@Jered

This finished again with no issues so I guess there is no problem.

Posts made by Jered

-

RE: Version 3.5.2 is giving me issues!posted in Firmware installation

-

RE: Version 3.5.2 is giving me issues!posted in Firmware installation

@chrishamm

I typed this in the terminal window, hit enter, and nothing happened. It didn't error either, just nothing. Would the output be in the terminal or does it store that somewhere else? -

RE: Version 3.5.2 is giving me issues!posted in Firmware installation

@infiniteloop

There error is this

Error: in job file (channel File) line 0: Illegal parameter letter ','and yes to your question.

I removed the quotes I had put around it. That being said, yes I agree, the error does not make sense. It was weird when this happened. It automatically canceled my job. Not sure if, due to the many nozzle heater faults I was having due to the bad autotune that somehow caused it.

I have never seen code with a line zero . -

RE: Version 3.5.2 is giving me issues!posted in Firmware installation

@infiniteloop

I can get rid of the comments if it helps.

Here it is without comments;

Freeze_Pipe_Joint_Adapter.gcodeThis file gave that error 75% of the way through the print. So the "line 0" part of the error doesn't even make sense.

-

RE: Version 3.5.2 is giving me issues!posted in Firmware installation

@Jered

So this ghost run of the file above worked fine with no problems, so now I am going to run it again with filament. -

RE: Version 3.5.2 is giving me issues!posted in Firmware installation

@infiniteloop

Oops, forgot about that. Below is the file.

Freeze_Pipe_Joint_Adapter.gcode -

RE: Version 3.5.2 is giving me issues!posted in Firmware installation

@Phaedrux

I believe the last version was 3.3, but honestly I never updated this data in the config.

I am running in SBC mode and I did update all boards. The thing that is really getting me is the temp overshoot. It seems the new autotune sucks. I found my old values before using the latest method from your site and now it works fine. It was over shooting be 15 deg then faulting out. The autotune process itself works fine, but the values for R is way off.Here is the M122 dataM122 Info.txt

Currently I am running the gcode with no filament as you suggested. This run has the old autotune values and has not faulted as of yet. If it finishes, I will consider this good and will run the file again with filament.

I do really appreciate this forum and your help. You guys are the best! And because of your dedication, I never really get worried that problems with your products will get fixed. I am still wondering what caused this error "Error: in job file (channel File) line 0: Illegal parameter letter ','". Any ideas?

-

Version 3.5.2 is giving me issues!posted in Firmware installation

Hey guys,

I just upgraded to the firmware version above and now I have issues with printing. I am using the same gcode as before and now I got this error 75% of the way through a print "Error: in job file (channel File) line 0: Illegal parameter letter ','". Now I have to start over!! Also, I constantly get nozzle heater faults. Never happened before. I did an auto tune, still have problems. The machine pauses for the nozzle heater faults. I don't see anything wrong with the temp, it just faults out when the tool changes and the temp swings due to filament being swapped. This is very annoying. Also I had to change some of my macros cause apparently the new firmware didn't like the way it was written. I have attached my config incase you want to see it. config.g -

RE: Creating height maps only where the part is being builtposted in Tuning and tweaking

@sebkritikel

I will look at this closer, but I still think scanning the bed is the best way.Thanks!

-

RE: Creating height maps only where the part is being builtposted in Tuning and tweaking

Thank you, I will have a look at that.

-

RE: Creating height maps only where the part is being builtposted in Tuning and tweaking

I had a feeling you might say that!

Honestly, I am biased as well! I have had nothing but good running and reliable machines with your products!

The main reason I ask about the Duet scanning probe is, I know it is pretty new. At least, it looks like it from the date that it was released last year. The other probe by Beacon has been out for a bit and has a new release. Usually when a product is released, there is somethings that could be changed to make it better, so I usually wait until the second rendition of products. I know this because I to am an engineer and create products for others. The second one is always much better.

Anyway, I do appreciate your help!

-

RE: Creating height maps only where the part is being builtposted in Tuning and tweaking

@Phaedrux

That's what I have been doing, but I noticed that the bed does not take the same shape every time it is heated to the same temp. Before I print, I have to let the bed heat up and acclimate for 1 hour. Then I print on it. Even after waiting an hour for the bed to acclimated, from one day to the next, I noticed that the height maps don't quite match (took a long time to get those test results). For large prints, that first layer is very crucial (like any print really) as it can get expensive if I have to keep starting over.Honestly, I would much rather upgrade to a scanning probe as there are many more data points, which adds to the accuracy. I just want to make sure I get a good quality scanning probe that will work with Duet.

It will require a lot of work and changes to my current mechanical config to get it going. I was kind of hoping that, as a temporary fix, I could automatically have the area where the part is printed to be probed, but it looks like I would have to program this for every part made.

-

RE: Creating height maps only where the part is being builtposted in Tuning and tweaking

@Phaedrux

Interesting post, but not automated enough to matter for me. I think I will look into the scanning probes as they don't require a lot of time to use. My printer is a 500mm ratrig, so it is large and requires about 25min to probe with a standard probe type.Would still be interested to know how Duet's scanning probe compares to the Beacon.

-

Creating height maps only where the part is being builtposted in Tuning and tweaking

I was wondering if there is any feature that allows for height maps to be generated only where the part is going to be build automatically? This would save a lot of time. Just wondering.

Also, I was wondering how your Duet 3 Scanning Z Probe compares to the Beacon RevH? And can the Beacon RevH be used with the Duet's scanning probe board?

If the Duet scanning probe is comparable to the Beacon RevH, I would rather just use Duet.

Thanks!

-

RE: Using the keyboard to manually drive the printer?posted in Plugins for DWC and DSF

@Phaedrux

I will have a look at this, but the keyboard is cheaper and easier. Have you guys ever looked at Mach4 (Newfangled Solutions) and the way that they handle code and their software solutions? They are kind of the standard for consumer grade cnc controller software. It would be nice if you guys could steal some of their business by integrating some of those features they offer into your DWC. Real time gcode viewing and manually manipulating the machine while the DRO's update in real time as well are some major features that are needed.Being able to see the gcode scrolling by as the machine is milling is very handy when there is a problem. If a problem occurs, I can pause the machine, look at the line of code it is on, correct the problem, put the machine at the correct line of gcode and hit go again. This way I don't have to start over or scrap something that could be saved.

You guys have a very good product! I think it is under utilized do to a few missing elements that could be added (for the cnc world that is).

I use your product to build incredible industrial 3d printers that have 13 stepper on one machine! I also build industrial cnc's for people in all kinds of industries. Unfortunately, I have to use a different software/controller package to do it. I would like to switch to using one controller for all applications.

I should have minored in programing so I could help out with this. I am a EE, and can program PLC's, but anything else is out of my reach.

Anyways, your product is amazing for 3D printers. It's the only one I use! I hope someday it will be the best all around controller!!

Thanks for your help!

Below is my latest project, which is converting an Ender 5 to a multi material Duet machine.

-

RE: Using the keyboard to manually drive the printer?posted in Plugins for DWC and DSF

@Jered

I guess this works, but was hoping for a continuous jog mode. Seems to only support incremental jogging, set by the chosen increments at the top of the game pad page.For this reason, there is no way i would use this controller for a cnc. Not enough support yet.

I have been using large cnc's for years. When positioning them for certain jobs, you need a pendant, keyboard or handheld jog wheel that will reach where you need to go with the cnc. You can't run back to the display every time and jog a bit more, then a bit more, and a bit more.... ect. This would take forever and is not convenient for anyone.

In the future, I would like to build a cnc using this controller, but it's just not there yet.

-

RE: Using the keyboard to manually drive the printer?posted in Plugins for DWC and DSF

@Sindarius

Thanks!!This did install! I will play around with it today!

-

RE: Using the keyboard to manually drive the printer?posted in Plugins for DWC and DSF

@Jered

Here is a pic of my current version.

-

RE: Using the keyboard to manually drive the printer?posted in Plugins for DWC and DSF

@Jered

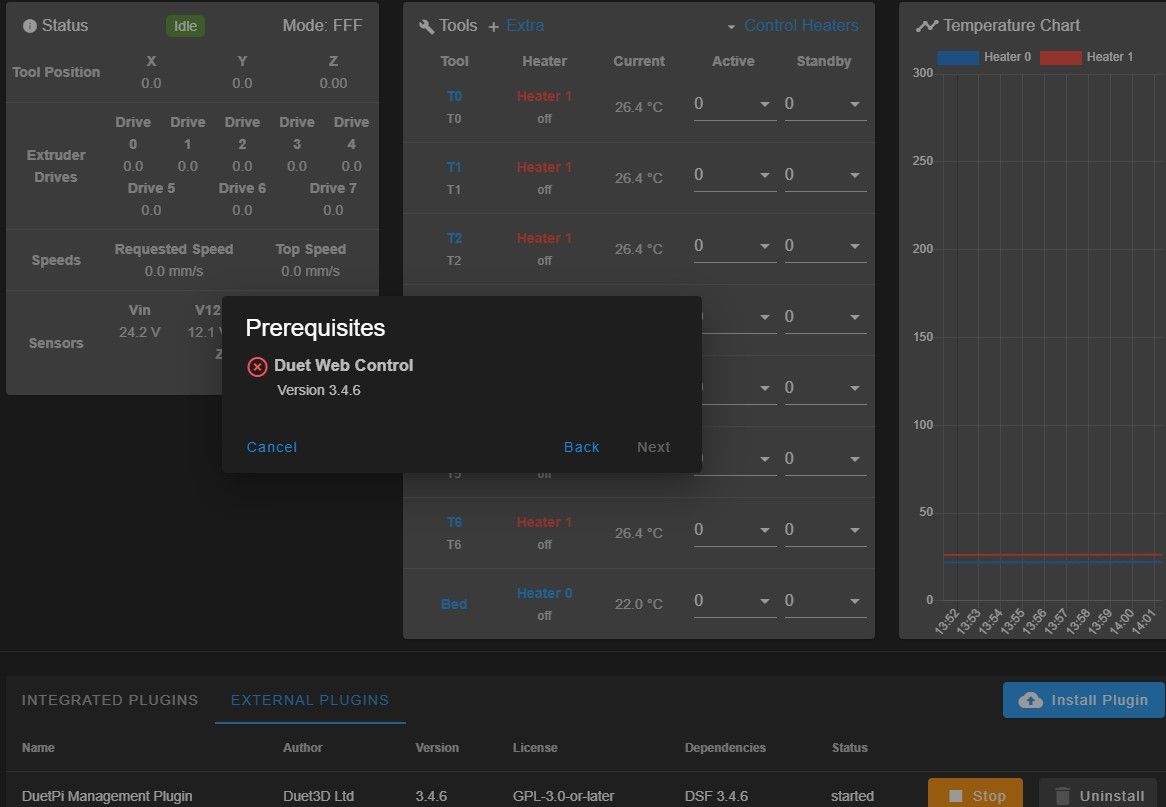

So, I am guessing this is not compatible with DWC 3.4.6. I have attached a pic of what happens when I try to install it.

-

RE: Using the keyboard to manually drive the printer?posted in Plugins for DWC and DSF

@Jered

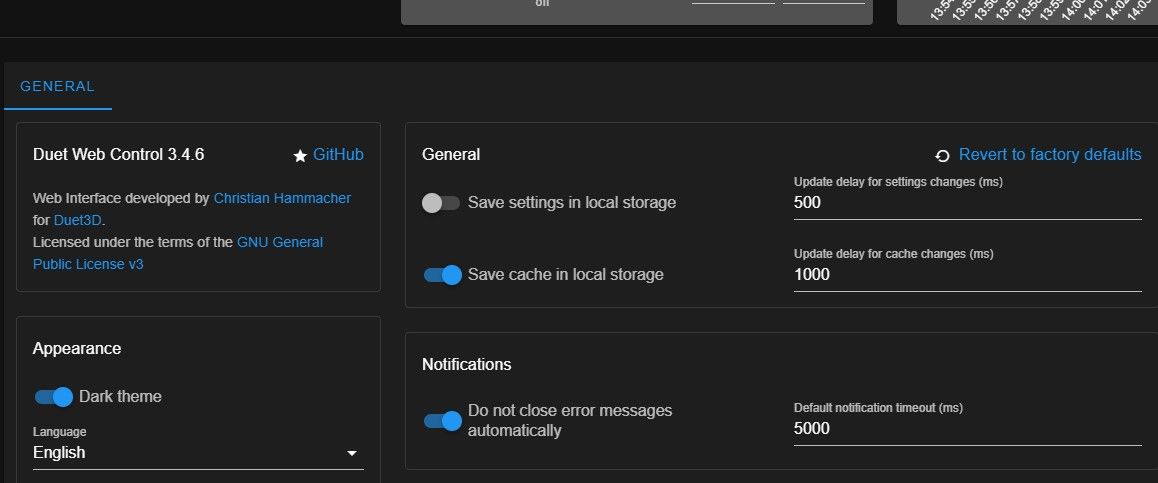

I just noticed that I have the latest Duet Web Control 3.4.6