Smart Effector including toolboard-capabilities?

-

@Dougal1957 said in Smart Effector including toolboard-capabilities?:

I encountered the same issue on my effectors which also uses those mounting holes (For a Zesty Nimble in my Case) the fix for me was to remove the housing on the effector and rotate it by 180 degrees and to wire the lead that connects to it appropriately.

That wouldn't help for this particular model. The same interference would be encountered for all three mounting holes (and would actually be worse on the other two.) The nimble adapter works because one of the three mounting holes is only about 3mm high and so sits under the clip for the micro-fit connector.

-

@Dougal1957 said in Smart Effector including toolboard-capabilities?:

the fix for me was to remove the housing on the effector and rotate it by 180 degrees

Do you say, the connector was on the bottom side of the SE after the rotation? Or the nose of the housing pointed the other way?

-

@garyd9 said in Smart Effector including toolboard-capabilities?:

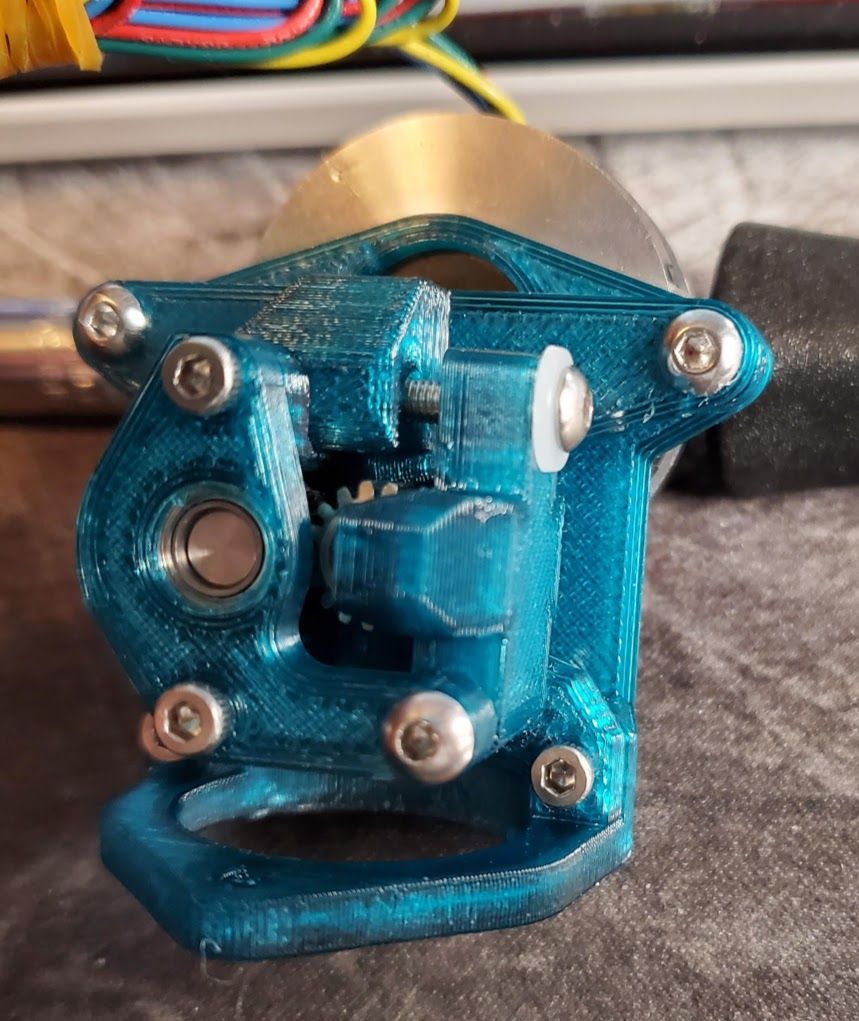

The extruder's plastic was in the way of the little latch on the connector. (Below are images of the area I'm referring to.)

You are right, it's to tight there. On my Deltas I'm using my first version without brass inserts.

At this point you could take away some material without getting problems with the inserts, I think. Otherwise - it also works if the screws are simply screwed into the plastic. Then there is enough space at that point. -

@o_lampe said in Smart Effector including toolboard-capabilities?:

@Dougal1957 said in Smart Effector including toolboard-capabilities?:

the fix for me was to remove the housing on the effector and rotate it by 180 degrees

Do you say, the connector was on the bottom side of the SE after the rotation? Or the nose of the housing pointed the other way?

i turned the nose out on the connector @garyd9 the first nimble adaptors (I was the guinea pig there) was just as high as the others that's how my solution helped it just moved the locking Tab to the outer edge of the connector.

Doug

-

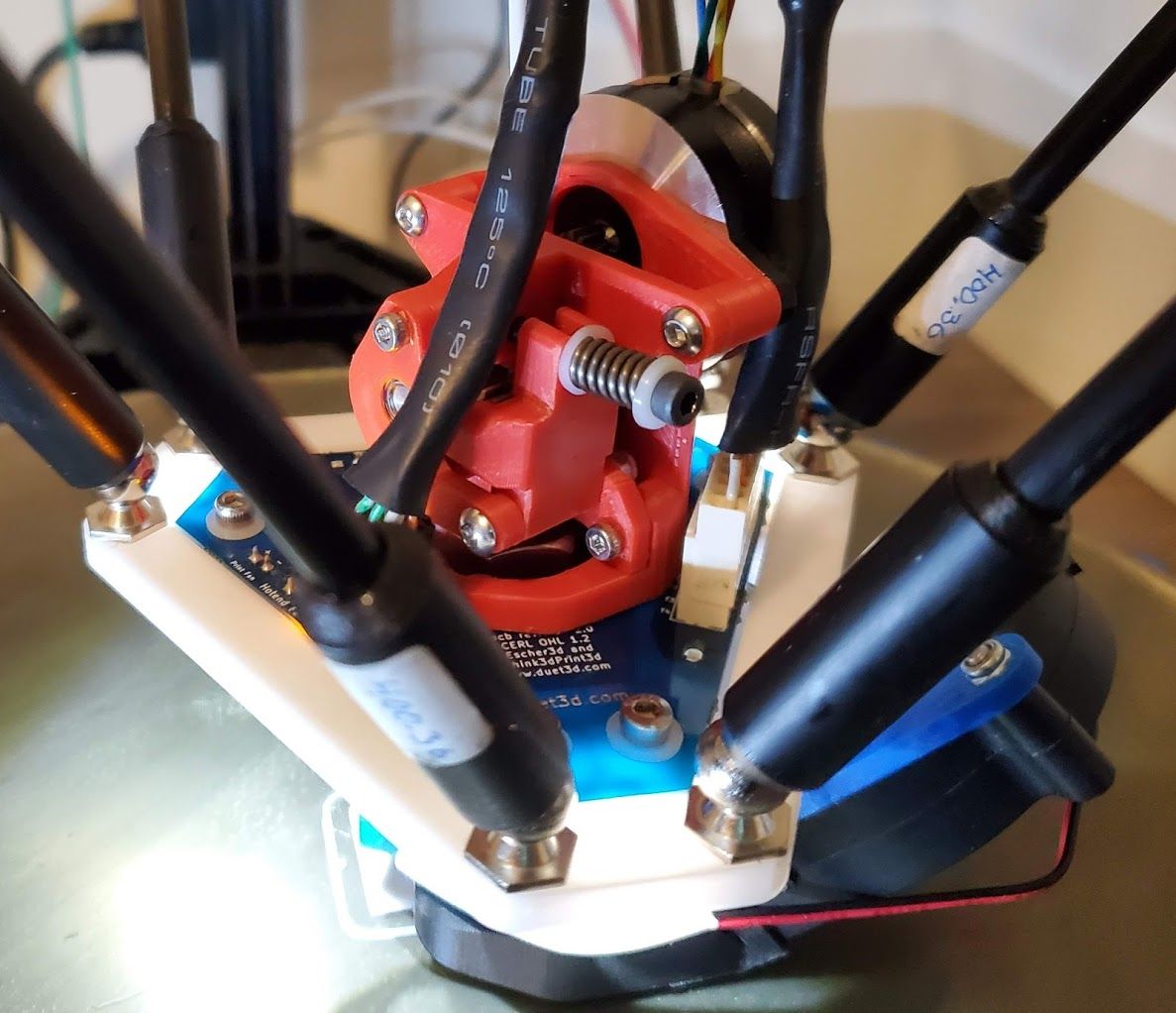

Still untested, but thought you might appreciate seeing your work:

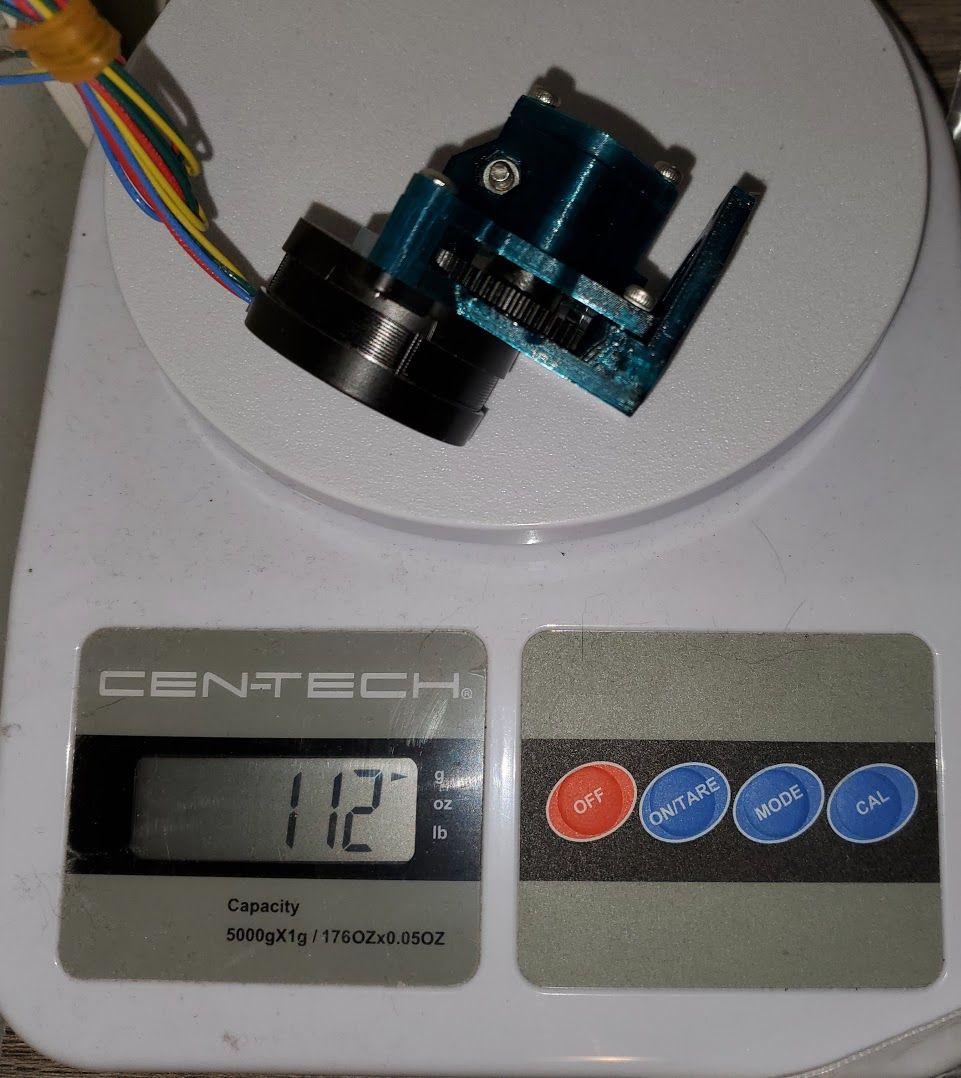

Everything printed with a 0.2mm layer height using SnoLabs "atrovirens" PETG. Only 112g including the stepper! (If you take into account all the dust on that scale, the extruder is probably only 111 grams.)

If you ever decide to publish this on thingiverse or something, feel free to use my photo (and I'd be happy to provide some more.) As well, the following might help anyone else that decides to try this out:

You need to really press the BMG 3x20 shaft into the idler lever. Pliers help. If the shaft falls out easily, or if the idler lever doesn't easily close, it's likely not in there properly.

On the motor mount piece and the 3 holes for mounting to the smart effector: I'm able to use just a M3 screw and nut for the front hole, but I couldn't find a good method for securing the rear two holes. I ended up using my "less than 100% reliable" M3x3 brass inserts. They seem to be secure, but only time will tell.

Manually lining up the BMG gear that mounts on the wheel/gear shaft is annoying. It's made much easier by sticking something all the way through the filament path and lining up the gear based on that.

Buying a BMG thumbscrew was a waste for an extruder this tiny. The "thumb" part of the screw rubs against the extruder, and there's just not enough space for the spring. An M3x25 with nylon washer appears to work well enough, but I might try to find a short spring I can use there. I've found that they're useful for irregular filament. (Edit: I found a long M3x40 screw I can use with the thumbscrew spring!)

It might still be a day or so before I'm able to properly test this. I need to verify that 74mm arm spacing will work on my particular printer, and then design/print new carriages.

Take care

Gary -

@garyd9 said in Smart Effector including toolboard-capabilities?:

Buying a BMG thumbscrew was a waste for an extruder this tiny

Yes, a M3 screw is provided here

Looks good, looking forward to seeing pictures of your first prints. Set the retract to 0.6 mm (PLA) and 1.0 mm (PETG) at 50 mm/s.

-

@dc42 In case the new smart effector becomes a reality, can we have an accelerometer on it to help with the detection of a crash or ringing? (Similar to this)

I don't know how feasible that is but one could even use it for the delta calibration by measuring effector tilt. (Maybe it could even replace the strain gauge if precise enough?)Might be a nice addition for the "normal" toolboards too.

-

@mrac1 said in Smart Effector including toolboard-capabilities?:

@garyd9 said in Smart Effector including toolboard-capabilities?:

Buying a BMG thumbscrew was a waste for an extruder this tiny

Yes, a M3 screw is provided here

I ended up finding an M3x35 that can work with the spring. It's probably not needed, but it makes me feel better.

After initial setup, I calibrated the feedrate on my setup to 698.4 steps/mm, and left jerk/accel/current at the values you suggested above. (That little LDO motor is impressive.)One other change I made with your model was the shorten the bottom of the filament guide and motor mount by 2mm (and then reshape the bottom of the filament guide to fit around the heatsink nut.) Then, because all the exact dimensions are there in fusion360, I made a little tool that lets me cut a piece of PTFE to the perfect length to go up into the extruder (from inside the E3D heatsink.)

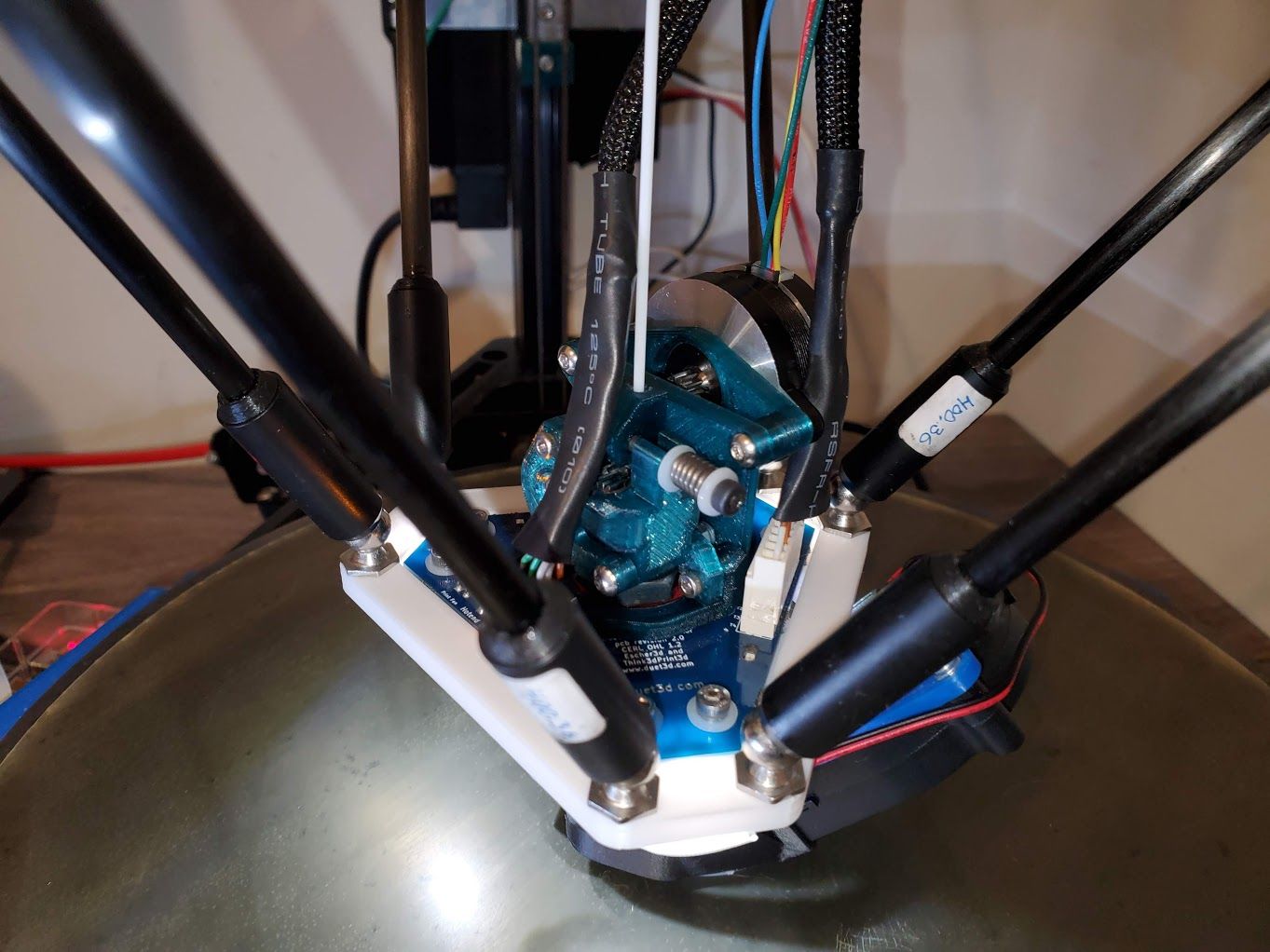

I ended up using a 74mm arm spacing. I could have gone as short as 65-70, but 74 made the smart effector adapter easier.

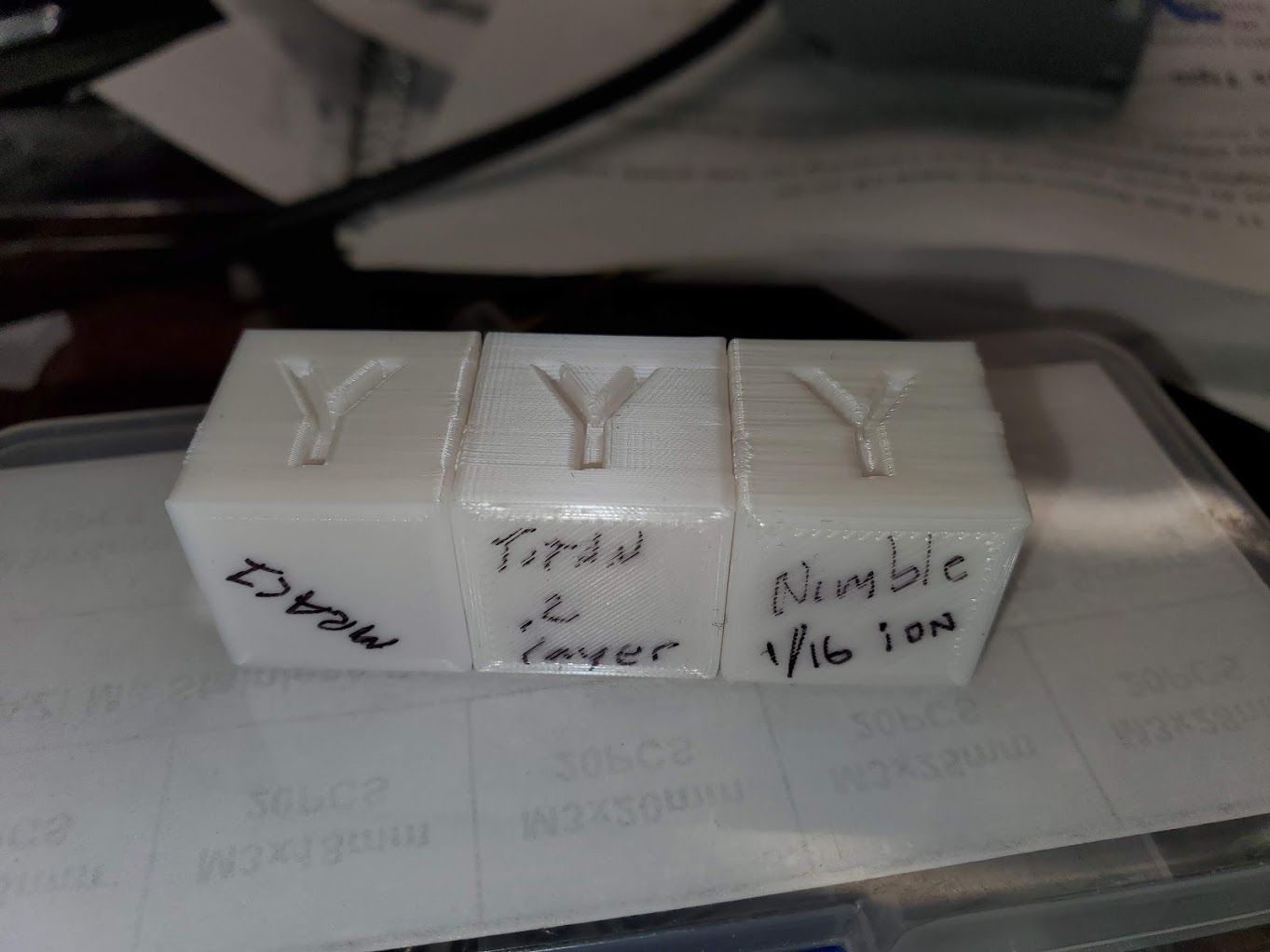

I printed a quick XYZ calibration cube, and it looks better than the Zesty Nimble ever did in terms of consistent extrusion, and no ringing/ghosting. That was sliced with old retraction settings (1.5mm@60mm/sec with a retract prime speed of 20mm/sec.) I also still have pressure advance at 0.04.

I'll need to sit down and recalibrate retraction, pressure advance, etc.

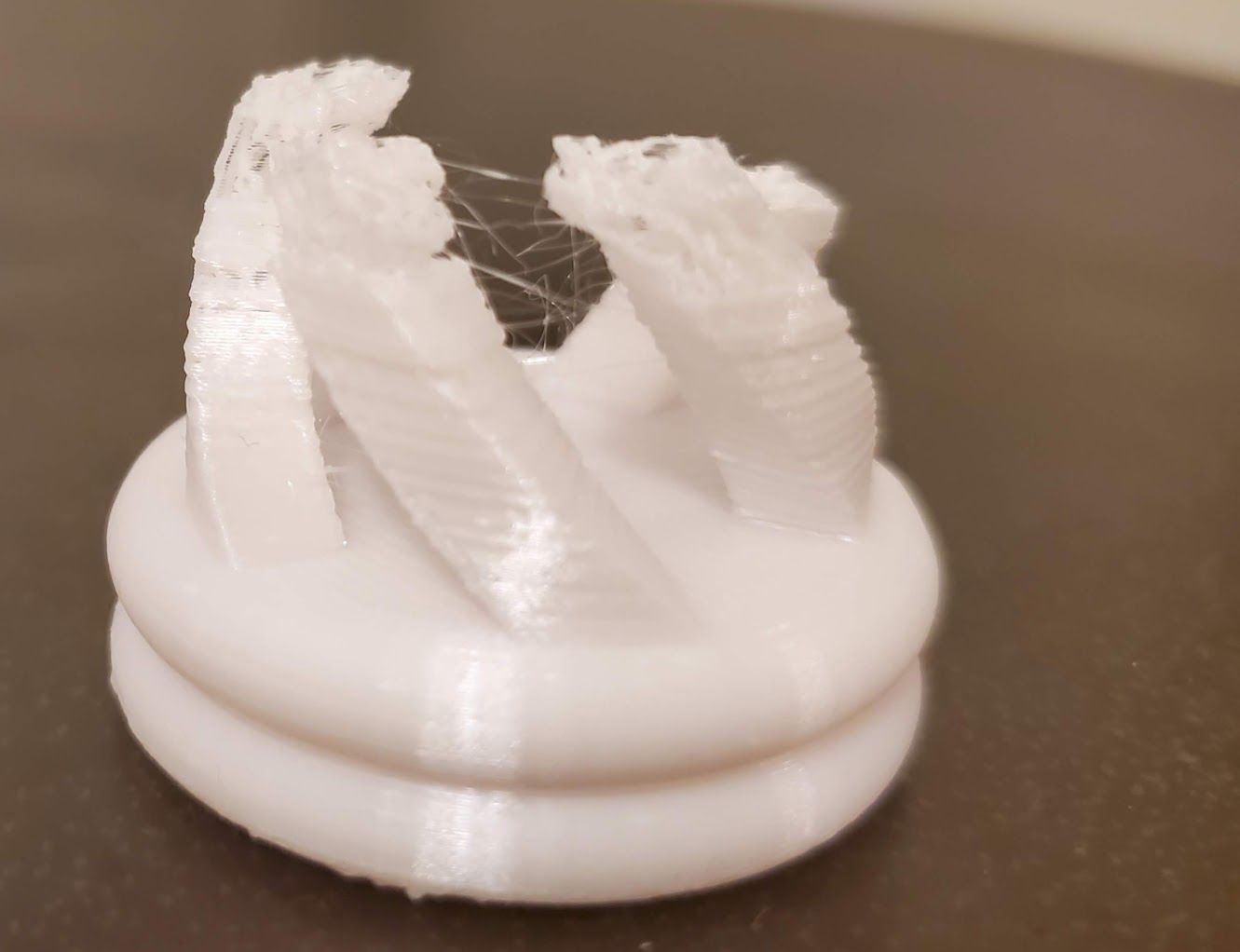

In the meantime, here's a couple more pictures. The first is your extruder mounted and working....

...and the other is a quick short of three XYZ calibration cubes. From left to right, they show your extruder, a titan extruder (with pancake NEMA17) hanging from a (not smart) effector, and finally a Zesty Nimble v1.2. The nimble shows inconsistent extrusion (that actually looks good compared to the nimble v2), and the titan shows obvious ringing. All three show bad retraction settings on the starts/stops.

Thank you again!

-

@garyd9

Looks promising, but I still see room for improvement. This quality is possible without any problems:

This was a test of the D3E and two different slicers (S3D on the left, PrusaSlicer on the right).

-

@garyd9

Looks good, although I wouldn't have taken PETG. IMHO it's to flexible.

What do you think, why does the Titan show more ringing, than the D3E? Because it was mounted below the effector?

I have 3 BMG clones (for 22€!) and a roll of Carbon PLA on my way. I'll give it a try, when they arrive. -

@o_lampe said in Smart Effector including toolboard-capabilities?:

What do you think, why does the Titan show more ringing, than the D3E?

The factors for ringing are, to my knowledge, the combination of speed, acceleration, jerk in relation to the mass of the effector. Thus, there should be more problems with a direct extruder than with a bowden extruder or a flying extruder due to the higher mass.

Fortunately, the LDO motor is very light and the print result is flawless.

My PA values are by the way:

PLA 0.10

PETG 0.15 -

@o_lampe said in Smart Effector including toolboard-capabilities?:

I have 3 BMG clones (for 22€!)

I have made the experience that the cheap BMG clones have very inaccurately manufactured components which also wear out very quickly.

If you want clone parts, I can recommend the parts from Trianglelabs and Mellow. They are very good, but nothing beats the original Bondtech. -

@garyd9 that's very promising! congrats! (I've just realized that we've exchanged not so long ago about my 5015 mount, I've recognized your remix on the picture

)

)What's the current BOM of your mrac1's D3E? I'm starting to be impatient and may join you and mrac1 too in this endeavor

-

@mrac1 said in Smart Effector including toolboard-capabilities?:

@garyd9

Looks promising, but I still see room for improvement. This quality is possible without any problems:!This was a test of the D3E and two different slicers (S3D on the left, PrusaSlicer on the right).

That is nice. As I mentioned, the calibration on my side also needs some work. I'll surely be using the settings you've posted as a starting place when I start calibrating! First, I need to redo some things...

@o_lampe said in Smart Effector including toolboard-capabilities?:

Looks good, although I wouldn't have taken PETG. IMHO it's to flexible.

You are right about PETG and I encountered that last night. I was trying to print the bishop spiral chess piece (from here: https://www.thingiverse.com/thing:470700) and encountered all kinds of issues doing the spiraling columns. As with certain other test prints, I didn't re-slice this model just for this extruder, so the extraction is at 1.5mm @60mm/sec. When it starts the "columns", over time, it appears that the extruder is having a harder and harder time un-retracting, and the entire body of the extruder flexes. Eventually, the hot end appears to be getting starved of filament.

Note that I have MANY examples of this exact .gcode file working with this exact same spool of filament, temps, etc (all with different extruders.) I already know how I can get this to continue printing (increase the temp 5C.) Increasing/decreasing motor current doesn't help. I think (but I don't yet know for sure) if the extruder body was less flexible, it would push through (but even then I'm wondering if the temps should be higher for this filament.)

Regardless, I think I'm going to try to print the extruder parts again using ABS instead of PETG. First, I want to sit with the model and see if there's anything I can do to make it structurally stiffer. (Sadly, I'm not an structural engineer, so it's just guess work for me.)

@o_lampe said in Smart Effector including toolboard-capabilities?:

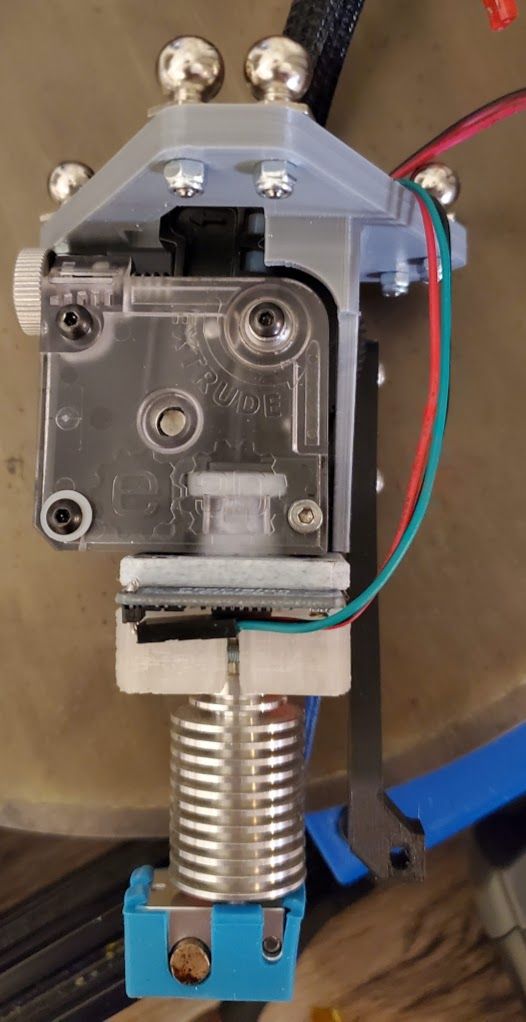

What do you think, why does the Titan show more ringing, than the D3E? Because it was mounted below the effector?

The effector with the titan is big, heavy, and poorly designed (by me.) Imagine an effector with a bracket attached to it's underside to hold a NEMA17. Mount a Titan Extruder on there. Then hang a Precision Piezo Orion from the titan extruder. From that, hang an E3D heatsink and hot end. Here's what it looks like (without a part cooling fan):

@Hergonoway said in Smart Effector including toolboard-capabilities?:

@garyd9 that's very promising! congrats! (I've just realized that we've exchanged not so long ago about my 5015 mount, I've recognized your remix on the picture

)

)Yep - I had to modify the effector arm again to shorten it 3mm to compensate for the 3mm thick effector adapter used here. Of course, once I had everything in fusion360 set up with parameters, making adjustments is a matter of changing a parameter or two and everything else falls into place.

@Hergonoway said in Smart Effector including toolboard-capabilities?:

What's the current BOM of your mrac1's D3E? I'm starting to be impatient and may join you and mrac1 too in this endeavor

At the moment, here's what I've purchased and what I already had on hand that I've used:

- Lots of filament

- M2.5 screw assortment

- M3 screw assortment + nuts (I prefer nylocks when there's room)

- M3 plastic or nylon washers (I have both 0.5mm and 1mm thick)

- 2 MR85ZZ (5x8.2.5mm) bearings (I bought a pack of 10 from amazon)

- LDO Stepper motor 36STH17-1004AHG

- Bondtech Drivegear Kit for 1.75mm/5mm (includes both drive gears, 3x20 shaft, 2 needle bearings)

- Bondtech Shaft/Gear assembly (this is the shaft with big plastic gear)

- Assorted wires and wiring connectors (for extending and added a connector to the stepper motor)

- M3x3 brass inserts. (https://www.amazon.com/gp/product/B01IYWTCWW)

I included an amazon link for the brass inserts I used. Different vendors have different meanings and sizes for "M3x3 brass insert" so I wanted to be clear. Note that these are not great inserts for 3D printing, but they are all I had on hand that fit in the tiny space.

Take care

Gary -

thanks! just ordered the pancake, already got the hardware (screws and brass inserts), and found this kit that should cover the rest (Bondtech and bearing stuff): https://www.aliexpress.com/item/thingiverse-BMG-Direct-Drive-Basic-kit-for-Great-DIY-player-can-be-use-for-ender-3/4000021186440.html?spm=a2g0s.9042311.0.0.42164c4dt7vaan

-

@Hergonoway said in Smart Effector including toolboard-capabilities?:

thanks! just ordered the pancake, already got the screws and brass insert, and found this kit that should cover Bondtech and bearing stuff (https://www.aliexpress.com/item/thingiverse-BMG-Direct-Drive-Basic-kit-for-Great-DIY-player-can-be-use-for-ender-3/4000021186440.html?spm=a2g0s.9042311.0.0.42164c4dt7vaan)

That aliexpress item does appear to cover the parts. I'm not sure if the gears are 5mm ID or not (and I can't find anything that states either way.)

Wherever in the world you are, I hope you have more reasonable shipping times than what I see for shipping to the US. The only way I'd get it within a month is if I paid 50 USD for shipping (for a total of over 70 USD.) At that point, it's actually cheaper for me to get real Bondtech parts shipped from the US.

-

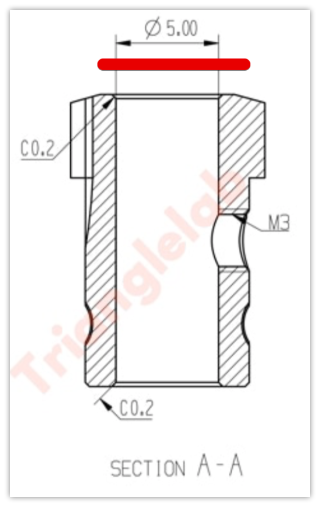

it's got the 5mm ID drivegear:

where the only drivegear alternative trianglelabs proposes (the 8mm) got this fatty look and doesn't have the same barrel bearings. The 8mm kit pic:

VS The ones in the kit:

VS The ones in the kit:

-

@garyd9 Can you post your Fusion360 files? I've got all the bits and bobs here and wouldn't mind giving this a go to replace my nimble with the mods you made to the D3E.

-

Sure thing. I'm not sure how complete the fusion360 export is, but the plastic parts to print are in the main component.

For just the extruder, you need "idler lever", "motor mount", "front bearing idler bracket" and "filament guide."

If you use my modifications to the parts, the motor mount requires 0.5mm thick M3 washers to be between it and the smart effector (one for each screw.) (The original model from mrac1 had spacing built in.)

Assuming Fusion360 parameters are intact in the archive file, "BearingHoleDiameter" can be made slightly larger than 8.1mm. I found this was needed when I printed in ABS, as the bearing holes were too small (and forcing the bearings in would damage the ABS.) I used 8.3mm for ABS and the resulting post-print holes were ~7.9mm (which gave a nice snug fit for the 8mm OD bearings.)

"BrassInsertDia" and "BrassInsertIndent" slightly change the 2 holes on the bottom of the motor mount where the brass inserts should go. The intention was to allow me to better line up the inserts. It didn't work out very well.

The remaining parameters relate to the "effector adapter" piece. ArmSpacing is self explanatory. DesiredTES relates to the "TES" parameter I discussed earlier in this thread. MagBallMounting parameters should probably be left as-is. One is how big of a hole for the magball thread, and the other is how much flat space is needed to secure the magball.

The "PTFE Size Guide" is intended to be printed and placed on your smart effector (assuming the enter heatsink/hotend is assembled and attached.) Then put a piece of 4mm OD PTFE tubing through the smart effector into the heat sink as far as it'll go. Thread the size guide on top of that, all the way against the smart effector. Cut the PTFE tube flush with the top of the size guide, and it should be within 0.5mm of perfect.

Finally, please forgive the absolute mess I made of the fusion360 project. I'm hardly fluent with it, and sometimes I just kind of shove things together and hope they work.

Here's a link to the fusion360 shared from my google drive: https://drive.google.com/file/d/1d7YBo-knfZ-HGiYp8PYGQUGXExMkRIlC/view?usp=sharing

-

@garyd9 Awesome, thanks a lot. I'll give it a go this week. My setup looks a bit similar to yours, I've got hayden's magball arms too. I'll have to rework some carriages for the new spacing but that shouldn't be too bad.