DUET WIFI for dispenser machine

-

Hello,

has anyone tried to make glue/silicone/whatver dispensing machine with 3d printer or speicifically with DUET WIFI?

Reason why I want to make it is that dispensing heads has pretty reasonable price 2-5k Eur.

But dispensing machines are unbelievably expenisve. Cheapest working thing starts at 10k.

-

It sounds like a good application for a Duet WiFi/Ethernet-controlled machine to me. My choice would be a delta.

-

@dc42 for first I thought I will go for fast delta design.

However recently I got info that for most of the dispensing works 2 heads are needed, so delta will not work.I already have RIGID3DP platform and I am thinking to use to hang dispensing heads.

Main question is, what software I should use to generate gcode for 3D motion in 3axis.

Because hardware is pretty much straight forward... -

@dc42 would you help me a little?

I am moving with dispenser project and i have few questions.

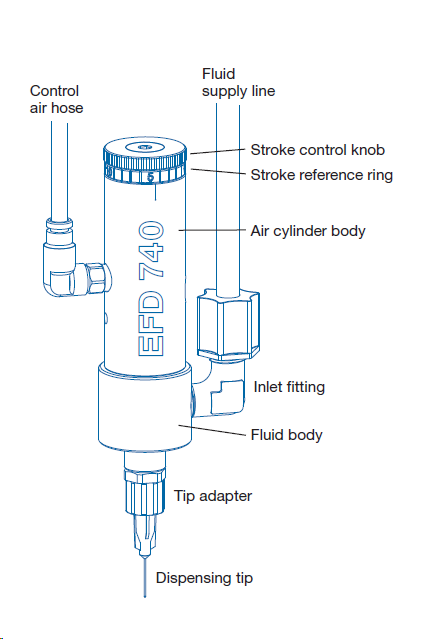

I bought simple (but good) dispensing head. It is controlled on/off by air pressure.

The idea is to use Festo (or similar) electronic air valve that will be controlled by DUET board.

-

Usually these solenoids are controlled by 6/12/24 volts. Which output I should use in DUET board lets say for 12V output?

Or should I use additional relay? Sequence would be DUET->Relay->Solenoid. I can use 5V then. -

Which pins are the best to use for this application, so I can easily control them by G-Code later?

I hope you will find time to help me for this project

-

-

Maybe a solid state relay, but I think that I'd want something fairly fast response.

This seems like something that could be adapted like the duty cycle pulses that the laser guys use using the motor pulse circuits.

-

This would be really cool.

I don't know anything about these machines, but that image you posted lists a 1 micron resolution. If this is the case, there might be a real reason the machines cost 10k. I'm sure the accuracy isn't clost to 1 micron, but merely having 1 micron resolution is nothing to sneeze at (unless they're merely listing micro stepping resolution, and not full-step resolution, in the case that the machines use steppers).

-

@alishkus, how much current do the 12V and 24V solenoid valves need?

You may be able to use the "output on extrude" GCode to control the valve.

-

@bot thats cool machines and it becomes more and more popular. Ofcourse use of it is very specific.

They declare 1micron precision, but its more like 0.2mm because you place objects by hand on table and repeatability depends on your jig.

Accuracy is really not the most important thing there@dc42 Solenoid is 24V

You mean I should use extruder motor output? -

@alishkus, yes 24V but how much current does it draw? You may be able to use a heater or fan output to drive it.

-

depending on what your dosing the supporting infastructure is where the cost is, i do industrial maintenance and used to work in a DVD manufacturing plant. the resin dosing heads were relatively simple like the one you show above but the vacuum systems and deforming tanks where the resin had the bubbles removed and was filtered was worth a fortune.

just some info if your curious

-

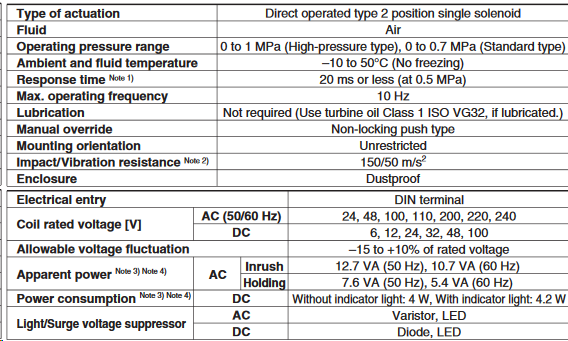

@dc42 they do not provide exact power needed for solenoid, only this spec sheet

I assume easiest way would be to use 12V relay and use fan output. As heater is PID or can I turn of PID?@gavatron3000 I already have this info. There are to different things. One when you have continuous manufacturing and you need resin degassed in line process (that is bloody expensive) and other process is where you degass resin manually and fill it to pressurized container. Thats pretty cheap.

-

If the power consumption is only 4W or 4.2W as specified in that data, you can run it directly from a fan output.

-

@dc42

Looks like it is 4.2W as they don not mention any other consumption only for solenoid.

So basically I could control dispenser with M106 S0/S1 and fan outputs if I understood good.Another thing that bothers me is G-Code generating. What I need is basically a line in space.

It is all clear with 2D lines. I generate G-Code. Edit it manually when to start and when to end dispensing. I make some macros to find X0/Y0/Z0. Wollia.

What is more interesting its 3D line in space. I can draw it, but I dont really understand what program to use to generate Gcode for 3D line.Anyone has experience with it?

-

@dc42 I have a question.

I want to use 12V fan output to control 24V 4.2W (166mA) solenoid.

I would use booster for 12V output to have 24V. It will become ~400mA.Am I allowed to do that?

-

@alishkus said in DUET WIFI for dispenser machine:

@dc42 I have a question.

I want to use 12V fan output to control 24V 4.2W (166mA) solenoid.

I would use booster for 12V output to have 24V. It will become ~400mA.Am I allowed to do that?

I don't advise that, because the boost converter will have a high starting current, which might blow the mosfet. Can't you either use a 12V solenoid, or power the Duet from 24V?

-

@dc42 ok, going to buy 24V power supply. Will be less problems.....

-

So its is working

Will update on process of project as its pretty nice use of Duet Board

-

@dc42 can I have some consultation?

Machine is working (only compressed air hook up left) but I have strange behavior....When I upload Gcode duet executes it normally, buuuuut it wont execute -X lines.... So it moves only half X distance needed. Am I missing something here?

Head travels from X100 to X0 and then it decides to move to Y direction...

-

Have you used M208 in config.g to define the X axis limits?

-

@dc42 and yes you are right

Thanks

Thanks