@MintyTrebor

WORKS GOOD!

Thanks for your help.

Posts made by Gianluca

-

RE: BtnCmd-DWC Plugin for DWC 3.5.2-rc.1posted in General Discussion

-

RE: BtnCmd-DWC Plugin for DWC 3.5.2-rc.1posted in General Discussion

@MintyTrebor

Is there a release for DWC 3.5.4 planned? -

RE: PRINTING INTERRUPTION WITH NEW CHAMBER CLOSED AND NOT HEATEDposted in General Discussion

@dc42

It is an unheated chamber, I estimate that the temperature does not go above 45-50°C.

I'm having "tooMuchMovement" errors even with open ports, with very wide sensitivity parameter: (M591 D0 P3 C"121.io0.in" R10:190 L24.5 E10.0 S1).

I also tried with another toolboard but it gives the same error.

After the pause due to the error, if I exclude the sensor, the printing continues without problems, with good quality (no underextrusion).

I will try to change the current nema 14 (LDO hi temperature) with another one, I will also try to see if mechanically the magnetic sensor is ok.

If there are any other suggestions I'll be happy to try. -

RE: PRINTING INTERRUPTION WITH NEW CHAMBER CLOSED AND NOT HEATEDposted in General Discussion

Bug fixes on 3.5.2.:

[Duet 3] Simple switch type filament monitors that are connected to a main board but assigned to an extruder on a tool or expansion board now workI find it...

-

RE: PRINTING INTERRUPTION WITH NEW CHAMBER CLOSED AND NOT HEATEDposted in General Discussion

@droftarts

I did a test print last night and it stopped for this error, "Magnetic filament sensor: tooMuchMovement"

The magnetic sensor hasn't given me any problems for a long time, but now it has started to do so.

I associated this problem with the construction of the closed chamber, but it is probably not this.

The sensor is positioned just above the extruder, and connected to the Toolboard 1LC, this means it is subjected to a lot of vibrations.

Has the possibility of having the magnetic sensor connected to the Motherboard and the extruder to the Toolboard been implemented with the new firmware (3.5.2.)?

As a possible solution, I also replace the nozzle. -

RE: PRINTING INTERRUPTION WITH NEW CHAMBER CLOSED AND NOT HEATEDposted in General Discussion

thanks for the tips.

The magnetic sensor cables are flying and not particularly near to the stepper motor (small LDO nema 14). I'll take a photo this evening.

However, even with the engine off and without printing, there are some errors on the magnetic sensor.

Can I check or replace the magnetic sensor cables?

I can also replace the 1LC board and try with another one...9/7/2024, 16:30:39 m122 b121

=== Filament sensors ===

Interrupt 4 to 9us, poll 8 to 1221us

Driver 0: pos 2160.0, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 09/7/2024, 16:33:48 m122 b121

=== Filament sensors ===

Interrupt 4 to 9us, poll 8 to 1188us

Driver 0: pos 2160.0, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0 -

RE: PRINTING INTERRUPTION WITH NEW CHAMBER CLOSED AND NOT HEATEDposted in General Discussion

No, I don't have a switch on the doors, I still have to put the handles...

Yes, the thread presence sensor gave me an error, but I didn't copy it. This evening I'll make some prints so I can copy it...

In any case the problems are only behind closed doors...

I don't have a daemon.g, and if you see my config.g the filament monitoring It has a very wide tolerance (M591 D0 P3 C"121.io0.in" R10:190 L24.5 E10.0 S1 )MY CONFIG.G

; Voron 2.4 355x355mm Duet3 6MBHC - Toolboard 1LC - SBC with RASPBERRY PI-4 4GB and SD 64GB ; Data di aggiornamento: 04/07/2024 ; ; ---------- GENERAL PREFERENCES --------- G90 ; absolute coordinates... M83 ; relative extruder moves M669 K1 ; Select CoreXY mode M564 S1 H1 ; Forbid axis movements when not homed M575 P1 S1 B57600 ; enable support for Paneldue display M290 R0 S0 ; reset babystepping ; ; ---------- DRIVES MAPPINGS ---------- ; ; Rear ; | Z1 | Z2 | ; -----+----- ; | Z0 | Z3 | ; -----+----- ; Front ; M584 X4 Y5 Z0:1:2:3 E121.0 ; set drive mapping M569 P0 S1 ; Z0 motor FL goes forwards M569 P1 S0 ; Z1 motor RL goes backwards M569 P2 S1 ; Z2 motor RR goes forwards M569 P3 S0 ; Z3 motor FR goes backwards M569 P4 S1 ; A motor goes forwards M569 P5 S1 ; B motor goes forwards M569 P121.0 S0 ; E1 motor Extruder goes backwards (scheda 1LC porta 121) M671 X-67.5:-67.85:422.5:422.5 Y-10:443.8:443.8:-10 S15 ; Define Z belts locations (Z0=Front_Left Z1, Z2, Z3...ecc) S15=mm di correzione massima ; ; ---------- DRIVES GENERAL PARAMETERS ---------- M350 X32 Y32 Z32 E16 I1 ; configure microstepping with interpolation M92 X159.94 Y159.94 Z800 E745 ; set steps per mm (417 afterburner, 745 stealthburner) M84 S20 ; riduzione potenza motori dopo 20sec ; ; ---------- DRIVES SPEED PARAMETERS ---------- M566 X500 Y500 Z100 E1000 ; JERK (mm/min) M203 X24000 Y24000 Z6000 E1000 ; MAX SPEED (400mm/min) M201 X7000 Y7000 Z500 E3000 ; ACCELERAZIONE (mm/s^2) M906 X2000 Y2000 Z2000 E850 I30 ; set motor currents (mA) and motor idle factor 30% ; IN ALTERNATIVA USARE IL FILE SOTTO: ; M98 P"/sys/print_scripts/setup_printing_med.g" ; FILE PER STAMPA PRESTAZIONI MEDIE - FINO A 400mm/sec ; M98 P"/sys/print_scripts/setup_printing_low.g" ; FILE PER HOMING - FINO A 250mm/sec ; M98 P"/sys/print_scripts/setup_printing_high.g" ; FILE PER STAMPA PRESTAZIONI ELEVATE - FINO A 500mm/sec ; ; ---------- AXIS LIMITS ---------- M208 X0 Y0 Z-0.15 S1 ; set axis minima (S1) M208 X340 Y350 Z320 S0 ; set axis maxima (S0) Portato ad H=320mm per presenza barra LED ; ; ---------- ENDSTOP SWITCH MECCANICO --------- M574 Y2 S1 P"io1.in" ; Configure enstop Y(2) posizione alta dello switch e pin !io1.in invertito M574 X2 S1 P"io2.in" ; Configure enstop x(2) posizione alta dello switch e pin !io2.in invertito ; ; ---------- SENSORE MAGNETICO FILAMENTO --------- M591 D0 P3 C"121.io0.in" R10:190 L24.5 E10.0 S1 ; Rotating magnet sensor for extruder drive 0 is connected to 121.io0.in on Toolboard 1LC, ; M591 D0 P0 ; Disabilita controllo sensore magnetico ; ---------- Z-PROBE ---------- M558 P8 C"!121.io1.in" H10 F600 T5000 ; set Z probe type inductive (P8), altezza tastatura (H10), velocità tastatura mm/min (F600), velocità di spostamento mm/min (T6000) su scheda espansione 1LC porta 121 G31 P500 X0 Y24 Z1.35 ; set Z OFFSET, ( * PEI * ), PIU' ALTO E' Z PIU' SI AVVICINA AL LETTO ; G31 P500 X0 Y24 Z1.65 ; set Z OFFSET, ( * TEXTURE * ) PIU' ALTO E' Z PIU' SI AVVICINA AL LETTO M557 X40:315 Y40:315 S55 ; define mesh grid (GRIGLIA maglia 6 x 6 con 55mm di spazio) EVITA I MAGNETI ; ; ----------- HO - HEATERS BED ---------- M308 S0 P"temp0" Y"thermistor" T100000 B4138 A"LETTO" ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out1" T0 ; create bed heater output on out1 and map it to sensor 0 M307 H0 R0.856 K0.199:0.000 D4.53 E1.35 S1.00 B0 ; DOPO AUTOTARATURA LETTO CON (M303 H0 P1 S100) il 03/12/2023 (R=Velocità di riscaldamento °C/sec) M140 H0 ; map heated bed to heater 0 ; ; ----------- H1 - HEATERS NOZZLE ---------- M308 S1 P"121.temp0" Y"thermistor" T100000 B4138 A"ESTRUSORE" ; Configure sensor 1 as thermistor on pin temp0/121 M950 H1 C"121.out0" T1 ; Create nozzle heater output on out0 su scheda espansione 1LC porta 121 and map it to sensor 1 M307 H1 S0.8 B0 ; H1=riscaldatore 1 S0.8=Potenza al 80% B0=BsngBang (consigliato per gli estrusori) ; M307 H1 R7.21 K0.492:0.000 D5.65 E1.35 S1.00 B0 V29.3 ; (orig. R5.331) DOPO AUTOTARATURA NOZZLE CON (M303 H1 P1 S240) il 03/12/23 HOTEND RAPIDO. (R=Velocità di riscaldamento °C/sec) M143 H1 S275 ; set temperature limit for heater 1 to 275C ; ; ---------- TOOLS ---------- M563 P0 S"TOOLS-0" D0.5 H1 F0 ; DEFINE TOOL 0 => P0=Tool 0, S"..."=Tool name, D0.5=drive 0.5, H1=heather 1, F0=fan 0. G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; ; ---------- FAN 0 VENTOLA RAFFR. STAMPA PWM (out4) 24v ---------- M950 F0 C"121.out2" Q500 ; Fan 0 su 121.out2, use PWM, using 121.out2 M106 P0 C"VENTOLA FILO" S0.0 H-1 ; set FAN_0 name and value. ; ; ---------- FAN 1 VENTOLA HOTEND (out8) 24v ---------- M950 F1 C"121.out1" Q500 ; Fan 0 su 121.out2, use PWM, using 121.out2 M106 P1 C"HOTEND" H1 L0.35 X0.6 B0.3 T60:250 ; PARAMETRICA Termostatica ( da L=35% a X=60% con temp. da 60°C a 250°C ) ; ; ---------- FAN 2 VENTOLA MCU MB6HC PWM (out5) 24v --------- M308 S2 Y"mcu-temp" A"MCU 6HC" ; configure sensor 2 (S2) as thermistor for MCU M950 F2 C"!out5+out5.tach" ; Fan 2 su out5, use PWM (needs ! inverted), using out5.tach M106 P2 C"VENTOLA MCU" L0.1 X0.8 B0.1 T26:35 H3 ; set FAN_2 value T26:32°C velocità ventola L-10% X-80% ; ; ---------- FAN 3 VENTOLA PWM RASPBERRY (out4) 12v --------- M308 S3 P"temp2" Y"thermistor" T100000 B4138 A"RASPBERRY" ; Configura il sensore 3 (S3) come riscaldatore sul pin temp2 con nome RASPBERRY M950 F3 C"!out4+out4.tach" ; Fan 3 su out6, use PWM (needs ! inverted), using out4.tach M106 P3 C"VENTOLA RASPBERRY" L0.1 X1.0 B0.5 T20:48 H4 ; set FAN_3 value T20:42°C velocità ventola L-10% X-100% B=blip time ; ; ---------- FAN 4 VENTOLA 1LC (out7) 24v ---------- M308 S4 Y"mcu-temp" P"121.dummy" A"MCU 1LC" ; configure sensor 4 (S4) Temp MCU 1LC M950 F4 C"out7" Q1000 ; create FAN_4 on pin ou7 Toolboard and set its frequency at 1000hz M106 P4 C"FAN 1LC MCU" H1 L0.2 X0.7 B0.3 T38:55 ; H1=Termostatic L=Min.Spd. X=Max.Spd. B=Blips Time T=Temp Range 30-50°C ; M106 P4 S0.65 ; PER ACCENDERE LA VENTOLA ; M106 P4 S0.0 ; PER SPEGNERE LA VENTOLA ; ; ---------- FAN 5 VENTOLA CHASSIS (out8) 24v ---------- M950 F5 C"out8" Q1500 ; create FAN_5 on pin ou8 VENTOLE LATERALI DX ASPIRANTI M106 P5 S0.00 C"CHASSIS_SX" B1 ; ACCENDE LA VENTOLA AL 30% ; ; ---------- FAN 6 VENTOLA CHASSIS (out9) 24v ---------- M950 F6 C"out9" Q1500 ; create FAN_6 on pin ou9 VENTOLE LATERALI SX SOFFIANTI M106 P6 S0.00 C"CHASSIS_DX" B1 ; ACCENDE LA VENTOLA AL 30% ; ; ---------- TEMPERATURA E0 NEMA 14 SU TOOLBOARD 1LC ---------- M308 S5 P"121.temp1" Y"thermistor" T100000 B4138 A"NEMA14" ; Configure sensor 5 (S5) as thermistor on pin temp1/121 ; ; ---------- PORT 1 RELE' ACCENSIONE (io4.out) IO PORT PWM ---------- M950 P1 C"io4.out" Q500 ; allocate GPIO PORT.1 to io4.out at 500Hz ; M42 P1 S0.0 ; Printer OFF set 0% PWM on GPIO port 1 ; M42 P1 S1.0 ; Printer ON set 100% PWM on GPIO port 1 ; ; ---------- ACCELEROMETRO ---------- M955 P121.0 I05 ; ACCELEROMETRO SU SCHEDA 1LC ( I05 = orientamento scheda 1CL ) M593 P"ZVDDD" F36 ; INPUT SHAPING: Configura i parametri di riduzione risonanza ; ; ---------- TASTI FISICI SU 1LC ---------- M950 J5 C"121.button0" ; Crea pin 5 su porta 121.button0 della scheda 1LC M581 P5 T2 S1 R0 ; P5=pin 5 creato con M950 (J5), T2=Trigger logico a cui associare gli ingressi, S1=funziona da inattivo ad attivo, R0=attivo in ogni momento ; ; Qualsiasi numero di trigger # maggiore di 1 provoca l'esecuzione del file della macro sys/trigger2.g (T2) M950 J6 C"121.button1" ; Crea trigger n°6 su porta "121.button0" M581 P6 T3 S1 R0 ; Crea pin 6 su porta 121.button1 della scheda 1LC ; ; ---------- NEOLED "0" 4 BARRE LED RGB SUPERIORI (PORTA DEDICATA DOTSTAR SU 6HC) ---------- M950 E0 C"led" T1 U155 Q3000000 ; Crea PIN "led" striscia LED E0 T1=RGB U160=160LED disponibili M98 P"0:/macros/5-NEOLED ITALIA.g" ; Tutti i led superiori accesi al 10% (41+41+32+41=155 LED RGB) ; ; ---------- NEOLED "1" RGBW - STEALTHBURNER (PORTA IO8 OUT SU 6HC) ---------- M950 E1 C"io8.out" Q3000000 T2 U5 ; Crea PIN "io8.out" striscia LED E1 T1=RGB T2=RGBW ; M150 E2 B250 P100 S1 M98 P"0:/macros/LED/Logo_blu.g" ; Esegue la Maco "Logo_verde.g" ; ; ---------- IMPOSTA L'AUTOSALVATAGGIO IN CASO DI MANCATA ALIMENTAZIONE ---------- M911 S29.2 R29.4 P"M913 X0 Y0 G91 M83 G1 Z3 E-2 F500" ; Autosalvataggio stampa per mancanza di corrente, sospende a 29.2v e riparte a 29.4v ; ; ---------- MISCELLANEUS ---------- M912 P0 S-1 ; parametro per tarare la temperatura della MCU (-1°C) M300 S2500 P3000 ; Emette suono a S=2500Hz per P=3 secondi T0 ; select first tool ACTIVE ; END -

RE: PRINTING INTERRUPTION WITH NEW CHAMBER CLOSED AND NOT HEATEDposted in General Discussion

Sorry, the second M122 B12 was wrong.

The mainboard is external with cooling fan, the toolboard in inernal with a small cooling fan.

This is the correct.

CORRECT SECOND M122

8/7/2024, 22:12:37 m122 b121 Diagnostics for board 121: Duet TOOL1LC rev 1.1 or later firmware version 3.5.2 (2024-06-10 13:24:04) Bootloader ID: SAMC21 bootloader version 2.8 (2023-07-25) All averaging filters OK Never used RAM 2948, free system stack 49 words Tasks: Move(3,nWait 7,0.1%,90) HEAT(2,nWait 6,0.4%,90) CanAsync(5,nWait 4,0.0%,48) CanRecv(3,nWait 1,0.0%,70) CanClock(5,nWait 1,0.0%,58) ACCEL(3,nWait 6,0.0%,52) TMC(2,delaying,3.7%,52) MAIN(1,running,90.5%,314) IDLE(0,ready,0.0%,26) AIN(2,delaying,5.2%,112), total 100.0% Owned mutexes: Last reset 01:34:53 ago, cause: power up Last software reset data not available Driver 0: pos 0, 745.0 steps/mm, ok, SG min 0, read errors 0, write errors 0, ifcnt 18, reads 54703, writes 0, timeouts 0, DMA errors 0, CC errors 0, steps req 0 done 115894 Moves scheduled 17888, completed 17887, in progress 1, hiccups 0, segs 18, step errors 0, maxLate 0 maxPrep 167, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0, ebfmin 0.00 max 1.00 Peak sync jitter 0/4, peak Rx sync delay 219, resyncs 0/0, no timer interrupt scheduled VIN voltage: min 29.3, current 29.9, max 30.1 MCU temperature: min 28.3C, current 43.4C, max 57.4C Last sensors broadcast 0x00000032 found 3 112 ticks ago, 0 ordering errs, loop time 1 CAN messages queued 2659, send timeouts 0, received 1533, lost 0, errs 0, boc 0, free buffers 18, min 18, error reg 0 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 324, adv 36336/74650 Accelerometer: LIS3DH, status: 00 I2C bus errors 0, naks 0, contentions 0, other errors 0 === Filament sensors === Interrupt 4 to 81us, poll 24 to 1281us Driver 0: pos 13967.6, errs: frame 55 parity 0 ovrun 0 pol 0 ovdue 0 -

PRINTING INTERRUPTION WITH NEW CHAMBER CLOSED AND NOT HEATEDposted in General Discussion

Problem:

I recently closed my printer with panels, and when I print with a closed unheated chamber, the printing is paused as if the magnetic sensor detected a wire jam.

If I open the front doors and restart the printing, it continues without problems.

It happened twice, I attach reports M122 and M122 B121 copied after the error.

If there is any other information needed, please let us know.

My system:

Mainboard Duet 3 6HC

Toolboard 1Lc

SBC mode

Core XY printer (Voron)

Frimware 3.5.2.FIRST M122

m122 === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.5.2 (2024-06-11 17:13:58) running on Duet 3 MB6HC v1.01 (SBC mode) Board ID: 08DJM-956BA-NA3TN-6JTDJ-3SJ6S-1T82V Used output buffers: 12 of 40 (40 max) === RTOS === Static ram: 155360 Dynamic ram: 91568 of which 3320 recycled Never used RAM 92168, free system stack 124 words Tasks: SBC(2,rWait:,0.9%,819) HEAT(3,nWait 6,0.0%,321) Move(4,nWait 6,0.8%,211) CanReceiv(6,nWait 1,0.0%,771) CanSender(5,nWait 7,0.0%,325) CanClock(7,delaying,0.0%,339) TMC(4,nWait 6,9.9%,53) MAIN(2,running,88.3%,101) IDLE(0,ready,0.0%,29), total 100.0% Owned mutexes: HTTP(MAIN) === Platform === Last reset 10:54:17 ago, cause: power up Last software reset at 2024-06-30 17:28, reason: User, Gcodes spinning, available RAM 95744, slot 0 Software reset code 0x6003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0044a000 BFAR 0x00000000 SP 0x00000000 Task SBC Freestk 0 n/a Error status: 0x04 Aux0 errors 0,1,0 MCU temperature: min 22.8, current 32.6, max 35.6 Supply voltage: min 29.4, current 29.6, max 29.7, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 12.1, current 12.1, max 12.2, under voltage events: 0 Heap OK, handles allocated/used 99/0, heap memory allocated/used/recyclable 2048/128/128, gc cycles 0 Events: 1 queued, 1 completed Driver 0: standstill, SG min 0, mspos 572, reads 59351, writes 25 timeouts 0 Driver 1: standstill, SG min 0, mspos 300, reads 59352, writes 25 timeouts 0 Driver 2: standstill, SG min 0, mspos 308, reads 59352, writes 25 timeouts 0 Driver 3: standstill, SG min 0, mspos 420, reads 59352, writes 25 timeouts 0 Driver 4: standstill, SG min 0, mspos 52, reads 59352, writes 25 timeouts 0 Driver 5: standstill, SG min 0, mspos 140, reads 59352, writes 25 timeouts 0 Date/time: 2024-07-04 07:11:49 Slowest loop: 406.91ms; fastest: 0.05ms === Storage === Free file entries: 20 SD card 0 not detected, interface speed: 37.5MBytes/sec SD card longest read time 0.0ms, write time 0.0ms, max retries 0 === Move === DMs created 125, segments created 30, maxWait 104209ms, bed compensation in use: mesh, height map offset 0.000, max steps late 0, min interval 0, bad calcs 0, ebfmin 0.00, ebfmax 0.00 no step interrupt scheduled Moves shaped first try 4072, on retry 954, too short 3032, wrong shape 102433, maybepossible 7 === DDARing 0 === Scheduled moves 130318, completed 130318, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 10], CDDA state -1 === DDARing 1 === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 Heater 0 is on, I-accum = 0.0 Heater 1 is on, I-accum = 0.0 === GCodes === Movement locks held by null, null HTTP* is doing "M122" in state(s) 0 Telnet is idle in state(s) 0 File* is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger* is idle in state(s) 0 Queue* is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause* is idle in state(s) 0 File2 is idle in state(s) 0 Queue2 is idle in state(s) 0 Q0 segments left 0, axes/extruders owned 0x80000007 Code queue 0 is empty Q1 segments left 0, axes/extruders owned 0x0000000 Code queue 1 is empty === Filament sensors === check 0 clear 0 Extruder 0: no data received, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0 === CAN === Messages queued 465281, received 872659, lost 0, errs 5960, boc 0 Longest wait 5ms for reply type 6024, peak Tx sync delay 63080, free buffers 50 (min 49), ts 196290/196287/0 Tx timeouts 0,0,2,0,0,1 last cancelled message type 30 dest 127 === SBC interface === Transfer state: 5, failed transfers: 0, checksum errors: 0 RX/TX seq numbers: 37124/37124 SPI underruns 0, overruns 0 State: 5, disconnects: 0, timeouts: 0 total, 0 by SBC, IAP RAM available 0x24cfc Buffer RX/TX: 0/0-0, open files: 0 === Duet Control Server === Duet Control Server version 3.5.2 (2024-06-12 07:09:26, 32-bit) HTTP+Executed: > Executing M122 File 0:/gcodes/Castello2_ASA_Prusa.gcode is selected, paused Code buffer space: 4096 Configured SPI speed: 8000000Hz, TfrRdy pin glitches: 1 Full transfers per second: 33.78, max time between full transfers: 172.9ms, max pin wait times: 53.4ms/18.9ms Codes per second: 2.95 Maximum length of RX/TX data transfers: 4456/1664FIRST M122 B121

m122 b121 Diagnostics for board 121: Duet TOOL1LC rev 1.1 or later firmware version 3.5.2 (2024-06-10 13:24:04) Bootloader ID: SAMC21 bootloader version 2.8 (2023-07-25) All averaging filters OK Never used RAM 2444, free system stack 49 words Tasks: Move(3,nWait 7,0.0%,90) HEAT(2,nWait 6,0.4%,90) CanAsync(5,nWait 4,0.0%,48) CanRecv(3,nWait 1,0.0%,70) CanClock(5,nWait 1,0.0%,58) ACCEL(3,nWait 6,0.0%,52) TMC(2,delaying,3.7%,52) MAIN(1,running,90.7%,314) IDLE(0,ready,0.0%,26) AIN(2,delaying,5.1%,112), total 100.0% Owned mutexes: Last reset 10:52:59 ago, cause: power up Last software reset data not available Driver 0: pos 0, 745.0 steps/mm, standstill, SG min 0, read errors 2, write errors 0, ifcnt 15, reads 46731, writes 15, timeouts 16, DMA errors 0, CC errors 0, failedOp 0x01, steps req 0 done 30880081 Moves scheduled 111797, completed 111797, in progress 0, hiccups 0, segs 39, step errors 0, maxLate 0 maxPrep 530, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0, ebfmin 0.00 max 1.00 Peak sync jitter -1/10, peak Rx sync delay 256, resyncs 0/0, no timer interrupt scheduled VIN voltage: min 28.7, current 30.1, max 30.2 MCU temperature: min 25.7C, current 54.8C, max 76.7C Last sensors broadcast 0x00000032 found 3 215 ticks ago, 0 ordering errs, loop time 0 CAN messages queued 871036, send timeouts 0, received 464570, lost 0, errs 4262, boc 0, free buffers 18, min 18, error reg 310000 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 372, adv 35571/74670 Accelerometer: LIS3DH, status: 00 I2C bus errors 0, naks 3, contentions 0, other errors 0 === Filament sensors === Interrupt 4 to 142us, poll 6 to 2005us Driver 0: pos 2490.5, errs: frame 182 parity 0 ovrun 0 pol 0 ovdue 0SECOND M122

8/7/2024, 22:12:05 m122 === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.5.2 (2024-06-11 17:13:58) running on Duet 3 MB6HC v1.01 (SBC mode) Board ID: 08DJM-956BA-NA3TN-6JTDJ-3SJ6S-1T82V Used output buffers: 9 of 40 (40 max) === RTOS === Static ram: 155360 Dynamic ram: 91568 of which 3320 recycled Never used RAM 92000, free system stack 112 words Tasks: SBC(2,rWait:,1.0%,807) HEAT(3,nWait 6,0.0%,323) Move(4,nWait 6,1.4%,211) CanReceiv(6,nWait 1,0.0%,792) CanSender(5,nWait 7,0.0%,334) CanClock(7,delaying,0.0%,346) TMC(4,nWait 6,10.3%,53) MAIN(2,running,87.1%,101) IDLE(0,ready,0.1%,29), total 100.0% Owned mutexes: HTTP(MAIN) === Platform === Last reset 01:34:21 ago, cause: power up Last software reset at 2024-07-08 20:31, reason: AssertionFailed, Gcodes spinning, available RAM 92964, slot 1 Software reset code 0x4123 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0043c000 BFAR 0x001f22c1 SP 0x2041bc7c Task MAIN Freestk 2215 ok Stack: 0000151c 004bde58 0049c19b 20419960 20419960 0000000a 00000001 20425354 0049b449 fffc0040 ffffffff fffeffe6 2042f95f ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff Error status: 0x04 Aux0 errors 0,0,0 MCU temperature: min 24.6, current 34.7, max 34.8 Supply voltage: min 29.4, current 29.6, max 29.7, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 12.1, current 12.2, max 12.2, under voltage events: 0 Heap OK, handles allocated/used 99/1, heap memory allocated/used/recyclable 2048/100/88, gc cycles 0 Events: 1 queued, 1 completed Driver 0: ok, SG min 0, mspos 988, reads 20918, writes 27 timeouts 0 Driver 1: ok, SG min 0, mspos 652, reads 20918, writes 27 timeouts 0 Driver 2: ok, SG min 0, mspos 148, reads 20918, writes 27 timeouts 0 Driver 3: ok, SG min 0, mspos 492, reads 20918, writes 27 timeouts 0 Driver 4: standstill, SG min 0, mspos 644, reads 20923, writes 23 timeouts 0 Driver 5: ok, SG min 0, mspos 927, reads 20923, writes 23 timeouts 0 Date/time: 2024-07-08 22:12:04 Slowest loop: 413.45ms; fastest: 0.05ms === Storage === Free file entries: 20 SD card 0 not detected, interface speed: 37.5MBytes/sec SD card longest read time 0.0ms, write time 0.0ms, max retries 0 === Move === DMs created 125, segments created 37, maxWait 185085ms, bed compensation in use: mesh, height map offset 0.000, max steps late 0, min interval 0, bad calcs 0, ebfmin 0.00, ebfmax 0.00 next step interrupt due in 27 ticks, disabled Moves shaped first try 69, on retry 11, too short 44, wrong shape 17759, maybepossible 0 === DDARing 0 === Scheduled moves 18046, completed 18035, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 12], CDDA state 3 === DDARing 1 === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 Heater 0 is on, I-accum = 0.0 Heater 1 is on, I-accum = 0.0 === GCodes === Movement locks held by null, null HTTP* is doing "M122" in state(s) 0 Telnet is idle in state(s) 0 File* is doing "G1 X167.380997 Y162.423996 E45.051701" in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger* is idle in state(s) 0 Queue* is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 0, running macro Aux2 is idle in state(s) 0 Autopause* is idle in state(s) 0 File2 is idle in state(s) 0 Queue2 is idle in state(s) 0 Q0 segments left 1, axes/extruders owned 0x80000007 Code queue 0 is empty Q1 segments left 0, axes/extruders owned 0x0000000 Code queue 1 is empty === Filament sensors === check 0 clear 0 Extruder 0: no data received, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0 === CAN === Messages queued 68686, received 133930, lost 0, errs 1, boc 0 Longest wait 6ms for reply type 6024, peak Tx sync delay 265, free buffers 50 (min 49), ts 28309/28308/0 Tx timeouts 0,0,0,0,0,0 === SBC interface === Transfer state: 5, failed transfers: 0, checksum errors: 0 RX/TX seq numbers: 24716/24716 SPI underruns 0, overruns 0 State: 5, disconnects: 0, timeouts: 0 total, 0 by SBC, IAP RAM available 0x24cfc Buffer RX/TX: 3024/456-4080, open files: 0 === Duet Control Server === Duet Control Server version 3.5.2 (2024-06-12 07:09:26, 32-bit) HTTP+Executed: > Executing M122 File 0:/gcodes/7vlDMEE2ADp.gcode is selected, processing File: Buffered code: G1 X167.381 Y162.424 E45.0517 Buffered code: G1 X166.787 Y162.424 E45.0673 Buffered code: G1 X183.867 Y145.344 E45.6999 Buffered code: G1 X183.273 Y145.344 E45.7155 Buffered code: G1 X166.193 Y162.424 E46.3482 Buffered code: G1 X165.599 Y162.424 E46.3637 Buffered code: G1 X182.679 Y145.344 E46.9964 Buffered code: G1 X182.085 Y145.344 E47.0119 Buffered code: G1 X165.005 Y162.424 E47.6446 Buffered code: G1 X164.411 Y162.424 E47.6602 Buffered code: G1 X181.491 Y145.344 E48.2928 Buffered code: G1 X180.897 Y145.344 E48.3084 Buffered code: G1 X163.817 Y162.424 E48.9411 Buffered code: G1 X163.223 Y162.424 E48.9566 Buffered code: G1 X180.303 Y145.344 E49.5893 Buffered code: G1 X179.709 Y145.344 E49.6049 Buffered code: G1 X162.629 Y162.424 E50.2375 Buffered code: G1 X162.035 Y162.424 E50.2531 Buffered code: G1 X179.115 Y145.344 E50.8858 Buffered code: G1 X178.521 Y145.344 E50.9013 Buffered code: G1 X161.441 Y162.424 E51.5340 Buffered code: G1 X160.847 Y162.424 E51.5495 Buffered code: G1 X177.927 Y145.344 E52.1822 Buffered code: G1 X177.333 Y145.344 E52.1978 Buffered code: G1 X160.253 Y162.424 E52.8304 Buffered code: G1 X159.659 Y162.424 E52.8460 Buffered code: G1 X176.739 Y145.344 E53.4787 Buffered code: G1 X176.145 Y145.344 E53.4942 Buffered code: G1 X159.065 Y162.424 E54.1269 Buffered code: G1 X158.472 Y162.424 E54.1424 Buffered code: G1 X175.552 Y145.344 E54.7751 Buffered code: G1 X174.958 Y145.344 E54.7907 Buffered codes: 1536 bytes total Code buffer space: 2568 Configured SPI speed: 8000000Hz, TfrRdy pin glitches: 0 Full transfers per second: 36.52, max time between full transfers: 253.5ms, max pin wait times: 57.5ms/14.6ms Codes per second: 2.13 Maximum length of RX/TX data transfers: 4884/1696SECOND M122 B 121

8/7/2024, 22:12:05 m122 === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.5.2 (2024-06-11 17:13:58) running on Duet 3 MB6HC v1.01 (SBC mode) Board ID: 08DJM-956BA-NA3TN-6JTDJ-3SJ6S-1T82V Used output buffers: 9 of 40 (40 max) === RTOS === Static ram: 155360 Dynamic ram: 91568 of which 3320 recycled Never used RAM 92000, free system stack 112 words Tasks: SBC(2,rWait:,1.0%,807) HEAT(3,nWait 6,0.0%,323) Move(4,nWait 6,1.4%,211) CanReceiv(6,nWait 1,0.0%,792) CanSender(5,nWait 7,0.0%,334) CanClock(7,delaying,0.0%,346) TMC(4,nWait 6,10.3%,53) MAIN(2,running,87.1%,101) IDLE(0,ready,0.1%,29), total 100.0% Owned mutexes: HTTP(MAIN) === Platform === Last reset 01:34:21 ago, cause: power up Last software reset at 2024-07-08 20:31, reason: AssertionFailed, Gcodes spinning, available RAM 92964, slot 1 Software reset code 0x4123 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0043c000 BFAR 0x001f22c1 SP 0x2041bc7c Task MAIN Freestk 2215 ok Stack: 0000151c 004bde58 0049c19b 20419960 20419960 0000000a 00000001 20425354 0049b449 fffc0040 ffffffff fffeffe6 2042f95f ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff ffffffff Error status: 0x04 Aux0 errors 0,0,0 MCU temperature: min 24.6, current 34.7, max 34.8 Supply voltage: min 29.4, current 29.6, max 29.7, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 12.1, current 12.2, max 12.2, under voltage events: 0 Heap OK, handles allocated/used 99/1, heap memory allocated/used/recyclable 2048/100/88, gc cycles 0 Events: 1 queued, 1 completed Driver 0: ok, SG min 0, mspos 988, reads 20918, writes 27 timeouts 0 Driver 1: ok, SG min 0, mspos 652, reads 20918, writes 27 timeouts 0 Driver 2: ok, SG min 0, mspos 148, reads 20918, writes 27 timeouts 0 Driver 3: ok, SG min 0, mspos 492, reads 20918, writes 27 timeouts 0 Driver 4: standstill, SG min 0, mspos 644, reads 20923, writes 23 timeouts 0 Driver 5: ok, SG min 0, mspos 927, reads 20923, writes 23 timeouts 0 Date/time: 2024-07-08 22:12:04 Slowest loop: 413.45ms; fastest: 0.05ms === Storage === Free file entries: 20 SD card 0 not detected, interface speed: 37.5MBytes/sec SD card longest read time 0.0ms, write time 0.0ms, max retries 0 === Move === DMs created 125, segments created 37, maxWait 185085ms, bed compensation in use: mesh, height map offset 0.000, max steps late 0, min interval 0, bad calcs 0, ebfmin 0.00, ebfmax 0.00 next step interrupt due in 27 ticks, disabled Moves shaped first try 69, on retry 11, too short 44, wrong shape 17759, maybepossible 0 === DDARing 0 === Scheduled moves 18046, completed 18035, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 12], CDDA state 3 === DDARing 1 === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 Heater 0 is on, I-accum = 0.0 Heater 1 is on, I-accum = 0.0 === GCodes === Movement locks held by null, null HTTP* is doing "M122" in state(s) 0 Telnet is idle in state(s) 0 File* is doing "G1 X167.380997 Y162.423996 E45.051701" in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger* is idle in state(s) 0 Queue* is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 0, running macro Aux2 is idle in state(s) 0 Autopause* is idle in state(s) 0 File2 is idle in state(s) 0 Queue2 is idle in state(s) 0 Q0 segments left 1, axes/extruders owned 0x80000007 Code queue 0 is empty Q1 segments left 0, axes/extruders owned 0x0000000 Code queue 1 is empty === Filament sensors === check 0 clear 0 Extruder 0: no data received, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0 === CAN === Messages queued 68686, received 133930, lost 0, errs 1, boc 0 Longest wait 6ms for reply type 6024, peak Tx sync delay 265, free buffers 50 (min 49), ts 28309/28308/0 Tx timeouts 0,0,0,0,0,0 === SBC interface === Transfer state: 5, failed transfers: 0, checksum errors: 0 RX/TX seq numbers: 24716/24716 SPI underruns 0, overruns 0 State: 5, disconnects: 0, timeouts: 0 total, 0 by SBC, IAP RAM available 0x24cfc Buffer RX/TX: 3024/456-4080, open files: 0 === Duet Control Server === Duet Control Server version 3.5.2 (2024-06-12 07:09:26, 32-bit) HTTP+Executed: > Executing M122 File 0:/gcodes/7vlDMEE2ADp.gcode is selected, processing File: Buffered code: G1 X167.381 Y162.424 E45.0517 Buffered code: G1 X166.787 Y162.424 E45.0673 Buffered code: G1 X183.867 Y145.344 E45.6999 Buffered code: G1 X183.273 Y145.344 E45.7155 Buffered code: G1 X166.193 Y162.424 E46.3482 Buffered code: G1 X165.599 Y162.424 E46.3637 Buffered code: G1 X182.679 Y145.344 E46.9964 Buffered code: G1 X182.085 Y145.344 E47.0119 Buffered code: G1 X165.005 Y162.424 E47.6446 Buffered code: G1 X164.411 Y162.424 E47.6602 Buffered code: G1 X181.491 Y145.344 E48.2928 Buffered code: G1 X180.897 Y145.344 E48.3084 Buffered code: G1 X163.817 Y162.424 E48.9411 Buffered code: G1 X163.223 Y162.424 E48.9566 Buffered code: G1 X180.303 Y145.344 E49.5893 Buffered code: G1 X179.709 Y145.344 E49.6049 Buffered code: G1 X162.629 Y162.424 E50.2375 Buffered code: G1 X162.035 Y162.424 E50.2531 Buffered code: G1 X179.115 Y145.344 E50.8858 Buffered code: G1 X178.521 Y145.344 E50.9013 Buffered code: G1 X161.441 Y162.424 E51.5340 Buffered code: G1 X160.847 Y162.424 E51.5495 Buffered code: G1 X177.927 Y145.344 E52.1822 Buffered code: G1 X177.333 Y145.344 E52.1978 Buffered code: G1 X160.253 Y162.424 E52.8304 Buffered code: G1 X159.659 Y162.424 E52.8460 Buffered code: G1 X176.739 Y145.344 E53.4787 Buffered code: G1 X176.145 Y145.344 E53.4942 Buffered code: G1 X159.065 Y162.424 E54.1269 Buffered code: G1 X158.472 Y162.424 E54.1424 Buffered code: G1 X175.552 Y145.344 E54.7751 Buffered code: G1 X174.958 Y145.344 E54.7907 Buffered codes: 1536 bytes total Code buffer space: 2568 Configured SPI speed: 8000000Hz, TfrRdy pin glitches: 0 Full transfers per second: 36.52, max time between full transfers: 253.5ms, max pin wait times: 57.5ms/14.6ms Codes per second: 2.13 Maximum length of RX/TX data transfers: 4884/1696 -

BtnCmd-DWC Plugin for DWC 3.5.2-rc.1posted in General Discussion

@MintyTrebor

When will a DWC 3.5.2 rc1 compatible version of BtcCmd be released?

Unfortunately BtnCmd 01.03.01 does not work with DWC 3.5.2 rc1.

Thank you -

RE: RGB & RGBW LED MALFUNCTION 3.5.1posted in Beta Firmware

@dc42

Thank you!

Could the change already be present in the first Beta versions of 3.5.2? -

RE: RGB & RGBW LED MALFUNCTION 3.5.1posted in Beta Firmware

-- Are your LEDs GRBW vs RGBW for color order? ---

To do an accurate test I installed a 155-element RGB LED strip in the dedicated LED port (working perfectly), a 3-element RGBW LED strip on the io.8 port, a 4-element RGB LED strip on the io.7 port, and a 3-element RGBW LED strip on the io.5 port ( like in my config.g)-- If you try and send green to the light is it red? --

Of the 3 LED strips connected to the io.port of the MB6HC, the first LED on the strip always remains green with any command sent. The first green LED never turns off with any command.

The 2 RGBW LED strips are buy new for the Voron stealthburner...It is possible that the upgrade from Fw. 3.5.0 Rc4 to Fw. 3.5.1 could have caused this malfunction?

Since the printer is now fully functional, I wouldn't want to experiment with a fw. downgrade, since I'm in SBC mode.

-

RGB & RGBW LED MALFUNCTION 3.5.1posted in Beta Firmware

It seems to me, that after the update to 3.5.1. the LEDs controlled by the MB6HC on io.port have stopped working correctly.

The same LED strips connected to the Dotstar port continue to work properly.

in tests done with multiple LEDs (see instructions in config.g at the end of the file) the behavior of the various LEDs is very similar.

After the M150 command e.g.:

M150 E1 R255 U0 B0 W0 P50 S1 F1

M150 E1 R0 U0 B0 W255 P50 S2 F0

The first LED is light green, while the other two are correctly white. If I give the command to turn everything off e.g. M150 E1 R0 U0 B0 W0 P0 S3 F0 the first LED always remains lit green.

After turning on the printer if I do homing, the LEDs in the extruder automantically light up green. (I have no active macros).

I would like to avoid downgrading to 3.5.0 because I would have to update the mainboard, toolboard and DWC.

I would like to receive some suggestions or understand if I'm doing something wrong.My config.g

; Voron 2.4 355x355mm Duet3 6MBHC - Toolboard 1LC - SBC with RASPBERRY PI-4 4GB and SD 64GB ; Firmware 3.5.1 ; Data di aggiornamento: 02/05/2024 ; ; ---------- GENERAL PREFERENCES --------- G90 ; absolute coordinates... M83 ; relative extruder moves M669 K1 ; Select CoreXY mode M564 S1 H1 ; Forbid axis movements when not homed M575 P1 S1 B57600 ; enable support for Paneldue display M290 R0 S0 ; reset babystepping ; ; ---------- DRIVES MAPPINGS ---------- ; ; Rear ; | Z1 | Z2 | ; -----+----- ; | Z0 | Z3 | ; -----+----- ; Front ; M584 X4 Y5 Z0:1:2:3 E121.0 ; set drive mapping M569 P0 S1 ; Z0 motor FL goes forwards M569 P1 S0 ; Z1 motor RL goes backwards M569 P2 S1 ; Z2 motor RR goes forwards M569 P3 S0 ; Z3 motor FR goes backwards M569 P4 S1 ; A motor goes forwards M569 P5 S1 ; B motor goes forwards M569 P121.0 S0 ; E1 motor Extruder goes backwards (scheda 1LC porta 121) M671 X-67.5:-67.85:422.5:422.5 Y-10:443.8:443.8:-10 S15 ; Define Z belts locations (Z0=Front_Left Z1, Z2, Z3...ecc) S15=mm di correzione massima ; ; ---------- DRIVES GENERAL PARAMETERS ---------- M350 X32 Y32 Z32 E16 I1 ; configure microstepping with interpolation M92 X159.94 Y159.94 Z800 E745 ; set steps per mm (417 afterburner, 745 stealthburner) M84 S20 ; riduzione potenza motori dopo 20sec ; ; ---------- DRIVES SPEED PARAMETERS ---------- M566 X800 Y800 Z100 E1000 ; JERK (mm/min) M203 X24000 Y24000 Z6000 E1000 ; MAX SPEED (400mm/min) M201 X7000 Y7000 Z500 E3000 ; ACCELERAZIONE (mm/s^2) M906 X2000 Y2000 Z2000 E850 I30 ; set motor currents (mA) and motor idle factor 30% ; IN ALTERNATIVA USARE IL FILE SOTTO: ; M98 P"/sys/print_scripts/setup_printing_med.g" ; FILE PER STAMPA PRESTAZIONI MEDIE - FINO A 400mm/sec ; M98 P"/sys/print_scripts/setup_printing_low.g" ; FILE PER HOMING - FINO A 250mm/sec ; M98 P"/sys/print_scripts/setup_printing_high.g" ; FILE PER STAMPA PRESTAZIONI ELEVATE - FINO A 500mm/sec ; ; ---------- AXIS LIMITS ---------- M208 X0 Y0 Z-0.15 S1 ; set axis minima (S1) M208 X350 Y350 Z320 S0 ; set axis maxima (S0) Portato ad H=320mm per presenza barra LED ; ; ---------- ENDSTOP SWITCH MECCANICO --------- M574 Y2 S1 P"io1.in" ; Configure enstop Y(2) posizione alta dello switch e pin !io1.in invertito M574 X2 S1 P"io2.in" ; Configure enstop x(2) posizione alta dello switch e pin !io2.in invertito ; ; ---------- SENSORE MAGNETICO FILAMENTO --------- M591 D0 P3 C"121.io0.in" R10:190 L24.5 E10.0 S1 ; Rotating magnet sensor for extruder drive 0 is connected to 121.io0.in on Toolboard 1LC, ; M591 D0 P0 ; Disabilita controllo sensore magnetico ; ---------- Z-PROBE ---------- M558 P8 C"!121.io1.in" H10 F600 T5000 ; set Z probe type inductive (P8), altezza tastatura (H10), velocità tastatura mm/min (F600), velocità di spostamento mm/min (T6000) su scheda espansione 1LC porta 121 G31 P500 X0 Y24 Z1.45 ; set Z OFFSET, ( * PEI * ), PIU' ALTO E' Z PIU' SI AVVICINA AL LETTO ; G31 P500 X0 Y24 Z1.65 ; set Z OFFSET, ( * TEXTURE * ) PIU' ALTO E' Z PIU' SI AVVICINA AL LETTO M557 X40:315 Y40:315 S55 ; define mesh grid (GRIGLIA maglia 6 x 6 con 55mm di spazio) EVITA I MAGNETI ; ; ----------- HO - HEATERS BED ---------- M308 S0 P"temp0" Y"thermistor" T100000 B4138 A"LETTO" ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out1" T0 ; create bed heater output on out1 and map it to sensor 0 M307 H0 R0.856 K0.199:0.000 D4.53 E1.35 S1.00 B0 ; DOPO AUTOTARATURA LETTO CON (M303 H0 P1 S100) il 03/12/2023 (R=Velocità di riscaldamento °C/sec) M140 H0 ; map heated bed to heater 0 ; ; ----------- H1 - HEATERS NOZZLE ---------- M308 S1 P"121.temp0" Y"thermistor" T100000 B4138 A"ESTRUSORE" ; Configure sensor 1 as thermistor on pin temp0/121 M950 H1 C"121.out0" T1 ; Create nozzle heater output on out0 su scheda espansione 1LC porta 121 and map it to sensor 1 M307 H1 S0.8 B0 ; H1=riscaldatore 1 S0.8=Potenza al 80% B0=BsngBang (consigliato per gli estrusori) ; M307 H1 R7.21 K0.492:0.000 D5.65 E1.35 S1.00 B0 V29.3 ; (orig. R5.331) DOPO AUTOTARATURA NOZZLE CON (M303 H1 P1 S240) il 03/12/23 HOTEND RAPIDO. (R=Velocità di riscaldamento °C/sec) M143 H1 S275 ; set temperature limit for heater 1 to 275C ; ; ---------- TOOLS ---------- M563 P0 S"TOOLS-0" D0.5 H1 F0 ; DEFINE TOOL 0 => P0=Tool 0, S"..."=Tool name, D0.5=drive 0.5, H1=heather 1, F0=fan 0. G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; ; ---------- FAN 0 VENTOLA RAFFR. STAMPA PWM (out4) 24v ---------- M950 F0 C"121.out2" Q500 ; Fan 0 su 121.out2, use PWM, using 121.out2 M106 P0 C"VENTOLA FILO" S0.0 H-1 ; set FAN_0 name and value. ; ; ---------- FAN 1 VENTOLA HOTEND (out8) 24v ---------- M950 F1 C"121.out1" Q500 ; Fan 0 su 121.out2, use PWM, using 121.out2 M106 P1 C"HOTEND" H1 L0.35 X0.6 B0.3 T60:250 ; PARAMETRICA Termostatica ( da L=35% a X=60% con temp. da 60°C a 250°C ) ; ; ---------- FAN 2 VENTOLA MCU MB6HC PWM (out5) 24v --------- M308 S2 Y"mcu-temp" A"MCU 6HC" ; configure sensor 2 (S2) as thermistor for MCU M950 F2 C"!out5+out5.tach" ; Fan 2 su out5, use PWM (needs ! inverted), using out5.tach M106 P2 C"VENTOLA MCU" L0.1 X0.8 B0.1 T26:35 H3 ; set FAN_2 value T26:32°C velocità ventola L-10% X-80% ; ; ---------- FAN 3 VENTOLA PWM RASPBERRY (out4) 12v --------- M308 S3 P"temp2" Y"thermistor" T100000 B4138 A"RASPBERRY" ; Configura il sensore 3 (S3) come riscaldatore sul pin temp2 con nome RASPBERRY M950 F3 C"!out4+out4.tach" ; Fan 3 su out6, use PWM (needs ! inverted), using out4.tach M106 P3 C"VENTOLA RASPBERRY" L0.1 X1.0 B0.5 T20:48 H4 ; set FAN_3 value T20:42°C velocità ventola L-10% X-100% B=blip time ; ; ---------- FAN 4 VENTOLA 1LC (out7) 24v ---------- M308 S4 Y"mcu-temp" P"121.dummy" A"MCU 1LC" ; configure sensor 4 (S4) Temp MCU 1LC M950 F4 C"out7" Q1000 ; create FAN_4 on pin ou7 Toolboard and set its frequency at 1000hz M106 P4 C"FAN 1LC MCU" H1 L0.2 X0.7 B0.3 T38:55 ; H1=Termostatic L=Min.Spd. X=Max.Spd. B=Blips Time T=Temp Range 30-50°C ; M106 P4 S0.65 ; PER ACCENDERE LA VENTOLA ; M106 P4 S0.0 ; PER SPEGNERE LA VENTOLA ; ; ---------- FAN 5 VENTOLA CHASSIS (out8) 24v ---------- M950 F5 C"out8" Q1500 ; create FAN_5 on pin ou8 VENTOLE LATERALI DX ASPIRANTI M106 P5 S0.00 C"CHASSIS_SX" B1 ; ACCENDE LA VENTOLA AL 30% ; ; ---------- FAN 6 VENTOLA CHASSIS (out9) 24v ---------- M950 F6 C"out9" Q1500 ; create FAN_6 on pin ou9 VENTOLE LATERALI SX SOFFIANTI M106 P6 S0.00 C"CHASSIS_DX" B1 ; ACCENDE LA VENTOLA AL 30% ; ; ---------- TEMPERATURA E0 NEMA 14 SU TOOLBOARD 1LC ---------- M308 S5 P"121.temp1" Y"thermistor" T100000 B4138 A"NEMA14" ; Configure sensor 5 (S5) as thermistor on pin temp1/121 ; ; ---------- PORT 1 RELE' ACCENSIONE (io4.out) IO PORT PWM ---------- M950 P1 C"io4.out" Q500 ; allocate GPIO PORT.1 to io4.out at 500Hz ; M42 P1 S0.0 ; Printer OFF set 0% PWM on GPIO port 1 ; M42 P1 S1.0 ; Printer ON set 100% PWM on GPIO port 1 ; ; ---------- ACCELEROMETRO ---------- M955 P121.0 I05 ; ACCELEROMETRO SU SCHEDA 1LC ( I05 = orientamento scheda 1CL ) M593 P"ZVDDD" F36 ; INPUT SHAPING: Configura i parametri di riduzione risonanza ; ; ---------- TASTI FISICI SU 1LC ---------- M950 J5 C"121.button0" ; Crea pin 5 su porta 121.button0 della scheda 1LC M581 P5 T2 S1 R0 ; P5=pin 5 creato con M950 (J5), T2=Trigger logico a cui associare gli ingressi, S1=funziona da inattivo ad attivo, R0=attivo in ogni momento ; ; Qualsiasi numero di trigger # maggiore di 1 provoca l'esecuzione del file della macro sys/trigger2.g (T2) M950 J6 C"121.button1" ; Crea trigger n°6 su porta "121.button0" M581 P6 T3 S1 R0 ; Crea pin 6 su porta 121.button1 della scheda 1LC ; ; ---------- NEOLED "0" 4 BARRE LED RGB SUPERIORI (PORTA DEDICATA DOTSTAR SU 6HC) ---------- M950 E0 C"led" T1 U155 Q3000000 ; Crea PIN "led" striscia LED E0 T1=RGB U160=160LED disponibili M98 P"0:/macros/5-NEOLED ITALIA.g" ; Tutti i led superiori accesi al 10% (41+41+32+41=155 LED RGB) ; ; ---------- NEOLED "1" RGBW - STEALTHBURNER (PORTA IO8 OUT SU 6HC) ---------- M950 E1 C"io8.out" Q3000000 T2 U5 ; Crea PIN "io8.out" striscia LED E1 T1=RGB T2=RGBW ; ; ---------- NEOLED "2" TEST-1 LED RGB ---------- M950 E2 C"io7.out" T1 U5 Q3000000 ; Crea PIN "led" striscia LED E0 T1=RGB U160=160LED disponibili ; ; ---------- NEOLED "3" TEST-2 LED RGBW ---------- M950 E3 C"io5.out" T2 U4 Q3000000 ; Crea PIN "led" striscia LED E0 T1=RGB U160=160LED disponibili ; ; ---------- IMPOSTA L'AUTOSALVATAGGIO IN CASO DI MANCATA ALIMENTAZIONE ---------- M911 S29.2 R29.4 P"M913 X0 Y0 G91 M83 G1 Z3 E-2 F500" ; Autosalvataggio stampa per mancanza di corrente, sospende a 29.2v e riparte a 29.4v ; ; ---------- MISCELLANEUS ---------- M912 P0 S-1 ; parametro per tarare la temperatura della MCU (-1°C) M300 S2500 P3000 ; Emette suono a S=2500Hz per P=3 secondi T0 ; select first tool ACTIVE ;My homeall.g

G91 ; relative positioning G1 H2 Z5 F2000 ; lift Z relative to current position G1 H1 X350 Y350 F4000 ; move quickly to X or Y endstop and stop there (first pass) G1 H1 X350 ; home X axis G1 H1 Y350 ; home Y axis G1 X-10 Y-10 F4000 ; go back a few mm G1 H1 X10 F800 ; move slowly to X axis endstop once more (second pass) G1 H1 Y10 F800 ; then move slowly to Y axis endstop once more (second pass) G90 ; absolute positioning G1 X175 Y175 F4000 ; muovi al centro del piatto G30 ; home Z by probing the bed -

RE: NEW PROBLEM WITH 1LC CARDposted in General Discussion

@droftarts

After many attempts and many tested CAN-FD cables, I was able to get the locked Toolboards working.

It was definitely the faulty cable. it was cut off about halfway down the length and was making false contact.

I managed to restore the two original 1LC cards and also a clone that I had purchased for testing.

The quality of the cables is very important!Thanks, you can mark it as resolved.

-

RE: NEW PROBLEM WITH 1LC CARDposted in General Discussion

@droftarts

First of all, thanks for your help, I hope to have a working printer again soon.I don't understand why in stand alone mode, the Status LED ( in both toolboards ) doesn't flash, while in SBC mode it does.

It would seem more logical to me to try to restore the firmware with the fastest boot (St. alone) and not waiting for the 30 seconds of the Raspberry (SBC).

In SBC, it seems that after the toolboard reset, the mainboard can give the firmware too late, only when the 1LC is no longer asking for it.Before the firmware update, both toolboards worked quite well, except for the "Expansion board 121 stopped sending status" error that was occasionally shown on the display. Printing was not interrupted.

In any case, making a new CAN cable costs nothing and I will do it right away.I also measure the resistance on the pins of the CAN cable connector, is actually working.

I'll report back as soon as all the tests have been done.

-

RE: NEW PROBLEM WITH 1LC CARDposted in General Discussion

@jay_s_uk said in NEW PROBLEM WITH 1LC CARD:

@Gianluca i was just suggesting remove all variables, but if you want to stick to the resistor thats fine

I didn't solder the terminal, just to keep the board without any modifications...

-

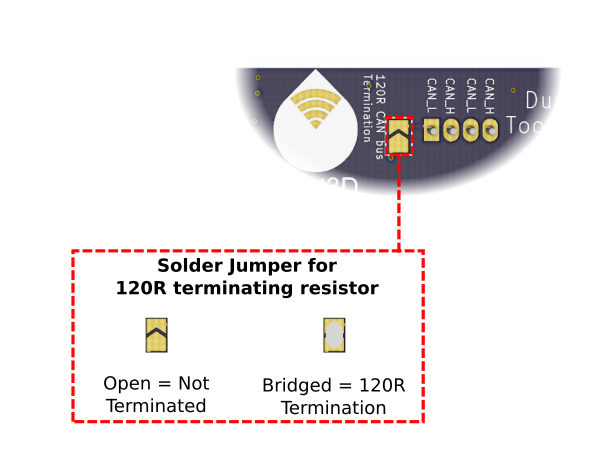

RE: NEW PROBLEM WITH 1LC CARDposted in General Discussion

@jay_s_uk said in NEW PROBLEM WITH 1LC CARD:

@Gianluca can you remove everything from the toolboard so nothing is plugged in except the CAN and power connections?

I see you are using a 1LC v1.3

If you just have the one toolboard in the setup and its on the end of the CAN run, I would use the built in terminating resistor rather than have a resistor on the CAN connection

Thanks, I'll try this too, just CAN and power connected.

No need to cut the track, if you look, there is the resistor on the CAN connector.

I have two v1.3 boards blocked by updates, one with the electrical track cut and one with the resistor. -

RE: NEW PROBLEM WITH 1LC CARDposted in General Discussion

Have you seen the videos?

Can you help me get a working printer again?

Thank you -

RE: NEW PROBLEM WITH 1LC CARDposted in General Discussion

@droftarts said in NEW PROBLEM WITH 1LC CARD:

@Gianluca All the videos are marked as private, so I can't see them.

Ian

Sorry... Could you try now?

-

RE: NEW PROBLEM WITH 1LC CARDposted in General Discussion

@dc42 said in NEW PROBLEM WITH 1LC CARD:

@Gianluca what happens if you connect just one of the non-functioning tool boards to the CAN bus and hold both buttons down while powering up? What sequence of LED flashes do you see on the tool board?

I answer the questions by attaching videos.

VIDEO_1: startup in stand alone mode.

The beep at the end indicates boot completion.

link textVIDEO_2: startup in stand alone mode with reset 1LC.

The beep at the end indicates boot completion.

link textVIDEO_3: startup in SBC mode.

The beep at the end indicates boot completion.

link textVIDEO_4: startup in SBC mode with reset 1LC.

The beep at the end indicates boot completion.

link textThe file "Duet3Firmware_TOOL1LC.bin" is present in both the firemware and SYS folders, both in the SD card (st. alone mode) and in the raspberry (SBC mode).

Unfortunately the toolboard reset procedure did not work with any attempts.

Before the toolboards were blocked, they worked fine, except for the "Can't turn heater 1 on while in fault state" error, that perhaps arose with the RC3 version.

Is it not possible to send the cards to load the firmware in your laboratory?

Thanks for the help, I really need it to get a usable printer again.