frame expands differently than the main frame, that might cause problems at the bed/slide mounts.

- Jubilee's kinematic mount:

- Pro: Absolutely no problems with thermal expansion. The bed (or in my example: the bed frame) can just slide on the dowel pins when it expands or contracts.

- Cons: most expensive solution.

- Unsure: alignment! It seems quite hard to me to get them perfectly aligned. If they aren't, the bed will rotate around the Z axis when it's lifted/lowered. Or do I miss something?

So far, I like option 2 (two linear guides) best. However, I'm nost sure about thermal expansion. Let's assume I build bed frame and main frame from the same material. Then the distance between the two linear guides should grow by the same amount as the bed frame. The same should be true for the distance between the front lead screws and the back lead screw. If not, the lead screws will get bent a tiny bit (probably not relevant for print quality), so nothing should bind.

I would be glad for any thoughts and opinions.

-

RE: Choosing a Z axis styleposted in 3D Printing General Chat

Thanks for all the answers so far. There are so many ways to do basically the same thing: lift the bed up and down

What I'm quite sure about is that I want to avoid guide rods, and use linear guides instead. It seems those tend to be more precise than rods, and I've got the budget for linear guides. But I think many considerations are the same, no matter if rods or guides.

@mrehorstdmd: Yeah, that lever is troublesome, now that I think about it. Moving the guides more towards the front results in a more balanced structure. Here's a mock-up of that change:

I think I'll place the guides roughly 1/3 of the way from front to back.What I'm not sure about yet, and maybe someone else got some experience with, is what happens when the printer heats up. Assuming the printer has a width of 50cm and is built of aluminum, when heated up from 20 °C to 70 °C it will expand by 500mm * 50 °C * 24*10^-6/°C = 0.6mm. That would cause quite some pull on the bed frame from the left and right.

However, the bed frame will also expand. Would it be safe to assume that it will expand similary enough to the main frame, and thus not cause issues?If that's not a safe assumption, one of the two slide mounts would have to be replaced with something more flexible. The same would apply to the lead screw mount. I'll mock something up in Fusion and post it a bit later today.

-

RE: Choosing a Z axis styleposted in 3D Printing General Chat

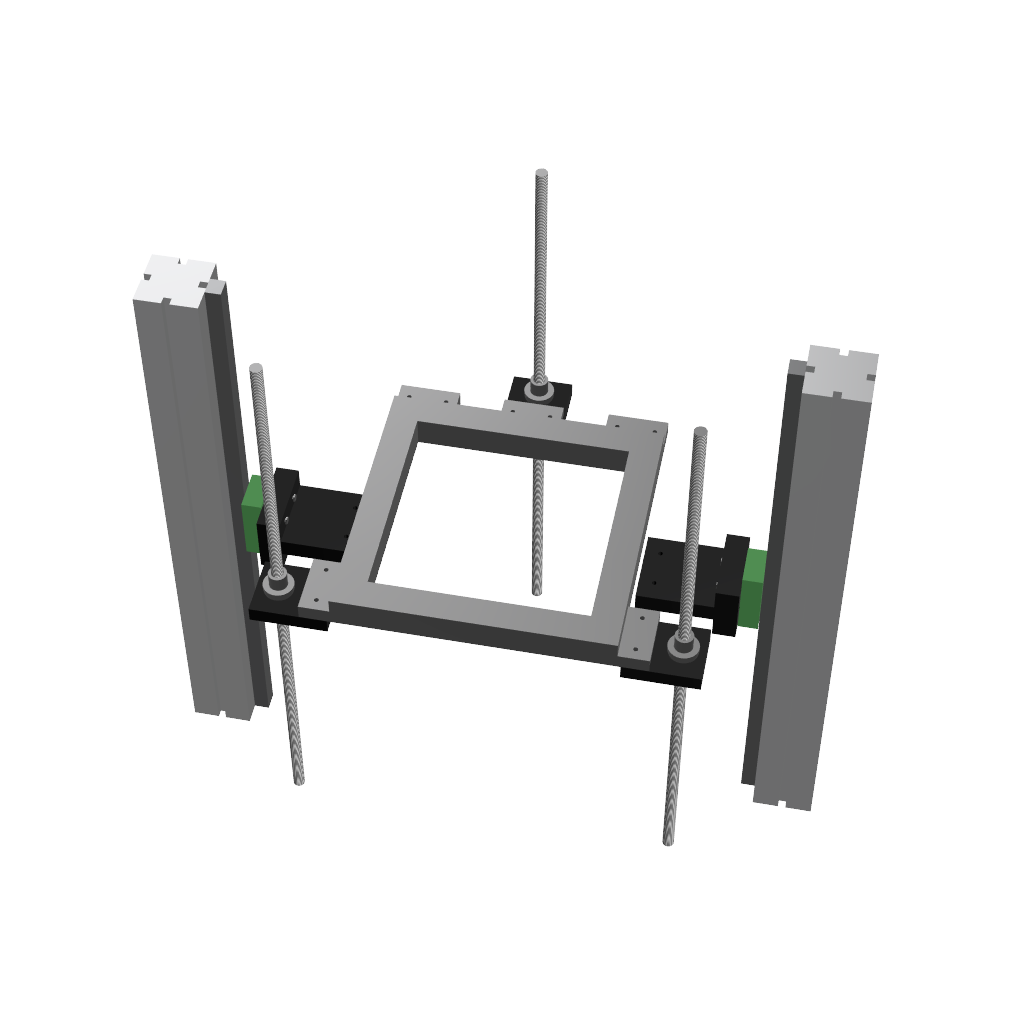

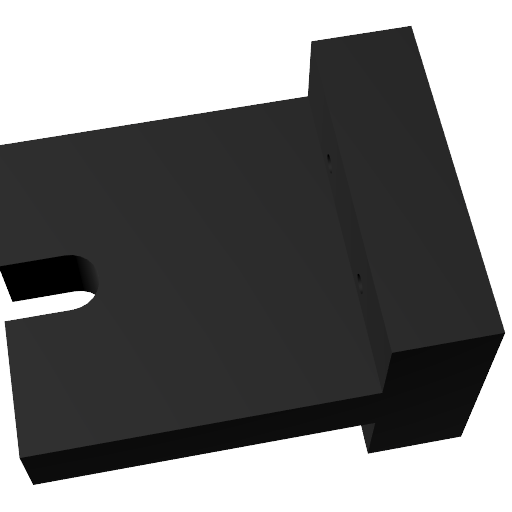

So here's a quick mock-up of the kind of flexible mount I was thinking about:

One of the two mounts on the slides would stay unchanged; let's say the left one. Then the right one would be replaced by this flexible mount. This would allow the print frame's right side to move in the X direction, while not allowing any flexibility in the Y directions.

I would also replace the lead screw mounts with this. The lead screws only need to restrict Z; with the slot in the mount, they wouldn't be able to interfere with X and Y movements.

Does this make sense? Or is this just massive overkill?

-

RE: Choosing a Z axis styleposted in 3D Printing General Chat

If it's working for you, @mrehorstdmd, then I'll start with that as well. Should it ever cause problems, then I can still replace it with a more fancy mount.

The bed itself will definitely need a kinematic mount. I also plan to add thermal decoupling using PTFE blocks, just to be sure that the bed won't heat the bed frame to a point where it will melt its mounts.

-

RE: Choosing a Z axis styleposted in 3D Printing General Chat

The book looks promising.

I'll have to sleep a night over the decision to order it, as shipping to Germany is about as much as the book itself... -

RE: Choosing a Z axis styleposted in 3D Printing General Chat

@whopping-pochard That bed mount really looks cool. It also reminds me of how the Jubilee printer mounts its bed.

What I'm most interested in is how well the small extrusions isolate the mounts from the bed's heat. When you've got some first test results, please report back.

The "worst case" scenario that I'm planning for is an ambient temperature of 70 °C and a bed temperature of 150 °C. I don't dare to try that without PTFE blocks as isolator.