hello

FDM/FFF Printers are getting faster and faster by every week in the community.

Carbonfiber rods, Mosquito magnum+ with almost 100mm3 flow allows for extremely fast extrusions even with small nozzles.

Printing large objects fast generally isnt a problem. But once small detail is introduced (benchy roof pipe for example) that requires lower speed for cooling, or lower speed for the fine details.

So what if we could type in the Slicer:

Detail temperature

Speed temperature

Heater VIN readings (to accruately time the temperature changes)

Slicers already have Minimum layer time for cooling. But when I print PLA at 280Celcius to match the flow, that is just waaay to much for that benchy pipe.

So if the slicer could set temperature to 210C some time before the pipe comes, the printer could gradually slow down the speed match that temp.

at 280C it runs 300mms

at 250 it runs 200mms

and at 215 it runs 60mms (just exampes)

That way we theoretically would get a perfect benchy at the highest possible speed.

Thoughts on this?

am I being uselessly creative here?

best regards

jhb

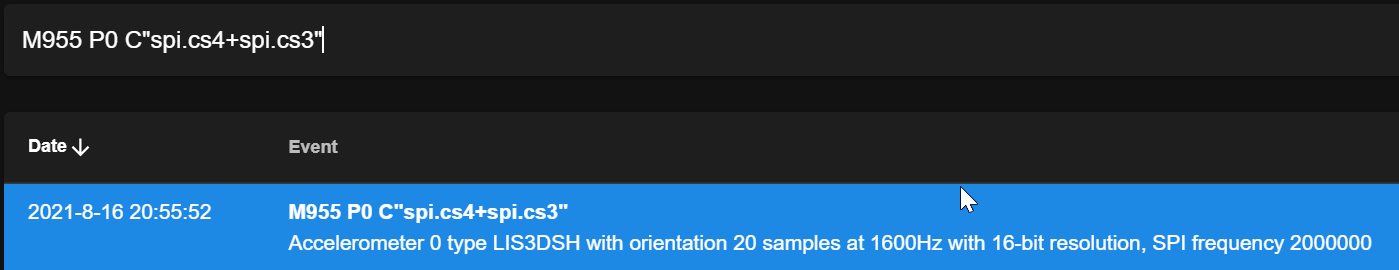

maybe ill just try the DSH that arrived yesterday. that one says

maybe ill just try the DSH that arrived yesterday. that one says