How to debug heater faults

-

If your hot end temperature sensor is a regular thermistor, then sudden temperature jumps are generally caused by a bad thermistor connection, or a thermistor wire shorting to something else such as the hot end metalwork. Leakage between the cartridge heater element and its case can be a contributory factor.

If the sensor is a PT100 or thermocouple, then sudden temperature jumps can be caused by the sensor cables picking up interference, typically from the extruder stepper motor cable.

-

Its a regular thermistor.

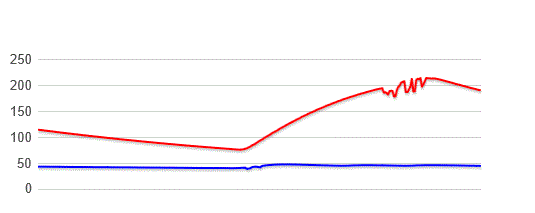

I'm currently trying to reproduce the error and while the hotend is very stable i noticed a very small jitter at the heatbed. It's minimal and may be nothing, but i can't remeber seeing these spikes on heatbed before. It's a 3mm aluminium heatbed with 3mm glas on top, so there is a lot of thermal capacity.Jittery Hotend: (red line)

Jittery Heatbed: (blue line)

Sadly i don't have a screenshot of the spike to 250 degrees, so i painted it out of memory:

-> temperatur got to 195 and print started, then suddenly a spike to 250 continuously falling back to 195 and staying thereI would suspect a wiring issue too, but how would this explain the spike to 250 degrees?

-

The fact that the displayed bed heater temperature jitters when you turn on the hot end heater suggests to me that you have a leaky cartridge heater, and either a leaky thermistor in the hot end too or a short between a thermistor wire and the hot end metalwork. But there are probably other possible causes that I haven't thought of.

-

The thermistor wires dont't touch the hotend or any other metal part. In fact they go directly to the connector on the smart effector and only may touch the insulation of the heater cartridge.

I'm not familiar with the issue of leaking heaters and thermistors, can i just measure resitance of all heater cartridge and thermistor wires to the heatblock when powered of and if yes how high should the resistance be? (>1 MOhm i suspect?)

Currently i'm printing for 1 hour continuously and got no issues other then the one small spike on the heatbed.

How do you come to your conclusion of "The fact that the displayed bed heater temperature jitters when you turn on the hot end heater"

The hotend was continuously at 195 wihtout jitter (red line), only the heatbed (blue line) had small jitter.I just remembered 3 changes i made in the last weeks:

- Switched the nozzle (0.4mm brass to 0.25mm plated copper)

i didn't touch any connections and didn't remove the heater cartridge or thermistor. - replaced the bed clips with these "swiss clips": https://e3d-online.com/swissclips

I just realized these swiss clips could damage the 24V heated silicon bed? - added a cross bracing on two sides of the printer. I will check after the print has finsihed if i may have damaged a wire during installation as these run quite close to one of the bracings.

- Switched the nozzle (0.4mm brass to 0.25mm plated copper)

-

Better version of my drawing:

Bad wiring or parasitic voltages from leaking cartridges can explain the jitter in my other images, but this looks like the heater continued to heat up while temperature reading stayed bang on at 195.

Looks like the temperature reading freezes while the heater is running away? -

@nuvag jumping in a little late to the party. Have you been able to repeat it?

-

I couldn't find the cause yet, probably will have to disable it and inspect the wiring and connectors in detail. I measured the heater cartridge and thermistor against the heatblock and resistance was >20MOhm, so no short.

I printed another 20 hours without any problems and then got again small jitters at the heated bed:

(blue line, near end of graph)

This time it was during heatup, so no movement on the printer.

I monitored it at the PanelDue and it jumper 2-3 degrees up and down, then stabilized by itself and print started shortly after. No problems during printing.

After this printed again 6 hours without issues.I'm really puzzled about the cause of this, especially as it sometimes affects the hotend and sometimes the heated bed and never both at at the same time.

-

Just a quick update: (i hadn't time to disasemble the printer yet)

I was printing a vase and didn't touch the printer.

Just after an hour of printing without problems, the hotend temperature started to fluctuate. It was commanded to 255 and jumped between 240 and about 265. On the print it was very obvious the temperature was much too high, as the PCTPE filament began to cook.

I manually reduced the temperature a few degrees and the problem was gone and temperature stopped fluctuating.However the PanelDue touchscreen was no longer working while otherwise the display was working (temperatures did update)

Webinterface worked, but only a few seconds at a time so i don't have a graph of the temperature fluctuation.

Reset did not resolve this, a powercycle was necessary to get the PanelDue touchscreen responding again.

Could this problem be correlated to the temperature issues? -

I disasembled the printer and checked the wiring, connections, board, heated bed and so on. Sadly no issues whatsoever.

But this time i noticed my multimeter picking up something right at the limit of the 20 MOhm range when measuring heatblock against wiring of the thermistor. I switched to another multimeter with a wider input range and sure enough there is a current path from heatblock to thermistor wiring just around 20 MOhm.

Interestingly the resistance drops over time to around 15 MOhm and there is no current path the other way around (input range is 60 MOhm). I'm not familiar with the construction of these thermistors so i'm not sure if this diode effect is normal.

After removing the thermistor i measured directly against its housing and its just 4 MOhm.I checked my old thermistor and there is no current path, so i replaced the thermistor with the old one.

As the error is very rare i cannot be sure this fixed it.It would be pretty unlikely to have additionally a sporadic leaking heater cartridge, so i wonder if static electricity could be to blame? It could be provided by the gearing of the zesty nimble, the plastic flowing through the nozzle or the nozzle rubbing on the previously printed layer.

-

@nuvag said in How to debug heater faults:

It would be pretty unlikely to have additionally a sporadic leaking heater cartridge, so i wonder if static electricity could be to blame? It could be provided by the gearing of the zesty nimble, the plastic flowing through the nozzle or the nozzle rubbing on the previously printed layer.

Any leak inside a heater cartridge is likely to be temperature-sensitive.

It's certainly possible that static electricity could be part of the problem. Ideally the hot end metalwork should be grounded, either directly or through a resistor. Anyway, I think you've found the main explanation - a leaky thermistor cartridge.