It usually happens at this point first.

It usually happens at this point first.

@Phaedrux said in Delta Calibration & Mesh calibration:

config.g, homedelta.g, bed.g, slicer start gcode, image of your current heightmap. other printer details.

M122

=== Diagnostics ===

RepRapFirmware for Duet 3 MB6HC version 3.2.2 running on Duet 3 MB6HC v0.6 or 1.0 (SBC mode)

Board ID: 08DJM-956L2-G43S8-6JTDA-3S06N-1B2YD

Used output buffers: 4 of 40 (12 max)

=== RTOS ===

Static ram: 149788

Dynamic ram: 61788 of which 108 recycled

Never used RAM 147148, free system stack 178 words

Tasks: Linux(ready,75) HEAT(blocked,317) CanReceiv(blocked,817) CanSender(blocked,371) CanClock(blocked,352) TMC(blocked,51) MAIN(running,1203) IDLE(ready,19)

Owned mutexes: HTTP(MAIN)

=== Platform ===

Last reset 00:27:22 ago, cause: power up

Last software reset at 2021-03-18 17:59, reason: User, GCodes spinning, available RAM 146940, slot 2

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0x00000000 SP 0x00000000 Task Linu Freestk 0 n/a

Error status: 0x00

Aux0 errors 0,0,0

Aux1 errors 0,0,0

MCU temperature: min 22.7, current 44.8, max 44.8

Supply voltage: min 24.0, current 24.0, max 24.2, under voltage events: 0, over voltage events: 0, power good: yes

12V rail voltage: min 12.2, current 12.2, max 12.2, under voltage events: 0

Driver 0: position 77876, standstill, reads 42020, writes 14 timeouts 0, SG min/max 0/0

Driver 1: position 77876, standstill, reads 42020, writes 14 timeouts 0, SG min/max 0/0

Driver 2: position 77876, standstill, reads 42020, writes 14 timeouts 0, SG min/max 0/0

Driver 3: position 0, standstill, reads 42022, writes 14 timeouts 0, SG min/max 0/0

Driver 4: position 0, standstill, reads 42022, writes 14 timeouts 0, SG min/max 0/0

Driver 5: position 0, standstill, reads 42022, writes 14 timeouts 0, SG min/max 0/0

Date/time: 2021-03-22 10:19:48

Slowest loop: 0.63ms; fastest: 0.05ms

=== Storage ===

Free file entries: 10

SD card 0 not detected, interface speed: 37.5MBytes/sec

SD card longest read time 0.0ms, write time 0.0ms, max retries 0

=== Move ===

DMs created 125, maxWait 0ms, bed compensation in use: none, comp offset 0.000

=== MainDDARing ===

Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters = 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamberHeaters = -1 -1 -1 -1

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP* is doing "M122" in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger* is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty.

=== CAN ===

Messages queued 6497, send timeouts 0, received 19480, lost 0, longest wait 1ms for reply type 6031, free buffers 48

=== SBC interface ===

State: 4, failed transfers: 0

Last transfer: 3ms ago

RX/TX seq numbers: 57188/57188

SPI underruns 0, overruns 0

Number of disconnects: 0, IAP RAM available 0x2c884

Buffer RX/TX: 0/0-0

=== Duet Control Server ===

Duet Control Server v3.2.2

Code buffer space: 4096

Configured SPI speed: 8000000 Hz

Full transfers per second: 0.24

Maximum length of RX/TX data transfers: 4036/648

M98 P"config.g" just gives back the same line in the console.

;config_real.g funktioniert mit Simplify3D

; Configuration file for LPU02b Duet 3 (firmware version 3) by JT. 26.01.2020

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2.1.8 on Fri May 15 2020 18:21:38 GMT+0200

;General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"LPU02" ; set printer name

;M665 L472.5 R310 H394.75 B160 X0 Y0 Z0 ;(Höhe plz. 394,75; war 393.3) Set delta radius, diagonal rod length, printable radius and homed height B105 (R242.28 L408.55)

;M666 X0 Y0 Z0 A0 B0 ; put your endstop adjustments here, or let auto calibration find them

M665 L472.500:472.500:472.500 R275.330 H394.765 B160.0 X-0.400 Y0.021 Z0.000

M666 X0.460 Y-0.367 Z-0.093 A0.00 B0.00

;Raspberry Pi; user: yy; password: xxx

;password for attached raspberry pi

; Drives

M569 P0 S0 ; physical drive 0 goes backwards; x-Stepper

M569 P1 S0 ; physical drive 1 goes backwards; y-Stepper

M569 P2 S0 ; physical drive 2 goes backwards; z-Stepper

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3:4:5 ;W6 A7 B8 C9 ; set drive mapping

M350 X16 Y16 Z16 E16 ; configure microstepping with interpolation

M92 X100.00 Y100.00 Z100.00 E424.20 ; set steps per mm

;M92 W1500 A84 B84 C84 ; set steps per mm

M566 X1200.00 Y1200.00 Z1200.00 E1200.00:1200.00:1200.00 ; set maximum instantaneous speed changes (mm/min)

;M566 W800 A1200 B1200 C1200 ; set maximum instantaneous speed changes (mm/min)

M203 X36000.00 Y36000.00 Z36000.00 E3400.00:3400:3400 ; set maximum speeds (mm/min)

;M203 W2000 A6000.00 B6000.00 C6000.00 ; set maximum speeds (mm/min)

M201 X900.00 Y900.00 Z900.00 E1000.00:1000.00:1000.00 ; set accelerations (mm/s^2)

;M201 W500.00 A600.00 B600.00 C600.00 ; set accelerations (mm/s^2)

M906 X1800 Y1800 Z1800 I100 ; set motor currents (mA) and motor idle factor in per cent

;M906 A700 B700 C700 I90 ; set motor currents (mA) and motor idle factor in per cent

M906 E700:700:700 I30; W500 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

;Axis Limits

;M208 X-5:200 Y0:200 Z0:90 ; set axis minima and maxima X Y Z

M208 Z0 S1 ; set minimum Z

;M208 W0:50 S0 ; Set minimum

;M574 W1 S3 ; Set active high endstops 2, low endstops 1, S3 load detection

;Endstops

M574 X2 S1 P"io0.in"

M574 Y2 S1 P"io1.in"

M574 Z2 S1 P"io2.in" ; axis max (2), NC endstops(1)

;Z-Probe

M558 P1 I0 C"!io3.in" H5 R0.20 F350 T6000 ; set Z probe type to unmodulated and the dive height + speeds

G31 P600 X0 Y0 Z-0.175 ; set Z probe trigger value, offset and trigger height

M557 R120 S20 ; define mesh grid

; HEATERS

;;Bed heater

M308 S0 P"temp0" Y"thermistor" T100000 B4700 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

;M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

; TOOLS

;SingleToolSetup

;;ToolHeater

M308 S1 P"1.temp2" Y"thermistor" T100000 B4138 ; configure sensor 5 as thermistor on pin 1.temp2

M950 H1 C"1.out2" T1 ; create nozzle heater output on 1.out2 and map it to sensor 5

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

;; M308 S1 P"temp1" Y"thermistor" T100000 B3950 ; Ino Paul

;; M950 H1 C"out6" T1 ; Ino Paul

;; M307 H1 R36.066 C10.4 D0.25 S1.00 V24.0 ; Ino Paul

M143 H1 S260 ; set temperature limit for heater 5 to 280C

;;TOOLFAN

M950 F2 C"out9" Q500 ; create fan 0 on pin out9 and set its frequency

M106 P2 H1 T40 ; set fan 0 value. Thermostatic control is turned off

;;PARTFAN

M950 F0 C"1.out7" Q500 ; create fan 0 on pin out9 and set its frequency

M106 C"Partcooler" P0 S1 H-1 ; set fan 0 value. Thermostatic control is turned off

;LED

M950 F4 C"out8" Q500 ; create fan 0 on pin out9 and set its frequency

M106 C"LED" P4 S1 H-1 ; set fan 0 value. Thermostatic control is turned off

;;SINGLETOOL

M563 P0 S"SingleTool" H1 D0 F2e ; define SingleTool

G10 P0 R20 S215 ; Tool number 6, Standby temperature 20, Active temperature 215

G10 P0 X0 Y0 Z0 ; set tool 6 axis offsets

; bed.g

; called to perform automatic delta calibration via G32

;

; generated by RepRapFirmware Configuration Tool v2.1.4 on Thu Dec 12 2019 21:34:19 GMT+0100 (Central European Standard Time)

M561 ; clear any bed transform

; Probe the bed at 3 peripheral and 3 halfway points, and perform 6-factor auto compensation

; Before running this, you should have set up your Z-probe trigger height to suit your build, in the G31 command in config.g.

G30 P0 X0 Y84.9 H0 Z-99999

G30 P1 X73.53 Y-42.45 H0 Z-99999

G30 P2 X-73.53 Y-42.45 H0 Z-99999

G30 P3 X0 Y42.4 H0 Z-99999

G30 P4 X36.72 Y-21.2 H0 Z-99999

G30 P5 X-36.72 Y-21.2 H0 Z-99999

G30 P6 X0 Y0 H0 Z-99999 S6

; Use S-1 for measurements only, without calculations. Use S4 for endstop heights and Z-height only. Use S6 for full 6 factors

; If your Z probe has significantly different trigger heights depending on XY position, adjust the H parameters in the G30 commands accordingly. The value of each H parameter should be (trigger height at that XY position) - (trigger height at centre of bed)

Slcier Start gcode is irrelevant as of now, as it does not need to run to get this wonky behaviour.

The one most reliable error I can provoke it to repeatedly do is after commands in this order:

G28

G1 Z10 F10000

G30

G32

G29

than it does the mesh bed and at some point it slows to a crawl and presses down hard on the piezos...

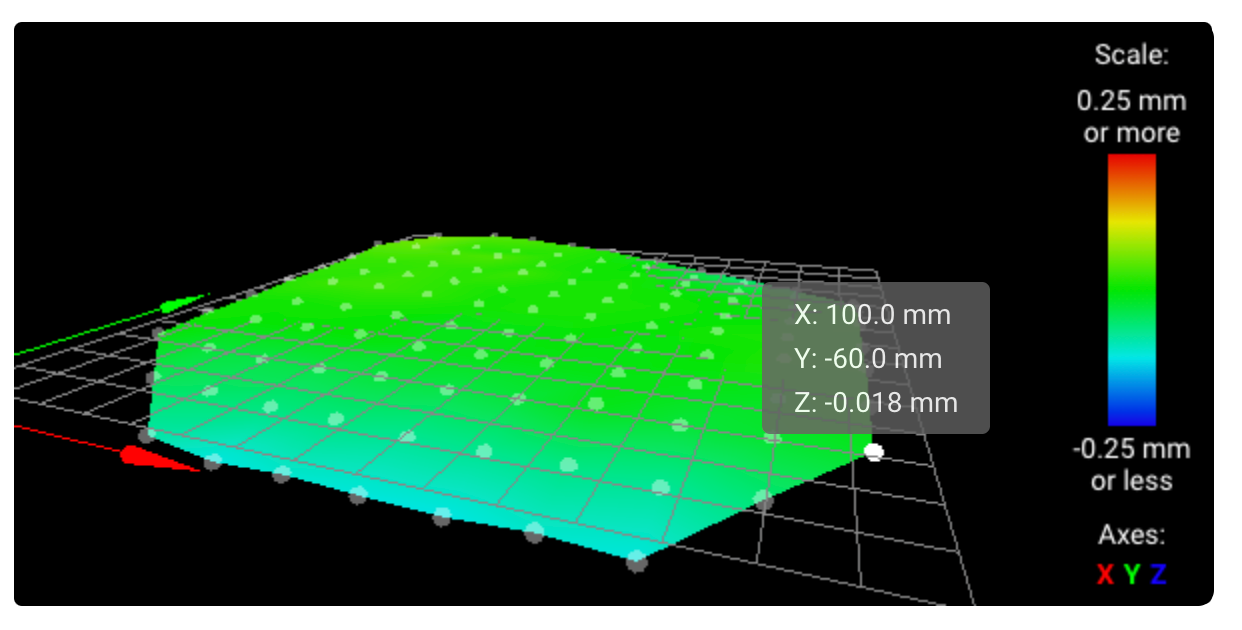

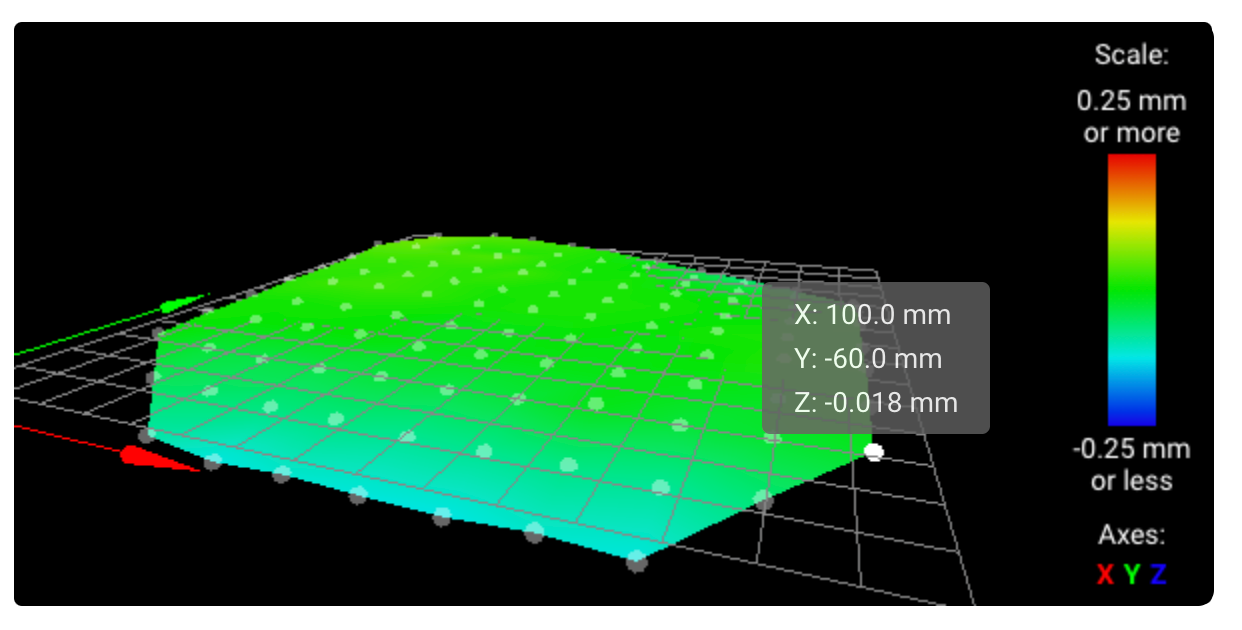

image url)

image url)

Delta Calibration & Mesh calibration, those two have given me some headache since a while.

Sometimes when I do a calibration run the speed for a probing suddenly changes, it is usually far slower than usually and therefor does not trigger the zprobe in the same way as the other points in my piezoprecision setup.

This happens randomly at different points.

Is anyone familiar with this behavior or do I need to give more detailed information?

@MikeS

I am 100% sure.

However it's not quite up there with the Marlin engine in sophistication.... but close.

What is the limit to the PID values that are available?

I have a very fast heater and would like to use the integrated PID tuning, but unfortunately it heats too quickly (3 seconds to target temp), until now I have only gotten errors. "not heating at expected rate"...

Thank you!

This helps with displaying the offset, but should the offset displayed not switch around depending on the chosen tool?

Is the bug "tool offset honored but not displayed correctly" not fixed yet?

Regards

Hey there!

So I have an issue with the tool changing capability of my printer as I cant seem to make heads and tails of the tool offset function in conjunction with the coordinate system.

I planned to use one coordinate system for machine commands that shall not be altered by the tool offset., however the tool offsets persisted and so a tool drop of, after homing G30 S-2 was not possible.

Now, to pick up tools, I knock all relevant commands into G53 (unaltered machine coordinate system). This works kind of.

My tools are of slightly different sizes and I cycle trough the tools and use the G30 S-2 command on each to properly set Z=0 for each of them. Now the funky stuff happens. I have not found a function/gcode to print the current offset of the tool. However I can switch off the tool (T-1 P0). As I have not moved the tool yet, it should report back the position the tool has relative to the position without the tool offset.

This is an approximation of what I ran:

T0 ; call tool 0

G1 X0 Y0 Z10 F9000 ; Move to center ready for probe

G30 S-2 ; probe bed and set tool offset

G1 X0 Y0 Z10 F9000 ; Move to safe position

Now my position is X0 Y0 Z10 with the tool. Next step is to switch into a non-tool-offset

T-1 P0 ; deactivate tool

Nw the funny thing happens: My position is X0 Y0 Z10. However this should be the actual position plus (or minus) the tool offset. Now when I activate the tool again.

T0 P0 ; activate tool

I get X0 Y0 Z10.88.

T-1 P0 ; deactivate tool

I get X0 Y0 Z10. Even though it should now show me the position with the tool offset.

So when the tool is activated the first time its at Z10, when I deactivate it stays at Z10 which I think it shouldn't . When I reactivate the tool it adds the offset. And voila, I got nearly one mm offset where there was not supposed to be one.

This shows me a couple of things:

My probing is in the heated bed at the bottom and provides reasonably accurate results (< 30mue @ 100 reps ), so I can rule this out.

As of now I solved this problem with hard coding the z-offsets of the tools into G10. However this is not an longterm option as I intend to switch around the tools frequently.

If you know your way around this issue, please help me!

But if the printer was just warming up and I do a G28, than probe again another 100x it shouldnt do the same drift again, or am I mistaken?

Hi David and thanks for joining in!

I am afraid it is not the speed, as I have already reduced it to F150 which is rather slow. The problem persists whether I measure with dial gauge OR with piezo precision z-probe. The coordinate system slumps as a whole as I show in this video. Don't follow it along all the time, rather download it (its large) and use a slider in a local program to move it from one pause to the next. You will see that the coordinate system as a whole is lowering itself down.

I just made a test without any resistance other than the weigth of the delta-kinematic and the linear rail bearing. I did not measure the position this time, in order not to scew the results, but attached a camera so I was able to record the turning angle of the motor. Drifting of the coordinate system yet again.

Unfortunately no, it is losing only 150-300mue. My setup is a 16T pulley with a GT2 belt, so circumference is 32mm. Motor is 200 Steps (1.8°) thus 32/200=0,16mm/step.

If it was in fact only losing multiples of 160mue (0,16mm) it would mean at least 640mue (0,64mm) for a lost step.

My settings are as follows:

; General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M665 R242.280 L408.55 B105 H471.703 X0.054 Y-0.053 Z0 ; Set delta radius, diagonal rod length, printable radius, homed height

M666 X-0.01 Y0.31 Z-0.30 A0.48 B-0.52 ; Put your endstop adjustments here, or let auto calibration find them

; Drives

M584 X0 Y1 Z2 E3:4:5 W6 A7 B8 C9 ; Drive Mapping

M569 P0 S1 ; Drive 0 goes forwards A-Tower

M569 P1 S1 ; Drive 1 goes forwards B-Tower

M569 P2 S1 ; Drive 2 goes forwards C-Tower

M569 P3 S1 ; Drive 3 goes clockwise Extr 1

M569 P4 S1 ; Drive 4 goes clockwise Extr 2

M569 P5 S1 ; Drive 4 goes clockwise Extr 3

M569 P6 S1 ; Drive 6 goes forwards Function X

M569 P7 S1 ; Drive 7 goes forwards cA

M569 P8 S1 ; Drive 8 goes forwards cB

M569 P9 S1 ; Drive 9 goes forwards cC

M350 X16 Y16 Z16 A16 B16 C16 I1 ; Configure microstepping with interpolation (C16)

M350 W16 E16:16:16 I1 ; Configure microstepping with interpolation

M92 X100 Y100 Z100 A84 B84 C84 ; Set steps per mm (100 bei 16fach)

M92 W1500 E438:450:450 ; Set steps per mm (E bei 5mms, B2D Extruder 263.00)

M566 X1200.00 Y1200.00 Z1200.00 A1200 B1200 C1200 ; Set axis maximum instantaneous speed changes (mm/min) before adapt 3000

M566 W1200 E1200.00:1200:1200 ; Set extruder & x-stepper max instant speed changes (mm/min)

M203 X60000.00 Y60000.00 Z60000.00 A10000.00 B10000.00 C10000.00 ; Set maximum speeds (mm/min)

M203 W3000 E3400.00:2000:2000 ; Set maximum speeds extruders & wechsler (mm/min)

M201 X900.00 Y900.00 Z900.00 A600.00 B600.00 C600.00 ; Set accelerations axis (mm/s^2) before tune 2500 (C900.00)

M201 W900.00 E1000.00:1000.00:1000.00 ; Set accelerations extruders & x-stepper (mm/s^2) before tune 2500

M906 X1428.00 Y1428.00 Z1428.00 I100 ; Set axis motor currents (mA) at 85% of max Amps/Phase and idle factor in per cent

M906 A700 B700 C700 I90 ; Set c-stepper motor currents (mA) and idle factor in per cent

M906 W500.00 E1275.00:1275.00:1275.00 I30 ; Set x-stepper and extruder motor currents (mA) and idle factor in per cent

M84 S30 ; Set idle timeout

@T3P3Tony Any thoughts on this?

Further food for thought: I am running all this with 17HS19-1684S1 Stepper motors from Stepperonline. Could it be the motors & their quality/inductance/resistance or maybe they are just broken?

Here is a spec-sheet of a comparable motor from another supplier as the stepperonline resource pdf is a broken link.

Hi Danal!

I was evaluating the theory of dropped steps, however as I have 200 stp/rev Steppers a 16T GT2 pulley the min amount of lost steps should be 0,16 mm. So when the Idle value is low, we get a (repeatable) drift of roughly 0,15. So if it was losing the 0,15 in one jump I would agree with you, however, it gradually approaches the max offset. Which would indicate losing microsteps which obviously does not work. Therefor I am unsure whether this is the problem. And I seem to remember that the stepper motor cannot lose a single step, but only multiples of 2 (or 4?). Maybe @T3P3Tony can verify this as he appears to have joined the conversation.

If I evaluate the possibility that it loses one step in each stepper (why would it only lose one step, I dont know) than I would see plateaus developing in the measurements, which are not there either.

Mechanics could be at fault, however the behaviour of the movement, when you look at the curve does not look like an elastic deformation, as this would be more gradual which would exclude the Belt and softness in the parts. So in therms of mechanical assembly errors I checked the Motor mount, it is not turning. As well as the Pulley, Idler and the belt-fastener. None show real movement when I wiggle them around.

@T3P3Tony The Kossel is running Arduino Mega 2560 + RAMPS + 4x DRV8825. I will switch the Klipper to the Kossel now, as the Duet is hard-mounted on the large Delta. I may have time to test the Duet on the Kossel tonight. Any more suggestions of what I can try?

Hello!

Some may have followed the z-probe issue I had, unfortunately it wasn't the z-probe after all, rather a coordinate system problem.

When i repeatedly probe the same spot 100 times I get a strong drift of the coordinate system. So much so I get a funny looking curve that shows a drift of apprx 200-300 mue for roughly the first 30 attempts and than levels out. You may think this is not important as I will not be probing the same point 100 times ever anyway, however when doing the mesh bed leveling, 30 points that are constantly off a couple of mue give you a very tilted bed. Let alone when you are using more than one tool.

So the first thing I did was to eliminate the "Idle" Setting, setting the I Value from 30 to 100. This resulted for me in a reduction of the drift of roughly 100 mue leaving me with a total drift of apprx. 150 mue. This is the whole test including the setup I used that you may verify. 150mue is still too much for my taste, as it should actually be 0 or at least oscillating around a value and not drifting into one direction.

I have the same issue with my duet3 on a similar system, with only a 150 mue drift. I also set up a klipper, using the same drivers, with the same result. Inly my Kossel Mini running on the Mega/Ramps/Marlin setup does not have this issue.

Please if anyone has an idea, please let me know what you think could be causing this drift!

Best regards!

DSQ

Hi All!

Thank you for your help!

Apparently the problem wasn't the z-probe at all. The z-probe was diligently reporting the right value all the time. However, the delta-konfiguartion appears to be at fault. The coordinate system drifts apprx. 0.25mm when i repeatedly probe the same point 100 times.

As this is a whole different thread with different keywords etc. I will start another thread in order to reach the right audience for that.

Thanks to everyone for supporting me with this up until now, I certainly know the piezo-precision probe far better by now.

Best regards,

DSQ

Hi gtj0!

Thank you for your input! I thought there has been a change as I was confused last time I saw a digital and an anlog input on the universal Piezo Z-Probe PCB!

Unfortunately I have not got my hands on an Orion sensor, as we are only using Andromeda sensors which only have two leads coming out compared to the 6 from the Orion. What do you suggest for the Andromeda? Would you have it plugged into Analog or Digital? (On this topic: Is the Orion the better solution of the two? I could also mount 3 Orions under the bed)

However here the Versions:

Connection PCB <-> Duet is via the "Probe" plug.

![Picture of duet Board with version number and duet "Probe" Plug attached to the z-probe]

https://drive.google.com/file/d/1VvkJIHuc_7ZN2v5XB3PSSQCO7H-Kn-x8/view?usp=sharing

Firmware Version: 2.05 (2019-12-13b1)

WiFi Server Version: 1.23

Web Interface Version: 1.22.6

So I implemented the changes as suggested. There is no change.

In this attempt I have run 3 scripts twice each. The results are supporting one another in most cases.

Run1 & 2 were with the previous test script.

Run 3 & 5 were with the suggested improvements:

Improvements:

M558 H5 T9000 A10 P8 I1 R0.4 S0.02 F120 ; M558 dive Height, Travel speed, probing Attempts, Probe type, Remain, dive speed F

G31 X0 Y0 Z-0.15 P100 ; Set Z probe trigger value, offset and trigger height Z-0.012 / Z-0.45

Script Z5:

G28 X

G1 Z5 F3000

G30 S-1

... above two lines x100

G28 X

and out of curiosity i also run the same settings with following script, to move the sliders a little more, as it is likely to happen in my setup.

Script Z5 updown:

G28 X

G1 Z5 F3000

G30 S-1

G1 Z40 F6000

G1 Z5 F6000

... above three lines x100

G28 X

Results you can find here, mind the tabs:

https://drive.google.com/file/d/19arr1t3R8NCq5BxTw2s26OPm-Wabvvv0/view?usp=sharing

Hi Ian!

Thank you for your quick reply!

ad dive height.:

I have run apprx 20 tests with 100 reps each for distinguishing the optimal probing height. I previously got the least offset when probing from 25mm height. My guess is that at 25mm is a multiplier of the full steps required to get to the bed.

ad analog vs digital.:

I had the impression that the analog was supposed to be the more accurate, is this not true?

I am implementing all your suggestions as I am writing. I will be getting back with results.

thk

dsq

Hey all!

So I have been playing with the piezo probes a couple of times now. However, even after having had my hands on 4 sets of piezo probes, it just does not work.

My setup is a Duet Wifi with under-the-bed piezo sensors. They are Andromeda sensors hanging under the bed, screwed to the frame, with the central Screw propping up the bed.

The relevant Duet Code I am using is as follows:

M558 H25 T9000 A10 P3 I1 R0.4 S0.02 F500

G31 X0 Y0 Z-0.15 P100

In order to test I run following script:

G28 X

G1 Z25 F8000

G30 S-1

...the above two lines *100

G28 X

I get a drift or roughly 0,3mm over the first 30 measurements, with increments of drift ranging from 0 to 0,018mm. After leveling out at approximately the 30-probe mark (this is by no means a hard limit) measurements jump back and forth between 0,002mm to max 0,015mm altough the larger differences are usually followed by an equally large countermovement (so if it measures 0,015 higher than the previous measurement, it is likely it is going to measure 0,015 lower the next cycle around).

I don't know what it is but with this problem I can not work with the piezo probes especially not with the arrangement I have got here.

I tried a lot and t kills me that it does not work. On top, I actually thought it was the perfect system for our business 3D printer and it not working doe not really help me at all.

I posted a similar request in the reprap forum, as I am trying to cover all my bases here and the problem persists for more than 12 months already.

Best regards

Deltasquare

dc42 said I can simply plug the RasPi into the output of the paneldue, which is a 4-pin plug where I populated the 5V pin on the far right as well as the ground left of it. Before plugging the Raspberry into that I checked the voltage and there is nothing....

So, I suppose I also need activate the PanelDue somehow?

I attached my VoltMeter at the two different paneldue output, but unfortunately no voltage.

Am I doing something wrong? Do I need to set a jumper?

The RPi Zero runs a camera, so it might actually draw a little more.

So you suggest attaching it to the paneldue 5V pin right beside the zprobe plug? Or to the panel due pins that run next to the expansion (5x2x2)?