And with these 5 photos I close the discussion.

Thank you all

And with these 5 photos I close the discussion.

Thank you all

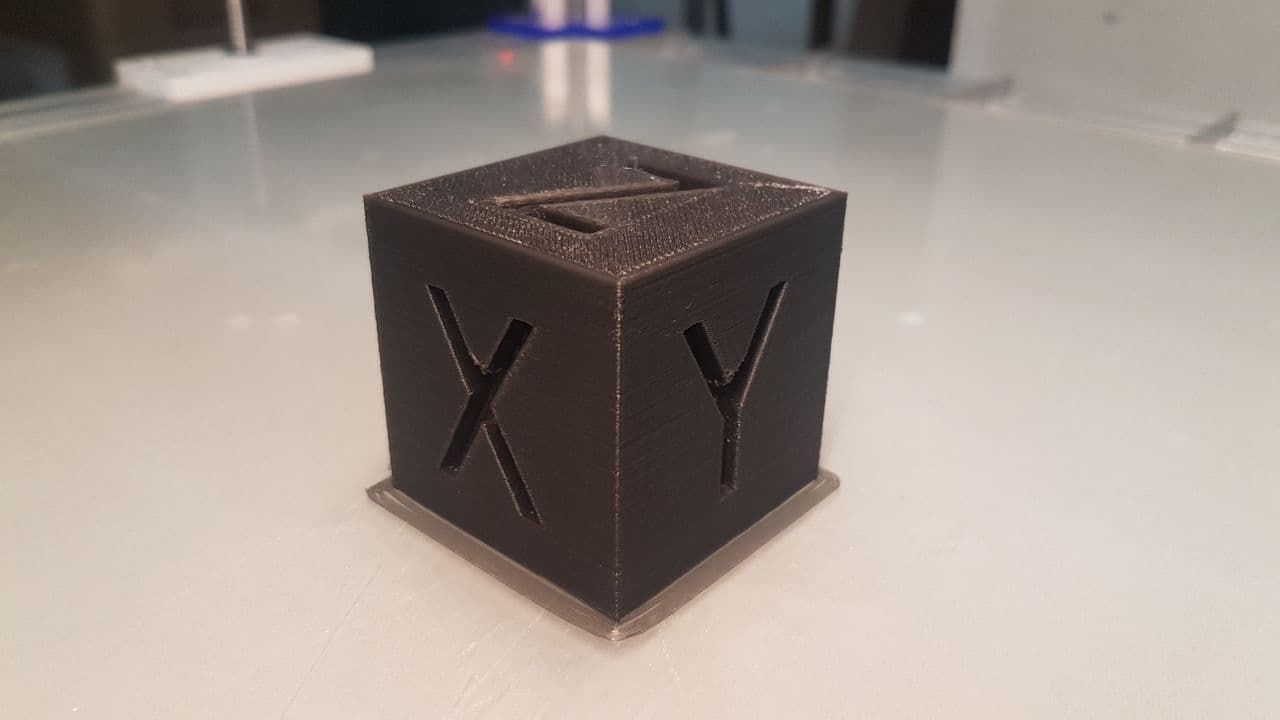

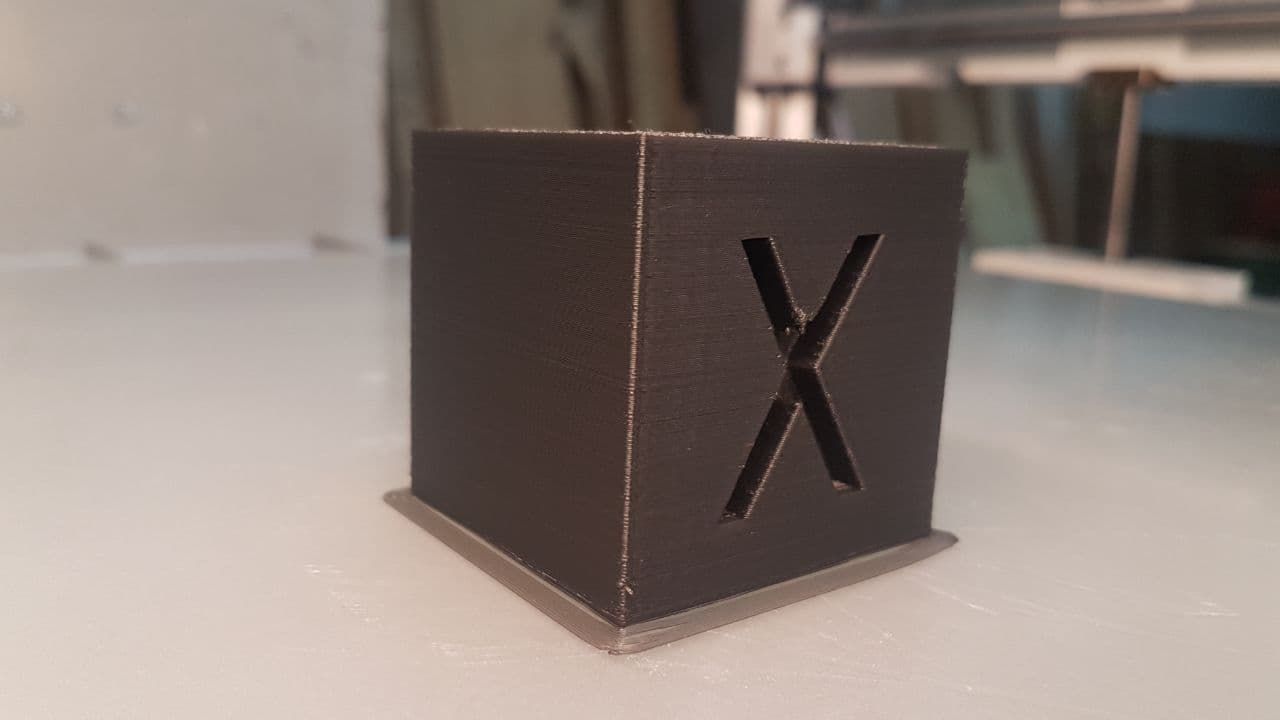

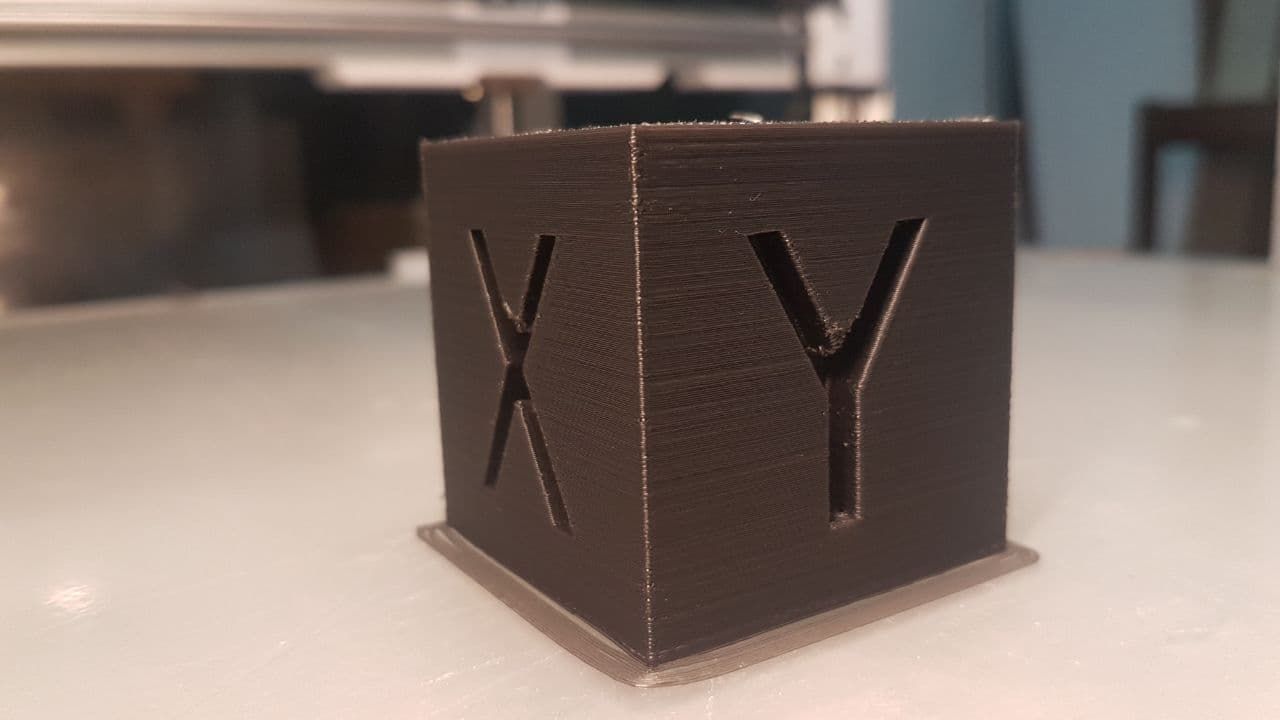

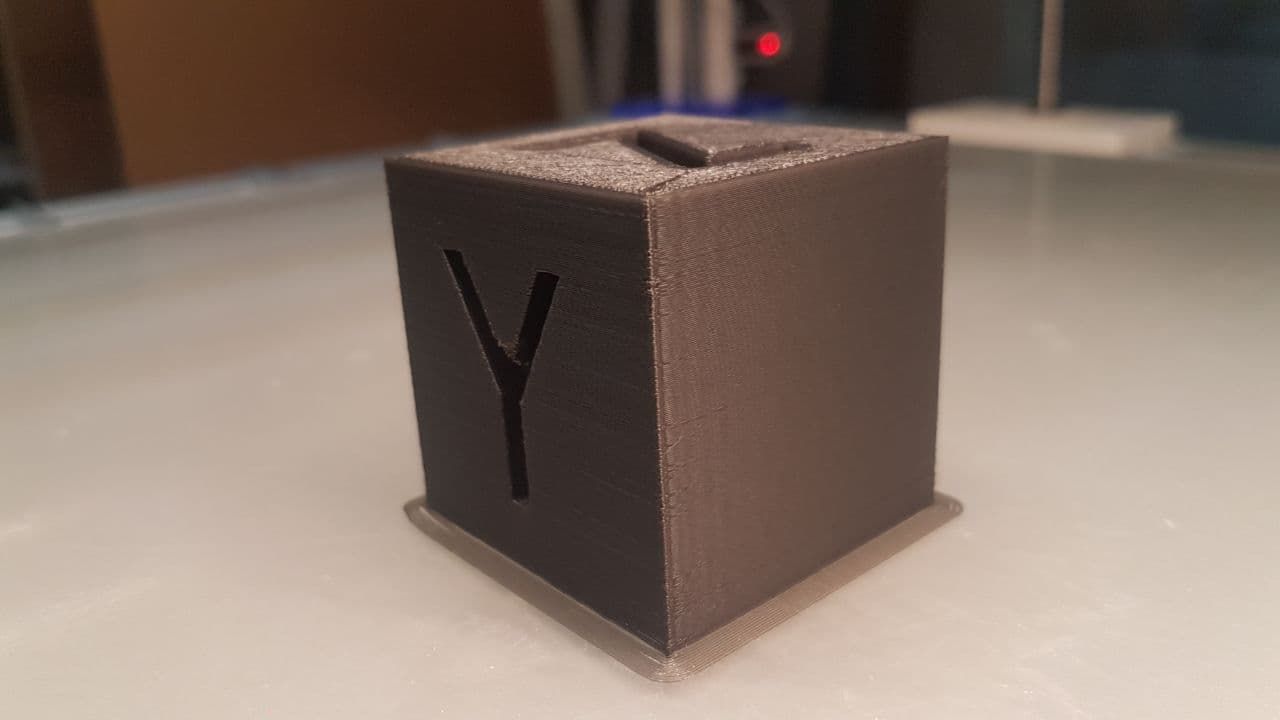

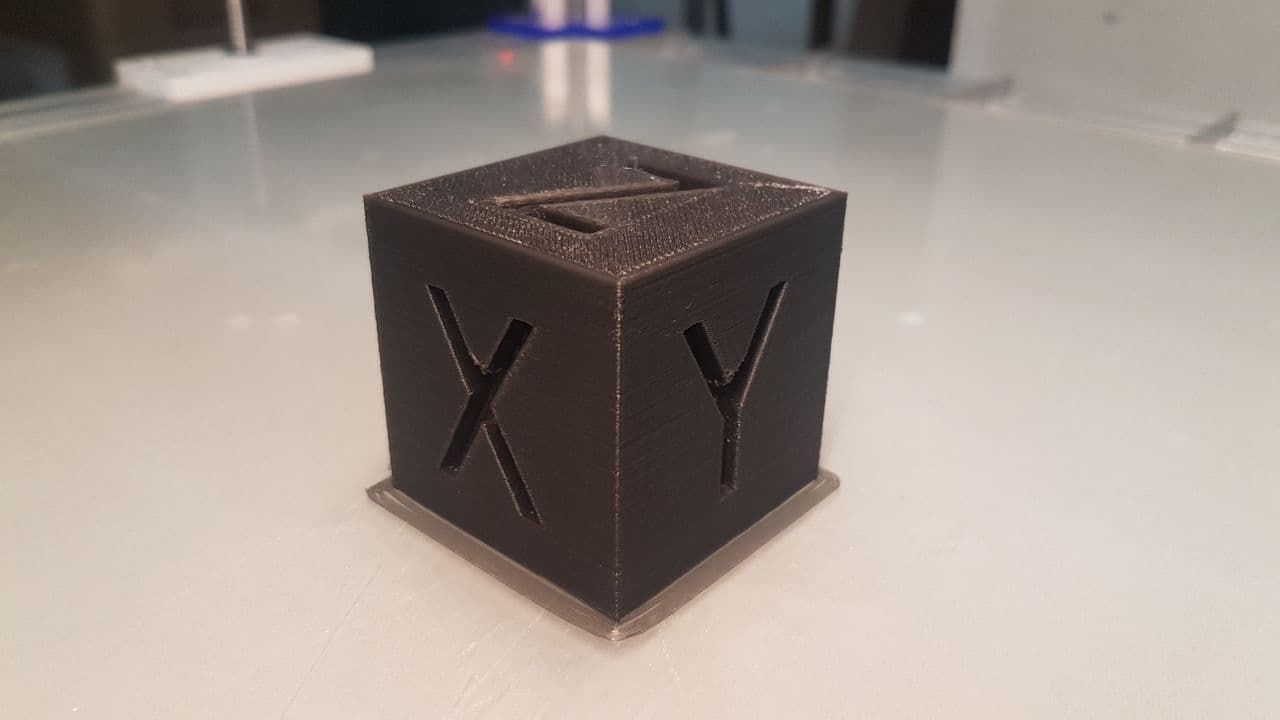

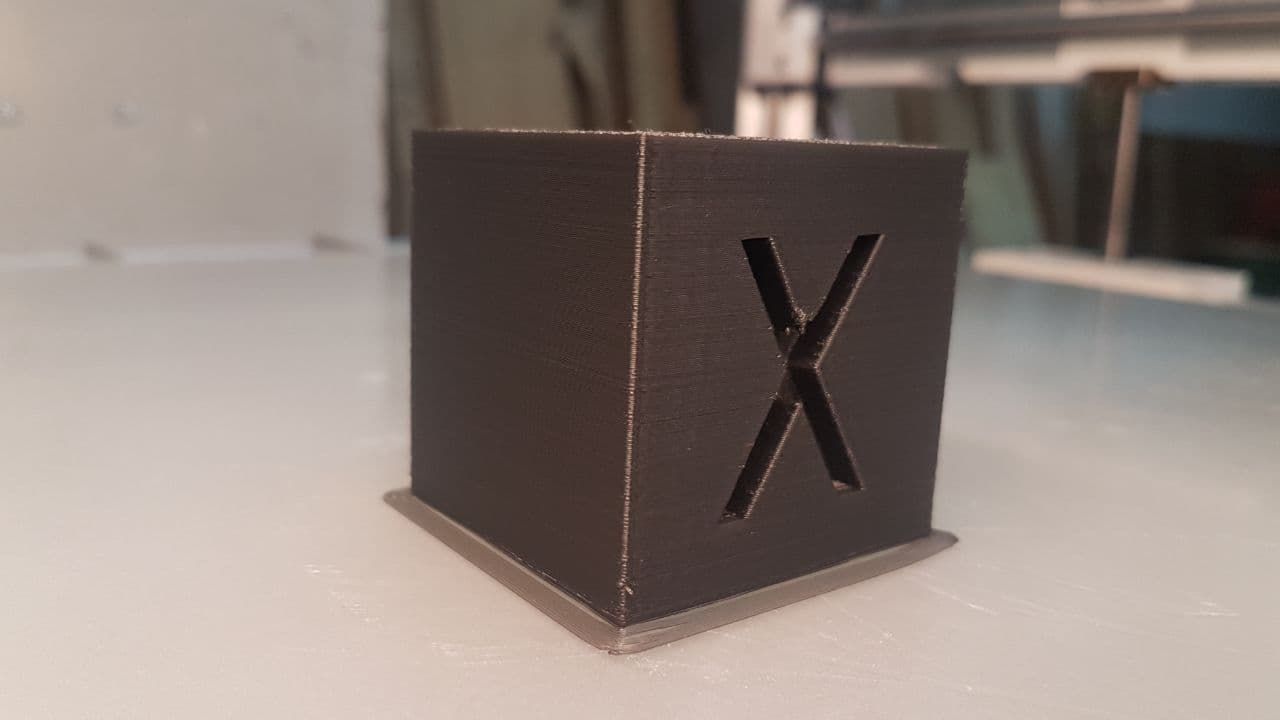

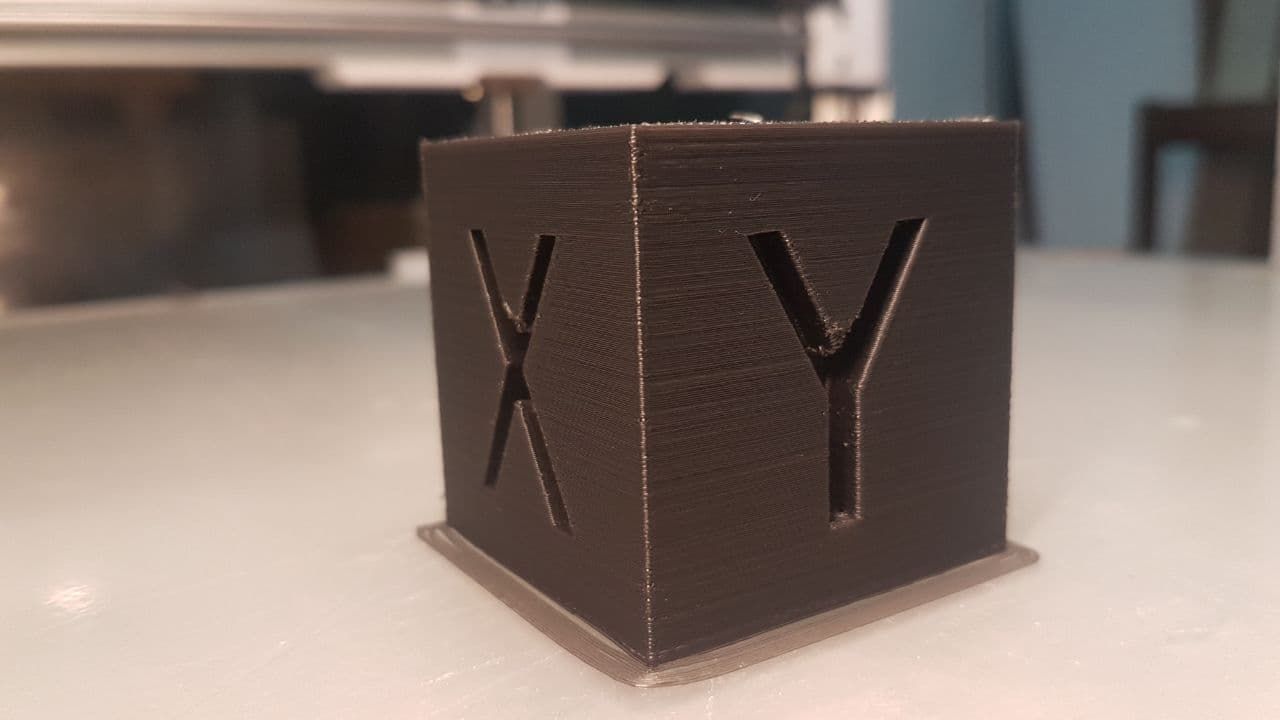

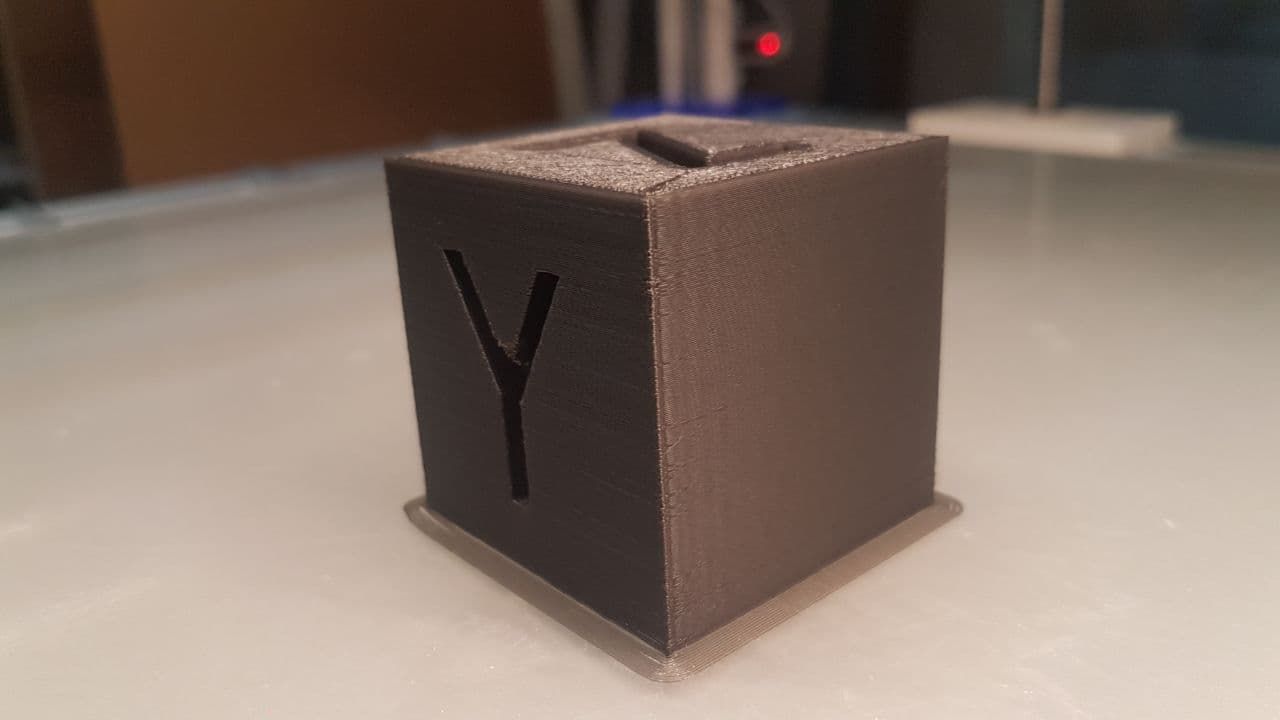

It's not perfect but it's still acceptable.

With a 5x5 or denser map, the result would undoubtedly be better, but having built the 3x3 map entirely by hand, with a series of print runs in succession, I can be satisfied. Also because, I repeat, it is a prototype!

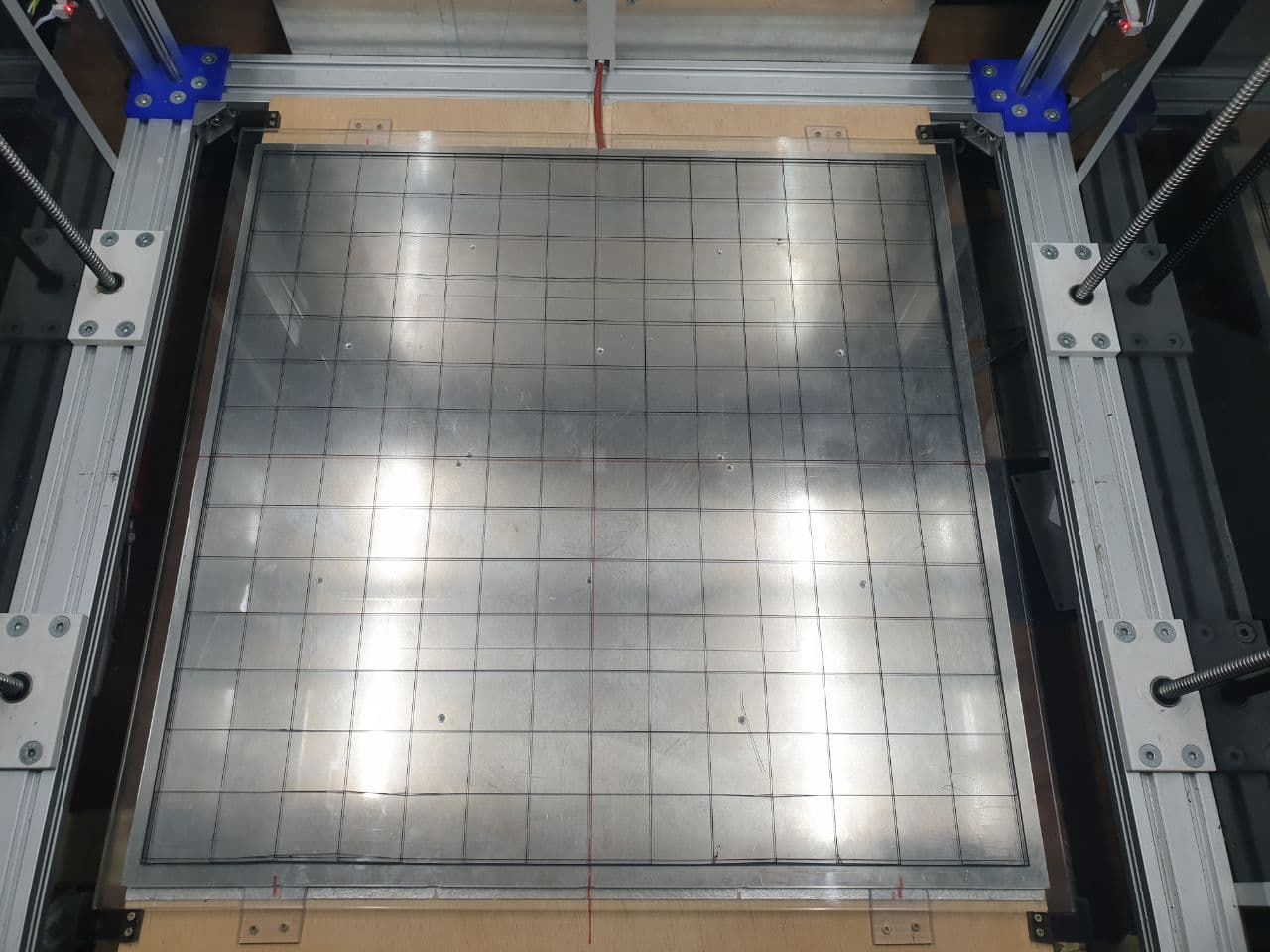

Test grid: 595x595x0.2 with 1% filling (printed in 32 minutes @25-30mm/s)

Everything starts moving ... and if it weren't for the power supply fan, you wouldn't hear anything (or almost)!

very beautifull!

Goodmorning everyone

I had entered the codes M566, M203 and M201 in the config.g file to find the speed "limits" of the X and Y axes.

Now the 3 instructions in the file have been commented out.

From the Console I get this:

Custom M566

;M566 X4000.00 Y4000.00 Z300.00 E1500.00 ; set maximum instantaneous speed changes (mm/min)

Original M566

Maximum jerk rates (mm/min): X: 900.0, Y: 900.0, Z: 12.0, E: 120.0, jerk policy: 0

Custom M203

;M203 X20000.00 Y20000.00 Z1000.00 E5000.00 ; set maximum speeds (mm/min)

M203

Max speeds (mm/min): X: 6000.0, Y: 6000.0, Z: 300.0, E: 1200.0, min. speed 30.00

Custom M201

;M201 X5000.00 Y5000.00 Z100.00 E4000.00 ; set accelerations (mm/s^2)

M201

Accelerations (mm/sec^2): X: 500.0, Y: 500.0, Z: 20.0, E: 250.0

I'll do some printing tests with the default values and let you know.

@fcwilt At the moment I cannot change anything, so I would like to use compensation. The problem is that the compensation doesn't seem to work... because on the left side it manages to give me a relatively acceptable height in relation to the plane, while on the right side it doesn't. And I don't understand why.

Tomorrow I will try to modify the map manually, so that I can "force" the compensation only on the right side of the plate.

The new deck is being designed, but it requires structural modifications that I cannot install on this one due to lack of space. I will also have to completely redo the Y-axis, which in this way has limitations that I don't like. But we'll talk about that in late spring!

Good morning

It all seems to work quite well.

Now I just have to figure out how to solve a problem on the Y axis, mostly due to the type of "transmission" used and complete the settings ... before moving on to the print tests!

This is the X axis test: https://youtu.be/UG27txKxALk

@fcwilt Yes, I know that, but at the moment I am not interested in exceptional quality. I just want it to print what I want, how I want it and without too many mistakes.

I will slowly replace the various "definitive" PLA parts with aluminium alloy equivalents, so that all the mechanics become more stable. At that point, having in the meantime replaced the round guides (X and Z with MGN15 recirculating ball bearings), I will be able to create the 20x20 mesh.

Thank you

I fixed the errors in the code.

if job.build != null

if job.layer != null && job.layer <= 5

M140 S50

elif job.layer != null && job.layer > 5

if job.layer < 20

if heat.heaters[0].current < 40

M140 S50

if heat.heaters[0].current > 50

M140 S40

else

M140 S0

if job.build != null

if job.layer != null && job.layer <= 5

M140 S50

elif job.layer != null && job.layer > 5

if ((job.file.numLayers*20)/100) < 20

if heat.heaters[0].current < 40

M140 S50

if heat.heaters[0].current > 50

M140 S40

else

M140 S0

seems to be working