Hi

https://duet3d.dozuki.com/Wiki/Duet_2_Pinout_table

is there a new site replacing this site? or does anyone have the pinout table?

best regards

Hi

https://duet3d.dozuki.com/Wiki/Duet_2_Pinout_table

is there a new site replacing this site? or does anyone have the pinout table?

best regards

Ok i was printing a thin piece of sheet at

first layer 60mms.

once I saw good adhesion i increased 300% to 180mms

PRinter is configured to run at maxium 400mm/s (24000mm/min)

However, once I Resumed the print, it used the previous 180mms as 100% and now ran the printer at 540mms.

So there are 2 bugs. First is that it used the old speed values to set new 100% value, and second is that it printed above the hard-coded configured speed.

I Tried to revert it by setting the speed to 33% -> Pause -> resume -> speed 100%

it now ran 60mms again as base speed.

Version 3.4.0 B3

hey

running latest versions of beta 3.4

latest version paneldue and latest DWC

When I plug in the SD into the Paneldue, I have to detect it first via the DWC by pressing SD card #1

If i dont do that it never shows up on the SD card list on panel due.

@o_lampe Yeah  maybe ill just try the DSH that arrived yesterday. that one says

maybe ill just try the DSH that arrived yesterday. that one says

2304 - DSH - YP3HC"

Do you know the orientation of the purple LISD3DSH board? X Y Z

I cant find that information anywhere

@jbergene Now I get another issue and that is the Duet2 just reset every time I try to record. It some how manages to record something, but the CSV file is invalid.

Duet also states that the LISD3H is aLIS3DSH which is incorrect. (the board have LIS3DH typed in on it)

@jbergene

update

it worked when removing the Paneldue and disabling paneldue in the config file.

(still using Daughter board pins)

@diy-o-sphere M955 P0 I61 C"io0.out+io0.in"

Error: M955: Unknown pin name 'io0.out'

@diy-o-sphere switched the wiring from the daughterboard pinouts to the Paneldue pinout with same results.

@diy-o-sphere ah sorry my bad, i have tried swapping this too without success. Just forgot to edit the text. my bad

Hello

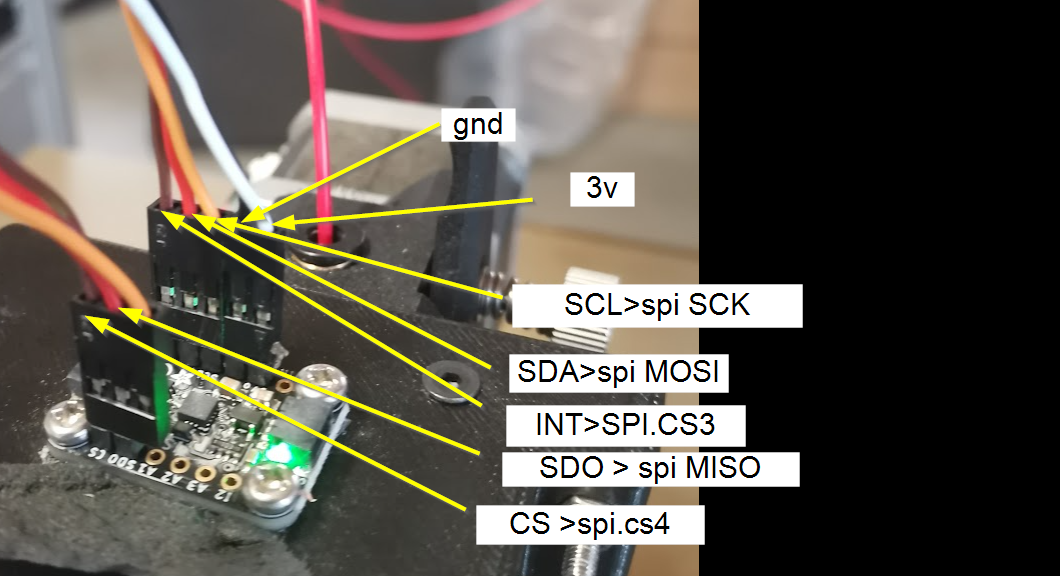

I have connected the Adafruit LIS3DH exactly as mentioned on the Accelerometer page, to my duet 2.

I Get "M955 P0 C"spi.cs4+spi.cs3"

Error: M955: Accelerometer not found on specified port"

I have tried switching MISO and MOSI, and Cs3 and cs4 ports to just check against myself.

I have also quadruple checked the wiring and its exactly the same. Wire length is 500mm. (bl touch extension wires)

However many images I see on this post is people have wired the VIN instead of 3v?

Web control, firwmare etc are all the latest beta 3.4.

@o_lampe watercooling the heatsink would make little difference in my opinion. As the magnum already had very low thermal transfer.

So that's why I thought the speed could just dynamically while the temperature is decreasing and increasing.

It also cools a lot quicker while extruding, since new filament will absorb the heat

hello

FDM/FFF Printers are getting faster and faster by every week in the community.

Carbonfiber rods, Mosquito magnum+ with almost 100mm3 flow allows for extremely fast extrusions even with small nozzles.

Printing large objects fast generally isnt a problem. But once small detail is introduced (benchy roof pipe for example) that requires lower speed for cooling, or lower speed for the fine details.

So what if we could type in the Slicer:

Detail temperature

Speed temperature

Heater VIN readings (to accruately time the temperature changes)

Slicers already have Minimum layer time for cooling. But when I print PLA at 280Celcius to match the flow, that is just waaay to much for that benchy pipe.

So if the slicer could set temperature to 210C some time before the pipe comes, the printer could gradually slow down the speed match that temp.

at 280C it runs 300mms

at 250 it runs 200mms

and at 215 it runs 60mms (just exampes)

That way we theoretically would get a perfect benchy at the highest possible speed.

Thoughts on this?

am I being uselessly creative here?

best regards

jhb

@phaedrux That is true. I havent tried these stall detections yet but have to give it a try it seems.

on the PRusa i3, it works flawlessly and you can barely see it on the print.

My experience with skipped steps have come from nozzle crashing into blobs that have fallen of the nozzle during printing (generally PETG).

@engikeneer No. Honestly I didnt know this existed.

Will definitively have to try this on my corexy printer  thank you

thank you