New Product Release - Precision Piezo Orion

-

I see that DJDemonD is traveling, is it still possible to buy the Orion?

-

Absolutely, I took over running Precision Piezo in January though he still offers his help and advice when he's available. The Orion is available on the Precision Piezo website here

Idris

-

My Orion groove mount snapped on Monday. I have ordered one made in ABS to get me printing again. But what are the OEM mounts made of? And would Taulman 910 be one of the best materials to print the parts in? I plan to print full sets of spare parts, as I should have in the first place.

Since installing my Orion I have had a resonance at various points above the print surface. It seems to be an interaction between various parts of my CoreXY. It feels like it will shake things loose eventually somewhere, but so far it's not super obvious in the actual print. It's quite loud, and I could see it causing bed adhesion issues since the frequency seems perfect for shaking the parts loose from the bed. If the resonance originates in the Precision Piezo assembly like I think it does, this could be an achilles heel of this type of sensor.

-

@3dmntbighker said in New Product Release - Precision Piezo Orion:

My Orion groove mount snapped on Monday. I have ordered one made in ABS to get me printing again. But what are the OEM mounts made of? And would Taulman 910 be one of the best materials to print the parts in? I plan to print full sets of spare parts, as I should have in the first place.

Since installing my Orion I have had a resonance at various points above the print surface. It seems to be an interaction between various parts of my CoreXY. It feels like it will shake things loose eventually somewhere, but so far it's not super obvious in the actual print. It's quite loud, and I could see it causing bed adhesion issues since the frequency seems perfect for shaking the parts loose from the bed. If the resonance originates in the Precision Piezo assembly like I think it does, this could be an achilles heel of this type of sensor.

Here's my modified Orion groove mount that overcame some difficulties that I had with the original. It's somewhat beefier than the original. I printed the replacement in PLA and it hasn't broken yet.

This forum is damn annoying that it won't let you attach stl or zip files!

-

-

@burtoogle said in New Product Release - Precision Piezo Orion:

Here's my modified Orion groove mount that overcame some difficulties that I had with the original. It's somewhat beefier than the original. I printed the replacement in PLA and it hasn't broken yet.

Thanks, I'll try a couple of materials. At the very least the frequency of the resonance should change

I plan to enclose the printer, so PLA is probably not the best choice.

I plan to enclose the printer, so PLA is probably not the best choice. -

The OEM mounts are made of ABS, layer adhesion is the critical factor and generally I think PLA has better layer adhesion than ABS, I keep tweaking the design and slicing it to try and improve the strength of the parts.

If you run into resonance issues perhaps try changing your print speed? My printer sounded terrible at 6000mm/m (travel) speed but smooth as anything at 7000.

Idris

-

@burtoogle said in New Product Release - Precision Piezo Orion:

This forum is damn annoying that it won't let you attach stl or zip files!

stls should now work.. zips i would not be so happy about..

-

@moriquendi said in New Product Release - Precision Piezo Orion:

The OEM mounts are made of ABS, layer adhesion is the critical factor and generally I think PLA has better layer adhesion than ABS, I keep tweaking the design and slicing it to try and improve the strength of the parts.

If you run into resonance issues perhaps try changing your print speed? My printer sounded terrible at 6000mm/m (travel) speed but smooth as anything at 7000.

Idris

Thanks for the pointers and info. I'll let you know how the Taulman 910 works posting here. The parts I ordered are white ABS. The groove mount seems like a good fit in my BondTech BMG, but I think there is room for improvement. Though I don't think that interface is the source of the resonance.

edit:

Used the ABS part to print your part in 910. 910 was impossible to print until I used glue stick on the PEI. And 910 warps like crazy, but it's a really good material from what I can tell. Your part seems to have a LOT less resonance so far. Apparently Taulman has Nylons with carbon fiber that supposedly helps the warping.

edit2:

Actually your part seems to have eliminated all of the resonance.... yay!!!!Bravo sir.

-

@Moriquendi Can you add the screw lengths required for the different configurations here or to the Thingiverse page?

-

I've just updated the thingiverse details, everything's up there now.

Idris

-

@moriquendi said in New Product Release - Precision Piezo Orion:

I've just updated the thingiverse details, everything's up there now.

Idris

Thank you!

-

Hi,

how big are the wholes in the Orion PCB?

With the wholes big enough, it is possible to use it with Chimera/Cyclops aqua. It is needed to put the filament tube and the water tubes through the whole (each tube outer diameter is 4mm). A second solution would be 2 more wholes to have there for the water tubes.Kind regards

-

The holes are 10mm in diameter and 19.8mm apart. I doubt you'd be able to get both the water tubes and the bowden tubes through. There is a beta module for the chimera+ (air cooled) on thingiverse here

Idris

-

Thanks,

with ID 10mm I should get 1 x bowden and 1 x water tube in 1 whole, not? Should be 2 mm air theoretic

What printed parts are needed (in general)

Can you give me an example how to mount the Chimera air cooled? (With thingiverse links which parts I need)

I'm asking, because I want to think about a Chimera Aqua mount solution -

In theory yes but in practice the bowden tube has to go through the centre of the hole which I don't think will leave enough room for the cooling tubes.

With respect to the mounting, I don't think that the aqua variant has mounting holes on the top which will make mounting it to an Orion more difficult. I don't have an example of how to mount the Chimera Orion to a printer except that it mounts the same way as the screwmount standard Orion. The top part has four 3mm holes in an 18mm square that you would mount to your printer with some form of bracket. The rest of the Orion assembles in the normal way.

The chimera mount was intended as an example of how it could be done, for other people to take and adapt to their printers which is why it's marked as beta.

Idris

-

Why does the bowden tube has to go through the centre?

If I still got the bowden couplers on the heatsink, the bowden tube doesn't need to go in the centre, right?

Can you give a simple drawing of the orion pcb? I just want to try a design and have no orion

-

The bowden tube doesn't have to go through the centre. With the chimera you'll have two bowden tubes and one will have to go through each of the two diagonal holes. I don't have a drawing of the Orion to hand, the assembly holes are 26mm apart, the 10mm holes are on the diagonal and 19.8mm apart, the centre hole is 6mm and the overall PCB is 32x43mm

Idris

-

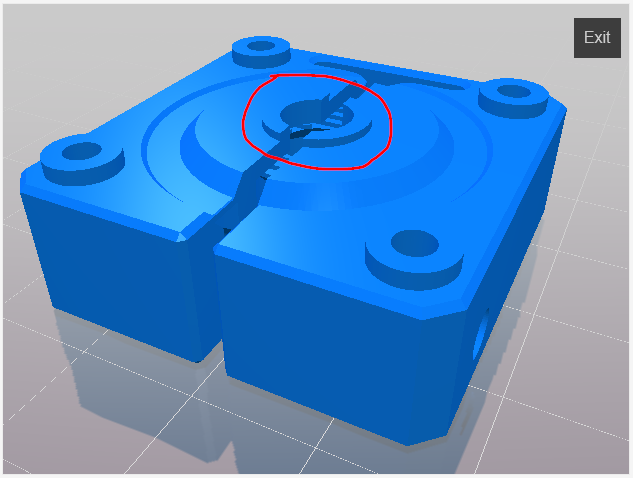

Is the part circled in red the part that deforms the piezo board during contact? I am going to attempt to make more room under it as it currently doesn't fit an E3D without depressing the PTC collet which allows the PTFE tubing to float causing problems on a Lite6 which has it all the way down to the nozzle. I was also not able to get it to clamp on either of the J-Heads I have, it appears to be hitting the chamfers. I think the groove height could be reduced so the width includes the ends of the chamfers.

I did find a way to constrain the PTFE liner on the E3D using the extruder and its working great.

-

Hi, how does the Chimera+ mount will mounted on a carriage? How was the idea to mount with parts given in the link?