Hi,

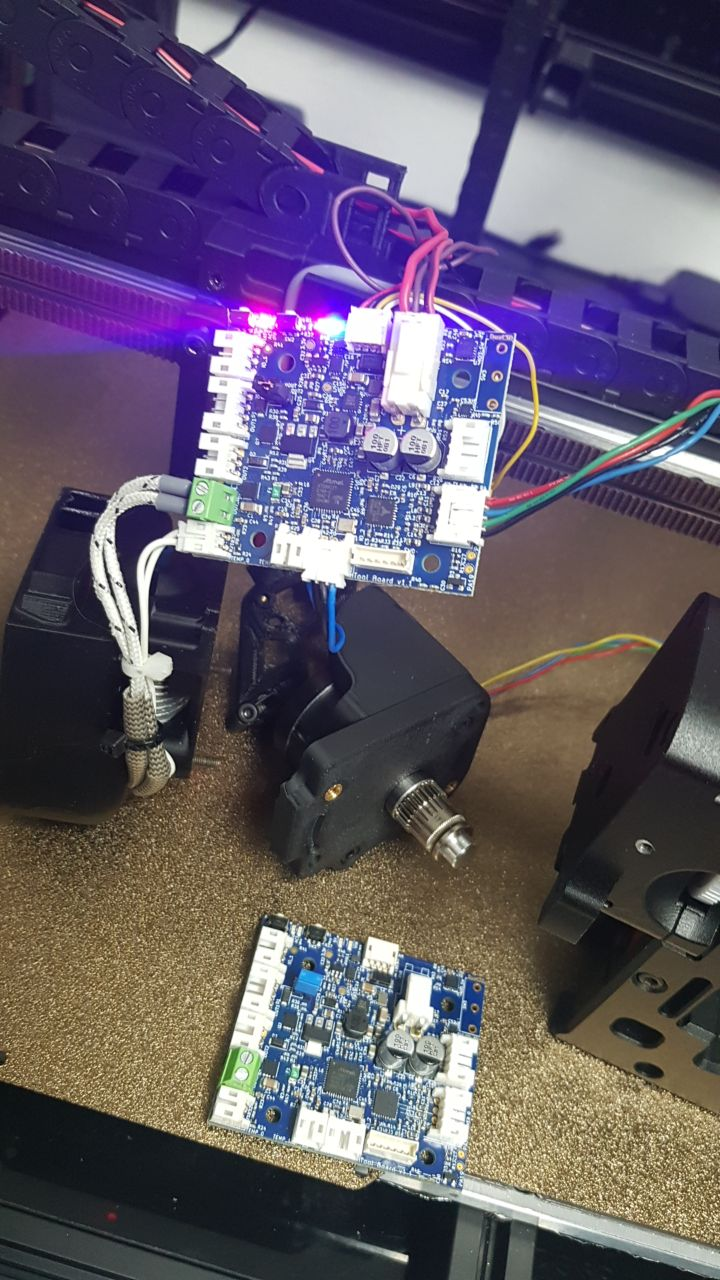

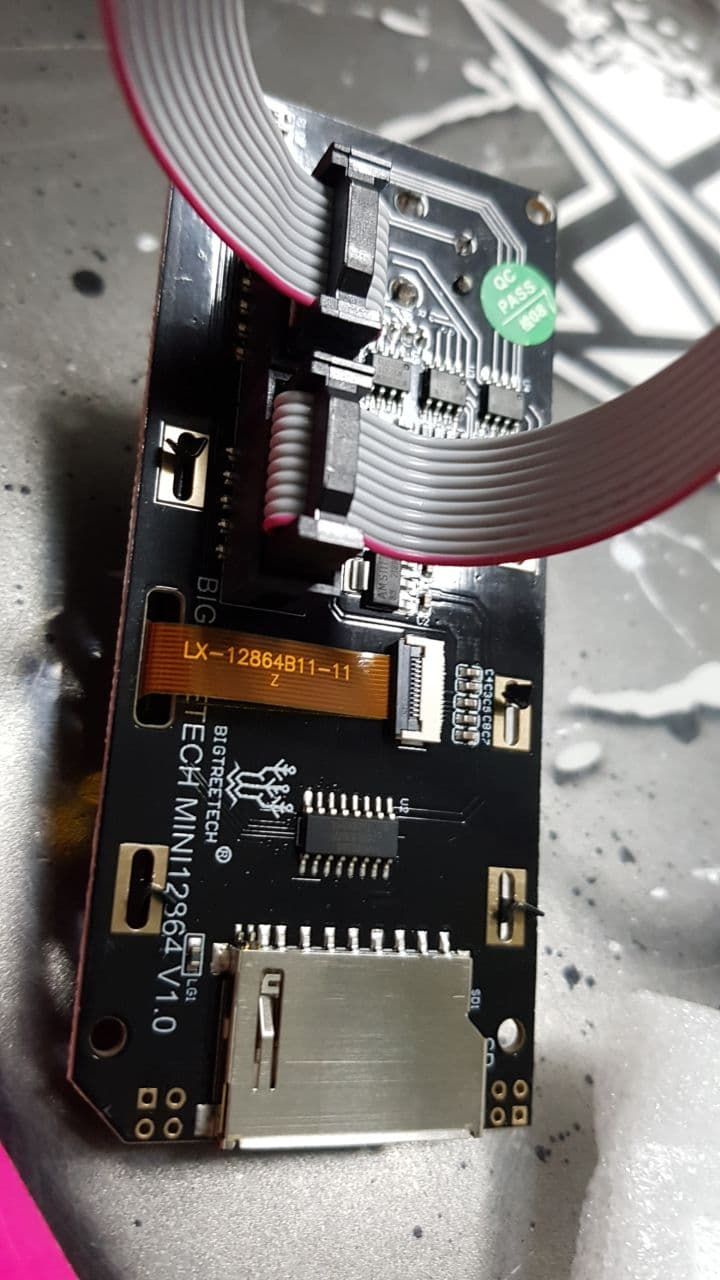

I installed a original brand new Toolboard 1.1 in my new voron 2.4, equipped with Duet 3 mini 5.

The toolboard is perfectly working (fans, cartdrige ecc) but the stepper extruder is not working.

I checked with diagnostics and the is a "Not Present" about the driver 0.

This is the diagnostic

m122 b121

Diagnostics for board 121:

Duet TOOL1LC rev 1.1 or later firmware version 3.4.0beta6 (2021-11-06 11:56:11)

Bootloader ID: SAMC21 bootloader version 2.3 (2021-01-26b1)

Never used RAM 2576, free system stack 2788 words

Tasks: Move(notifyWait,0.0%,153) HEAT(notifyWait,0.2%,113) CanAsync(notifyWait,0.0%,64) CanRecv(notifyWait,0.0%,77) CanClock(notifyWait,0.0%,64) ACCEL(notifyWait,0.0%,61) TMC(notifyWait,0.4%,67) MAIN(running,94.4%,350) IDLE(ready,0.0%,27) AIN(delaying,4.9%,142), total 100.0%

Last reset 00:09:54 ago, cause: power up

Last software reset data not available

Driver 0: pos 0, 656.0 steps/mm,not present, steps req 0 done 0

Moves scheduled 0, completed 0, in progress 0, hiccups 0, step errors 0, maxPrep 0, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0

Peak sync jitter -4/6, peak Rx sync delay 213, resyncs 0/0, no step interrupt scheduled

VIN voltage: min 24.2, current 24.2, max 24.2

MCU temperature: min 30.3C, current 30.6C, max 35.0C

Last sensors broadcast 0x00000002 found 1 135 ticks ago, 0 ordering errs, loop time 0

CAN messages queued 10672, send timeouts 0, received 4800, lost 0, free buffers 37, min 37, error reg 0

dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 0

Accelerometer detected: yes, status: 00

I2C bus errors 0, naks 0, other errors 0

This is my config

; Configuration file for Duet3 Mini5+ with Mini2+ expansion (firmware version 3.3 or newer)

; executed by the firmware on start-up

; General preferences

M80 C"pson" ; Turns on the ATX power supply

M111 S0 ; Debugging off

G21 ; Work in millimetres

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M669 K1 ; Select CoreXY mode

M564 S1 H1 ; Forbid axis movements when not homed

;M918 P2 E4 F2000000 C30 R6 ; Fysetc 12864 display

; Wait a moment for the CAN expansion boards to start

G4 S2

; M575 P1 S1 B57600 ; enable support for PanelDue

; Network

M550 P"Voron V2.4" ; Set machine name

M552 S1 ; enable network

M587 S"xxxxx" P"xxxxxx" ; Configure access point. You can delete this line once connected

M586 P0 S1 ; enable HTTP

M586 P1 S1 ; disable FTP

M586 P2 S0 ; disable Telnet

; --- Z Drive map ---

; _______

; | 1 | 2 |

; | ----- |

; | 0 | 3 |

; -------

; front

;

; (looking at the printer from the top)

; Drive directions

M569 P0 S1 D2 ; Z0

M569 P1 S0 D2 ; Z1

M569 P2 S1 D2 ; Z2

M569 P3 S0 D2 ; Z3

M569 P121.0 S0 ; Extruder

M569 P5 S1 D2 ; A

M569 P6 S1 D2 ; B

; Motor mapping and steps per mm

M584 X5 Y6 Z0:1:2:3 E121.0

M350 X16 Y16 Z16 E16 I1 ; Use 1/16 microstepping with interpolation everywhere

M92 X160 Y160 Z413 ; Set XY(0.9 deg motors)and Z(1.8deg motors)steps per mm

;M92 E432 ; BMG Extruder steps per mm

M92 E656 ; GALILEO Extruder steps per mm

; Drive currents

M906 X1250 Y1250 Z1400 E600 ; XYZ and E current

M906 I30 ; Idle current percentage

M84 S120 ; Idle timeout

; Accelerations and speed

M98 P"/macros/print_scripts/setup_printing.g"

; Axis travel limits

M208 X0 Y0 Z-8 S1 ; Set axis minima

M208 X300 Y306 Z275 S0 ; Set axis maxima

; Endstops

M574 X2 S1 P"io3.in" ; Xmax endstop on hall effect board

M574 Y2 S1 P"io1.in" ; Ymax endstop on hall effect board

M574 Z0 P"nil" ; No Z endstop

; Bed leveling

M671 X-65:-65:365:365 Y0:395:395:0 S20 ; Define Z belts locations (Front_Left, Back_Left, Back_Right, Front_Right)

M557 X25:275 Y25:275 P8:8 ; Define bed mesh grid (inductive probe, positions include the Y offset!)

;********************************************************************* Z PROBES

;SENSORE INDUTTIVO HOTEND

M558 K0 P8 C"121.io2.in" T18000 F120 H5 A5 S0.01 R0.2

G31 K0 P500 X0 Y25 Z2 ; Offset sensore

;MICROSWITCH Z

M558 K1 P8 C"^io6.in" T18000 F240:60 H2 A10 S0.005 R0.2

G31 K1 P500 X0 Y0 Z0.73 ; Z switch offset (if positive, greater value = lower nozzle. if negative, more negative = higher nozzle)

;*******************************************************************************

; Heaters

M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S115 ; set temperature limit for heater 0 to 100C

M308 S1 P"121.temp0" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin 121.temp0

M950 H1 C"121.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

;M307 H1 B0

M143 H1 S280 ; set temperature limit for heater 1 to 280C

; Fans

M950 F0 C"121.out1" Q500 ; create fan 0 on pin 121.out1 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"121.out2" Q500 ; create fan 1 on pin 121.out2 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on

; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Misc

; M572 D0 S0.075 ; Pressure Advance

; M592 D0 A0.015 B0.0012 L0.2 ; Non-linear extrusion

; DAA tuning

M955 P121.0 I05 ; create accelerometer on P121.0

; M572 D0 S0.01 ; Pressure Advance

; M376 H10 ; Fade mesh out compensation over 10mm Z

M575 P1 S1 B57600 ; enable support for PanelDue

M501 ; load config-override.g

T0 ; select tool 0

What i'm doing wrong?

Thanks