@T3P3Tony

Thank you a lot for help you provided with my case!

Also want to use this opportunity to thank all Duet team for your great work - best support ever from all of you

Best posts made by caviara

-

RE: Duet 3 Mini 5+ : Initial announcementposted in General Discussion

-

RE: Frustration with PLA prints not stickingposted in 3D Printing General Chat

Hi again,

Just want to tell the outcome:

cleaned the bed with 95% IPA one and then printed the first layer with 10mm/sec for 3 parts one after over.

These two steps (especially printing first layer slow) made THE difference!Thank you so much for the advises!

PS

and sorry for the delay with confirmation

-

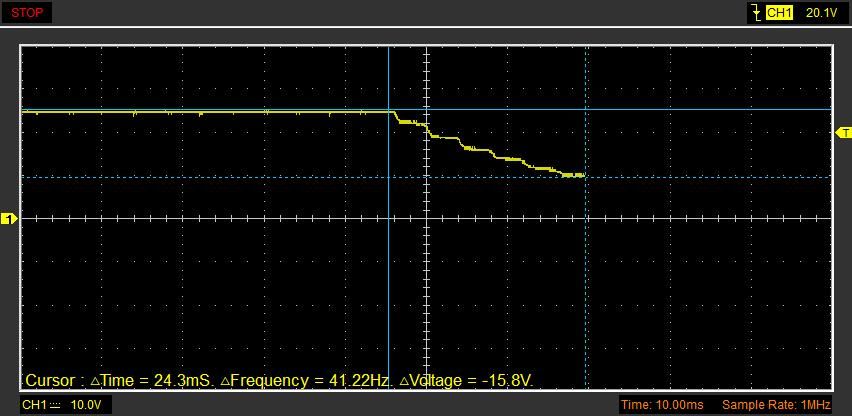

RE: Duet3 freezesposted in Duet Hardware and wiring

Good morning!

Just wanted to finish this thread by confirming that it is (was) a power-supply issue.

yesterday night after almost 3 hours printing i was able to capture the problem:

It was a cheap Chinese brand 480W power-supply and the time increased from 1 to 3 hours because i did some re-soldering for the transistors inside to get them align better to the heat sink (in this case aluminum block connected to the chassis).

Anyways i received yesterday brand new MeanWell power-suply and hope that it will finish my waste of filament for good.Thank you for your help!

-

Frustration with PLA prints not stickingposted in 3D Printing General Chat

Hi all,

i decided to get here for the advise after many hours of frustration and half spool of PLA wasted.

Usually i print mainly ABS and ASA and don't complain from the results, but this timeFirst some basic information.

Printer:

My main machine and the one i try to use for this project is modified self-constructed HEVO based printer. Linear rails for movement with 20x20 extrusion to support X;

Hemera extruder with titanium heat-brake, copper heat block, PT1000 and 0.5mm "nozzel X";

300x300 MK3 Chinese knock-off aluminum heat-bed (not perfectly flat i know) with BuildTak FlexPlate system on top and BuldTak original sheet on the flex plate.

Duet3 6CH MB (standalone) with IR sensor for bed leveling.Material used for the project:

FormFutura white rPLA3D Model i try to print:

https://www.thingiverse.com/thing:4073663Setting tried so far:

40 to 75 deg C for heat bed

190-215 deg on nozzle

from so close to bed that it leaves a permanent mark on BuildTak to so far that get almost perfect circle on initial layer lines.

Glued "painters tape" on second plate and used all of the above settings again.

Finally - upgraded from RRFW 3.2.2 to 3.3all of this leads only to peeling edges and on 10-ish millimeters form build plate i stop the print as it is so badly pealed that start hitting IR probe. (forgot to mention that on one of the experiment i used brim)

In conclusion:

Any ideas what to do in order to get this cursed PLA to stick would be highly appreciated.

I apologize for this long post, but i am really frustrated -

RE: Black frame (cover lens?) for the PanelDue 7iposted in Duet Hardware and wiring

Just to mention:

PanelDue uses resistive touchscreen not capacitive one - so putting any glass lens in front of it will make touch unusable. -

RE: Ender 5 plus with Duet3d mini5+ PD7i and E3D Hemera config helpposted in Duet Hardware and wiring

this can be useful:

https://docs.duet3d.com/en/How_to_guides/Commissioning

or more specific from section 8, 9 and 10 of it