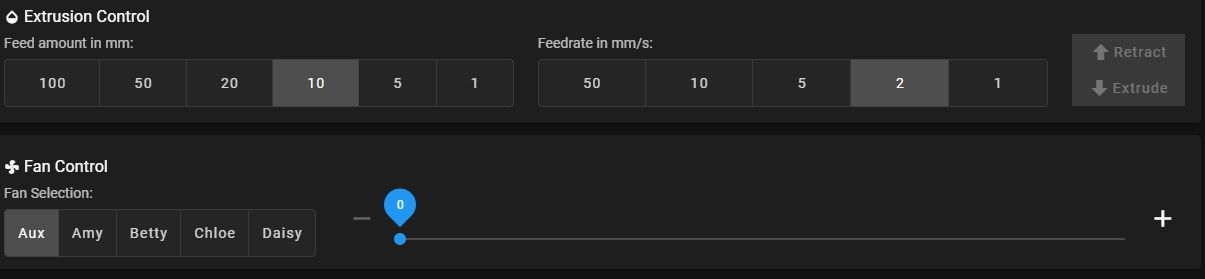

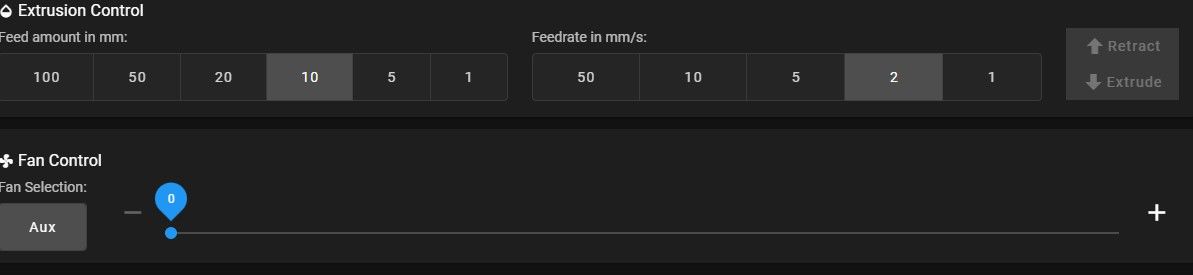

@gloomyandy Follow up several prints and a couple of hundred tool changes on 3.5.1, reverted to the latest 3.6.0 A5, (2) prints in and a tool is dropped while pulling away from the parking post. Config.g below

; Jubilee CoreXY ToolChanging Printer - Config File

; This file intended for Duet 3 hardware, main board plus Tool Boards

; Name and network

; This is configured from the connected Raspberry Pi or here if in stand alone

; mode

; Connect to PanelDue 7i

M575 P1 S0 B57600

;------------------------NETWORKING IF NOT HANDLED BY SBC------------------------------

; Networking

;M540 PBE:43:37:31:51:31

M550 P"Jubilee" ; Name used in ui and for mDNS http://Jubilee.local

M552 P0.0.0.0 S1 ; configure Ethernet adapter

M586 P0 S1 ; configure HTTP

;M552 S1 P192.168.1.19 ; Use Ethernet with a static IP, 0.0.0.0 for dhcp

;M553 P255.255.255.0 ; Netmask

;M554 192.168.1.1 ; Gateway

; General setup

;-------------------------------------------------------------------------------

M550 P"Printster" ; Set Machine Name

G4 S2 ; Pause for 2 seconds to allow CAN boards to initiate

M111 S0 ; Debug off

M929 P"eventlog.txt" S0 ; Start logging to file eventlog.txt (turned logging off)

; General Preferences

M555 P2 ; Set Marlin-style output

G21 ; Set dimensions to millimetres

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

; Stepper mapping

;-------------------------------------------------------------------------------

; Connected to the MB6HC as the table below.

; Note: first row is numbered left to right and second row right to left

; _________________________________

; | X(Right) | Y(Left) | U(lock) |

; | Z(Back) | Z(Right) | Z(Left) |

M584 X0 Y1 ; X and Y for CoreXY

M584 U2 ; U for toolchanger lock

M584 Z3:4:5 ; Z has three drivers for kinematic bed suspension.

;*********************RRF-36 Stepper Mapping ******************************************

M584 E20.0:21.0:22.0:23.0 ; "AMY" "BETTY" "CHLOE" "DAISY" Extruder drive mapping

M569 P0 S0 ; Drive 0 | X stepper

M569 P1 S0 ; Drive 1 | Y Stepper

M906 X{0.6*sqrt(2)*2500} ; LDO XY 2500mA RMS the TMC5160 driver on duet3

M906 Y{0.6*sqrt(2)*2500} ; generates a sinusoidal coil current so we can

; multply by sqrt(2) to get peak used for M906

; Do not exceed 90% without heatsinking the XY

; steppers.

M569 P2 S0 ; Drive 2 | U Tool Changer Lock 670mA

M906 U{0.7*sqrt(2)*670} I60 ; 70% of 670mA RMS idle 60%

; Note that the idle will be shared for all drivers

M569 P3 S0 ; Drive 3 | Front Left Z

M569 P4 S0 ; Drive 4 | Front Right Z

M569 P5 S0 ; Drive 5 | Back Z

M906 Z{0.6*sqrt(2)*2500} ; 70% of 2500mA RMS

;********************RRF-36 Tool steppers on expansion board****************************

M569 P20.0 S0 D2 ; Drive 0 "AMY" direction | Extruder 0 in Spreadcycle Mode

M569 P21.0 S0 D2 ; Drive 1 "BETTY" direction | Extruder 1 in Spreadcycle Mode

M569 P22.0 S0 D2 ; Drive 2 "CHLOE" direction | Extruder 2 in Spreadcycle Mode

M569 P23.0 S0 D2 ; Drive 3 "DAISY" direction | Extruder 3 in Spreadcycle Mode

;======================SET MAXIMUM PRINTING SPEEDS============================================

M204 P5000 T5000

; Kinematics

;-------------------------------------------------------------------------------

M669 K1 ; CoreXY mode

; Kinematic bed ball locations.

; Locations are extracted from CAD model assuming lower left build plate corner

; is (0, 0) on a 305x305mm plate.

M671 X297.5:2.5:150 Y313.5:313.5:-16.5 S10 ; Front Left: (297.5, 313.5)

; Front Right: (2.5, 313.5)

; Back: (150, -16.5)

; Up to 10mm correction

; Axis and motor configuration

;-------------------------------------------------------------------------------

M350 X1 Y1 Z1 U1 ; Disable microstepping to simplify calculations

M92 X{1/(0.9*16/180)} ; step angle * tooth count / 180

M92 Y{1/(0.9*16/180)} ; The 2mm tooth spacing cancel out with diam to radius

M92 Z{360/0.9/4} ; 0.9 deg stepper / lead (4mm) of screw

M92 U{13.76/1.8} ; gear ration / step angle for tool lock geared motor.

; Enable microstepping all step per unit will be multiplied by the new step def

M350 X32 Y32 I1 ; 16x microstepping for CoreXY axes. Use interpolation.

M350 U4 I1 ; 4x for toolchanger lock. Use interpolation.

M350 Z16 I1 ; 16x microstepping for Z axes. Use interpolation.

M350 E16 I1 ; 16x microstepping for Extruder axes. Use interpolation.

; Speed and acceleration

;-------------------------------------------------------------------------------

M201 X8000 Y8000 ; Accelerations (mm/s^2)

M201 Z100 ; LDO ZZZ Acceleration

M201 U800 ; LDO U Accelerations (mm/s^2)

M203 X24000 Y24000 Z800 U9000 ; Maximum axis speeds (mm/min)

M566 X2000 Y2000 Z100 U50 P1 ; Maximum jerk speeds (mm/min)

;********************RRF-36 motor configuration ***************************************

M906 E800:800:800:800 I10 ; Motor currents for all E (mA).

M201 E18000:18000:18000:18000 ; E600:600:600 E Acceleration (mm/s^2)

M203 E7200:7200:7200:7200 ; Maximum axis speeds (mm/min) was 3600

M566 E3000:3000:3000:3000 ; Maximum jerk speeds (mm/min)

M92 E719:719:719:719 ;E Steps VZ-Hextrudort - 0.9 deg/step Tool0:Tool1:Tool3

; Endstops and probes

;-------------------------------------------------------------------------------

; Connected to the MB6HC as the table below.

; | U | Z |

; | X |

; | Y |

M574 U1 S1 P"^io4.in" ; homing position U1 = low-end, type S1 = switch

M574 X1 S1 P"^io1.in" ; homing position X1 = low-end, type S1 = switch

M574 Y1 S1 P"^io2.in" ; homing position Y1 = low-end, type S1 = switch

M574 Z0 ; we will use the switch as a Z probe not endstop

M558 P8 C"io3.in" H3 F360 T6000 ; H = dive height F probe speed T travel speed

G31 K0 X0 Y0 Z-2 ; Set the limit switch position as the "Control Point."

; Note: the switch free (unclicked) position is 7.2mm,

; but the operating position (clicked) is 6.4 +/- 0.2mm.

; A 1mm offset (i.e: 7.2-6.2 = 1mm) would be the

; Z to worst-case free position, but we add an extra 1mm

; such that XY travel moves across the bed when z=0

; do *not* scrape or shear the limit switch.

; Set axis software limits and min/max switch-triggering positions.

; Adjusted such that (0,0) lies at the lower left corner of a 300x300mm square

; in the 305mmx305mm build plate.

M208 X-13.75:313.75 Y-44:341 Z0:295

M208 U0:200 ; Set Elastic Lock (U axis) max rotation angle

; Heaters and temperature sensors

;----------------------------------------------------------------------------------------------------

; Bed

M308 S0 P"temp0" Y"thermistor" T100000 B3950 A"Bed" ; Keenovo thermistor

M950 H0 C"out0" T0 ; H = Heater 0

; C is output for heater itself

; T = Temperature sensor

M143 H0 S130 ; Set maximum temperature for bed to 130C

M307 H0 A589.8 C589.8 D2.2 V24.1 B0 ; Keenovo 750w 230v built in thermistor

; mandala rose bed

M140 H0 ; Assign H0 to the bed

;**********************FLY-RRF 36 Extruder configurations**********************************************

;---------------------Tool 0 aka "AMY" With CAN Address 20.0 ------------------------------------------

;Heater Thermistor

M308 S1 P"20.TEMP0" Y"thermistor" T100000 B4725 C7.06e-8 A"Amy" ;"T1" Semtec Thermistor defined

;M308 S6 P"20.temp1" Y"thermistor" A"Amy Fly RRF" T100000 B4092

; Cooling Fans

M950 F0 C"20.out1" ; Fan 0, part cooler fan on Tool 0

M106 P0 C"Amy" ; Set Fan Name

M950 F1 C"20.out2" ; Fan 1, hotend fan on Tool 0

M950 H1 C"20.out0" T1 ; Heater 1 "H1" uses the Out0 pin and Temp0

M570 H1 P15 T20 R5 ; An anomaly on "H1" must persist for 15 seconds, and must be greater or less than 20C from the setpoint, to raise a heater fault.

M143 H1 S280 ; Maximum H1 (Extruder 1) heater temperature

M106 P1 S1.0 T45 H1 ; Tool 0 Hotend Fan to start cooling at 45C Monitoring Heater 1 (H1)

M563 P0 S"Amy" D0 H1 F0 ; Define tool 0 "AMY" using H1 heater, F0 cooling

;G10 P0 X0.188 Y32.637 Z-0.345 ; Set tool 0 offset from the bed FOR INITIAL SETUP ONLY SEE VALUES IN CONFIG OVERRIDE

G10 P0 S0 R0 ; Set tool 1 operating (S) and standby temperatures (R) (-273 = "off")

M572 D0 S0.04 ; Set pressure advance on Extruder Drive 1

;Turn on tool Lights

M950 E0 C"20.rgbled" T2 U2 ; Strip number, Pin ID, type, Max # of LED'S

;M150 E0 U0 R0 B0 W255 S1 F1 P255 ; for RGBW LED Only

;M150 E0 U0 R0 B0 W255 S1 F0 P255 ; for RGBW LED Only

M955 P20.0 I52 ; Enable accelerometer on Amy

;---------------------End of Tool 0 aka "AMY" -----------------------------------------------------------

;---------------------Tool aka "BETTY" With CAN Address 21.0 ------------------------------------------

;Heater Thermistor

M308 S2 P"21.TEMP0" Y"thermistor" T100000 B4725 C7.06e-8 A"Betty" ;"T1" Semtec Thermistor defined

;M308 S7 P"21.temp1" Y"thermistor" A"Betty Fly RRF" T100000 B4092

; Cooling Fans

M950 F2 C"21.out1" ; Fan 2, part cooler fan on Tool 1

M106 P2 C"Betty" ; Set Fan Name

M950 F3 C"21.out2" ; Fan 3, hotend fan on Tool 1

M950 H2 C"21.out0" T2 ; Heater 2 "H2" uses the Out0 pin and Temp0

M570 H2 P15 T20 R5 ; An anomaly on "H2" must persist for 15 seconds, and must be greater or less than 20C from the setpoint, to raise a heater fault.

M143 H2 S280 ; Maximum H2 (Extruder 1) heater temperature

M106 P3 S1.0 T45 H2 ; Tool 1 Hotend Fan to start cooling at 45C Monitoring Heater 2 (H2)

M563 P1 S"Betty" D1 H2 F2 ; Define tool 1 "BETTY" using H2 heater, F2 cooling

;G10 P1 X0.188 Y32.637 Z-0.345 ; Set tool 1 offset from the bed FOR INITIAL SETUP ONLY SEE VALUES IN CONFIG OVERRIDE

G10 P1 S0 R0 ; Set tool 1 operating (S) and standby temperatures (R) (-273 = "off")

M572 D1 S0.04 ; Set pressure advance on Extruder Drive 2

;Turn on tool Lights

M950 E1 C"21.rgbled" T2 U2 ; Strip number, Pin ID, type, Max # of LED'S

;M150 E1 U0 R0 B0 W255 S1 F1 P255 ; for RGBW LED Only

;M150 E1 U0 R0 B0 W255 S1 F0 P255 ; for RGBW LED Only

M955 P21.0 I52 ; Enable accelerometer on Betty

;-------------------------------End of Tool 0 aka "BETTY". -------------------------------------

;---------------------Tool aka "CHLOE" With CAN Address 22.0 ------------------------------------------

;Heater Thermistor

M308 S3 P"22.TEMP0" Y"thermistor" T100000 B4725 C7.06e-8 A"Chloe" ;"T1" Semtec Thermistor defined

;M308 S8 P"22.temp1" Y"thermistor" A"Chloe Fly RRF" T100000 B4092

; Cooling Fans

M950 F4 C"22.out1" ; Fan4, part cooler fan on Tool 2

M106 P4 C"Chloe" ; Set Fan Name

M950 F5 C"22.out2" ; Fan 5, hotend fan on Tool 2

M950 H3 C"22.out0" T3 ; Heater 3 "H3" uses the Out0 pin and Temp0

M570 H3 P15 T20 R5 ; An anomaly on "H3" must persist for 15 seconds, and must be greater or less than 20C from the setpoint, to raise a heater fault.

M143 H3 S280 ; Maximum H3 (Extruder 2) heater temperature

M106 P5 S1.0 T45 H3 ; Tool 3 Hotend Fan to start cooling at 45C Monitoring Heater 3 (H3)

M563 P2 S"Chloe" D2 H3 F4 ; Define tool 2 "CHLOE" using H3 heater, F4 cooling

;G10 P2 X0.188 Y32.637 Z-0.345 ; Set tool 1 offset from the bed FOR INITIAL SETUP ONLY SEE VALUES IN CONFIG OVERRIDE

G10 P2 S0 R0 ; Set tool 1 operating (S) and standby temperatures (R) (-273 = "off")

M572 D2 S0.04 ; Set pressure advance on Extruder Drive 2

;Turn on tool Lights

M950 E2 C"22.rgbled" T2 U2 ; Strip number, Pin ID, type, Max # of LED'S

;M150 E2 U0 R0 B0 W255 S1 F1 P255 ; for RGBW LED Only

;M150 E2 U0 R0 B0 W255 S1 F0 P255 ; for RGBW LED Only

M955 P22.0 I52 ; Enable accelerometer on CHLOE

;-------------------------------End of Tool 0 aka "CHLOE". -------------------------------------

;---------------------Tool aka "DAISY" With CAN Address 22.0 ------------------------------------------

;Heater Thermistor

M308 S4 P"23.TEMP0" Y"thermistor" T100000 B4725 C7.06e-8 A"Daisy" ;"T3" Semtec Thermistor defined

;M308 S9 P"23.temp1" Y"thermistor" A"Daisy Fly RRF" T100000 B4092

; Cooling Fans

M950 F6 C"23.out1" ; Fan4, part cooler fan on Tool 3

M106 P6 C"Daisy" ; Set Fan Name

M950 F7 C"23.out2" ; Fan 7, hotend fan on Tool 4

M950 H4 C"23.out0" T4 ; Heater 4 "H4" uses the Out0 pin and Temp0

M570 H4 P15 T20 R5 ; An anomaly on "H4" must persist for 15 seconds, and must be greater or less than 20C from the setpoint, to raise a heater fault.

M143 H4 S280 ; Maximum H4 (Extruder 2) heater temperature

M106 P7 S1.0 T45 H4 ; Tool 4 Hotend Fan to start cooling at 45C Monitoring Heater 4 (H4)

M563 P3 S"Daisy" D3 H4 F6 ; Define tool 4 "DAISY" using H4 heater, F4 cooling

;G10 P3 X0.188 Y32.637 Z-0.345 ; Set tool 4 offset from the bed FOR INITIAL SETUP ONLY SEE VALUES IN CONFIG OVERRIDE

G10 P3 S0 R0 ; Set tool 4 operating (S) and standby temperatures (R) (-273 = "off")

M572 D3 S0.04 ; Set pressure advance on Extruder Drive 4

;Turn on tool Lights

M950 E3 C"23.rgbled" T2 U2 ; Strip number, Pin ID, type, Max # of LED'S

;M150 E3 U0 R0 B0 W255 S1 F1 P255 ; for RGBW LED Only

;M150 E3 U0 R0 B0 W255 S1 F0 P255 ; for RGBW LED Only

M955 P23.0 I52 ; Enable accelerometer on DAISY

;-------------------------------End of Tool 0 aka "DAISY". -------------------------------------

;*******************************END OF RRF-36 TOOLS **********************************************

M593 P"ZVD" F55 L0.25 S0.1 ; Set Dynamic Acceleration Adjustment

M376 H10 ; bed compensation taper

M98 P"config-user.g" ; Load custom user config

M501 ; Load saved parameters from non-volatile memory