Bondtech (or similar) extruders

-

@deckingman given your use case is pretty unique (1000s of retracts over the same bit of filament) maybe get just 1? You can set it up to test with the bondtech being the one that is unused for the first N layers of the print so it gets a workout.

Also we need to talk about filament monitoring and pause/purge/restart so that even if bondtech type dual toothed extruders dont work you can have the print pause and you can sort it out manually and then resume (but i wont want to hijack this thread and i don't have the laser monitors to hand yet).

-

@t3p3tony said in Bondtech (or similar) extruders:

@deckingman given your use case is pretty unique (1000s of retracts over the same bit of filament) maybe get just 1? You can set it up to test with the bondtech being the one that is unused for the first N layers of the print so it gets a workout.

Also we need to talk about filament monitoring and pause/purge/restart so that even if bondtech type dual toothed extruders dont work you can have the print pause and you can sort it out manually and then resume (but i wont want to hijack this thread and i don't have the laser monitors to hand yet).

Hi Tony,

That's spooky - the thought had just occurred to me that I ought to get just a single unit to start with before parting with my "hard earned" on 5 of the beasts (which as you rightly point out, may not be a solution due to my somewhat unique usage case). Also, it shouldn't be too hard to devise a torture test to compare BondTech with Titan back to back.

Ref filament monitoring - it's all related to the same issue so I have no problem discussing it in this thread (although we can always converse via email if you think it would be better). It'd also be good to test filament monitoring with my other unique usage case which is when I fade one colour into another. So I have mixing ratios, and therefore extrusion rates, as low as 1% of what most users would see. David has indicated that this should not be a problem but I guess it would be good to run some tests.

But, I have a couple of problems. I only have 2 or 3 spare estops. CoreXYUV plus Z then I use a couple for emergency stop and axis maxima. So even with Duet plus Duex5 I'm struggling with connectors. I guess I could probably disconnect these last two temporarily but I'd rather not if I can help it. The other issue the shear number of conductors that already go to the hot end and extruder gantries. 5 steppers with 4 conductors each, plus all the other associated gubbins like heater, fans, switches, thermistor, lights etc. I think the last time I did a count, it was in the order of 38 conductors. So if I had 5 filament monitors, I'd really struggle to run all the cables - I'd certainly need to change the cable chain which, with all the existing conductors, is no easy thing to do. I could possibly common up a few conductors but not all that many. Just to complicate things, the part cooling fans are 12v but the hot end fan is 24v.

So as an aside, it would be really good if next gen Duet was a bit more modular to cut down on the number of conductors that have to all go back to the main board

-

Just my 2 cents - I've had my prints fail for the same reason on my switching setup with 2 E3D Titans. Since it had to retract and unretract 70mm of filament every layer, on smaller prints one of the filaments ended up being ground.

Bondtech extruders have completely solved the issue. Not only do they have a lot more grip, they deform the filament a lot less. Which additionally means less bowden tube resistance. Not that it would be an issue for you though.

-

@mike said in Bondtech (or similar) extruders:

Just my 2 cents - I've had my prints fail for the same reason on my switching setup with 2 E3D Titans. Since it had to retract and unretract 70mm of filament every layer, on smaller prints one of the filaments ended up being ground.

Bondtech extruders have completely solved the issue. Not only do they have a lot more grip, they deform the filament a lot less. Which additionally means less bowden tube resistance. Not that it would be an issue for you though.

That's also very encouraging to hear. Good to know that I'm not alone even if slightly different set ups. BTW I do use Bowden tubes, albeit small ones so filament deformation is an issue to some extent. It certainly increases friction which exacerbates the problem. Thanks for your input.

-

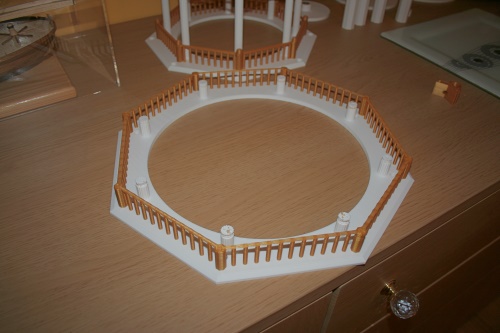

Just for info, here is pic of the latest failure. So switching between gold and white on every layer but retracting all filaments together. At some point during the night, the white filament got ground away during the retractions between each gold spindle (because the white filament wasn't moving forward).

It should look like the one in the background but a bit bigger. So those white towers should have been about 150mm tall. Wondering what to do it with now that I've aborted it. Frisbee maybe?

-

i have titan aeros and agree that they leave something to be desired in the power department, i had debated between replacing them with bondtech bmg’s or another interesting extruder, the flexion extruder.

It has an interesting feature, in that it automatically clears the hobbled bolt, would solve your problem.

I ended up going with the bondtech, because i have my doubts that the heartbreak on the flexion is up to the task of sinking enough heat away. Documentation on it is also limited and there isn’t a support forum.... that and i know bondtech makes great stuff (i’ve got a bondtech qr that worked great on my delta).

-

I exclusively use the BMG extruders and own a total of 4 of them across 3 printers. They seem to be the only one that can grip a wide variety of materials and don't require any re-tuning for feed rates or anything, even when using ninjaflex and switching right to PC-CF. Heck it even handled ninjaflex in a bowden setup quite well.

One note is that while they say to set your step/mm to 415, when you calibrate I find 415 to be a good average but find +/- 10mm / step is the tolerance. Once set though you never really have to adjust it.

I will be curious to see how you make out with the mixing nozzle as I may be upgrading to that soon as I really like the idea of a multi-color print.

-

@bpislife said in Bondtech (or similar) extruders:

I exclusively use the BMG extruders and own a total of 4 of them across 3 printers. They seem to be the only one that can grip a wide variety of materials and don't require any re-tuning for feed rates or anything, even when using ninjaflex and switching right to PC-CF. Heck it even handled ninjaflex in a bowden setup quite well.

One note is that while they say to set your step/mm to 415, when you calibrate I find 415 to be a good average but find +/- 10mm / step is the tolerance. Once set though you never really have to adjust it.

I will be curious to see how you make out with the mixing nozzle as I may be upgrading to that soon as I really like the idea of a multi-color print.

Thanks for that. Re the mixing hot end - I've been using them for years. Loads of stuff on my blog https://somei3deas.wordpress.com/blog/

-

@qdeathstar said in Bondtech (or similar) extruders:

i have titan aeros and agree that they leave something to be desired in the power department, i had debated between replacing them with bondtech bmg’s or another interesting extruder, the flexion extruder.

It has an interesting feature, in that it automatically clears the hobbled bolt, would solve your problem.

I ended up going with the bondtech, because i have my doubts that the heartbreak on the flexion is up to the task of sinking enough heat away. Documentation on it is also limited and there isn’t a support forum.... that and i know bondtech makes great stuff (i’ve got a bondtech qr that worked great on my delta).

Thanks. Ref the flexion, TBH I'm looking fr something that doesn't grind the filament away in the first place - clearing it from the hobbed bolt is the lease of my problems.

-

i think any time you use a hobbed bolt that bites into filament you are going to get small chips that accumulate on the hob bolts teeth, reducing its ability to bite the plastic till it can’t provide enough grip to push the filament and simply grinds on it. Keeping the hobbed bolt clean should help make sure you can get a consistent byte.

-

@qdeathstar said in Bondtech (or similar) extruders:

i think any time you use a hotbed bolt that bites into filament you are going to get small chips that accumulate on the hobbs bolt, reducing its ability to bite the plastic till it can’t provide enough grip to push the filament and simply grinds on it. Keeping the hobbee bolt clean should help make sure you can get a consistent byte.

Fair comment. I guess the ideal extruder would have 2 (or more) hobbed bolts plus a mechanism to keep them clean. AFAIK no such extruder exists so I'm inclined towards the Bondtech with 2 hobbed bolts over the flexion with a single hobbed bolt and cleaning mechanism. For "normal" use, that is to say without retracting and un-retracting the same piece of filament, I don't really get any build up on the hobbed bolt though.

-

It never really made a splash but the belt-friction extruder (Vaeder or something like that) of some while back seemed to be a novel solution for pushing filament without having to bite into it with sharp teeth.

-

@djdemond said in Bondtech (or similar) extruders:

It never really made a splash but the belt-friction extruder (Vaeder or something like that) of some while back seemed to be a novel solution for pushing filament without having to bite into it with sharp teeth.

Yeah, I wondered about those. As you say, it never made a splash and I can't find much info. Bit concerned about how much pushing power they might have compared to a hobbed bolt.

-

Well the one I saw some time ago gripped the filament between about 5 cm of belt, so I would expect it to be fairly tight. The big plus would be you could drive it as hard as you wanted, even if it slips, you won't grind it to nothing.

-

Update on this. Long story short but Martin Bondéus from Bondtech kindly sent me a BMG unit for evaluation. I've just got around to doing the tests and writing up my findings. Results and associated video are here https://somei3deas.wordpress.com/2018/05/11/bondtech-bmg-vs-e3d-titan-extreme-retraction-torture-test/.

It might surprise you ...........it did me!

-

It looks like you stumbled onto one of the Titan's "bearingate" problems. E3D had a variety of problems involving a bearing supplier that switched to a grease that damages polycarbonate, then switched to a grease that went bad. I'll let them explain it since I will probably get it wrong.

https://e3d-online.com/blog/2018/01/22/bearinggate/

https://e3d-online.com/blog/2018/02/05/bringing-an-end-to-bearinggate-improving-titan-and-titan-aero/I have a Titan but much prefer the BMG. I can sympathize on not wanting to buy 5 BMG kits.

-

@jrdm Thanks and yes, I'm well aware of the Titan bearing problems - just never noticed it on my own extruders until now.

-

The Titan is terrible.... I think a chinesium extruder would probably beat it.

With a .8mm nozzle, I can’t print faster than 30mm/s pla @ 210c.

I got the bmg sitting in a box but I need to make a mount for it first and I’m debating between dyzend and an v6 for the hot end... want to watercool the cold end and the dyzend is ready to in that regard.... but I’ve heard it clogs easily...

-

@deckingman said in Bondtech (or similar) extruders:

"My overall impression is that fitting the Bondtech BMG is a doddle but the E3D Titan is a bit fiddly."

Being that I'm not British (just a member of the commonwealth), I had to guess at the meaning of this one.

Thanks for the good read, very interesting results.Purely speculation, but I also wonder if the compression effect of the dual hobbed bolt from the Bondtech stiffens and strengthens the filament.

The bearing problems on the Titan are widespread and substantial. I had nothing but problems with my Titan Aero that never made any sense. First the hobbed gear was out of alignment causing the filament path to be off the center of the hob which lead to excessive stripping of the filament. E3D recommended I smack it with a hammer to get it back in alignment! I refused and they sent me a replacement free of charge which also had the same issue. I smacked it with a hammer and it improved that problem, but then the bearing gate issues started to become more apparent. I've since replaced both bearings with replacements sent from E3D and things seem to be back in order. For comparison, another printer was using a TriangleLabs Titan V6 clone that functioned perfectly from day one and has put twice the amount of plastic through it and hasn't shown a slight bit of wear.

The whole experience was a little disheartening. I really like E3D and their products and the work they do, but I feel the Aero was a fairly botched product. Kudos to them for being forthcoming with the problems and sticking by their customers with support and fixes, but the whole thing was a bit of a doddle. Did I use that right?

-

@phaedrux said in Bondtech (or similar) extruders:

@deckingman said in Bondtech (or similar) extruders:

"My overall impression is that fitting the Bondtech BMG is a doddle but the E3D Titan is a bit fiddly."

Being that I'm not British (just a member of the commonwealth), I had to guess at the meaning of this one.

but the whole thing was a bit of a doddle. Did I use that right?

Not quite. Sorry about the confusing use of language. "A doddle" means easy, simple or straightforward. So fitting the BMG was a doddle but E3Ds Aero is more of a hotchpotch and certainly not a doddle

At least I didn't use Cockney rhyming slang - then you would have been really screwed in trying to understand the meaning.