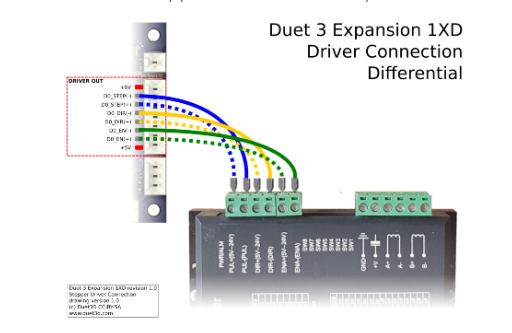

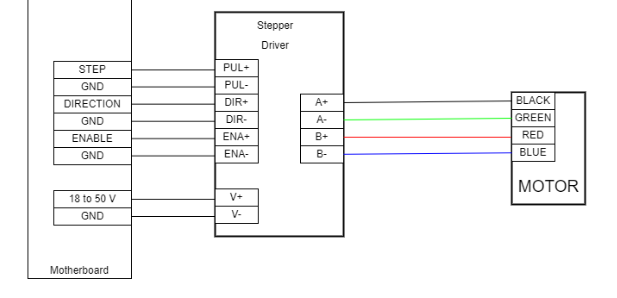

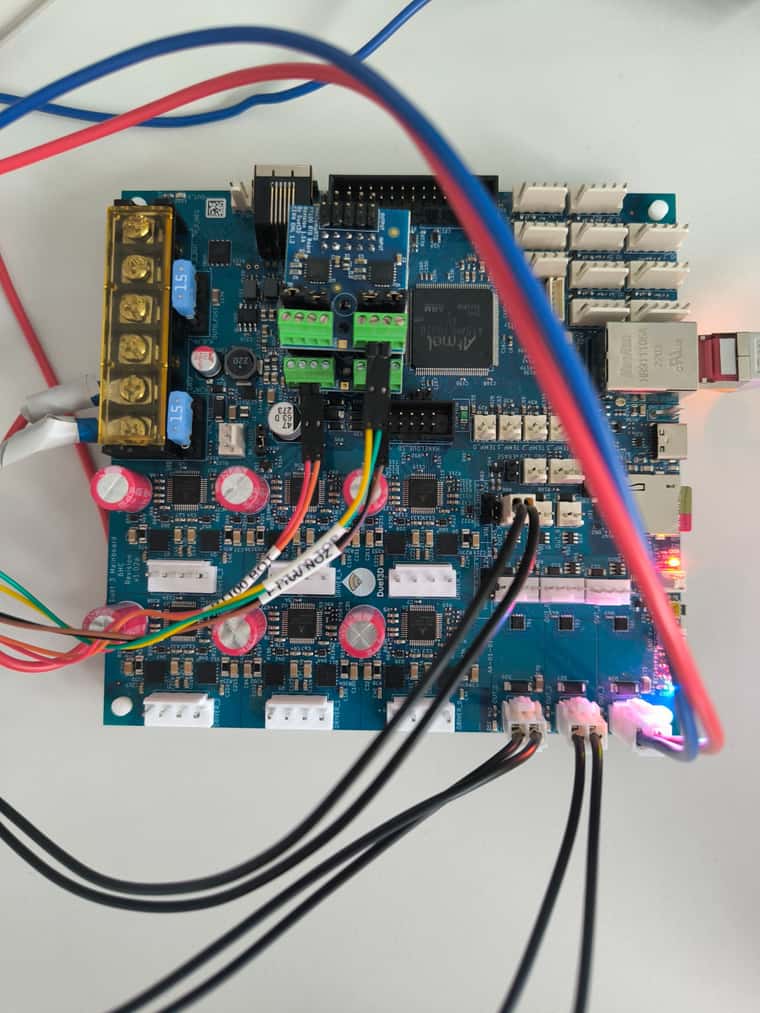

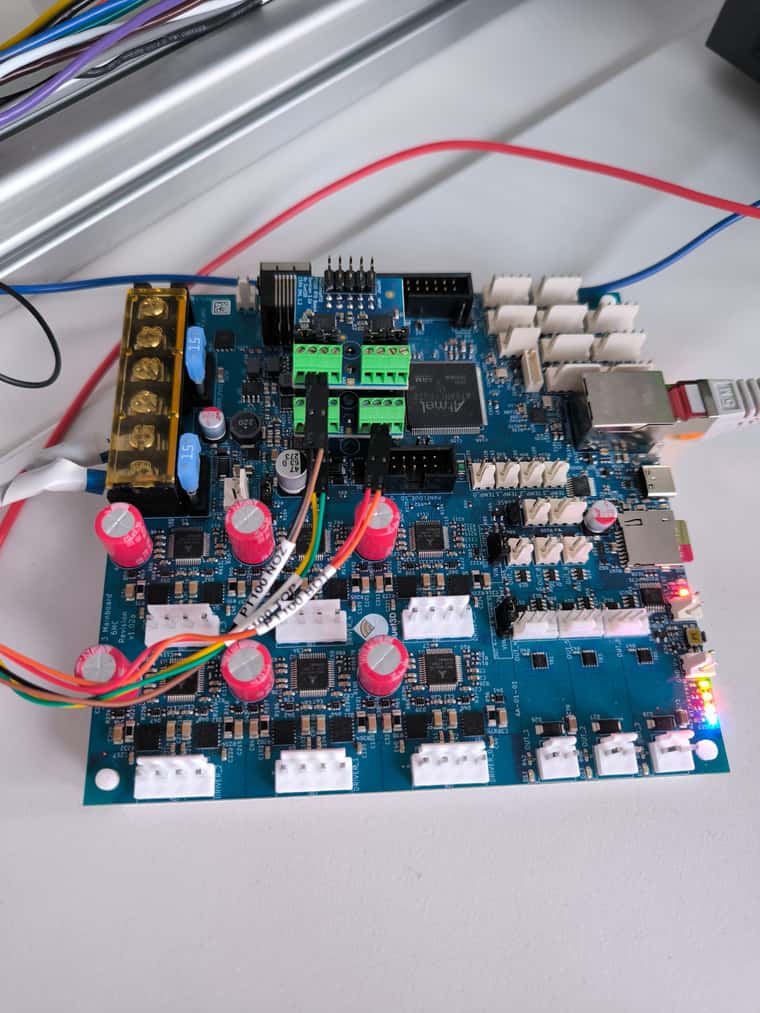

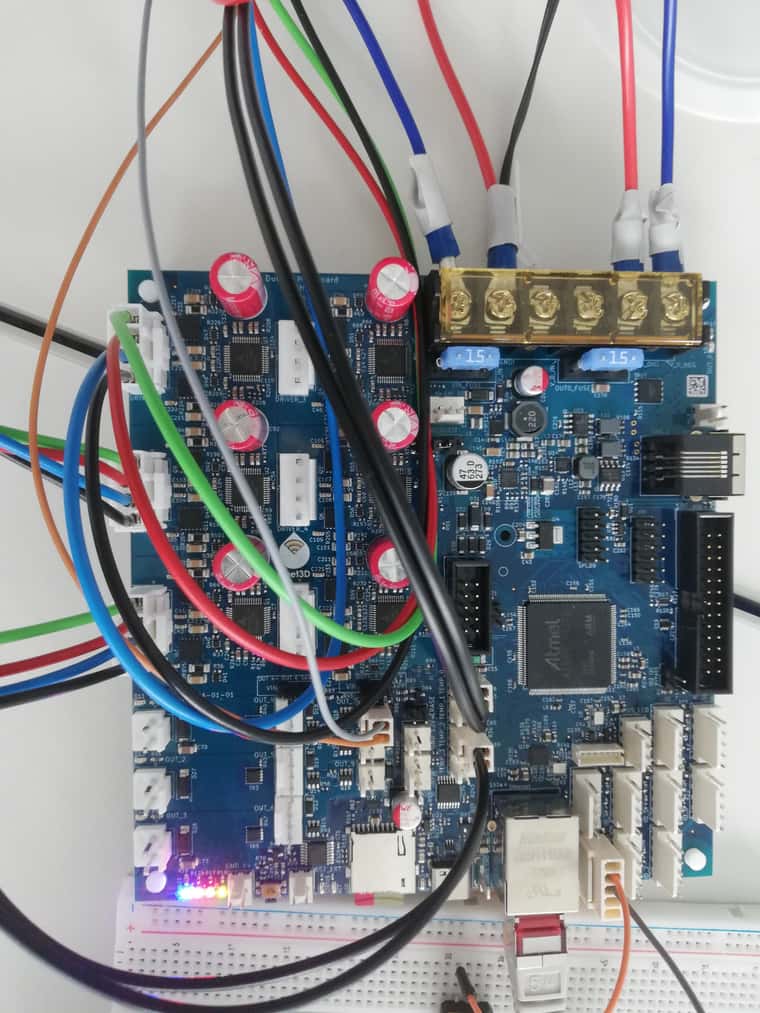

Hi I am configuring a pellet extruder which I wired up according to my previous question here.

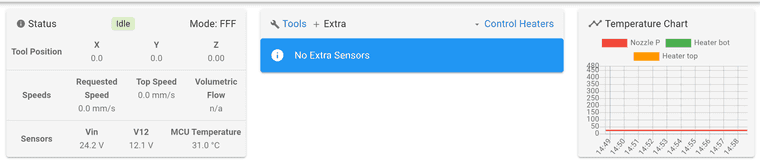

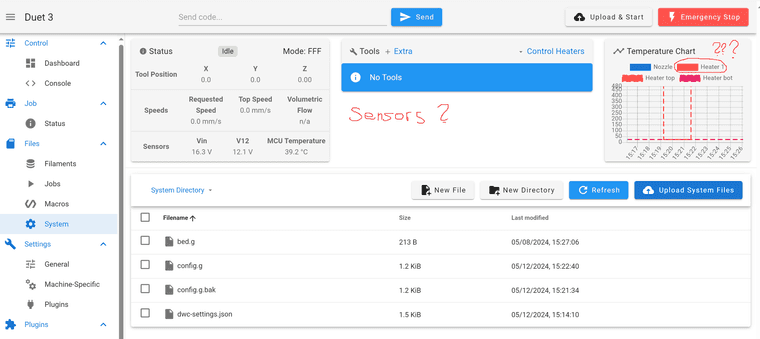

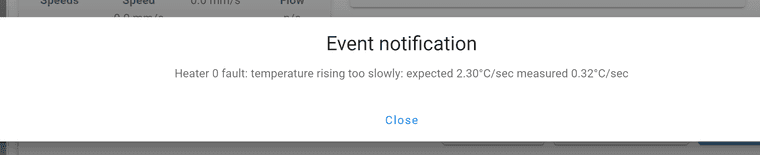

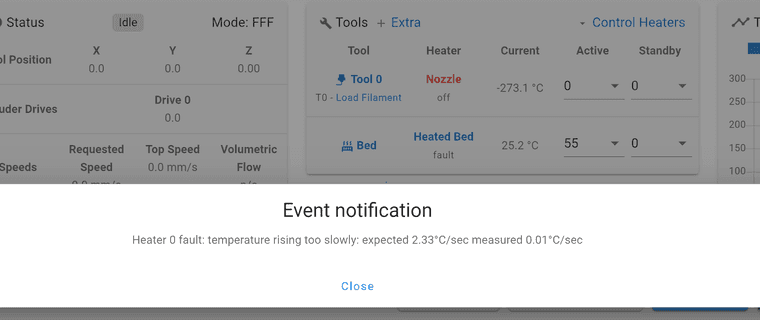

Configured it to my best knowledge and tried to run the extruder, by heating above 180°C. Running T0 and then G1 E100 F1000.

When I do this the top speed matches the requested speed in the duet web interface, but the screw does not actually start spinning. The Drive 0 value that shows the axes position is not changing when the status is 'Busy' and the value only changes when the move is 'finished'.

The lights for V+ and ENA on the stepper driver are on when the power is on and the lights for STEP and STall are not (stall is not connected atm). After the first time I run the G1 E100 F1000 the ENA turns off and stays off even after the move is 'finished', while the V+ is on all the time.

Communication between the 6HC mainboard and 1XD extension board should be fine since when I run M115 B122 the console givem me its firmware version - Duet EXP1XD firmware version 3.4.4 (2022-10-14 11:45:39)

I don`t know where to start looking for the rootcause of the error. Can you please help me?

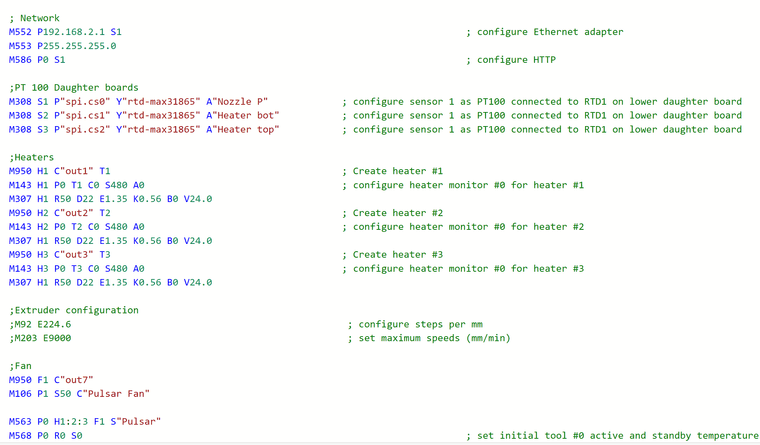

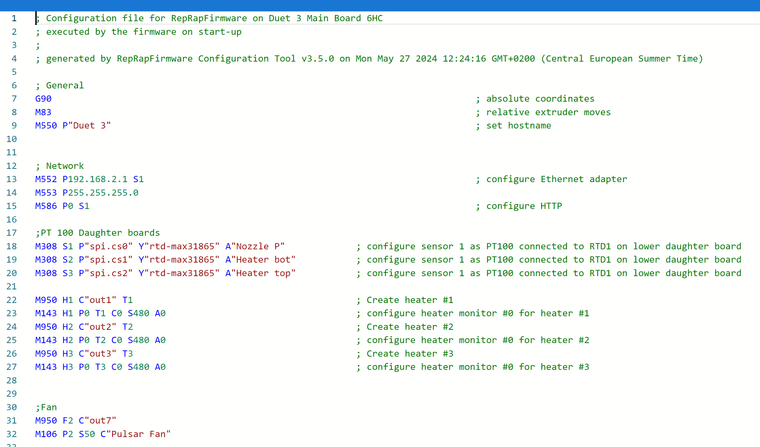

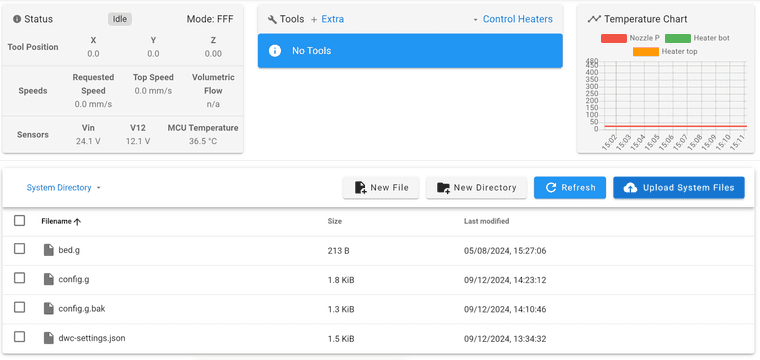

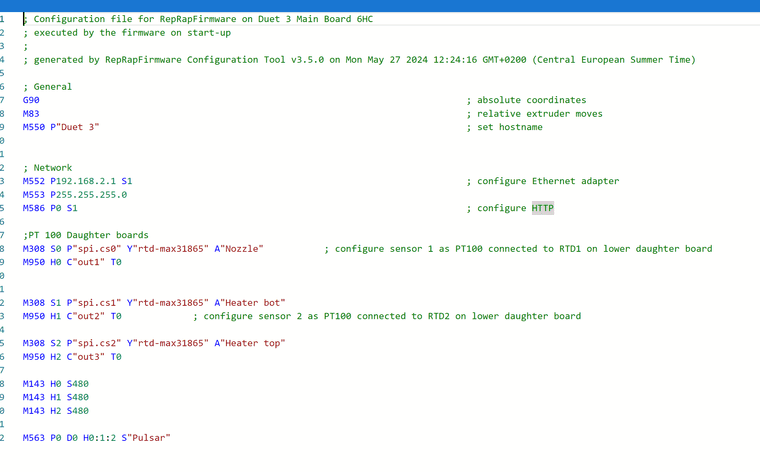

Here is my config.g file.

; Configuration file for RepRapFirmware on Duet 3 Main Board 6HC

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.5.0 on Mon May 27 2024 12:24:16 GMT+0200 (Central European Summer Time)

; General

G90 ; absolute coordinates

M83 ; relative extruder moves

M550 P"Duet 3" ; set hostname

; Network

M552 P192.168.2.1 S1 ; configure Ethernet adapter

M553 P255.255.255.0

M586 P0 S1 ; configure HTTP

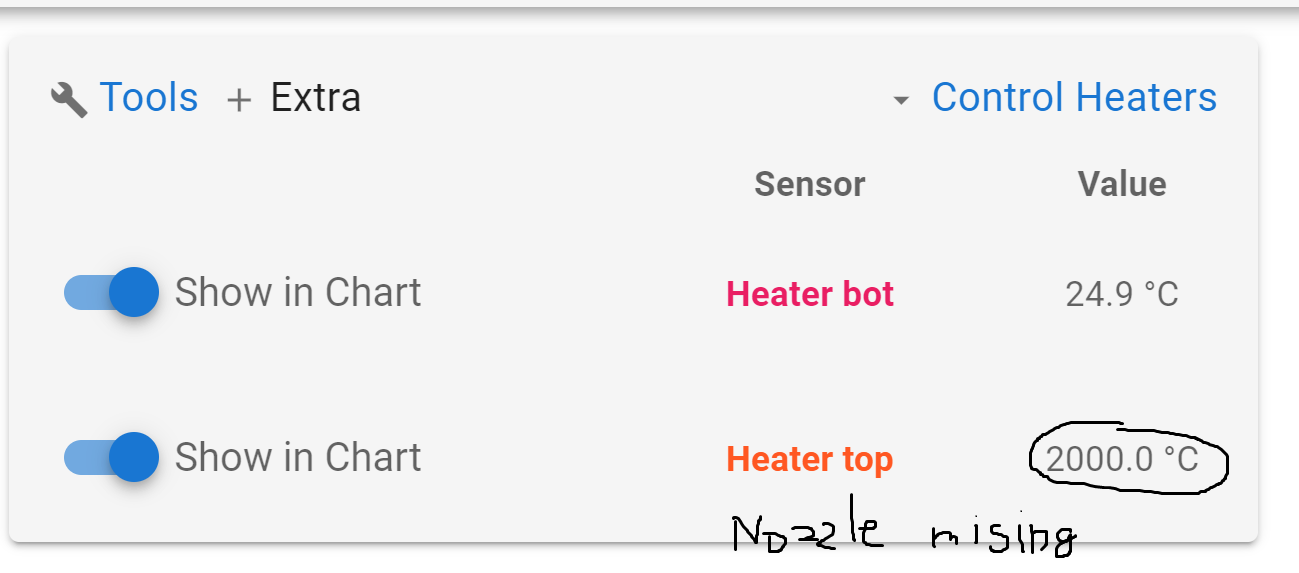

;PT 100 Daughter boards

M308 S1 P"spi.cs0" Y"rtd-max31865" A"Nozzle P" ; configure sensor 1 as PT100 connected to RTD1 on lower daughter board

M308 S2 P"spi.cs1" Y"rtd-max31865" A"Heater bot" ; configure sensor 1 as PT100 connected to RTD1 on lower daughter board

M308 S3 P"spi.cs2" Y"rtd-max31865" A"Heater top" ; configure sensor 1 as PT100 connected to RTD1 on lower daughter board

;Heaters

M950 H1 C"out1" T1 ; Create heater #1

M143 H1 P0 T1 C0 S480 A2 ; configure heater monitor #0 for heater #1

;M307 H1 R50 D22 E1.35 K0.56 B0 V24.0

M307 H1 R0.856 K0.198:0.000 D26.22 E1.35 S1.00 B0 V48.1 ; default values from pulsar docs

M950 H2 C"out2" T2 ; Create heater #2

M143 H2 P0 T2 C0 S480 A2 ; configure heater monitor #0 for heater #2

;M307 H1 R50 D22 E1.35 K0.56 B0 V24.0

M307 H2 R0.693 K0.148:0.000 D31.85 E1.35 S1.00 B0 V48.1 ;default values from pulsar

M950 H3 C"out3" T3 ; Create heater #3 (top heater)

M143 H3 P0 T3 C0 S480 A2 ; configure heater monitor #0 for heater #3

;M307 H1 R50 D22 E1.35 K0.56 B0 V24.0

M307 H3 R1.122 K0.127:0.000 D24.70 E1.35 S1.00 B0 V48.1

;M569 P0.0 S0 D2 ; driver 0.0 goes forwards (X axis)

;M569 P0.1 S0 D2 ; driver 0.1 goes forwards (Y axis)

;M569 P0.2 S0 D2

M569 P122.0 S0 R1 T3:3:5:0

; Drive Mapping X,Y,Z to be changed

M584 X0.0 Y0.1 Z0.2 E122.0 ;map

M350 X32 Y32 Z16 E16 I1 ;Microstepping with interpolation enabled

M906 X800 Y800 Z800 E3810

;Extruder configuration For all axeses (pulsar docs) M92 XXXX.X YXXX.X ZXXX.X E224.6

M92 E224.6 ; configure steps per mm, XYZ to be filled

M203 E9000 ; set maximum speeds (mm/min) XYZ to be filled

M563 P0 D0 H1:2:3 F1 S"Pulsar"

M568 P0 R0 S0 ; set initial tool #0 active and standby temperatures to 0C