@Hardware_SortingRobotics I'm seeing now that the 6XD documentation does actually have the correct pins listed. This information is, however, incorrect on the "connecting thermocouples" page.

Posts made by Hardware_SortingRobotics

-

RE: Duet 6XD Thermocouple Daughterboard Issueposted in Duet Hardware and wiring

-

RE: Duet 6XD Thermocouple Daughterboard Issueposted in Duet Hardware and wiring

@Hardware_SortingRobotics @CHRISHAMM We just discovered a serious discrepancy in the thermocouple daughterboard documentation.

When addressing the thermocouple daughterboard, spi.cs0 does not address the first sensor on the daughterboard. The documentation states that the pins are spi.cs0-spi.cs3. We have found that the actual addresses are spi.cs1-spi.cs4 instead. Spi.cs0 is not recognized by the system as a valid pin name.

-

RE: Duet 6XD Thermocouple Daughterboard Issueposted in Duet Hardware and wiring

@Hardware_SortingRobotics With some further testing, setting the input pin to spi.cs1 causes the temperature readout to go to 2000C instead. This is a type k thermocouple btw.

-

RE: Duet 6XD Thermocouple Daughterboard Issueposted in Duet Hardware and wiring

@gloomyandy Yes this is true. I copied and pasted this code into the post sloppily and must have mixed these up. The problem persists even when the heater/sensor numbers match.

-

Duet 6XD PWM Output for SSRposted in Duet Hardware and wiring

Hello,

I am currently trying to utilize the medium-current output pins on my Duet 6XD (out7, out8) to drive a pair of external SSRs. These SSRs are hooked up to heaters which are being measured with thermistors, which are connected to the Duet board. My objective is to use the 12V or VIN PWM output to drive these SSRs like I would any other heater, using M950 to set them up as a standard heater, and allow the duet to vary the PWM accordingly to control the heat output.

My issue is this: When I measure the voltage differential between V_OUTLC1 and out7-, I get a steady reading of VIN (24V). The config file runs just fine, setting up the heaters as expected, but the output is high by default. Here is the config setup:

M308 S2 P"temp2" Y"thermistor" T100000 B3950 ; configure sensor as thermistor M950 H2 C"out7" T2 ; create nozzle heater output and map it to sensor M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H2 S275 ; set temperature limit for heater M563 P2 S"Jar Heater" H2 F0 ; define tool G10 P2 R0 S0 ; set initial tool active and standby temperatures to 0CInverting the signal using an ! doesn't change anything either. It seems like these output pins are not switching at all, as my oscilloscope shows a steady voltage, even during heater tuning at 0.1 max PWM. I have also tried setting up the same pin using M950, but as a GPIO. Using M42 S0.5 does not have any effect on the voltage either, it just stays at 24V with no PWM switching. Please help!

-

Duet 6XD Thermocouple Daughterboard Issueposted in Duet Hardware and wiring

I have been trying to get a brand new thermocouple daughterboard to work on my also brand-new Duet 3 6XD. Unfortunately, I have not been able to get the board to read temperatures, or output any readings at all.

We have tried many different configurations in firmware. This is the current config we have set up. We have verified that the MAX3185 chip is the one that is installed on this thermistor daughter board.

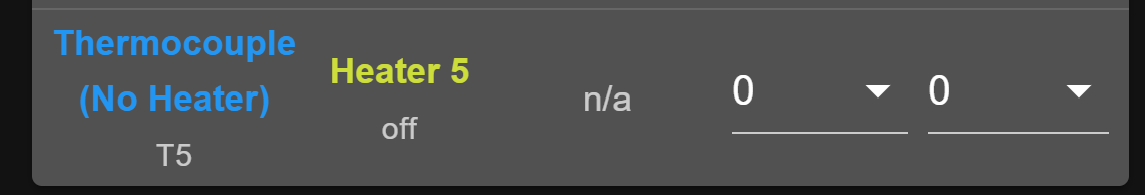

M308 S4 P"spi.cs0" Y"thermocouple-max31855" F60 ; configure sensor as thermocpuple M950 H5 C"out6" T5 ; create nozzle heater output and map it to sensor M307 H5 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H5 S275 ; set temperature limit for heater M563 P5 S"Thermocouple (No Heater)" H5 F0 ; define tool G10 P5 R0 S0 ; set initial tool active and standby temperatures to 0CWhen this config file is used, this is the result on the web interface:

This is the most common outcome as we reconfigure the firmware. There are some circumstances where the temperature shows up as "2000C" instead, usually when using another spi port.

Please let me know if there is any advice you could give to us.

-

Duet 6XD Driver Error Input Usageposted in General Discussion

Hello,

I am currently trying to find a way to read the value of the driver0.err pin after a driver error has been detected. The goal is to allow the system to run the driver-error.g macro upon the initial detection, wait 50ms, then check the status of the error input pin again in order to eliminate the chances of electrical noise causing a false driver fault (this has happened to us before).

I am struggling to find the correct object model name for the driver0.err pin. Previously, we used GPIO pins to detect driver errors. That allowed us to use a trigger to detect the error, which ran a macro that performed the second check after 50ms. We referenced this pin with the object model parameter as such:

if sensors.gpIn[6].value == 0How might we reference the state of this pin using RRF 3.4?

-

Duet 2 Ethernet PWM fan outputs as heatersposted in Duet Hardware and wiring

My team is currently trying to access a PWM output to control a heater from the Duet 2 Ethernet mainboard. We would like to do this without using the expansion board which exposes H6 and H7 PWM outputs.

We currently do not know how to achieve this. I believe it is possible to assign the PWM fan pins to heaters, but I do not know if this may pose a risk to the hardware, or have other unintended consequences.

Is there any way that we could use the E0 and E1 extruder heaters as simple PWM outputs?

-

RE: Duet 2 Expansion Board Malfunctioningposted in Duet Hardware and wiring

@dc42 We can't really reproduce the failure mode yet to this day. I do believe that once we transfer the board to a new ribbon cable, the problem persists. To make matters worse, the symptoms range a lot from one failure to another.

The last time this happened, there was a constant ~3V offset between H6_PWM and ground. Same with H7_PWM. However the triacs connected to this output did not activate despite this voltage difference. Which does lend some traction to the "bad ground" theory.

Could you elaborate more on what you mean by "bad ground"?

-

RE: Duet 2 Expansion Board Malfunctioningposted in Duet Hardware and wiring

@chrishamm We are using 3.1.1 at the moment.

-

Duet 2 Expansion Board Malfunctioningposted in Duet Hardware and wiring

Hello,

I am currently investigating a strange issue that has occurred on several Duet 2 Expansion Boards.

The issue centers around the two heater PWM outputs H6 and H7. When configured properly, these two outputs normally lie at 0V, and when the heaters are active, they output a 5V PWM signal. The issue is such: sometimes, the boards will output something like 2-3VDC without heaters being turned on. We see this voltage as soon as the duet board receives power from the mini USB cable. The presence of 24V at V_IN is not required for these pins to erroneously activate. Additionally, they are not outputting a PWM signal. Its just a straight 2-3V DC with no oscillations.

We believe that the cause has something to do with the U5 chip, which is responsible for inverting the 3.3V active-low signal which is sent from the 50 pin ribbon cable. Something is shorting and causing the chip to un-invert the signal.

Any advice on this? We have not been able to replicate this issue by shorting the ground of the 24V DC power supply.

-

Duet 2 Wifi: Expansion breakout board heater shortposted in Duet Hardware and wiring

Hardware setup:

Duet 2 wifi with a Duet Expansion Breakout Board connected. 3 stepper drivers on ports 5,6,7 and heater 6 and 7 populated (see pictures)Issue:

Heater 6 and heater 7 are contaminating each other's signal. When heater 7 (set up as a GPIO pin) is activated, Heater 6's PWM signal also sees a change in voltage (slightly out of phase with H7).We have been running these boards with a modified heater 7 pin. There is a resistor and capacitor in series, jumping the ground and signal pins in order to smooth out noise that we were experiencing. See picture.

After a few months of use, somehow signal from H6 and H7 are getting mixed together. When H6 is active, H7 sees voltage, and vice-versa. We are pretty sure that it is an issue of a contaminated ground signal, but even after the resistor+capacitor is removed, the problem persists.

We would like to prevent these issues from happening in the future.!

-

M564 for independent axesposted in Using Duet Controllers

Is it possible to set M564 for different axes? For example, I want allow my X axis to move without homing but not my y axis or my z axis.

-

Web Control organized really weirdposted in Duet Web Control

For some reason my web control is smashed together to the point where I can't read the temperatures very easily....Is there another way to just get the temperatures on a single page or reorganize the window layouts?

-

RE: Remove the "temperature not rising fast enough" errors??posted in General Discussion

Why is it that when my heater is in bang bang mode it still sends a temperature not rising fast enough error? It is super annoying...I can't disable it with the m570 command either I am still getting errors...

How do I delete "temperature not rising fast enough"?

-

RE: Remove the "temperature not rising fast enough" errors??posted in General Discussion

I'm not using it on a bed heater I'm using the temperature control for a heated fan for a side project. PID doesn't work or randomly fails.

-

Remove the "temperature not rising fast enough" errors??posted in General Discussion

Is there a way to complete remove the "temperature not rising fast enough errors? I just want to use bang bang mode without worrying about my heater faulting. IT IS GETTING EXTREMELY ANNOYING!!! I had bang bang mode enabled and removed my heater from the config.override but I am still getting "temperature not rising fast enough" errors and it is ruining everything....How do I just remove this heater fault completely???

-

How to read the current/force feedback of my Stepper Motors???posted in CNC

Is there a way to extract the current information from the duet that is being sent to the Motors? I want to analyze the current output so I can determine what force my stepper motor is applying to a leadscrew nut.

-

Commanding X motor to run foreverposted in General Discussion

Is it possible to command my X and Y motors to run continuously until I make them stop? I am using them on a conveyor system and currently I am just inputting a REALLY REALLY big number so they run for 2 hours. Is there a "set it and forget it" command?

-

How to Disable Hobby Servo Startup Sequenceposted in General Discussion

I am currently using two different servos with the Duex5 and I am having issues the startup sequence. The picture below shows a red servo and a blue servo. For some reason every time I turn on the red servo it moves to position 180degrees but when I turn on the blue servo it just turns on with no adjustment.

Is there a way to disable the startup sequence of the red servo so it behaves like the blue servo?