@droftarts Wow, i feel stupid! I don't remember changing it but must have as it now loads. Thanks!

Posts made by coseng

-

RE: New heated enclosure printerposted in General Discussion

-

RE: New heated enclosure printerposted in General Discussion

With the rework on the carriage I needed to redo the mesh compensation but am having problems loading heightmap.xls. I am using the G29 S1 command and getting the following console error:

G29 S1

Error: G29: Failed to load height map from file 0:/sys/heightmap.csv: bad header line or wrong version headerThis is the heightmap file:

RepRapFirmware height map file v3 generated at 2017-07-21 20:53,

axis0,axis1,min0,max0,min1,max1,radius,spacing0,spacing1,num0,num1

X,Y,-310.00,315.00,-288.00,288.00,-1.00,156.25,144,5,5

-0.46, -0.4, -.32, -0.25, 0.08

-0.3, -0.25, -.2, 0., 0.1

-0.02, 0.02, 0., 0., 0.02

-0.3, -0.3, -0.25, -0.3, -0.35

-.35, -0.36, -0.35, -.4, -.5I used to get the warning saying that it was loaded with Z not at zero so may be some offset, but it always worked. With this new error it is not loading at all. I didn't think i had changed anything in the heightmap file except the offset values. None of my older heightmaps load either, they all give the above error.

I am using Duet Web Control 3.4.1 and the printer is a Duet 3 MB6HC (MB6HC) with 3.4.1 Firmware.

Also, @dc42 is a negative value the bed being closer or further from the nozzle?

Thanks,

-

RE: New heated enclosure printerposted in General Discussion

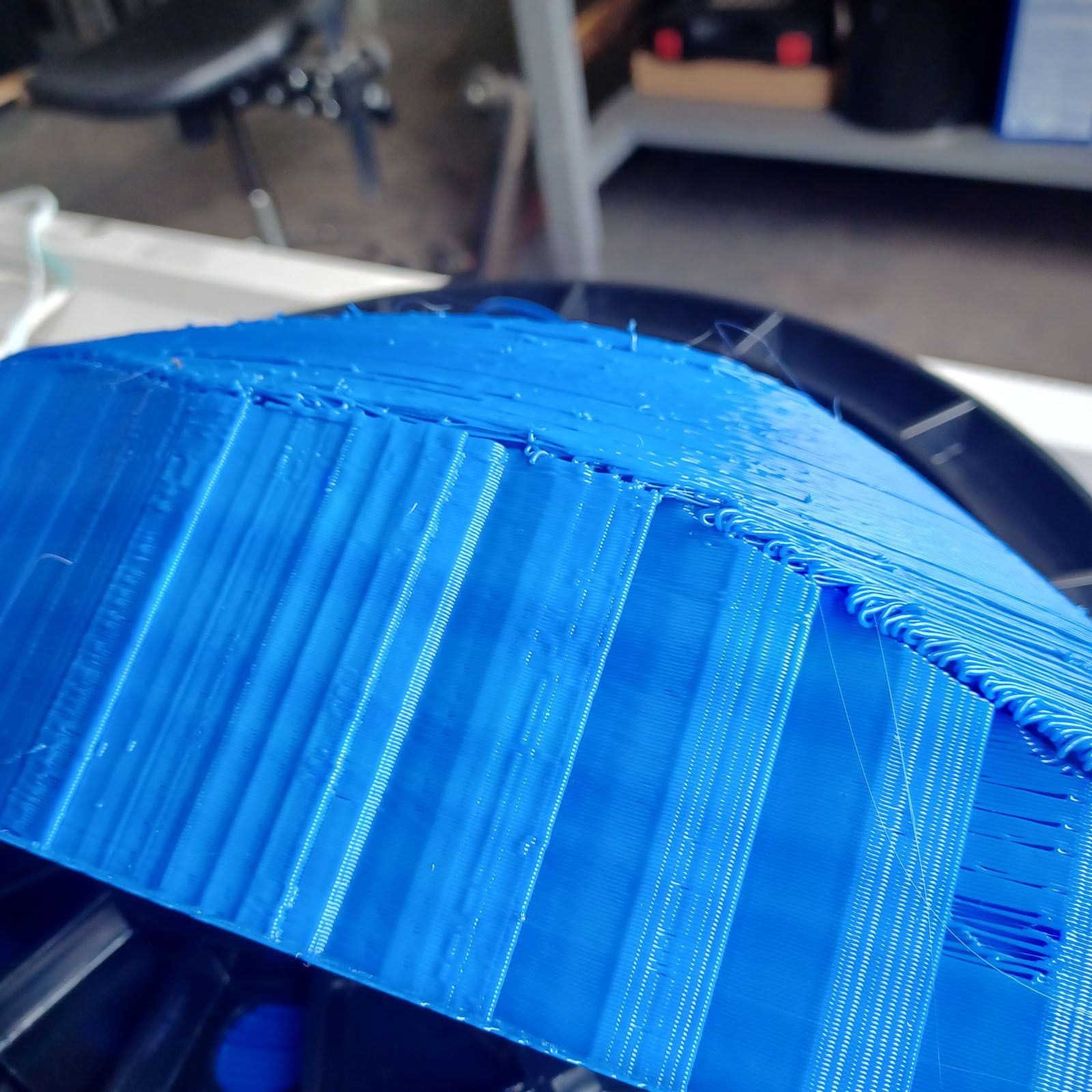

I am going to print another set of bodywork and finish it out for a nice high gloss paint job but wanted to get some better surface finish to minimize the amount of hand finishing needed. The added weight did help, but in reality my Z axis support structure was lacking in torsinoal stiffness. I didn't think that there would be a need for high torsional stiffness, but I was wrong. As the printhead traverses back and forth over the part sometimes it slightly makes contact with previously printed material and causes the table to wobble back and forth.

To fix this, I added an outboard table guide that is just a long straight piece of steel that a forked steel guide finger that bolts to the carriage engages with.

That is a gear rack, but I only used it because it was ground straight and flat and was available. Moral of the story, design sufficiently rigid structures!

It is a bit of a kludge, but it does work and significantly increases the torsional stiffness of the Z-axis. The parts did come out noticable better, especially the taller areas.

As an additional note, we are using the Smooth-On XTC-3D product and am finding it works very well.

-

RE: New heated enclosure printerposted in General Discussion

Well, the added weight to the Z carriage seems to have reduced the oscillations a bit which is great.

I am a bit under the gun for our next race outing in October, so looked to outsource some of the fairing parts. So far, 4 out of 4 vendors have refused a quote as the parts are too thin and difficult! They all recommended sectioning them into multiple pieces and gluing together. When I said that the parts have been printed successfully multiple times in one piece on a home built printer, they were very surprised.

On one hand those responses were pretty disappointing. I was expecting that industrial printers would be a step above what I hacked together. They are not. On the other hand it speaks volumes to the quality of product that Duet3D sells and the support from them and other users that is provided on this forum. Many thanks to everyone that has chimed in along the way, @dc42 and @mrehorstdmd in particular.

I've also recently printed a few big, chunky parts that came out excellent with none of the artifacts the tall, thin fairing parts have. I guess I will focus more on bracing for the fairing parts to keep them from shaking during printing. Maybe more retracts will help too. I do notice a little noise when it is doing the infill, which is assume is the printhead hitting slightly high areas of the previous layer. I am also having some issues with the fill areas on the first couple of layers looking really fuzzy, which I think is over extrusion, but I reduce the flow down to about 70% and it looks the same. The parts come out fine and I am still time constrained, so am kicking that can well down the road.

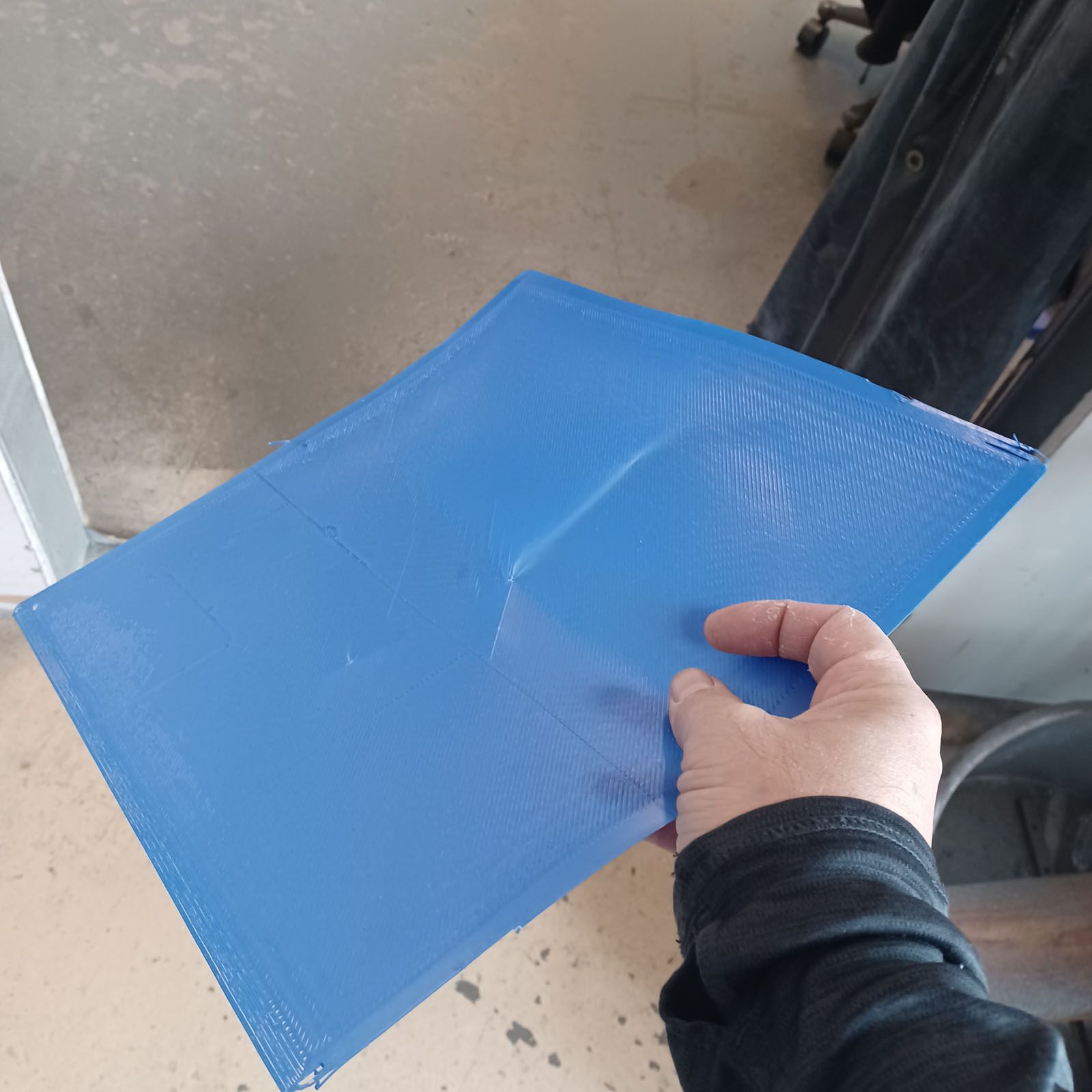

This is a pattern for a carbon fiber gas tank. Printed in two halves and glued together. About 3.5 gallon capacity. There was a slight bit of the print rising up from the build plate, but nothing major and easily taken care of when it is sanded and bondo'd to get a good surface finish to take a mold from. Also doing a mold for a bellypan that is coming out just as good.

-

RE: New heated enclosure printerposted in General Discussion

It's been a while, the printer has been working well, but am about to do another run of fairings so am going to try to improve it a bit.

There is some waviness to tall and slender parts that increases as the parts get slimmer and taller in Z. Looking at it while printing, it seems that my construction of a carbon fiber Z carriage works against me in one way. I used high temp CF for its rigidity and low thermal expansion and high enough temp rating. This means that my Z carriage is pretty light, and at high printhead accelerations, can see a slight bit of movement that comes from not enough torsional stiffness of my z-axis rail/leadscrew wended frame. 20+ inch parts can get a visible wiggle at the top as the vibrations die down. I am not interested in tearing it all apart and having to do welding and realignment/reassembly, so am going to try to take the easy way out by putting a large steel weight on the bottom of the z carriage. A heavier carriage means less reaction displacement for a given printhead acceleration, hopefully stabilizing it and reducing the waviness. It is an easily done and undone modification, so pretty low risk.

The waviness I am getting is not stepper induced oscillations as I am using servo/steppers which are silent and smooth.

-

RE: New heated enclosure printerposted in General Discussion

With this cold weather we're having my big industrial space is at least 15F colder than it was in spring/summer and the machine is misbehaving a bit. After a bunch of heater errors I had to rerun the heater optimization routines and think the bed 'shape' is a bit off as I am having first layer adhesion problems, but only on the corner of a big part. The first layer extrusion is mostly flat but is roundish where it is not adhering, so think the bed is drooping a bit. My bltouch is fried so I have been manually setting Z, but am not sure about the heightmap file format. I can use a plunge indicator mounted to the carriage to accurately map out the bed, but am not sure how the file entries are mapped to the bed.

For the heightmap file below are the matrix entries, does the first entry of -.094 correspond to (maxX, maxY) or (minX, MinY)? Are rows X and columns Y? Does a negative value mean the print is closer or further from the printhead?

RepRapFirmware height map file v2 generated at 2017-07-21 20:53,

axis0,axis1,min0,max0,min1,max1,radius,spacing0,spacing1,num0,num1

X,Y,-310.00,315.00,-288.00,288.00,-1.00,156.25,288.00,5,3

-0.094, -0.047, -.020, -0.127, -0.18

-0.094, -0.047, -.020, -0.127, -0.18

-0.094, -0.07, -.010, -0.127, -0.18

-0.10, -0.07, 0.000, -0.127, -0.18

-0.10, -0.09, 0.010, -0.127, -0.2Thanks.

-

RE: New heated enclosure printerposted in General Discussion

Hmm, IDEX is not as plug and play as I was hoping!

An alternate solution is to repurpose the extra UV Clearpath motors and build a CNC plasma cutter with them. They are more than strong enough to push a plasma gantry around pretty quickly and from what I can see with some friends that purchased stepper based tables, unless you spend well into the $10ks, the Duet control board seems to be a step up, and the Clearpath motors are two steps up! A 4'x4' CoreXY cutter would be pretty useful and more rigid than most of the table setups I see out there.

@dc42 , I saw some older threads about it but there never seemed to be any final results. Did you end up doing those software modifications you were talking about for the torch height control?

https://forum.duet3d.com/topic/8403/advice-on-adding-plasma-torch-height-control/10

@fall-apart-dave @mawildoer @andymidtf

Did any of you ever make it to a working Duet-based machine? -

RE: New heated enclosure printerposted in General Discussion

@sebkritikel A rabbit hole is exactly what I am trying to avoid!

Didn't see that Merlin firmware part, maybe they've made progress in the past year or 2?

Didn't see that Merlin firmware part, maybe they've made progress in the past year or 2? -

RE: New heated enclosure printerposted in General Discussion

@sebkritikel said in New heated enclosure printer:

Not quite ideal.......

Found this online which says IDEX support so will give it a try:

https://www.bcn3d.com/bcn3d-stratos/

https://support.bcn3d.com/knowledge/bcn3d-stratos-introductionIt is based on Cura so the settings should be familiar, and interestingly enough found a post online relating to native Cura IDEX support:

-

RE: New heated enclosure printerposted in General Discussion

@mrehorstdmd said in New heated enclosure printer:

@coseng Try printing in wider lines and thinner layers. Prusa slicer will automatically adjust layer thickness based on overhang angle/detail (I think) if you enable it.

Hmm, so you think the bead is falling off the edge of the part before adhering? I am printing the outer wall last to try to prevent that and this part has 3 walls. It is small enough to test with and I can cut off the lower section to get right to the problem area. Maybe higher print temp too to make the bead 'stickier'?

-

RE: New heated enclosure printerposted in General Discussion

I'd still like to tweak the settings to improve some of the print artifacts that are still happening if I knew what to tweak. Particularly on sloping underside surfaces.

This is a test fit part for a friend's vintage supercharged '53 Corvette that will be DMLS in aluminum from prtwd.com. This was a 4 hr print time. It will be a thin wall tube, but is easier to print as an infilled solid for mockup purposes.

I printed 3 of them and they all had consistent problems in the slightly sloping underside area.

To try to improve the finish of the area over the supports I increased the support roof from 1 to 2 layers and the support top looks nicer, but the part underside looks the same.

And there are print problems that are not above the support area.

These seem similar to the initial problems that were occuring back in the middle of the thread with the red and white panel-like parts. Those problems were never resolved, just avoided by changing the geometry. These parts are not thin or panel-like, but the printing quality problem has a similar look.

-

RE: New heated enclosure printerposted in General Discussion

@deckingman said in New heated enclosure printer:

That depends on what you want to do.

I'd like the printer to print two copies of the same part at the same time, or print a part and it's mirror copy both at the same time.

-

RE: New heated enclosure printerposted in General Discussion

@Phaedrux I am using Cura 4.13 now. Maybe it is time to check out the 5.2 as they also have another thin part slicing update to simulate injection molded parts, which is what my parts are (should be) like.

-

RE: New heated enclosure printerposted in General Discussion

And also now that it seems to be stable and printing well, I'll try to get to adding the second printhead soon. Immediately it could be used to embed a colored logo to the parts.

Mirrors and duplicates would be nice for several of the fairing parts. Any recommendations on a slicer that handles CoreXYUV?

-

RE: New heated enclosure printerposted in General Discussion

@Phaedrux said in New heated enclosure printer:

Seems like pretty bad under extrusion.

Yup, modified the extrusion steps/mm on a small print until it came out good. About 20% more. All the other settings remained the same. Not sure how this happened but I guess sloppy setting management is the most likely culprit.

The overall finish is decent, but I feel could be improved. The taller parts suffer from some sway during printhead rapid moves acceleration, which is a bit surprising as the overall printer is pretty heavy. The waviness is pretty minimal in the lower sections and becomes more noticable as you get taller in Z. Maybe I can stick some chunks of steel in the base and see if it reduces sway. I also think my attachment of the very rigid Z axis linear way/leadscrew assembly to the overall chassis could use more stiffness, but am a bit reluctant to dig into mechanicals as the parts are quite useable as-is. Just a good lesson to be learned (again) that in a 'machine tool', stiffness everywhere is important.

Another option could be to reduce the acceleration rate, as lots of these moves are long, so a small increase in acceleration time won't add that much to overall print time. That is a tough route to go, as I'm a racer at heart.

-

RE: 1XD Closed Loop Servo Setupposted in Duet Hardware and wiring

I know you may have different hardware, but I have 2 Clearpath SDSK servo/steppers running from Duet step and direction outputs and they are providing awesome acceleration, no vibration and near zero noise at any speed.

They are a bit expensive and the specs are quite overkill, but they are highly recommended.

-

RE: New heated enclosure printerposted in General Discussion

@phaedrux Ugh. I wonder why. Well, have to leave it as-is until next week and have some time to debug it.

-

RE: New heated enclosure printerposted in General Discussion

Heaven to hell!

After the first round of printing I left the printer off for a couple of months, and now have some revisions to print.

Not sure what happened, but quality has taken a nosedive from previous results. Suspecting the PCD nozzle was an issue, I swapped back to the all copper but the results were the same. The blue parts were from an old spool. After a couple of bad ones, I baked it for a few hours at 65C but that did not improve things. I then tried a new spool of white and got a little better but still far from acceptable parts. I was using the same settings and for the blue parts tried importing the settings from the .gcode file of a previously successfully printed part. I even reran an old file with the same substandard results.

Any ideas on what could be going on? All the mechanicals seem to be tight. At the end of the 22hr white print (or any other print) there was no filament dust or shards at the pinch roller.

A single layer flat part prints fine.

I'm at a loss and tired of wasting filament.

-

RE: New heated enclosure printerposted in General Discussion

Just starting another round of prints and was having some serious first layer adhestion problems that was traced back to the 8mm thick aluminum build plate developing a slight droop to it. The center of the bed is X0Y0 and X0 is still level from Y- to Y+, but both the entire Xmax and Xmin edges are drooping by about 0.25mm so the edges are low and the middle is high. I guess all the heat cycles have induced this dimensional change. Just after installation I had manually scanned it with a dial indicator and it was flat to a TIR of about .08mm with no obvious directionality to it.

I'm also having some issues with my BLTouch not being repeatable, so I manually created a 5x3 bed mesh compensation file and not it seems to work as it was. When I try to scan with the BL touch I get over well 1mm of variance, which is not backed up by a mechanical scan. Also, sometimes the BLtouch won't initialize properly. I have a 75mm extension on the probe, so the solenoid has a little extra mass to move, so instead of really debugging it I manually set Z using a G28 and not turn the printer off much.