Thank you, this works:

button R37 C1 F0 H0 V5 T"- Unload" A"M98 P""/macros/3_Unload filament"""

Thank you, this works:

button R37 C1 F0 H0 V5 T"- Unload" A"M98 P""/macros/3_Unload filament"""

Macro calls with M98 from a 12864 display menu does not work in 3.5rc4.

e.g.:

button R25 C1 F0 H0 V5 T"- Load" A"M98 P/macros/2_Load filament"

There is also no error message.

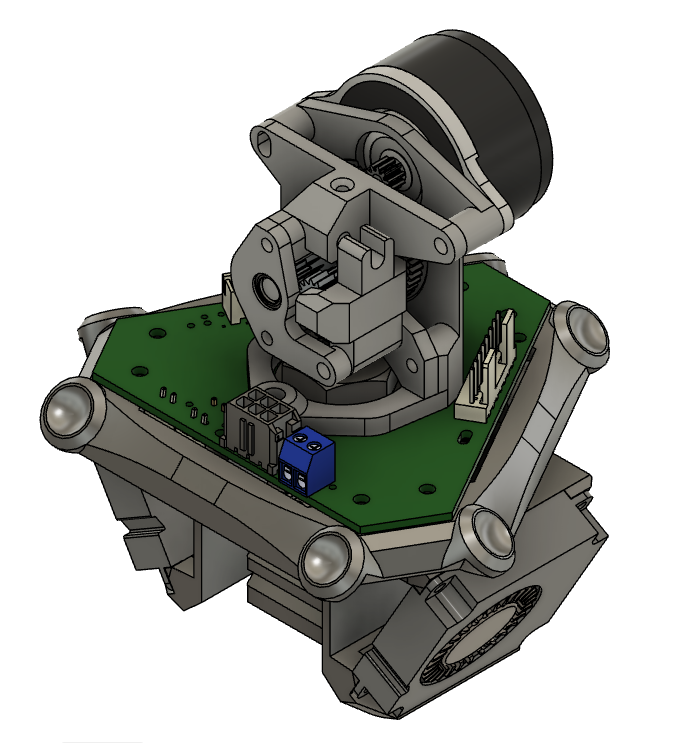

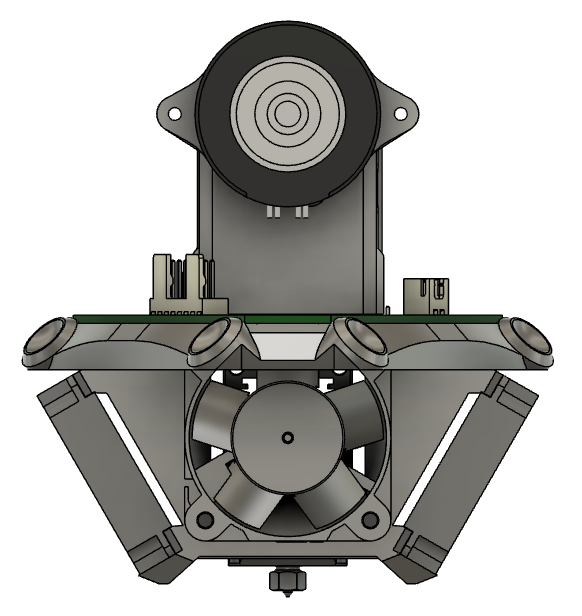

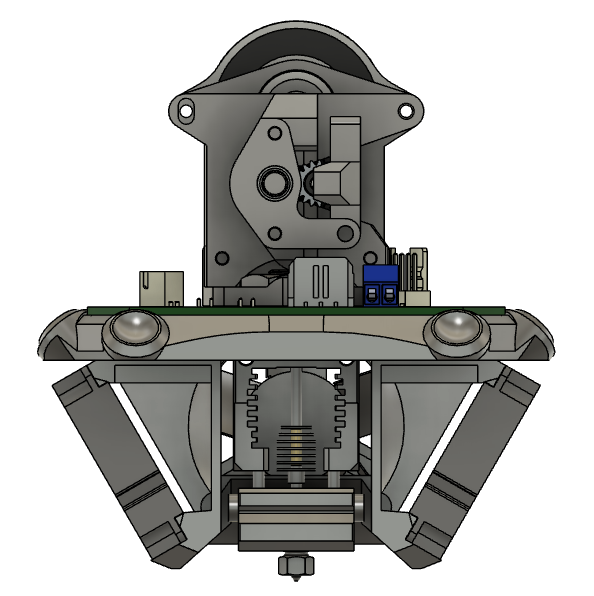

@garyd9 said in Smart Effector including toolboard-capabilities?:

Remember that if you change your arm spacing, you'll need new carriages with the same arm spacing

Already printed

@garyd9 said in Smart Effector including toolboard-capabilities?:

Assuming that theoretical work is accurate (or close to accurate), the effector from mrac1 has a much lower stability of ~134.94. (64^2 / 30.354)

I am reprinting my effector, this time with 82 (rod space) to 18,257 ("b" value). So "TES" = 368.3. Thanks again for the article and your work. I'm very curious if anything changes (I think levelling should be the best way to tell).

@garyd9 said in Smart Effector including toolboard-capabilities?:

Wow, that sherpa mini certainly appears to share a common ancestry with mrac1's extruder. I don't know which one came first, but having so many similarities allows people like us to enjoy the advantages of both.

The sherpa mini was the first. When I printed it, I noticed that the shaft of the 50 tooth gear grinds on the motor housing. Therefore, I have completely redrawn it. Because of the given Bondtech parts and the motor, there are not many possibilities for the design. Apart from that, the Sherpa mini is very nice and I wanted to get as close as possible to the look with my version.

@o_lampe said in Smart Effector including toolboard-capabilities?:

I have 3 BMG clones (for 22€!)

I have made the experience that the cheap BMG clones have very inaccurately manufactured components which also wear out very quickly.

If you want clone parts, I can recommend the parts from Trianglelabs and Mellow. They are very good, but nothing beats the original Bondtech.

@o_lampe said in Smart Effector including toolboard-capabilities?:

What do you think, why does the Titan show more ringing, than the D3E?

The factors for ringing are, to my knowledge, the combination of speed, acceleration, jerk in relation to the mass of the effector. Thus, there should be more problems with a direct extruder than with a bowden extruder or a flying extruder due to the higher mass.

Fortunately, the LDO motor is very light and the print result is flawless.

My PA values are by the way:

PLA 0.10

PETG 0.15

@garyd9

Looks promising, but I still see room for improvement. This quality is possible without any problems:

This was a test of the D3E and two different slicers (S3D on the left, PrusaSlicer on the right).

@garyd9 said in Smart Effector including toolboard-capabilities?:

Buying a BMG thumbscrew was a waste for an extruder this tiny

Yes, a M3 screw is provided here

Looks good, looking forward to seeing pictures of your first prints. Set the retract to 0.6 mm (PLA) and 1.0 mm (PETG) at 50 mm/s.

@garyd9 said in Smart Effector including toolboard-capabilities?:

The extruder's plastic was in the way of the little latch on the connector. (Below are images of the area I'm referring to.)

You are right, it's to tight there. On my Deltas I'm using my first version without brass inserts.

At this point you could take away some material without getting problems with the inserts, I think. Otherwise - it also works if the screws are simply screwed into the plastic. Then there is enough space at that point.

@o_lampe said in Smart Effector including toolboard-capabilities?:

5:1 ratio is enough torque for a fast Delta or are there speed limits?

It's tested up to 100 mm/s (normally I do not print faster than 80 mm/s).

@garyd9 said in Smart Effector including toolboard-capabilities?:

In my files, I'm calling it "mrac1 mini extruder", so I agree that it needs a name.

Sounds good

In my files I call it D3E (DeltaDirectDriveExtruder)

@garyd9 said in Smart Effector including toolboard-capabilities?:

From what I can tell of the diagram, you shouldn't need to print any gears. Only 4 housing pieces. I'm guessing that they can be printed with PETG, but I'm not sure how hot the LDO stepper might get. (I doubt it'd get over 70C, but if it does, I can reprint the plastic with a hybrid PC+.)

Yes, there are no extra gears to print. The LDO motor remains under 40° (motor current to 370 mAh) Except the fan duct, my hole effector and extruder ist printed in PLA.

I have tested various types of mounting and could not find any difference. As it is in the current version, the mounting is the easiest.

This is a very interesting article! I will optimize my effector in this direction.

One more thought, how strong is the effect of the magnets when they come closer together?

@garyd9 Print quality is a bit better than my Prusa MK3s.

There isn't much room for nuts and my first version, as I said, simply screws directly into the plastic.

Here are my values:

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X200.00 Y200.00 Z200.00 E709 ; set steps per mm

M566 X1200 Y1200.00 Z1200.00 E600.00 ; set maximum instantaneous speed changes (mm/min)

M203 X18000.00 Y18000.00 Z18000.00 E4800.00 ; set maximum speeds (mm/min)

M201 X3000.00 Y3000.00 Z3000.00 E4000.00 ; set accelerations (mm/s^2)

M204 P1250 T3000 ; set print and travel accelerations (mm/s^2)

M906 X1000 Y1000 Z1000 E370 I40 ; set motor currents (mA) and motor idle factor in per cent

@garyd9 Yes, all parts are from the BMG, and the ratio is 5:1. You also need M3/M2.5 screws and M3 brass inserts. Version 1.0 is without brass inserts and is still in use on my two deltas.

@Hergonoway the 64 mm rod spacing comes from my first design without smarteffector: https://www.thingiverse.com/thing:3609378

And yes, it should also look as good as possible

The two 40x10 fans work extremely well! However, it also took many attempts until the air flow was right.

@garyd9 Yes, it's my own design. Here is the step file: https://1drv.ms/u/s!AnpMmSRyS0cUkJ94Y0O-LqHwrEh7RQ?e=yLTPwj

This design work's pretty good an the rod spacing is 64 mm. Do you need the step file?