My custom Cartesian

-

Results are in they are about 5dB quieter and 5°C cooler than stock A8 steppers

Also, it seems I am melting. -

@obeliks Definitely sounds great!

At what settings do you run them?

At what settings do you run them? -

Just like on A8 steppers 50%, so 1200mA in case of Wantai.

The loudest ones are Z-axis, but that is related to M5 leadscrew. -

Just wanted to say thank you for your build log.

I went a very similar route to you, started with an Anet A8 and am now left with a box full of spare bits that looks suspiciously like an Anet A8 (Only thing left is the stepper motors and guides)...

The Duet was a bit of a pain to configure after using Marlin but the first test benches turned out like a dream with your settings.

So thanks again!

-

@witchdoctr said in My custom Cartesian:

The Duet was a bit of a pain to configure after using Marlin but the first test benches turned out like a dream with your settings.

I'm glad that this helped you.

-

@OBELIKS Can you measure the length of your Anet stock steppers? I just measured the length of the newer 0.9A steppers and they are not 40mm but only 37.3mm long.

So compared to the 48mm long Wantai steppers (would you be so kind to measure their length as well?) that is an extra of over 10mm and I have a feeling that I will not be able to fit them everywhere.

-

@wilriker sure, tomorrow. I wrapped up for today.

-

Eh, I needed to fetch a beer from the storage. So I hopped in to the "workshop"

Anet steppers are 37,8mm long and Wantai real length is 46,8mm.

And the beer is imperial IPA with 10% alcohol. And it is brilliant. -

@obeliks said in My custom Cartesian:

Eh, I needed to fetch a beer from the storage. So I hopped in to the "workshop"

Anet steppers are 37,8mm long and Wantai real length is 46,8mm.Thanks for that!

Will measure on the weekend of I can fit them. Biggest issue might be Y axis as my heat bed holder has only a certain width cutout for the motor.

Will measure on the weekend of I can fit them. Biggest issue might be Y axis as my heat bed holder has only a certain width cutout for the motor.And the beer is imperial IPA with 10% alcohol. And it is brilliant.

I am all but a beer type but happy that you have something you enjoy.

-

If it's aluminum bed holder, just chop it.

-

@obeliks It is aluminium. Though, I have some concerns of messing with the statics of it if I chop it. But first I need to find out if it will be an issue after all.

-

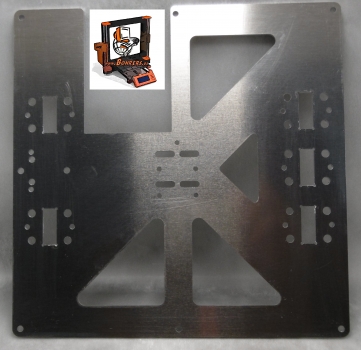

OK, I looked into the dxf file that is used to cut the bed holder and it has a clearance of 58mm for the Y motor. 46.8mm motor + 6mm damper leaves 5.2mm for the thickness of the motor holder (which I am not absolutely sure but I think is 3mm) and some clearance to compensate any amount of mounting skew... this will be tight... And as you can see on the image of the seller below there is not much room for removing further material without coming really close to some existing holes

-

Damper? I think those will not be needed.

As I said these are a lot quieter.

You should measure on the printer itself. Any other theoretical calculations will be off, by my experience. -

@obeliks For the current motors the dampers make a huge difference especially for the Y motor. I feel a little hesitant to assume that the "long" silent motors are even more silent without the damper - and they would at least have to be equal in noise to the current setup. But still it is tempting.

And 5dB are nearly 4-times louder/quieter (depending on reference).

And 5dB are nearly 4-times louder/quieter (depending on reference).

I never measured the actual difference when adding the damper, though, except for listening at them.And of course I will have to also measure on the printer itself to be sure about the cutout.

-

@wilriker A question regarding the dampers. Are they stiff enough not to introduce backlash?

-

@obeliks Actually I don't even know that. I guess so because they feel very stiff. But of course it introduces another elastic element besides the belt into the system. So it will at least add a very minimal amount of backlash.

Now that I think of it my ghosting problems with infill visible on the outside of a Benchy might be backlash issues...

-

Do you have a picture of that Benchy?

-

@obeliks This is the best one I could find (and not a good one to be honest):

Given this is actually printed on the original acrylic frame but sadly the aluminium frame did not improve in this very issue in any way.

And this is not just visible because the filament is a tiny amount transparent but also you can feel it.

EDIT: There already was belt tensioner in use and I used glass-fibre reinforced belts from the start - I never used the steel-reinforced belts that came with the A8.

-

This is not really ghosting, what value do you have for the perimeter/infill overlap?

-

@obeliks I knew that this would come up. It's at 10%. And I am using 2 perimeters with 0.4mm each so a total wall thickness of 0.8mm.