6th-order jerk-controlled motion planning

-

@bot said in 6th-order jerk-controlled motion planning:

Speed improvements and "vibration reduction" has thus far only been proposed for mechanical systems which are less than adequate.

Perhaps I'm misreading what you are saying. Personally, I want more speed, and I want it on my VERY GOOD mechanics. Mechanics that were custom designed for quality, and are at a price/performance point where the next few percent of mechanical perfection will double price, etc. Duet 1.21 and these mechanics produce excellent results at 100 to 120 mm/sec.

If a different motion planner gives shorter print times, with the same or improved quality, I'm all for trying it.

"vibration reduction" I agree should be in quotes, it is a very loosely defined goal. So lets just ignore it completely.

Speed with quality? I'm all in.

-

@danal and everyone else: Yes, I agree. If this (or any) different motion planning system gives improved speed on systems that are already at peak performance, I welcome that addition. I'm just worried that this is being driven (in the marlin community) by people with mostly inadequate hardware. Some of the first "academic" examples of these algorithms used obviously problematic mechanics to demonstrate the "usefulness" of the feature.

I'm not against exploring ideas, but we need to pick and choose which ideas we explore. Because the "we" is really only David at this point (though, I believe a Chris is helping a lot, too -- credit where it is due).

I would vote for not even exploring the implementation of "6th-order jerk controlled motion planning" until 100% of bugs are worked out of the the current firmware, and we can see demonstrable benefits from other firmware.

-

Yeah, I'm a lot more excited about RTOS than a different motion planner. At least for now.

At the same time, I'm using a TinyG on my big CNC because of its superior motion. It has plenty of other flaws and frustrations... the motion wins.

-

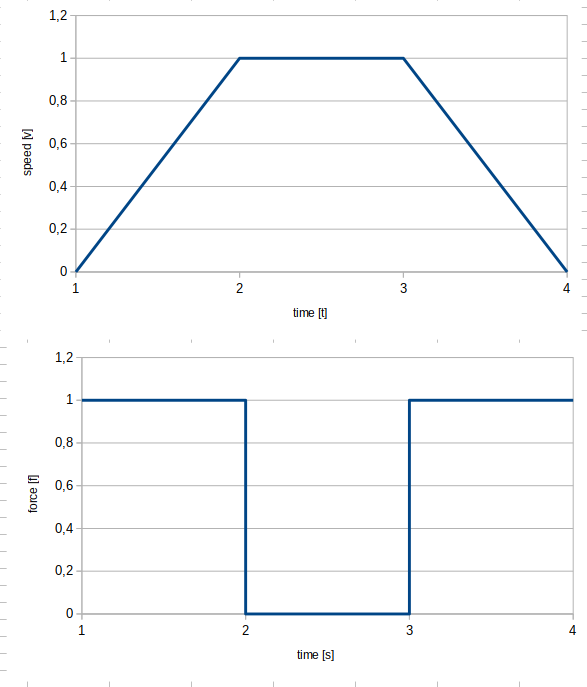

Yeah, I mead some graphs. And please - fell free to correct my if I am wrong because I am not a psychics, but as far my knowledge goes this is exactly how the force behaves in out current monition planning system.

-

My fiend, you should have taken your own advice and stopped there.

Force vs time is completely irrelevant to motion.

Starting with an object at rest, we start with zero velocity and apply a force in order to accelerate it to a higher velocity. For sure, too high a force would lead to a near instantaneous speed change resulting in jerk (in the physics sense) but linear acceleration doesn't do that. However, if there is a high level of static friction to be overcome, them we would need a high force to overcome that, but no amount of tuning of the motion system is going to to alleviate that inherent mechanical problem. You just have to keep applying more force until the static friction is overcome and something suddenly gives. It doesn't matter how quickly or slowly that force is applied. There will be no motion until the force is greater than that required to overcome the static friction.

So now we have the object accelerating at a constant rate of change. When we reach the desired velocity the force needs be reduced to maintain that constant velocity. It doesn't drop to zero as there are still friction factors to be overcome. Too little force and the object will decelerate, too much force and it will continue to accelerate. Therefore it follows that the change in force to go from acceleration to constant speed must be instant. This does not mean that there will be any vibration or jerk. You don't feel a sudden jerk when you drive your car. When you join a motorway, you accelerate up to speed then maintain that speed. There isn't any jerk or unpleasant behaviour when you change from acceleration to constant speed, even though you back off the throttle peddle and instantly change the force.

Let me give you an example of how jerk (in the physics sense) happens. Imagine a train consisting a locomotive with carriages attached and imagine that this is an old fashioned train which some slack in the couplings. When pulling away from the station, the engine starts to accelerate in a linear manner. For the first few cms, the first carriage remains stationary because of the slack in the coupling. When this slack has been taken up, the engine is already doing say 1km/hr, so first carriage has to have an instantaneous speed change to catch up with the engine, at which point all the passengers experience "jerk" after which this first carriage continues to accelerate at the same rate as the engine. This is an example of non-linear acceleration. Now look at what happens to the second carriage which has slack in the coupling between it and the first carriage. By the time that slack has been taken up the engine is now doing 2km/hr so this second carriage now has to "jerk" up to 2km/hr before it can then continue at the same rate of acceleration as the engine. And so on, down the length of the train. All the passengers experience non-linear acceleration and physical "jerks" but the engine driver is nice and comfortable because he is experiencing linear acceleration.

So the cause of vibration is mechanical (slack in the couplings) and so it is in badly designed or badly built printers (slack in the belts, loose parts, flex in the system, whatever..). The jerk or vibration doesn't come from the motion system (the locomotive engine had linear acceleration so was nice and smooth).

So what do we do? My take on it is that we should eliminate the mechanical causes of the jerks and vibrations, rather than alter the software to compensate. It isn't difficult or expensive to do.

Going back to our train analogy, lets assume that the engine driver is our software. What he can do is accelerate up to say 0.5km/hr then maintain that speed until the last carriage starts to move and from that point on accelerate as normal. (That would be like taking up all the slack and flex in a cheap and flimsy printer). This would be akin to "S" curve acceleration. For sure this would reduce the jerk felt by the passengers in the carriages (or the vibration of the cheap and flimsy printer) but it won't eliminate it, and it will slow down the time it takes to for the entire train to reach the desired speed (or in our case the time for the print head). So if you think that S curve acceleration will lead to faster printing - forget it. All it will do is increase the time for the acceleration and deceleration phases. Actually, it's quite easy to simulate S curve acceleration - change the belts from rigid ones to elastic ones

.

.Finally, forget the graphs and internet search results and all that theoretical pseudo scientific BS and look at some of the following real world, real printing examples using the current motion system.

https://somei3deas.wordpress.com/2017/06/22/exploration-of-print-speeds-with-a-diamond-hot-end/

https://www.youtube.com/watch?v=NAFd3Hj9Wmc&t=185s

https://somei3deas.wordpress.com/2017/06/25/duet-pressure-advance-experiments/

https://www.youtube.com/watch?v=lnYYNfVoxmQ&t=21s

https://somei3deas.wordpress.com/2018/01/15/an-attempt-to-investigate-pressure-in-the-extrusion-system-with-a-diamond-hot-end/

https://www.youtube.com/watch?v=-HhxSiv5ajs&t=58sThat's real world printing at up to 300mm/sec with the current motion system. For information, the earlier test with the 3 colour hot end the moving mass was around 2.7 kgs, and for the latter tests with the 5 extruders, the moving mass was around 4kg. The limiting factor is how fast we can melt and extrude filament, not the motion system.

-

@deckingman said in 6th-order jerk-controlled motion planning:

So now we have the object accelerating at a constant rate of change. When we reach the desired velocity the force needs be reduced to maintain that constant velocity. It doesn't drop to zero as there are still friction factors to be overcome. Too little force and the object will decelerate, too much force and it will continue to accelerate. Therefore it follows that the change in force to go from acceleration to constant speed must be instant. This does not mean that there will be any vibration or jerk. You don't feel a sudden jerk when you drive your car. When you join a motorway, you accelerate up to speed then maintain that speed. There isn't any jerk or unpleasant behaviour when you change from acceleration to constant speed, even though you back off the throttle peddle and instantly change the force.

Your example is because of inertia in the car itself, the IC engine, and the drive train of the car. And most drivers back smoothly off the peddle. For a similar example, try cutting the current to an electric motor that is direct drive to the wheels of an accelerating vehicle. There will be plenty of jerk.

Literally try it. Go test drive an electric car, preferably one of the performance Teslas, as they can accelerate very strongly (very close to 1G). Slide your foot downwards off the accelerator pedal while under hard acceleration.

Another way of phrasing this same idea: Jerk = rate of change of acceleration. If the force causing accel "changes instantly" then the rate of change of the accel will change equally abruptly. By definition.

Oh, and this is just humor, right?

Force vs time is completely irrelevant to motion.

Force vs time is the only factor in motion of a free body, and when friction, gravity, or other forces applied to that same body are also considered, it remains the major factor in motion of a body.

-

I was referring to the graphs but should have used velocity, not motion.

As for the rest, yes if you like.

We can talk about theory all day and if we tried to print at speeds and accelerations of an F1 car, we might have problems with the motion. The reality is that we can never melt and extrude filament at anything like those speeds or accelerations so we're never going to get those problems.

But I give in - you've worn me down. Whatever you say. You've won the argument. Everything I did and learnt in my 40 years of automotive engineering was and is wrong.

Personally I'm happy that my printer is capable of printing at speeds higher than I can melt filament, even when I get up to 300mm/sec by employing multiple melt chambers and using 5 extruders concurrently to push it into the hot end, without any apparent defects or artefacts that are a result of poor motion control. I've done the real world tests and I'm happy.

Edit. My final word. If you want to do this in a reliable and scientific way, fit accelerometers and vibration sensors and use high speed cameras and lasers to take measurements. These are some of the tools that I used during my career. I can pretty well guarantee that the measurements will reveal results that none of the theory predicted. This why every vehicle manufacture has an NVH department. N=Noise, V=Vibration, H=Harshness. If everything could be explained by theory, none of these departments would need to exist saving the automotive industry £millions a year.

After you've eliminated all the mechanical causes of errant motion behaviour, and you can show that there is still a problem which needs 6th order jerk to rectify, then you have a case for altering the software.

-

I'm all for trying new motion systems to see if they help, though I am not unhappy with the current one.

In the spirit of being conciliatory a lot of this comes down to the age-old debate that was had when auto bed-levelling first came about. We seem to be in two camps, those with stiff, precise machines which don't need it, and those with less solid machines (or less experience or resources) who do need it. Often the ideological divide can be seen between those who want quality but don't care how long it takes, and those who want speed (true they want speed and quality but when its impossible to achieve they settle for speed).

I've been in both camps. I design, make and sell sensors to do bed levelling (or tramming or compensation or whatever you want to call it), but I don't actually use them all that often, on some of my machines as they don't need them. Including my CR10 which has a flat bed, and can be physically levelled by turning screws in a few minutes, and stays in-tram quite well. And it's not an expensive machine. But this isn't an argument for having no software compensation, I've spent quite a bit of time making a piezo sensor system, firmware, and a bootloader flashing setup for this machine as people do want auto-bed-levelling.

Its a tough job for David and T3P3 who have to cater for both groups, but they are managing to do so very well. There is room for both approaches, precise hardware and versatile software.

-

I don't usually post, just lurk and read because it is always interesting.

However, this thread is a mirror of where the machine tool industry found itself in the 80's. Trajectory planning, ball screw compensation tables, etc. were the new and bleeding edge, and the same arguments were had. Long story short, we take these things for granted now. While @deckingman is 100% correct (and I really like/appreciate his systematic approach), he has exposed the next hiccup in the "need for speed". This also happened in the machining world which led to advances in tool materials and geometry, and in particular cutting strategy.

Someone, on another forum, at this moment could be figuring out how to extrude the volume required to travel at warp speed, which would put the ball back in motion controls court.

I also get the argument about build quality, but, while everyone wants a Dixie, most have Haas'es and it is a bit unrealistic to expect otherwise, particularly in the DIY space.

Also we are up against the reality that one very bright man who seems to live a 36 hour day is creating and maintaining the software we are using. Trajectory planning will eventually be a requirement to any 3d printer firmware, but right now, for practical reasons, it will fall into the "nice to have" category.

-

@djdemond said in 6th-order jerk-controlled motion planning:

In the spirit of being conciliatory a lot of this comes down to the age-old debate that was had when auto bed-levelling first came about. We seem to be in two camps, those with stiff, precise machines which don't need it, and those with less solid machines (or less experience or resources) who do need it.

And the third set: Those who have nice, stiff, precise machines that know that their bed is not in the EXACT same place after it has been removed and replaced (delta), or who have verticals long enough for room temperature to have at least some effect (XL to XXL delta), and who therefore run a basic G32 at the beginning of every print.

Yeah, there is a FANTASTIC parallel here with auto-bed-level. Much of the 'meat' of that parallel being those who state that Auto-Level it is for those with imprecise mechanics ONLY... phrasing that contains more than a little snobbery.

-

@acmeanvil said in 6th-order jerk-controlled motion planning:

However, this thread is a mirror of where the machine tool industry found itself in the 80's. Trajectory planning, ball screw compensation tables, etc. were the new and bleeding edge, and the same arguments were had. Long story short, we take these things for granted now.

YES YES YES

-

@danal said in 6th-order jerk-controlled motion planning:

@djdemond said in 6th-order jerk-controlled motion planning:

In the spirit of being conciliatory a lot of this comes down to the age-old debate that was had when auto bed-levelling first came about. We seem to be in two camps, those with stiff, precise machines which don't need it, and those with less solid machines (or less experience or resources) who do need it.

And the third set: Those who have nice, stiff, precise machines that know that their bed is not in the EXACT same place after it has been removed and replaced (delta), or who have verticals long enough for room temperature to have at least some effect (XL to XXL delta), and who therefore run a basic G32 at the beginning of every print.

Yeah, there is a FANTASTIC parallel here with auto-bed-level. Much of the 'meat' of that parallel being those who state that Auto-Level it is for those with imprecise mechanics ONLY... phrasing that contains more than a little snobbery.

Agreed. I did (shamefully) not also mention that there are many cases (deltas and large machines where flat beds are not achieveable) where probing is an extremely useful tool and not a compensation for a lack of precision or rigidity.

But the comparison still stands.

-

On the topic of building a mechanically sound machine, there seems to be a consensus that it's difficult and/or expensive to achieve. To be clear, I know nothing about Deltas, so they may be a special case. But for Cartesians or CoreXY, it really isn't difficult or expensive and in fact you can save money.

To illustrate.......

T3P3Tony and DC42 will vouch for the fact that I took the top off my machine, stuck the whole thing in the back of my van, bumped it up the motorway for about 50 miles to the TCT show, took it out, put the top back on, made a slight adjustment to the bed because it was about half a mm low at the back (due to being bumped about in the back of my van) turned it on and checked that everything worked (which it did). Then for the rest of the show, at the start of each day, I turned it on, picked a file, hit print and left it alone. Without doing anything apart from homing, it spent 3 days making 5 colour objects for staff on the E3D stand (which was a pretty cool thing to do) and one that went to museum in Switzerland. I did the same in reverse after the show only this time I didn't have to adjust the bed level when I got home as it was spot on, and I haven't adjusted it since (that was last September ish)

I'm not trying to boast or brag. I say all that just to illustrate that my machine is pretty robust. However, I don't have access to any fancy machining or fabrication facilities. I'm just an old guy pottering about in a spare bedroom. The frame is all stock V-slot extrusion and the mounts, plates, gantry parts etc are all printed PLA parts (it's a RepRap as far as possible).

Of course, I've been making things and fixing things all my life and I sometimes forget that there are people who don't know which end of screwdriver to hold and which end goes on the screw. I don't mean that in a disparaging way. I'm sure many people would laugh at my feeble attempts to write code - it's just a different skill set. So I apologise for forgetting that some people just don't have the skills.

But if you have a modicum of DIY skills, it really isn't difficult or expensive to build a printer that needs very little in the way of software compensation and it can actually be cheaper. Plus it's fun

For example, putting the frame together. Say you want to join a horizontal cross member to a vertical leg.You can use 90 degree cast corners at about £1.50 a pop with a couple of T nuts at about 25p each plus a couple of bolts but the connection can easily be twisted. (Those are the cheap brackets btw - you can pay £3.00 or so for hidden ones). Alternatively, you can tap the ends of the cross member. The extrusion already has holes that will take an M5 tap. Then drill clearance holes for a hex key in the leg (I did all mine by hand with a cordless drill) and simply use two button head screws (assuming 2040 section), slide the heads into slot and tighten. You'd need the screws anyway for the bracket. So you have a much better connection and save £2.00 each time plus it looks a lot better. If all you have is 4 rails at the top and and 4 at the bottom that's still 16 brackets (one at each end of each rail) so £32 saving and you've got a much more robust connection. If you can't tap the holes, you could pay 50p a hole and still save money. OK so it take a bit longer but ones own time is generally free.

Another example where you could potentially negate the need for any compensation and save money at the same time. If you are considering automatic bed levelling using 3 (or God forbid 4) screws and multiple Z motors, consider just using a single motor and a continuous belt. If you use automatic bed levelling the software will probe the bed and adjust the screws by turning the motors. Just think about that - software is going to turn a screw for you. Every time you remove power from the motors, they'll jump to the nearest whole step (actually I think it's worse than that) but anyway, the motors will get out of sync. So every time you power on the printer you will have to check and adjust the level (by turning each screw). So why not use a single motor and continuous belt? To level it, you position the hot end near a screw (I put slip gauge under the nozzle), and move the bed until it just touches. Then move the nozzle close to another screw, slacken a grub screw holding the pulley to the screw, and turn the screw until the bed just touches. Repeat for the other screw(s) and maybe recheck the datum, and that's it. Job done - for ever (well almost). That's what I do. Nothing special. I did throw a thrust bearing into the bottom of the hole that takes the screw but the mounts are just cheep plastic printed parts. So no need to run auto levelling and I save the cost of two steppers, wiring connectors, etc.

As for a flat bed, well that will cost a bit more but not much. Generally people use a heat spreader which is usually aluminium. So if it's 3mm thick, throw it away and use 6, 8 or even 10mm tooling plate. Or if you are building from scratch, buy that thickness instead of the thin stuff. Yes it costs a bit more but not all that much - nothing like say the cost of a Duet board

. But then that's it - no need to run mesh compensation and no need to probe the bed at multiple locations - ever. So you could probably save some of the cost of the plate by not having such an expensive probe.

. But then that's it - no need to run mesh compensation and no need to probe the bed at multiple locations - ever. So you could probably save some of the cost of the plate by not having such an expensive probe.I could go on, but I think I've illustrated that it really isn't difficult or expensive. I started out with RepRap Pro Mendel which needed all sorts of compensation applied - in fact there was no mechanical means of levelling the bed. So I know how much nicer it is just to pick a file and hit print without any faffing about. Printing a 3D object is literally as easy as printing a document on my PC (although it take longer of course) but it wasn't difficult or expensive to get there.

-

@deckingman Well said Ian and my CoreXY when finished will be the same and I hope will not need any of the trickery apart from bed levelling as I plan on using independent driven leadscrews just cos it is easier to achieve on my build but using 3 leadscrews driven by a looped belt would work just as well,

Doug

-

@deckingman Sometimes even best attempts at building a solid printer from the start end up missing the mark. Case in point, I spent a fairly exorbitant sum of money to obtain a 6mm thick MIC-6 aluminum tooling plate to use as my bed. Not easy to get in Canada. Along with the plate I got a sheet of PEI and silicone heater. I bonded the three together and mounted with a 3 point leveling system. And after all that planning and expense, I found out that the plate had been bent during shipping (I assume). You couldn't tell by eye that one corner was raised about 0.2mm, but you could tell from the failed leveling pattern prints and the mesh grid compensation map showed it clearly.

My options were to buy a new plate, PEI, and heater, or just use mesh bed compensation for free.

-

@phaedrux said in 6th-order jerk-controlled motion planning:

@deckingman Sometimes even best attempts at building a solid printer from the start end up missing the mark. Case in point, I spent a fairly exorbitant sum of money to obtain a 6mm thick MIC-6 aluminum tooling plate to use as my bed. Not easy to get in Canada. Along with the plate I got a sheet of PEI and silicone heater. I bonded the three together and mounted with a 3 point leveling system. And after all that planning and expense, I found out that the plate had been bent during shipping (I assume). You couldn't tell by eye that one corner was raised about 0.2mm, but you could tell from the failed leveling pattern prints and the mesh grid compensation map showed it clearly.

My options were to buy a new plate, PEI, and heater, or just use mesh bed compensation for free.

Well for sure things go wrong. This may sound harsh but the lesson is to check things when they arrive. OK, you may not have a straight edge so...........

Actually, you could have fixed it for (almost) free. I'm assuming that you fix the plate to some sort of frame. In which case, you could use some semi rigid packing (under floor heating insulation panels would work well) between the plate and frame. Something that can be compressed ever so slightly. Then, by altering the tension of the screws that fix the plate to the fame, you'd be able to straighten it. You'd need to play around with the fixing screw positions maybe but it'd be possible.

There is almost always a mechanical solution to a mechanical problem.

-

@dougal1957 said in 6th-order jerk-controlled motion planning:

@deckingman Well said Ian and my CoreXY when finished will be the same and I hope will not need any of the trickery apart from bed levelling as I plan on using independent driven leadscrews just cos it is easier to achieve on my build but using 3 leadscrews driven by a looped belt would work just as well,

Doug

Hi Doug,

I forgot, you were at the TCT show too.

Anyway, if my bed had been a bit bigger, I'd have been forced into using multiple motors too. The reason being that I'm using the longest continuous loop GT2 belt that I can find, and even then had to re-jig things a bit. (Damn - just realised that it doesn't have to be GT2 - could be any profile as long as the pulleys match).

I guess if you went seriously big, you'd likely need multiple motors to get the torque (or gearing). Mine (400mm x 400mm x 10mm) does OK in that respect with a single Nema 17 but I do use fine lead screws (1mm lead) which helps.

-

So, FWIW, I'll throw in my two cents. Three years ago I did some experiments with implementing s-curve / sinusoidal jerk in a Marlin based firmware (UM2) (I used a lookup table instead of calculating it). Let's see how much I remember...

I found it did not really improve print quality, at least not in any way I could see with the naked eye. But it did allow for faster usable movement without shaking the machine or wild oscillations. Especially non-printing moves, as my printer is mostly limited in printing speed by the extruder design. I was printing with good quality at 120mm/s, infill at 250mm/s, and non-printing moves in the 450-550mm/s range. Those are max speeds, but net average speed was within 80-90% of the max speed (depending on segment length mostly). I put up some videos (and a link to the code) here: https://www.youtube.com/watch?v=D9tGB-FtyJQ and a high speed non-printing movement / wobble test here https://www.youtube.com/watch?v=-L8scUiasVg (without S-curve, it was much more violent and that pen would fall over at less than half the max speed)

The main benefit of s-curves was I could use much much higher acceleration values. In theory I could get to those same speeds without s-curve, but I would have to keep the acceleration values low to prevent the machine shaking itself apart when it changed direction... but a high max speed with low acceleration doesn't help because the head would only reach those speeds on very long movement segments. The improvement to acceleration is what made those speeds achievable / beneficial, even on shorter movement segments.

550mm/s was pretty much the upper limit of my machine's design (belts, motor current, the rate at which the CPU could generate pulses, etc). Even then I had to make some dynamics optimizations to the Marlin movement stepper pulse generator code to move at that speed. But it would very very rarely skip steps. Like maybe once every couple hours; enough to mess up a print (it was an issue with the i2c comm interrupt blocking the stepper movement interrupts). Ultimately I think it came down to pushing hard against the limits of that 8 bit CPU. If I limited the speed to under 300mm/s, it was pretty rock solid.

I gave up on further code development when I switched to the Duet Wifi from the AVR based UM2 motherboard.

It's been three years since I did this code, so I've forgotten many of the implementation details, and I do not have the desire to debate. I am relaying my personal experience implementing this on a real world printer, with real world testing. I found the s-curve was well worthwhile in reducing oscillations, violence, noise, etc. and far less computational taxing than true 5-6th order calculations. I agree it should be optional.

I'll add that since I switched the the Duet and no longer use s-curve motion, I don't really miss it that much. Yes, it allowed faster net printing, but I'm still extruder-limited most of the time anyway.

-

@larzarus yours is a very interesting experience, which suggests me that there is still invaluable desirable effects on this S-Curve implementation. Beyond printing speeds, the hardware in the printers will be less exposed to wear and tear and the expected hardware life will increase. Also maintenance cycles will be lower. With less vibrations bolts will not become loose and steppers will not have to absorb the vibrations.

I have read the Movement code and it seems that DriveMovement.cpp also uses a trapezoid. There are references on the code to an "Acceleration phase", " Constant speed phase" and "Deceleration phase". In an analogy with TinyG implementation, they make a sub-division of the same trapezoid into 5 segments: First and second halves of the acceleration ramp (the concave and convex parts of the S curve in the "head" or "Acceleration Phase" in Duets movement.cpp"). Periods 3 and 4 are the first and second parts of the deceleration ramp (the tail), or "Deceleration phase" in Duets Movement.cpp. There is also a period for the "Constant Speed phase".

I wanted to give it a go, but adding this feature requires far more knowledge of the actual implementation that I have and the leaarning curve will take time. I am willing to help, but I would need the guidelines of the code maintainters.

-

To do it properly you need to limit the acceleration and deceleration. So the acceleration and deceleration phases need (in general) ramp up, constant acceleration/deceleration, and ramp down phases. That's 7 phases per move.